Have you ever wondered what lathe backlash is and why it matters? Well, you’re in the right place! In this article, we’ll break down the concept of lathe backlash in a simple and easy-to-understand way. So, let’s dive in and demystify this term together!

Imagine you have a lathe—a machine used for shaping metal or wood—with various moving parts. Now, when you turn the handle to move the cutting tool, there’s a tiny amount of play or slop before the tool starts to move. This play is known as backlash, and it can affect the precision and accuracy of your work on the lathe.

So, why is backlash a big deal? Well, let’s say you’re working on a project that requires precise measurements. If there’s too much backlash in the lathe, you might end up with inaccuracies and imperfections in your work. Understanding and managing backlash is crucial for achieving high-quality results. Don’t worry, though—I’ll explain how to deal with backlash in the upcoming sections. So, let’s get ready to tackle this challenge head-on!

– Check the backlash by moving the carriage back and forth.

– Adjust the Gib strips or adjuster screws to reduce the backlash.

– Recheck the backlash and make further adjustments if necessary.

– Lubricate the moving parts regularly.

By reducing backlash, you can achieve better machining results with your lathe.

What is Lathe Backlash?

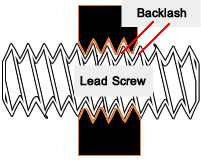

Lathe backlash refers to the lost motion or play that occurs in the movement of a lathe machine’s components. In simple terms, it is the amount by which the slide or toolpost may be moved before the lathe actually starts to cut or turn the workpiece. Backlash can occur in various parts of a lathe, including the leadscrew, cross-slide, compound rest, and tailstock. Although some level of backlash is inevitable in any machine, excessive backlash can significantly affect the accuracy and precision of the lathe’s operations.

The Causes of Lathe Backlash

Several factors can contribute to the presence of backlash in a lathe. One key factor is the wear and tear of components over time. As the machine is used, the constant movement and pressure can cause parts to become loose or worn, resulting in increased backlash. Another common cause is poor machine maintenance. If a lathe is not regularly lubricated, cleaned, and tightened, it is more likely to develop backlash. Additionally, incorrect adjustment and alignment of the machine’s components, such as the leadscrew and cross-slide, can also contribute to backlash.

Benefits of Reducing Backlash

- Improved accuracy and precision in machining operations

- Consistency in the dimensions and surface finish of the workpiece

- Reduced need for rework or scrap due to out-of-tolerance parts

- Enhanced overall productivity and efficiency

- Extended lifespan of the lathe machine

Methods to Minimize Lathe Backlash

While it may not be possible to completely eliminate backlash, there are several steps that can be taken to minimize its impact on lathe operations:

- Regular Maintenance: Perform routine cleaning, lubrication, and tightening of all components to reduce wear and looseness.

- Proper Adjustment: Ensure that all movable parts are correctly adjusted and aligned according to the lathe manufacturer’s guidelines.

- Backlash Compensation: Some modern lathes are equipped with backlash compensation mechanisms or software that automatically adjusts for backlash during operation.

- Use High-Quality Components: Invest in high-quality screws, nuts, and other components that have minimal inherent backlash.

- Regular Inspection: Regularly inspect the lathe for signs of wear or damage and address any issues promptly to prevent backlash from worsening.

Lathe Backlash vs. Accuracy

One of the primary concerns with lathe backlash is its impact on accuracy. Backlash can result in dimensional errors, inconsistent surface finish, and reduced repeatability. It can be particularly problematic when performing precise machining operations, such as thread cutting or facing. Therefore, minimizing backlash is crucial to maintaining the desired accuracy and achieving high-quality machined parts.

Conclusion:

Lathe backlash is a common issue that can affect the precision and quality of machining operations. By understanding the causes of backlash and implementing appropriate measures to minimize it, lathe operators can improve accuracy, consistency, and overall productivity. Regular maintenance, proper adjustment, and the use of high-quality components are key to reducing the impact of backlash on lathe performance. With careful attention to detail and proactive measures, lathe operators can minimize backlash and achieve the desired accuracy in their machined parts.

Key Takeaways: What is Lathe Backlash?

– It can affect the precision and accuracy of the workpieces produced.

– Backlash can occur in the leadscrew, gears, and other mechanical parts of the lathe.

– Regular maintenance and adjustment can help reduce backlash and improve machining quality.

– Minimizing backlash is crucial for achieving precise and consistent machining results.

Frequently Asked Questions

Welcome to our frequently asked questions section, where we provide answers to common queries related to lathe backlash. Whether you’re a seasoned machinist or just getting started in the world of lathes, we’ve got you covered. Read on to learn more about this important concept.

1. What causes lathe backlash?

Lathe backlash is primarily caused by the mechanical clearance between the mating parts of a lathe’s lead screw and nut. When you reverse the direction of the feed, this clearance can result in a small amount of play or “slop” in the system. Over time, wear and tear on the mechanical components can also contribute to backlash.

Other factors that can lead to lathe backlash include improper adjustments or maintenance, worn or damaged parts, and thermal expansion or contraction. It’s important to regularly inspect and maintain your lathe to minimize the effects of backlash.

2. How does lathe backlash affect machining?

Lathe backlash can have several negative effects on machining operations. Firstly, it can lead to dimensional inaccuracies in the workpiece. When the lathe reverses direction, the play in the system can cause the tool to move slightly before engaging the workpiece. This results in imprecise cuts and reduced machining quality.

Backlash can also contribute to poor surface finish. As the tool changes direction, the slight movement caused by backlash can create marks or chatter on the workpiece. This can be particularly problematic when working with delicate materials or when precision is crucial, such as in the manufacturing of aerospace components or medical devices.

3. How can I measure lathe backlash?

There are several methods to measure lathe backlash, but one common approach involves using a dial indicator. You can mount the dial indicator to a fixed point on your lathe and then use it to measure the movement of the carriage when the lead screw changes direction.

To accurately measure backlash, move the carriage in one direction until there is no further movement, note the position, and then reverse the carriage. The reading on the dial indicator will indicate the amount of backlash present in your lathe system.

4. Can lathe backlash be eliminated?

While it is challenging to completely eliminate lathe backlash, it can be minimized using various techniques. Regular maintenance and adjustment of the lathe components can help reduce backlash. Proper lubrication and keeping parts clean and in good condition are essential.

Using backlash compensation techniques, such as climb cutting or taking multiple light cuts, can also help mitigate the effects of backlash. Additionally, upgrading to a lathe with a higher precision lead screw and nut can reduce the amount of backlash present in the system.

5. How does backlash affect threading operations?

Backlash can have a significant impact on threading operations. When cutting threads, the tool moves back and forth, changing the direction of the feed frequently. The presence of backlash can cause the tool to momentarily disengage from the workpiece, resulting in inaccuracies in the thread pitch and potential threading errors.

To minimize the effects of backlash during threading, it is crucial to use cutting tools specifically designed for threading operations. These tools are designed to compensate for the slight movements caused by backlash, ensuring precise and accurate threading results.

Machinist’s Minute: What is lathe backlash? 1/2

Summary

Imagine you have a machine called a lathe. Sometimes, when you want it to move in one direction, it might move a tiny bit in the opposite direction. This is called backlash. Backlash can cause errors in the things you make with the lathe, like a crooked cut or a bad finish. It’s important to understand backlash and how to minimize it for better accuracy and quality in your work.

To reduce backlash, you can adjust the machine to make it more precise. By tightening or adjusting certain parts, you can make the lathe move smoothly and without any wiggling. It’s also helpful to be aware of backlash when using the lathe, so you can compensate for it and make adjustments as needed. With this knowledge, you’ll be able to work with your lathe more effectively and create better projects.