What if I told you there’s a machine that can bore holes with incredible precision? Yes, you heard it right! Let me introduce you to the jig boring machine. So, what is a jig boring machine, you ask? Well, buckle up and get ready to discover something fascinating!

Imagine a machine that can drill holes with such accuracy that it will leave you in awe. The jig boring machine is a beast when it comes to achieving high precision in hole drilling. Not only does it make holes, but it also ensures that they are perfectly straight, parallel, and aligned. Talk about taking accuracy to the next level!

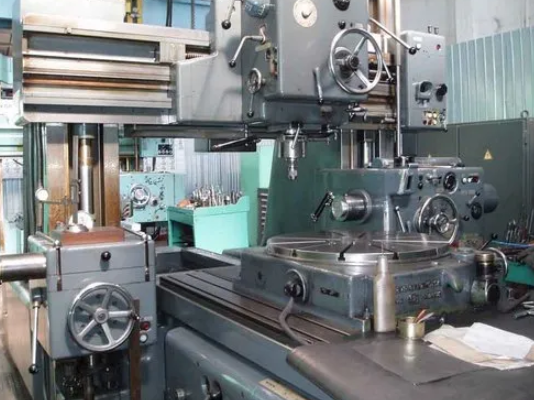

But how does it achieve such precision? The secret lies in its design and construction. The jig boring machine incorporates a unique setup, comprising a worktable, boring head, and a spindle. This setup enables the machine to perform intricate operations with utmost accuracy, making it an indispensable tool in fields like aerospace, automobile manufacturing, and toolmaking.

So, are you excited to delve into the world of jig boring machines? Get ready to uncover the fascinating details about their operation, applications, and how they have revolutionized the way we create precision holes. Let’s dive in and discover the wonders of this incredible machine together!

Jig boring machines are precision machining tools used to create highly accurate holes in metal workpieces. These machines utilize a rotating cutter and a stationary workpiece, enabling precise cutting movements. Jig boring machines offer superior accuracy and repeatability, making them ideal for industries such as aerospace and automotive. With their ability to produce holes with tight tolerances, these machines play a crucial role in achieving precise manufacturing standards.

What is a Jig Boring Machine? Exploring the Precision Engineering Tool

A jig boring machine is a precision engineering tool used to create highly accurate holes in workpieces. It is a type of machine tool that utilizes a single-point cutting tool to remove material and create precise holes with exceptional accuracy and surface finish. Jig boring machines are specially designed to handle complex machining operations that require high precision and strict tolerances. They are commonly used in industries such as aerospace, automotive, and medical manufacturing, where precision is of paramount importance.

In this article, we will delve into the intricacies of jig boring machines, exploring their features, applications, and benefits. We will also compare them to other types of machine tools and provide useful tips for optimizing their performance. So, let’s dive into the world of precision engineering and discover the capabilities of a jig boring machine.

Features of Jig Boring Machines: Precision at its Finest

When it comes to precision machining, jig boring machines are at the forefront. These machines possess several key features that make them ideal for applications requiring high accuracy and surface finish:

- Multi-axis Capability: Jig boring machines typically have at least three axes of movement – X, Y, and Z. This allows for precise positioning of the workpiece, enabling accurate hole creation from all angles.

- High Tolerance and Surface Finish: Jig boring machines can achieve extremely tight tolerances, often in the range of micrometers. Additionally, they produce excellent surface finishes, minimizing the need for post-machining operations.

- Tooling Stability: These machines are designed with robust structures and advanced damping systems to ensure tooling stability. This minimizes vibration and ensures consistent cutting performance.

- Temperature Control: Jig boring machines incorporate temperature control systems to maintain a stable thermal environment. This helps prevent dimensional variations caused by thermal expansion or contraction.

The combination of these features enables jig boring machines to tackle the most demanding machining tasks with unparalleled precision and accuracy.

The Versatile Applications of Jig Boring Machines

Jig boring machines find a wide range of applications across various industries. Some of the key sectors that benefit from the precision capabilities of these machines include:

- Aerospace: In the aerospace industry, where safety and reliability are paramount, jig boring machines are used to create precision holes in critical components such as turbine blades, engine casings, and structural elements.

- Automotive: Jig boring machines play a vital role in the automotive industry, where precise machining is crucial for engine components, transmission parts, and other critical systems.

- Medical Manufacturing: The medical field relies on jig boring machines to produce intricate and precise holes in surgical instruments, implants, and medical devices, ensuring the highest quality and safety standards.

- Tool and Die Making: Jig boring machines are extensively used in tool and die making to create accurate holes for punches, molds, and other intricate components.

These are just a few examples of the versatile applications of jig boring machines. From complex aerospace components to intricate surgical instruments, these machines excel in delivering precision and performance.

The Benefits of Jig Boring Machines: Precision, Efficiency, and Cost Savings

Investing in a jig boring machine offers numerous advantages for manufacturers seeking precision and efficiency in their operations. Some of the key benefits include:

- Unmatched Precision: Jig boring machines are known for their exceptional accuracy and surface finish, allowing manufacturers to achieve the tightest tolerances and high-quality machining results.

- Improved Efficiency: With their multi-axis capability and advanced features, jig boring machines enable efficient machining of complex workpieces, reducing the need for multiple setups and secondary operations.

- Time and Cost Savings: By eliminating the need for additional machining and finishing processes and ensuring accurate results in a single operation, jig boring machines contribute to significant time and cost savings.

- Enhanced Productivity: The precise and reliable performance of jig boring machines allows manufacturers to increase productivity by reducing errors, minimizing scrap rates, and achieving faster cycle times.

The benefits offered by jig boring machines make them an invaluable asset for manufacturers operating in industries that demand the highest levels of precision and efficiency.

Advanced Features and Innovations in Jig Boring Machines

Jig boring machines have witnessed significant advancements and innovations in recent years, further enhancing their capabilities and performance. Some of the notable features and technologies that have been incorporated into modern jig boring machines are:

1. Computer Numerical Control (CNC)

CNC technology has revolutionized the field of machining, and jig boring machines are no exception. The integration of CNC systems brings numerous benefits, including higher automation, improved accuracy, and enhanced programming capabilities. With CNC, complex machining operations can be easily programmed and executed with unmatched precision.

2. High-Speed Machining

High-speed machining (HSM) has become increasingly popular in various industries, and jig boring machines have embraced this technology. HSM techniques, such as trochoidal milling and constant tool engagement, allow for faster material removal rates while maintaining excellent surface finish and preserving tool life. This translates to increased productivity and reduced machining times.

3. Advanced Tooling Systems

Modern jig boring machines come equipped with advanced tooling systems that enhance performance and flexibility. These systems may include automatic tool changers, tool length measurement sensors, and tool condition monitoring. Such features streamline setup processes and ensure optimal tool performance throughout the machining operation.

Key Considerations for Jig Boring Machine Selection

Choosing the right jig boring machine for your specific needs requires careful consideration of several factors. Here are some key considerations to keep in mind:

1. Precision Requirements

Evaluate the precision levels your application demands and select a jig boring machine with the necessary accuracy and tolerances to meet those requirements.

2. Workpiece Size and Complexity

Consider the size and complexity of the workpieces you will be machining. Ensure that the machine you select can accommodate the size and weight of your parts and offers the desired level of multi-axis movement.

3. Software and Programming Capabilities

Assess the software and programming capabilities of the jig boring machine, particularly if you require advanced functionalities such as CNC programming, CAD/CAM compatibility, and simulation capabilities.

4. Tooling and Workholding Options

Examine the available tooling and workholding options compatible with the machine to ensure they align with your specific requirements. Look for systems that offer flexibility, easy setup, and sufficient rigidity to prevent vibration.

By considering these factors and carefully evaluating the features and capabilities of different jig boring machines, you can make an informed choice that aligns with your precision machining needs and goals.

Optimizing Performance: Tips for Using Jig Boring Machines

To make the most of your investment in a jig boring machine and achieve optimal performance, consider the following tips:

1. Select Appropriate Cutting Parameters

Understand the material properties of your workpiece and consult the cutting tool manufacturer’s guidelines to select the appropriate cutting speeds, feed rates, and depth of cut. This will ensure efficient material removal while prolonging tool life.

2. Maintain a Clean and Properly Lubricated Machine

Regularly clean and maintain your jig boring machine to prevent the accumulation of chips and debris. Proper lubrication is essential to prevent friction, reduce wear on machine components, and ensure smooth and precise movement.

3. Conduct Regular Tooling Inspections

Periodically inspect and measure your cutting tools to identify wear or damage. Replace worn tools promptly to maintain consistent quality and prevent potential issues that could affect precision.

The Future of Jig Boring Machines: Advancements and Innovations

The field of precision machining is continually evolving, and jig boring machines are set to embrace future advancements and innovations. Some of the areas where we can expect further developments include:

1. Artificial Intelligence (AI) Integration

AI technologies have the potential to revolutionize machining processes. Integration of AI into jig boring machines can optimize tool paths, predict and prevent errors, and enhance overall process control and efficiency.

2. Enhanced Automation and Robotics

Automation and robotics are already prevalent in manufacturing, and their presence in jig boring machines is likely to increase. Advanced robotic systems can further enhance productivity, reduce manual intervention, and enable unattended machining operations.

3. Improved Integration with Industry 4.0

The concept of Industry 4.0 revolves around the seamless integration of machines, processes, and data. Jig boring machines that adopt Industry 4.0 principles can provide real-time monitoring, predictive maintenance, and data-driven decision-making capabilities, leading to increased efficiency and productivity.

As technology continues to advance, the capabilities and performance of jig boring machines will reach new heights, empowering manufacturers to achieve unprecedented levels of precision and efficiency in their machining operations.

In Summary

Jig boring machines are precision engineering tools that offer exceptional accuracy and surface finish when it comes to creating highly accurate holes in workpieces. Their multi-axis capability, high tolerance levels, and stability make them ideal for industries that demand precision, such as aerospace, automotive, and medical manufacturing. Investing in a jig boring machine brings numerous benefits, including unmatched precision, improved efficiency, time and cost savings, and enhanced productivity. By considering key factors and maintaining best practices, manufacturers can optimize the performance of jig boring machines and achieve exceptional machining results. With future advancements on the horizon, these machines are set to continue revolutionizing precision engineering and shaping the manufacturing landscape for years to come.

Key Takeaways: What is a Jig Boring Machine?

- A jig boring machine is a precision tool used in machining to create highly accurate holes and bores.

- It uses a specialized tool called a jig, which guides the cutting tool with great precision.

- Jig boring machines are commonly used in industries like aerospace, automotive, and tool manufacturing.

- These machines are capable of producing holes with extremely tight tolerances, ensuring precise fits.

- They are essential for tasks that require high levels of precision and accuracy in hole machining.

Frequently Asked Questions

Welcome to our FAQ section on jig boring machines! If you’re new to this topic or just curious to learn more, you’ve come to the right place. Below, we’ve answered some common questions related to jig boring machines. Let’s dive in!

Q1: How does a jig boring machine work?

At its core, a jig boring machine is a precision machining tool used to create highly accurate holes. It works by securing the workpiece in a fixed position on the machine’s table. The machine then uses a spindle that moves vertically to bore the hole.

Unlike a regular drilling machine, a jig boring machine offers exceptional precision and control. It uses special jigs and fixtures to guide the movement of the spindle and ensure the hole is made accurately within tight tolerances. This makes it a perfect choice for industries where precision is crucial, such as aerospace and automotive manufacturing.

Q2: What are the advantages of using a jig boring machine?

Jig boring machines offer several advantages over traditional drilling machines. Firstly, they provide exceptional accuracy. With carefully designed jigs and fixtures, the machine’s spindle movement can be controlled to create holes with high precision and repeatability.

Secondly, jig boring machines allow for complex hole configurations. By using custom jigs, it’s possible to create holes at different angles, depths, and orientations, enabling the production of intricate parts. Lastly, these machines are known for their versatility. They can handle various materials, including metals, plastics, and composites, making them suitable for a wide range of industries.

Q3: What are some typical applications of jig boring machines?

Jig boring machines find applications in industries that require precision machining. Some common uses include the manufacturing of molds, dies, and fixtures for automotive, aerospace, and electronics industries.

These machines are especially valuable when creating complex parts or components that require multiple accurate holes with tight tolerances. They are also suitable for creating holes in parts where traditional drilling methods would not be precise enough. In addition, jig boring machines are often used in research and development facilities to create prototypes and test new designs.

Q4: How is a jig boring machine different from a regular drilling machine?

A jig boring machine and a regular drilling machine may appear similar, but they serve different purposes. While a regular drilling machine is designed for drilling holes quickly and efficiently, a jig boring machine focuses on accuracy and precision.

A jig boring machine offers specialized features like jigs and fixtures to guide the drilling process. It allows for finer control over hole size, depth, and position. Additionally, jig boring machines often have higher spindle speeds and advanced controls to ensure precise and repeatable results. On the other hand, regular drilling machines are more suitable for general drilling purposes that don’t require the same level of precision.

Q5: Are there any safety precautions to consider when using a jig boring machine?

Yes, ensuring safety when operating a jig boring machine is essential. Here are some key precautions to take:

1. Familiarize yourself with the machine’s user manual and follow all safety guidelines provided by the manufacturer.

2. Wear appropriate personal protective equipment (PPE), such as safety glasses and gloves, to protect yourself from any potential hazards.

3. Ensure the workpiece is securely clamped to the machine’s table to prevent movement during operation.

4. Keep the work area clean and free of debris to avoid accidents and interference with the machine’s operation.

Remember, if you’re uncertain about any aspect of using a jig boring machine, consult with a qualified professional or seek assistance from someone with experience operating these machines.

Summary:

Jig boring machines are super precise tools that make really accurate holes. They use special jigs to guide the cutting tool. This helps to make holes that are straight and the right size. These machines are used in industries like aerospace and automotive manufacturing to create very precise parts. Jig boring machines are all about making holes with precision!

So, next time you need a really accurate hole, remember the jig boring machine. It may not be the most exciting machine to look at, but it sure is important for making things just right. Now you know what a jig boring machine is and how it works. Keep on exploring the fascinating world of machines and technology!