If you’ve ever wondered, “What is a lathe dead centre?” you’re in the right place! In simple terms, a lathe dead centre is a critical component used in machining and woodworking. It plays a crucial role in providing support and stability to the workpiece. So, let’s dive in and explore this fascinating device together!

Picture this: a spinning lathe, a piece of material being shaped, and right at the center of it all, the lathe dead centre. It’s like the backbone of the operation, ensuring everything runs smoothly and precisely. Without it, the workpiece might wobble or lose alignment, leading to imperfect results.

Think of the lathe dead centre as the secret ingredient that holds everything together. It’s designed with a pointed tip that fits into a pre-drilled hole or groove in the workpiece, creating a solid connection. This connection allows the workpiece to rotate effortlessly and evenly, enabling the cutting tools to do their magic.

So, whether you’re a curious mind exploring the world of machining or a hobbyist looking to take your woodworking skills to the next level, understanding the role of a lathe dead centre is essential. Get ready to unlock the secrets behind this crucial tool and discover how it enhances precision and craftsmanship in a variety of industries. Let’s dive in, shall we?

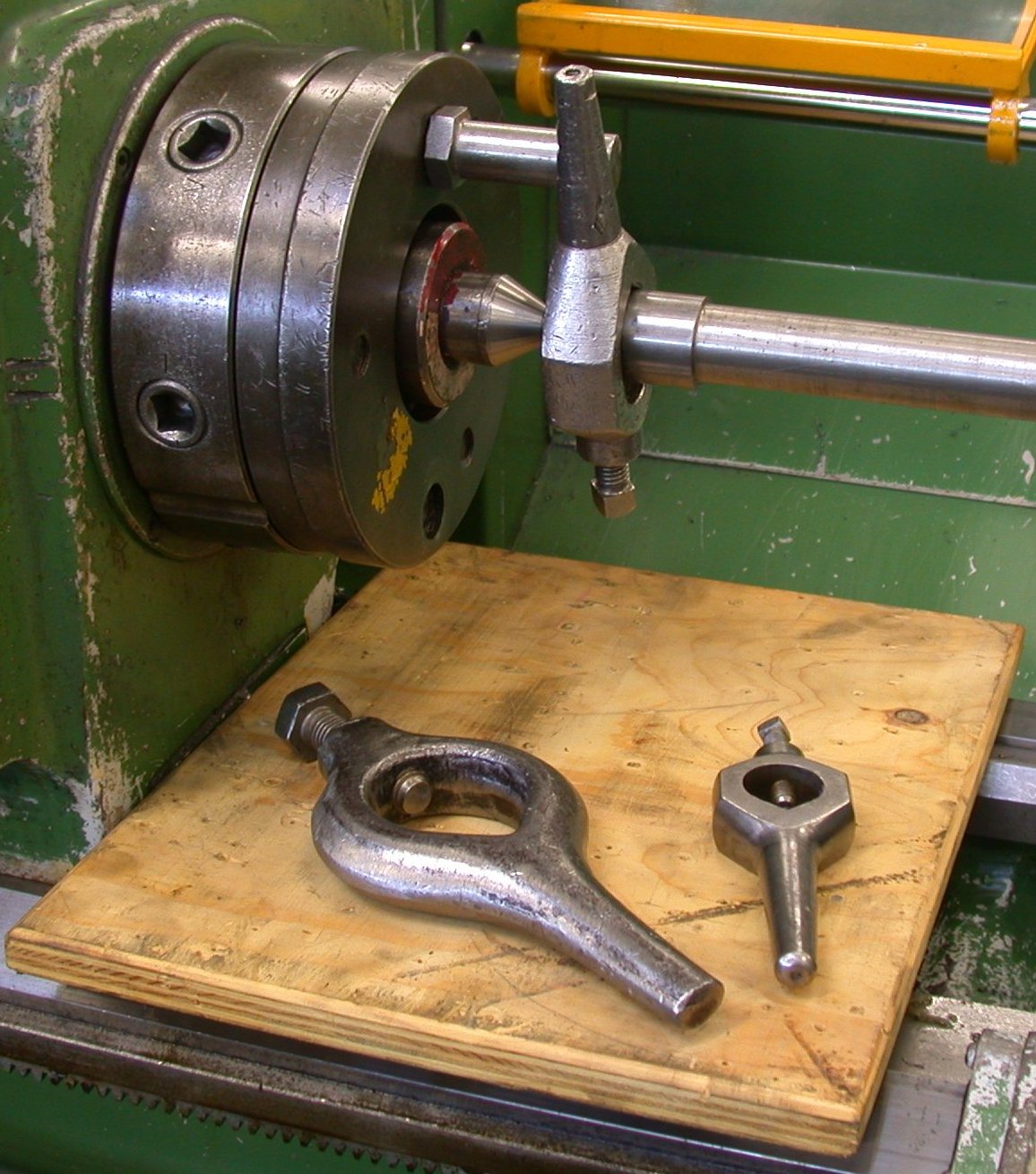

A lathe dead center is a tool used in machining to support the workpiece. It serves as a pivot point for cutting tools and helps maintain accuracy and stability during turning operations. The dead center is inserted into a hole in the end of the workpiece and rotates with it. This allows for precise machining and reduces the risk of deflection. Lathe dead centers come in different forms, such as live centers and dead centers. They are essential components in metalworking and woodworking industries.

Understanding the Lathe Dead Centre: A Comprehensive Guide

Welcome to our in-depth guide on the lathe dead centre, an essential component in lathe machines. In this article, we will delve into the functioning, types, and applications of the lathe dead centre. Whether you are a hobbyist or a professional machinist, understanding the importance and intricacies of the dead centre is crucial for achieving precise and accurate machining results. Let’s explore the world of lathe dead centres and discover their significance in the machining industry.

The Purpose and Types of Lathe Dead Centres

The lathe dead centre is a mechanical tool used in metalworking lathes to support the workpiece during machining operations. It plays a vital role in maintaining the alignment and rotational movement of the workpiece, ensuring precise and controlled machining. Dead centres come in various types, each with unique characteristics suitable for specific applications.

1. The Live Centre

The live centre, also known as the revolving centre, is the most commonly used type of dead centre. It features a bearing mechanism that allows it to rotate along with the workpiece. This rotation minimizes friction, reduces heat build-up, and increases the lifespan of the centre. Live centres are best suited for applications where both the workpiece and the tool require rotational movement.

Live centres are available in different designs, such as standard live centres, ball-bearing live centres, and interchangeable point live centres. Each design offers distinct advantages and is selected based on factors like load capacity, speed, precision, and type of material being machined.

2. The Dead Centre

Unlike live centres, dead centres do not rotate with the workpiece. They are primarily used in situations where only the workpiece needs to rotate while the tool remains stationary. Dead centres are often built with hardened steel to withstand the high pressures and heat generated during machining. They are particularly useful when heavy loads or interrupted cuts are involved.

Dead centres can be classified into two main types: the plain dead centre and the spring-loaded dead centre. The plain dead centre is a simple design with a conical point, while the spring-loaded dead centre incorporates a spring mechanism that provides a cushioning effect and minimizes the risk of damage when the workpiece encounters sudden resistance.

The Importance of Choosing the Right Lathe Dead Centre

Choosing the appropriate lathe dead centre is crucial for achieving optimal machining results. Here are some key factors to consider:

1. Material Compatibility

The dead centre material should be compatible with the type of workpiece material to prevent premature wear and damage. Hardened steel or carbide dead centres are commonly used for machining ferrous metals, while softer dead centres made from materials like bronze or brass are suitable for non-ferrous and delicate materials.

2. Load Capacity

The dead centre must be capable of supporting the maximum load encountered during machining. High-load applications often require heavy-duty dead centres with a robust design and enhanced load-bearing capacity. It is essential to consider the weight and dimensions of the workpiece to ensure the dead centre can handle the required load.

3. Precision and Taper Accuracy

Precision and taper accuracy are crucial for achieving precise machining results. It is important to select a dead centre with tight tolerances and excellent taper accuracy to ensure accurate alignment and minimal runout. This is especially important for applications that demand high precision, such as tool and die making.

Tips for Proper Use and Maintenance of Lathe Dead Centres

To maximize the performance and lifespan of your lathe dead centre, follow these essential tips:

1. Lubrication

Regularly lubricate the dead centre to minimize friction and prevent premature wear. Use a high-quality lubricant suitable for metalworking applications and follow the manufacturer’s recommendations for lubrication intervals.

2. Cleaning

Keep the dead centre clean from chips, debris, and coolant residue. Use compressed air or a soft brush to remove any contaminants that may affect the performance and accuracy of the centre.

3. Inspection

Regularly inspect the dead centre for signs of wear, damage, or misalignment. If any issues are detected, replace or repair the dead centre immediately to prevent poor machining quality and potential safety hazards.

The lathe dead centre is an indispensable tool in the machining industry, providing stability and precision during the manufacturing process. By understanding its various types, applications, and maintenance requirements, machinists can optimize their machining operations and achieve superior results. Remember to choose the right dead centre for your specific needs and follow proper care and maintenance practices to ensure its longevity and performance.

Key Takeaways – What is Lathe Dead Centre?

- A lathe dead center is a tool used in the lathe machine for supporting the workpiece during rotation.

- It has a pointed tip that fits into a corresponding hole on the workpiece, allowing for precise turning operations.

- Lathe dead centers come in various types such as the plain center, live center, and half center.

- They are made from hardened steel to withstand high pressure and rotational forces.

- Using a lathe dead center helps ensure accuracy and stability in machining processes.

Frequently Asked Questions

Welcome to our FAQ section where we answer some commonly asked questions about the lathe dead center.

What is a lathe dead center used for?

A lathe dead center is a tool used in machining processes, specifically in metalworking on a lathe machine. It is primarily used to support the workpiece, providing stability and reducing vibration during the turning process. The dead center is mounted in the tailstock, which holds it securely in place.

When the lathe machine is in operation, the dead center rotates along with the workpiece, ensuring that it runs smoothly and accurately. It also enables the machinist to perform precise turning operations, such as creating cylindrical shapes, facing, or tapering the workpiece.

What are the types of lathe dead centers?

There are two main types of lathe dead centers: the live center and the dead center. The live center has built-in bearings that allow it to rotate while supporting the workpiece. It is designed for heavy-duty work and is commonly used in high-speed machining applications.

On the other hand, the dead center does not have bearings and does not rotate. It is typically used for lighter work and lower-speed applications where minimal friction is desired. The dead center is suitable for softer materials or situations where a static support is needed.

How do I choose the right lathe dead center?

Choosing the right lathe dead center depends on various factors. First, consider the type of work you will be doing. If you anticipate heavy-duty machining, a live center with high-quality bearings is recommended. If you’re working with softer materials or require static support, a dead center might be more suitable.

Additionally, consider the material of the dead center. High-speed steel is a common choice for its durability and resistance to wear. However, carbide-tipped or ceramic-tipped dead centers may be preferred for specialized applications that involve high temperatures or specific cutting requirements.

How can I maintain a lathe dead center?

Maintaining a lathe dead center is essential for optimal performance. First, regularly clean the dead center by removing any debris or metal shavings that may have accumulated. This can be done using a brush or compressed air. Avoid using solvents or oils that may damage the bearings or interfere with its functionality.

Next, apply a small amount of lubricant, such as machine oil or grease, to the bearings or contact points of the dead center. This helps reduce friction and prolongs the lifespan of the tool. Finally, store the dead center in a clean, dry place when not in use to prevent corrosion or damage.

Are lathe dead centers interchangeable between different lathe machines?

While lathe dead centers may appear similar, they are not always interchangeable between different lathe machines. Each lathe machine may have specific dimensions or fitting requirements for the tailstock and dead center. It is important to consult the lathe machine’s manufacturer or refer to the machine’s manual to ensure compatibility.

To find the appropriate lathe dead center for your specific lathe machine, consider factors such as the taper size, mounting style, and compatibility with the tailstock. Using the wrong dead center can lead to inaccuracies or damage to the machine, so it is crucial to use the correct one recommended by the manufacturer.

COMPARING “dead” center and “live” center on a metal lathe tail stock

Summary

A lathe dead center is a tool used on a lathe machine to support and rotate the workpiece. There are two types: the pointed dead center and the ball-shaped dead center.

The pointed dead center helps to accurately align the workpiece, while the ball-shaped dead center is used for smoother rotation. These tools are important for precision in machining and ensuring the workpiece is held securely.