What is a good RPM for a circular saw? If you’re curious about the ideal speed for your saw’s blade, you’ve come to the right place! In this guide, we’ll explore the importance of RPM (Rotations Per Minute) when it comes to getting the best performance out of your circular saw. So, whether you’re a DIY enthusiast or a budding carpenter, let’s dive in and learn more!

When it comes to circular saws, RPM plays a crucial role in determining how efficiently and effectively the blade cuts through materials. The RPM refers to the number of times the blade rotates in a minute. The right RPM for your circular saw largely depends on the type of material you plan to cut. Different materials require different speeds to achieve clean and smooth cuts. So, choosing the appropriate RPM is key to ensuring optimal performance and safety during your cutting tasks.

Now, you might be wondering, “How do I determine the ideal RPM for my circular saw?” Don’t worry, we’re here to help you out! Factors such as the diameter of the blade, the type of material, and the depth of the cut all come into play when determining the right RPM. By understanding these factors and following manufacturer guidelines, you can ensure that your circular saw delivers the best results every time. So, let’s explore the world of RPM for circular saws together!

What is the Ideal RPM for a Circular Saw?

A circular saw is a versatile power tool that is commonly used in woodworking, construction, and home improvement projects. One important factor to consider when using a circular saw is the RPM, or revolutions per minute. The RPM determines how fast the saw blade rotates, which affects the cutting speed and the quality of the cut.

In this article, we will explore the concept of RPM and its significance in circular saws. We will discuss the ideal RPM range, factors that determine the appropriate RPM for different materials, and tips for choosing the right circular saw based on its RPM. Whether you’re a professional carpenter or a DIY enthusiast, understanding the ideal RPM for a circular saw will help you achieve accurate and efficient cuts in your projects.

Understanding RPM in Circular Saws

Before delving into the ideal RPM range for a circular saw, it’s important to understand what RPM actually means. RPM stands for revolutions per minute and refers to the number of full rotations the saw blade makes in one minute. Circular saws typically have a range of RPM settings that can be adjusted based on the specific application and material being cut.

The Importance of RPM in Cutting Speed and Quality

The RPM of a circular saw directly affects the cutting speed and the quality of the cut. In general, a higher RPM allows for faster cutting, while a lower RPM provides greater control and precision. However, different materials require different RPM settings to achieve optimal results.

When the RPM is too low for a particular material, the saw blade may struggle to cut through it smoothly, resulting in splintering, burning, or a rough finish. On the other hand, if the RPM is too high, the blade may create excessive friction, causing the blade or the material to overheat, resulting in a poor cut quality or even damage to the saw or the workpiece.

Tips for Choosing the Right RPM for Different Materials

When selecting the RPM for your circular saw, it’s crucial to consider the type and thickness of the material you’re cutting. Here are some general guidelines:

- For softwoods like pine, fir, or cedar, a higher RPM between 5,000 and 6,000 is suitable for fast and efficient cuts.

- Hardwoods like oak, maple, or cherry require a slightly lower RPM, ideally between 4,000 and 5,000, to prevent burning or splintering.

- When cutting plywood or other engineered wood products, a moderate RPM between 3,000 and 4,000 is recommended to ensure clean and precise cuts.

- For cutting metal or plastic, a lower RPM between 2,000 and 3,000 is appropriate to prevent melting or warping of the material.

Keep in mind that these are general guidelines, and you should always refer to the manufacturer’s recommendations for your specific circular saw model and blade type.

Factors Affecting the RPM of a Circular Saw

The RPM of a circular saw can vary depending on several factors. It’s important to understand these factors to ensure you choose the right saw for the job and set the appropriate RPM for the material you’re working with.

Motor Power

The motor power of a circular saw plays a significant role in determining its RPM capabilities. Higher-powered saws tend to have higher RPM ranges, allowing for faster cutting speeds. If you frequently work with dense or tough materials, opting for a more powerful circular saw with a higher RPM range may be beneficial.

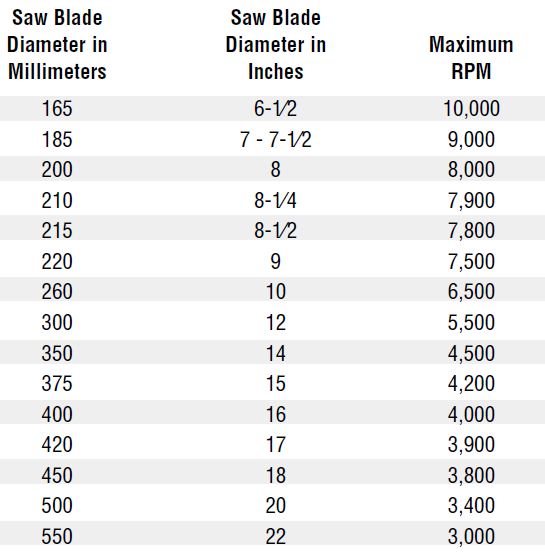

Blade Diameter

The diameter of the saw blade also affects the RPM. As the blade diameter increases, the circumference of the blade also increases. This means that the same RPM setting on a larger blade will result in a faster linear cutting speed compared to a smaller blade.

For example, if you have two circular saws with the same RPM setting but different blade diameters, the one with the larger blade will cut faster. However, it’s essential to adjust the RPM accordingly based on the specific material being cut, regardless of the blade diameter.

Blade Type

The type of blade being used in the circular saw can influence the ideal RPM setting. Different types of blades, such as those designed for cutting wood, metal, or masonry, have varying RPM recommendations. It’s important to select a blade that is compatible with your intended material and adjust the RPM accordingly.

Factors to Consider When Choosing a Circular Saw Based on RPM

Choosing the right circular saw for your needs involves evaluating several factors, with RPM being one of the key considerations. Here are some important factors to keep in mind:

Application

Consider the type of projects you typically work on. If you primarily work with softwoods or plywood, a higher RPM saw may be suitable. However, if you frequently cut hardwoods or metal, a saw with a lower RPM range may be more appropriate.

Blade Compatibility

The circular saw you choose should be compatible with the types of blades you commonly use. Different blades have different RPM requirements, so make sure the saw can accommodate the blade types you require for your projects.

Motor Power

The power of the circular saw’s motor is an important consideration. Higher motor power generally allows for higher RPM ranges, which can be advantageous when cutting through tough materials or working on larger projects.

Additional Features

Consider other features that may enhance your cutting experience, such as dust collection systems, blade guards, or bevel cutting capabilities. These features may not directly affect the RPM but can improve the overall functionality and safety of the saw.

Tips for Optimal Performance and Safety

To ensure optimal performance and safety when using a circular saw, keep the following tips in mind:

Choose the Right Blade

Using the correct blade type and size for the material you’re cutting is essential. Selecting the wrong blade can result in poor performance, increased risk of kickback, and damage to the workpiece or saw.

Wear Safety Gear

Always wear appropriate safety gear, including safety glasses, ear protection, and gloves, when operating a circular saw. This will help protect you from potential hazards, such as flying debris or excessive noise.

Maintain a Firm Grip

Ensure you have a secure and firm grip on the saw throughout the cutting process. This will allow you to maintain control and reduce the risk of accidents or injuries.

Keep the Work Area Clear

Clear away any obstacles or clutter from the work area before using a circular saw. This will help prevent accidental tripping or entanglements that could lead to accidents.

Follow Manufacturer’s Recommendations

Always refer to the manufacturer’s instructions and recommendations for your specific circular saw model. This will ensure that you set the appropriate RPM and follow any additional safety guidelines provided.

By following these tips and understanding the importance of RPM in a circular saw, you can achieve accurate, efficient, and safe cuts in your woodworking and construction projects.

Key Takeaways: What is a good RPM for a circular saw?

- A good RPM (revolutions per minute) for a circular saw is typically between 5,000 and 6,000.

- Higher RPMs are ideal for cutting through harder materials, while lower RPMs are better for cutting softer materials.

- The RPM range depends on the type and size of the circular saw blade being used.

- It’s important to match the RPM of the saw with the recommended RPM of the blade for optimal cutting performance and safety.

- Always refer to the manufacturer’s guidelines for the specific saw and blade you are using to ensure you’re operating within the recommended RPM range.

Frequently Asked Questions

In this section, we will address some common questions about finding the right RPM for a circular saw. Whether you’re a beginner or a seasoned DIY enthusiast, understanding the ideal RPM range for your circular saw will help you achieve better results and ensure your safety.

1. How do I determine the ideal RPM for my circular saw?

The ideal RPM (Rotations Per Minute) for your circular saw depends on the type of blade you are using and the material you are cutting. Different blades and materials have specific RPM recommendations provided by the manufacturers. As a general rule, always refer to the manufacturer’s guidelines and adjust the RPM settings accordingly.

Keep in mind that a higher RPM is typically used for cutting through softer materials like wood, while a lower RPM is suitable for harder materials like metal. Matching the correct RPM to the blade and material ensures clean cuts and prevents blade damage.

2. Can I use a circular saw with a higher RPM than recommended?

It is generally not recommended to use a circular saw with a higher RPM than what is recommended for the specific blade and material. Excessively high RPM can cause the blade to overheat, wear out faster, or even break. It may also lead to inferior cutting performance and pose a safety risk. Always prioritize safety and follow the manufacturer’s RPM guidelines.

If you frequently work with different types of materials and blades, consider investing in a circular saw with an adjustable RPM feature. This allows you to customize the speed based on your specific needs.

3. What are the risks of using a circular saw with an RPM that is too low?

Using a circular saw with an RPM that is too low can result in inefficient cuts, as the blade may struggle to penetrate the material. This can lead to splintering, chipping, or even kickback, which is when the saw forcibly jerks back towards the user. Kickback can be dangerous and cause injuries.

Additionally, when the RPM is too low, the saw blade may heat up excessively, again leading to potential blade damage. It’s important to find the appropriate balance between RPM and cutting material to ensure both effective cutting and personal safety.

4. Can I rely on the RPM listed on my circular saw’s label?

The RPM listed on your circular saw’s label is a useful starting point, but it’s always best to refer to the specific blade manufacturer’s recommendations. Different blades have different speed requirements, so the RPM listed on the saw’s label may not be suitable for all types of blades.

Additionally, factors such as blade diameter and teeth count can affect the ideal RPM for a specific cut. To ensure accuracy and safety, consult the blade manufacturer’s guidelines or contact them directly for the most accurate RPM information.

5. Is there a one-size-fits-all RPM for all circular saws?

No, there is no universal RPM setting that works for all circular saws. The ideal RPM for a circular saw varies depending on the blade type, material being cut, and other factors. It’s crucial to always refer to the manufacturer’s guidelines and recommendations for each specific combination of blade and material.

Remember, using the right RPM setting enhances the performance of your circular saw, ensures better cutting quality, and reduces the risk of accidents or blade damage. Prioritize safety and follow the guidelines provided by the manufacturer to achieve the best results.

Summary

Choosing the right RPM for a circular saw is crucial for safe and effective cutting. A higher RPM is ideal for cutting through dense materials like hardwood, while a lower RPM is better for cutting softer materials like plywood. It’s important to follow the manufacturer’s recommendations for RPM and adjust based on the thickness and type of material you’re cutting.

Additionally, wearing proper safety gear, like safety goggles and gloves, is essential when using a circular saw. Remember to always be cautious, take your time, and practice using the saw before tackling big projects. Happy cutting!