Are you curious about what a lathe bar is? Well, get ready to turn your curiosity into knowledge! In simple terms, a lathe bar is a long cylindrical piece of metal that is used in lathes to hold and rotate workpieces. It’s like the “magic wand” of a lathe that makes precision machining possible.

You might be wondering, “Why is a lathe bar so important?” Great question! Think of it like the backbone of a lathe. Without a sturdy and reliable bar, the lathe wouldn’t be able to perform its machining wizardry. The bar provides stability and support, allowing the workpiece to be accurately shaped and cut.

Now, you might be thinking, “How does this lathe bar actually work?” Well, my friend, it’s all about the power of rotation. When inserted into the lathe, the bar spins at high speeds, while the workpiece is securely attached to it. This rotation enables precise cutting, shaping, and drilling operations, turning raw materials into finished products.

So, now that you know what a lathe bar is and why it’s essential, let’s dive deeper into this fascinating world of machining. Get ready to explore the different types of lathe bars, their materials, and the incredible things they can create. Let’s embark on this mechanical journey together!

What is Lathe Bar? An In-depth Look at an Essential Tool for Precision Machining

When it comes to precision machining, the lathe bar is an indispensable tool. Whether you’re a seasoned professional or an amateur enthusiast, understanding the function and significance of this equipment is essential. In this article, we will explore the ins and outs of the lathe bar, from its construction and usage to the various applications it finds in industries like manufacturing, automotive, and aerospace. So, let’s dive in and unravel the world of lathe bars!

What Makes a Lathe Bar?

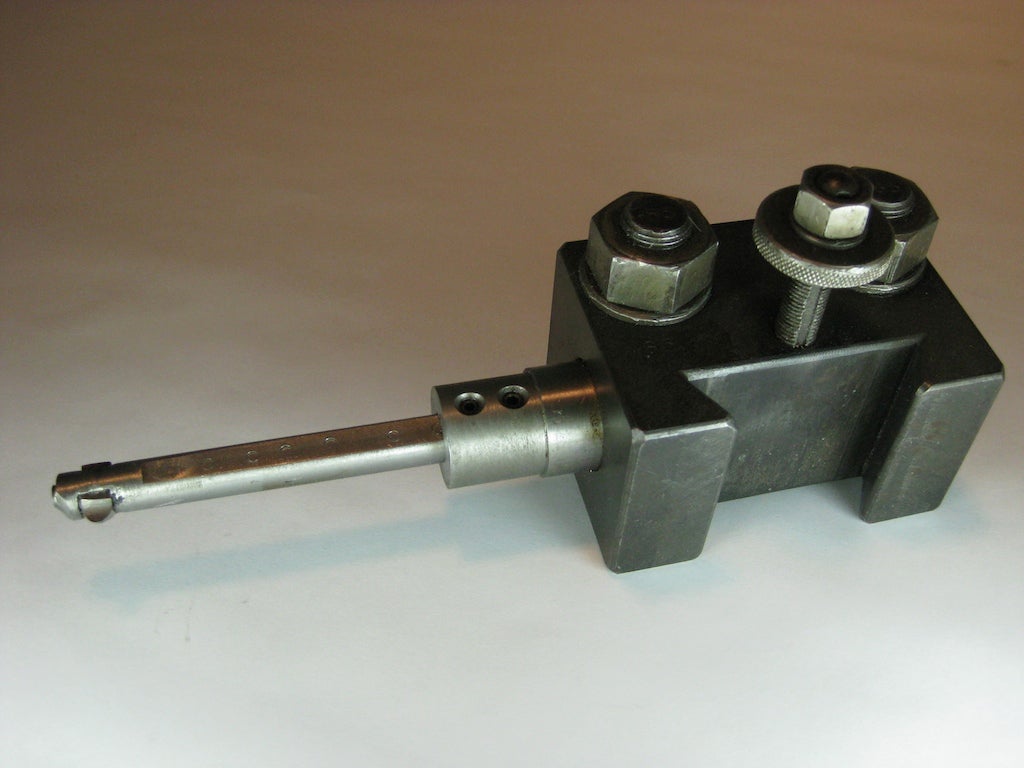

A lathe bar, also known as a lathe tool or turning tool, is a cylindrical rod made of high-quality steel or carbide. It is typically used in conjunction with a lathe machine, which rotates the bar against a workpiece to shape, cut, or carve the material with precision. The lathe bar consists of two primary parts – the shank and the cutting edge.

The shank is the main body of the lathe bar and is clamped into the lathe machine’s tool post or tool holder. It provides stability and rigidity during the machining process. The cutting edge, on the other hand, is the business end of the lathe bar. It is carefully shaped and ground to create different cutting geometries to suit various machining needs. The cutting edge can have square, round, or triangular profiles, each serving a specific purpose.

The Versatility of Lathe Bars

Lathe bars are incredibly versatile tools with a wide range of applications in different industries. Here are some of the most common uses:

- Turning: The primary function of a lathe bar is to perform turning operations. This involves removing material from the workpiece to create cylindrical shapes, such as shafts, rods, and tubes. The cutting edge of the lathe bar gradually removes the material as the workpiece rotates, resulting in precise and smooth surfaces.

- Facing: Lathe bars are also used for facing operations, where the cutting edge is perpendicular to the workpiece’s axis. This allows for the creation of flat surfaces, such as the ends of a cylinder or a plate.

- Parting: With a specialized lathe bar called a parting tool, machinists can cut off sections from the workpiece, creating separate parts. This is commonly used in manufacturing to create grooves, slots, and cut-offs.

The Benefits of Using Lathe Bars

Using lathe bars offers several advantages, making them a preferred choice for precision machining:

- Accuracy: Lathe bars provide exceptional accuracy, allowing machinists to achieve precise dimensions and tolerances.

- Efficiency: With the ability to remove material at a fast rate, lathe bars enable efficient machining processes, reducing overall production time.

- Versatility: The interchangeable nature of lathe bars allows for easy adaptation to different machining operations, making them versatile tools in various industries.

- Durability: High-quality lathe bars made from sturdy materials like carbide can withstand the demanding conditions of machining processes, ensuring long-lasting performance.

Tips for Using Lathe Bars Effectively

To make the most out of your lathe bars, here are some valuable tips:

- Select the right cutting edge: Depending on the material and the type of cut, choose the appropriate cutting edge geometry to achieve desired results.

- Pay attention to speed and feed: Optimize the cutting speed and feed rate to prevent premature wear and achieve optimal cutting performance.

- Maintain proper tool geometry: Regularly inspect and maintain the cutting edge geometry to ensure accurate and efficient cuts.

- Use cutting fluids: When working with challenging materials, applying cutting fluids can improve lubrication, cooling, and chip evacuation, enhancing tool life and performance.

- Replace worn-out bars: As lathe bars wear out over time, replace them promptly to maintain quality and precision in machining operations.

Additional Applications of Lathe Bars

Aside from the primary functions mentioned earlier, lathe bars are also used for:

- Threading: With specialized lathe bars and appropriate attachments, machinists can create external and internal threads on a workpiece.

- Boring: By using a lathe bar with a specially designed cutting edge, machinists can enlarge and refine the diameter of existing holes.

- Tapering: Lathe bars with tapered cutting edges allow for precision machining of tapered surfaces, such as conical shapes or chamfers.

- Knurling: Certain lathe bars have knurled cutting edges, enabling the texturing of workpiece surfaces for improved grip or aesthetic purposes.

As you can see, lathe bars are a critical tool in precision machining. Their versatility, accuracy, and efficiency make them indispensable in various industries. By understanding their construction, usage, and application, you can unlock the full potential of lathe bars in your machining endeavors. So, get your hands on one and start crafting precise creations!

Conclusion

In summary, the lathe bar is a cylindrical rod made of high-quality steel or carbide, consisting of a shank and a cutting edge. It is primarily used for turning, facing, and parting operations, offering accuracy, efficiency, versatility, and durability. By following tips for effective use and exploring additional applications, you can fully harness the power of the lathe bar in precision machining. So, go ahead and embrace this essential tool in your machining journey!

Key Takeaways: What is Lathe Bar?

- Lathe bar is a cylindrical metal rod used in lathes for machining operations.

- It is commonly made of materials like steel, aluminum, or brass.

- Lathe bars come in various lengths and diameters to suit different machining requirements.

- These bars are secured in the lathe machine and rotated to shape or cut the workpiece.

- Lathe bars play a crucial role in the precision manufacturing industry.

Frequently Asked Questions

In this section, we’ll answer some common questions about lathe bars and their uses.

1. How are lathe bars different from regular bars?

Lathe bars, also known as turning bars, are specifically designed for use with a lathe machine. Unlike regular bars, lathe bars have precise dimensions to fit into the lathe tool holders. They are made from high-quality materials, such as high-speed steel or carbide, to withstand the high cutting forces generated during turning operations. Regular bars, on the other hand, are more general-purpose and may not have the same level of precision or durability required for lathe machining.

When using a lathe machine, it is crucial to have the right lathe bar to ensure accurate and efficient cutting. Using regular bars in a lathe can lead to poor performance, inaccurate results, and can even damage the machine.

2. What are the different types of lathe bars available?

There are several types of lathe bars available, each designed for specific turning operations. Some common types include:

– Carbide Lathe Bars: Known for their excellent durability and high cutting speeds, carbide lathe bars are ideal for machining hard materials like stainless steel, cast iron, and titanium.

– High-Speed Steel (HSS) Lathe Bars: HSS lathe bars are versatile and can handle a wide range of materials. They are less expensive than carbide bars but may need to be sharpened more frequently.

– Indexable Lathe Bars: These bars feature replaceable cutting inserts, allowing for quick and easy tool changes. They are popular for their cost-effectiveness and versatility.

Choosing the right type of lathe bar depends on factors such as the material being machined, the desired surface finish, and the specific turning operation at hand.

3. How do I select the right lathe bar size?

When selecting a lathe bar size, it is important to consider the workpiece dimensions, the lathe machine’s capacity, and the desired cutting depth. The lathe bar size refers to its overall dimensions, including its diameter and length. It should fit properly into the lathe tool holder without any interference. You should also consider the rigidity of the lathe bar – a sturdier and thicker bar can handle heavier cuts without vibration or deflection.

Consult the lathe machine’s manual or a machining expert to determine the appropriate lathe bar size for your specific application. They can provide guidance based on the machine’s capabilities and the material you’ll be machining.

4. What are the advantages of using lathe bars?

Using lathe bars offers several advantages:

– Precision: Lathe bars are designed to meet strict dimensional tolerances, ensuring accurate and precise turning operations.

– Efficiency: With the right lathe bar, you can perform turning operations quickly and efficiently, reducing production time.

– Versatility: Lathe bars are available in various types, sizes, and cutting geometries, making them suitable for a wide range of turning applications.

– Durability: Lathe bars made from high-quality materials, like carbide or HSS, are built to withstand the demanding cutting forces involved in lathe machining.

Overall, using lathe bars improves machining performance, enhances accuracy, and helps achieve high-quality finished products.

5. How do I maintain and extend the lifespan of lathe bars?

To maintain and extend the lifespan of lathe bars, follow these tips:

– Keep them clean: After use, remove any chips or debris from the lathe bars to prevent buildup that can lead to poor performance and premature wear.

– Use proper cutting fluids: Applying suitable cutting fluids during turning operations reduces heat and friction, extending the life of the lathe bar.

– Handle with care: Avoid dropping or mishandling lathe bars, as this can cause chipping, deformation, or other damage.

– Store them correctly: Properly store lathe bars in a cool, dry place away from corrosive substances or excessive moisture.

– Sharpen or replace when necessary: Regularly inspect the lathe bar’s cutting edge and replace or sharpen it as needed to maintain optimal cutting performance.

By following these maintenance practices, you can maximize the lifespan of your lathe bars and ensure they perform well in your machining operations.

Summary

A lathe bar is a long, cylindrical piece of metal used in machinery. It is usually made of steel or other strong materials.

Lathe bars are essential for shaping and cutting objects in a lathe machine. They come in different sizes and can be customized for specific projects.

Using a lathe bar requires skill and safety precautions, as the machine spins the bar at high speeds. It is important to wear protective gear and follow instructions carefully.

In conclusion, a lathe bar is a versatile tool that plays a crucial role in precision metalworking.