Have you ever wondered what grounding is and why it’s important when using power tools? Well, you’re in the right place! In this article, we’ll explore the concept of grounding and why it’s crucial for your safety.

So, what exactly is grounding? Simply put, grounding is a safety measure that helps protect you from electrical shocks. When you work with power tools, there’s always a risk of a fault occurring, which could result in electricity flowing through your body. That’s where grounding comes in – it provides a pathway for the electricity to flow safely into the ground, preventing any harm to you.

Now, you might be wondering why grounding is so important. Well, think of it as a security blanket for your electrical devices. Grounding helps to stabilize the electrical system, reducing the risk of electrical fires and damage to your tools. It also helps to protect against electrostatic discharge, which can damage sensitive electronic components. So, by ensuring proper grounding, you’re not only keeping yourself safe but also prolonging the lifespan of your equipment.

In conclusion, grounding is an essential safety precaution when working with power tools. It protects you from electrical shocks, prevents damage to your tools, and reduces the risk of electrical fires. So, the next time you plug in your power tools, make sure they’re properly grounded for your peace of mind and safety. Let’s delve deeper into grounding and its importance in the upcoming sections!

Understanding the Importance of Grounding When Using Power Tools

Power tools have become an essential part of our everyday lives, whether it’s for DIY projects or professional use. However, it’s important to understand the concept of grounding and why it is crucial when working with power tools. Grounding is the process of providing a safe pathway for electric currents to flow into the ground, preventing electrical shock and potential harm. In this article, we will explore what grounding is, why it is necessary when using power tools, and the benefits it provides in terms of safety and protection.

The Basics: What Is Grounding?

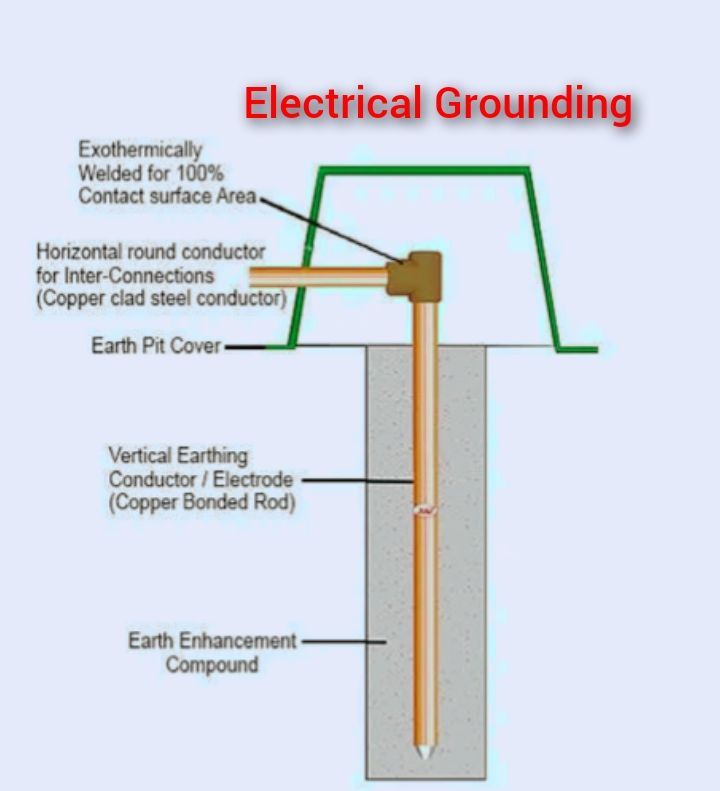

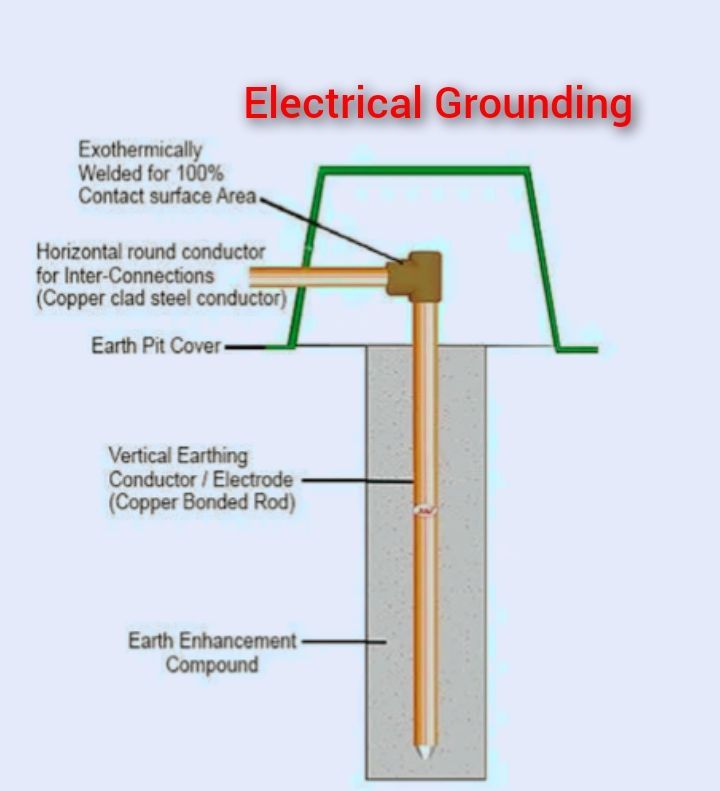

Grounding is a safety measure that ensures the flow of excess electrical current into the earth, protecting both individuals and electrical equipment from potential hazards. In simple terms, grounding involves connecting a conductive material, such as a metal rod or wire, to the ground in order to create a path for electrical currents to follow. This way, if a fault or abnormality occurs in an electrical circuit, the excess electrical charge is safely discharged into the ground. Grounding effectively reduces the risk of electric shock, fire, and damage to electrical components.

Benefits of Grounding

Grounding plays a crucial role in ensuring electrical safety and mitigating the risks associated with power tool usage. Here are some key benefits of proper grounding:

- Prevention of Electrical Shock: When working with power tools, there is always a risk of electrical shock. Grounding provides a safe path for electrical currents, directing them away from you and into the ground, significantly reducing the chances of being electrocuted. It acts as a safeguard against potential accidents.

- Protection of Electrical Equipment: Power tools are often expensive investments. Without proper grounding, electrical faults can damage these tools or render them useless. By grounding the electrical circuit, you help protect your tools from damage caused by electrical surges or overloads, extending their lifespan and ensuring optimal performance.

- Fire Prevention: Electrical malfunctions, such as short circuits or power surges, can generate heat and potentially cause a fire. Grounding plays a critical role in minimizing the risk of electrical fires by providing a path for excess electrical energy to safely dissipate, preventing overheating and potential ignition sources.

Grounding in Power Tools: Ensuring Safety

When it comes to power tools, proper grounding is essential to maintain a safe working environment. Most power tools come with a three-pronged plug that includes a grounding pin. This grounding pin connects to the grounding wire within the tool, allowing any excess electrical current to flow into the ground. Here are some important points to consider regarding grounding when using power tools:

Grounding and Corded Power Tools:

Corded power tools, such as drills, saws, and grinders, often rely on electricity from an outlet. To ensure proper grounding, it is crucial to use tools with three-pronged plugs and only plug them into grounded electrical outlets. The third prong of the plug, when connected to a grounded outlet, provides the necessary pathway for excess electrical energy to be safely discharged into the ground.

Grounding and Battery-Powered Tools:

Battery-powered tools, such as cordless drills or trimmers, do not require a direct external power source. However, the chargers and power supplies for these tools should still be grounded. When charging batteries or using power supplies, ensure that the charger or power supply has a three-pronged plug and is connected to a grounded outlet.

Regular Inspection and Maintenance:

It is crucial to regularly inspect power tool cords and plugs for any signs of damage or wear. Damaged or frayed cords can compromise the grounding integrity, increasing the risk of electric shock or electrical hazards. If any damage is detected, do not use the tool until it is fixed or replaced. Regular maintenance, including cleaning and lubrication, can also help ensure that power tools are operating safely and efficiently.

Grounding: A Necessity in Power Tool Usage

Understanding what grounding is and why it is vital when using power tools is crucial for the safety of both individuals and equipment. Grounding prevents electrical shocks, protects power tools from damage, and reduces the risk of electrical fires. Whether you are a DIY enthusiast or a professional tradesperson, ensuring proper grounding is an essential step towards creating a safe working environment. Always prioritize safety by using tools with grounded plugs, inspecting cords regularly, and following reliable grounding practices in all your power tool operations.

Key Takeaways: What is Grounding and Why is it Important When Using Power Tools?

- Grounding is the process of connecting a tool or equipment to the ground.

- It is important when using power tools as it helps prevent electric shocks.

- Grounding provides a safe pathway for electrical energy to be discharged.

- It reduces the risk of electrical fires by preventing a buildup of electrical charge.

- Proper grounding ensures stability and reliability of power tools.

Frequently Asked Questions

When it comes to using power tools, understanding grounding and its importance is crucial for safety. Here are some common questions people often have:

1. Why is grounding important when using power tools?

Grounding is essential when using power tools because it helps prevent electrical shocks and protects against electrical malfunctions. Grounding provides a safe path for electrical current to flow, directing it away from the user and back to the ground. Without proper grounding, the risk of electrocution increases significantly.

In addition to protecting individuals, grounding also safeguards the power tool itself. It helps prevent damage caused by electrical surges, short circuits, or static electricity. Proper grounding ensures the power tool operates safely and efficiently.

2. How does grounding work?

Grounding works by connecting the metal components of a power tool to the grounding system, which generally involves a grounding wire and a grounding prong on the power cord. This allows any excess electrical charge to flow through the grounding wire and into the ground, rather than through a person or causing damage to the tool.

The grounding prong on the power cord is designed to fit into the grounding slot of an electrical outlet, which is connected to the grounding wire in the electrical system. This connection creates a direct path for electricity to flow safely away if a fault occurs, minimizing the risk of electrical shock or damage.

3. How can I determine if my power tool is properly grounded?

To check if your power tool is properly grounded, you can inspect the power cord and plug. A properly grounded power cord will have a three-prong plug with one of the prongs specifically designed for grounding. The third prong is usually longer or wider than the other two.

Ensure that the grounding prong is intact and not damaged. Additionally, you can use a multimeter to perform a continuity test between the grounding prong and the metal parts of the power tool. If there is a connection, then your power tool is properly grounded.

4. Does every power tool need to be grounded?

Not every power tool needs to be grounded, but it is highly recommended for tools that have a metal housing or are more powerful. Tools such as drills, saws, and sanders should always be grounded to ensure electrical safety.

However, low-power tools like battery-operated devices or those with insulated plastic housings might not require grounding. Always refer to the manufacturer’s guidelines and instructions to determine if grounding is necessary for a particular power tool.

5. What are the consequences of not grounding a power tool?

The consequences of not grounding a power tool can be severe. Without grounding, there is an increased risk of electrical shock, especially if the tool comes into contact with live wires or faulty electrical systems. Electrical shocks can range from mild to life-threatening and may cause burns, muscle contractions, and even cardiac arrest.

In addition to the personal safety risks, not grounding a power tool may lead to damage or malfunction of the tool itself. Electrical surges, short circuits, and static electricity can cause expensive repairs, premature wear and tear, or render the tool inoperable. Grounding is a preventive measure to mitigate these risks and ensure a safer working environment.

Electrical Grounding Explained | Basic Concepts

Summary

Using power tools can be dangerous, and that’s why grounding is so important. When you ground a power tool, you make sure that any extra electrical charge goes safely into the ground. This helps protect you from getting shocked and keeps the tool working properly.

Grounding is easy to do – just plug your power tool into a grounded outlet or use a grounded extension cord. Remember, never remove the third prong from a plug, as it is there to provide grounding. By taking these simple precautions, you can stay safe and enjoy using power tools without worry.