Are you curious to know what a lathe dog is? Well, let me break it down for you! A lathe dog is a nifty tool used in machining to hold and rotate workpieces on a lathe. Think of it as a trusty sidekick that helps the lathe machine do its job efficiently.

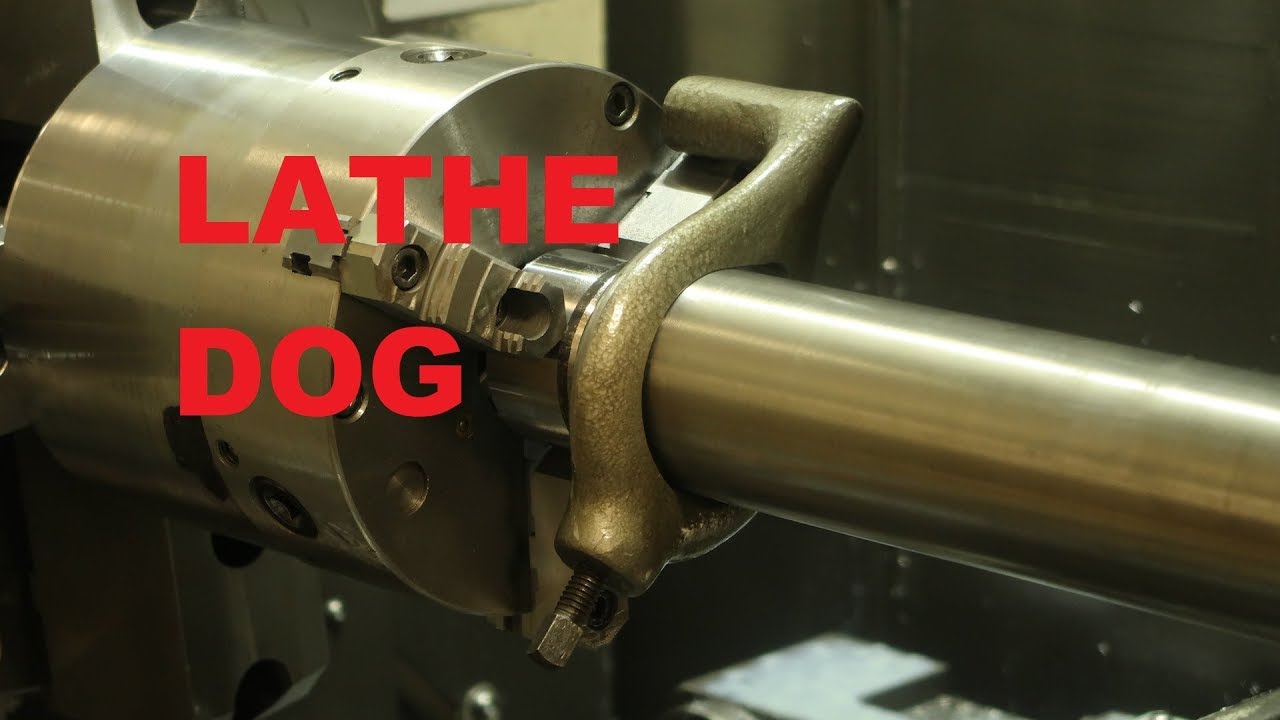

So, how does this lathe dog work its magic? Picture this: you have a long and slender workpiece that needs to be turned on a lathe. Without a lathe dog, it could slip or wobble, ruining the precision of your work. But fear not! The lathe dog comes to the rescue by clamping onto the workpiece and attaching to the lathe’s faceplate or spindle. This creates a solid connection, ensuring smooth and accurate machining.

Now, you might be wondering why it’s called a “dog.” Well, it doesn’t have anything to do with our furry friends. The term “dog” actually comes from the Old English word “docga,” meaning a powerful breed of dog. In the world of machining, the lathe dog is certainly a powerful ally that helps craftsmen create amazing things! So, are you ready to dive deeper into the wonderful world of lathe dogs? Let’s go!

Welcome to the World of Lathe Dogs!

In the realm of machining and metalworking, there exists a tool that is crucial for precise turning operations on a lathe. This tool, known as a lathe dog, plays a significant role in enhancing the efficiency and accuracy of the lathe. Whether you are a seasoned professional or just starting your journey in the fascinating world of machining, understanding what a lathe dog is and how it works is essential. Join us as we delve into the details, functions, and benefits of the mighty lathe dog.

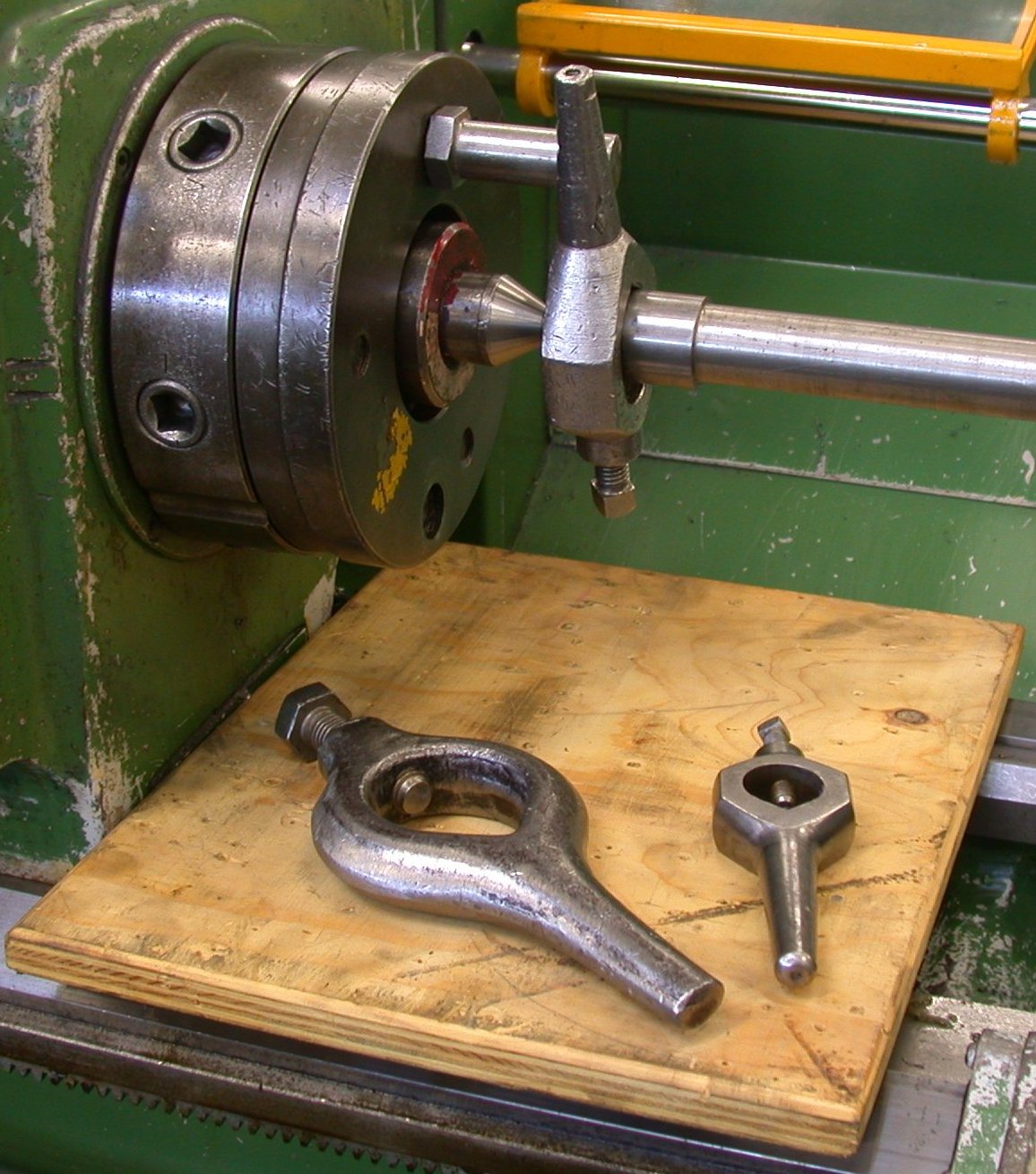

Types of Lathe Dogs

Lathe dogs come in various shapes and sizes, each designed to cater to specific turning operations and workpiece dimensions. Let’s explore the different types of lathe dogs:

1. Bent-Tail Lathe Dog:

The bent-tail lathe dog is the most commonly used design. It consists of a bent tail portion that serves as the gripping mechanism and a straight body that extends parallel to the axis of the lathe. The bent-tail allows for a secure connection to the workpiece while ensuring minimal interference during the turning process. Bent-tail lathe dogs are ideal for gripping cylindrical workpieces with a uniform diameter.

When using a bent-tail lathe dog, it is important to position the tail against the faceplate or chuck jaws to avoid any rotational slippage. This ensures a firm grip and prevents any accidents during the turning process.

2. Straight-Tail Lathe Dog:

The straight-tail lathe dog is similar to the bent-tail design, with the only difference being the absence of the bent portion. It features a straight body that extends perpendicular to the axis of the lathe. This type of lathe dog is primarily used for irregularly shaped workpieces that cannot be securely gripped by bent-tail lathe dogs.

When using a straight-tail lathe dog, it is crucial to position the tail against the faceplate or chuck jaws to ensure a reliable grip. Dedicating extra care during setup and alignment is essential to prevent any potential accidents or workpiece damage.

3. Faceplate Lathe Dog:

As the name suggests, the faceplate lathe dog is specifically designed for gripping workpieces on the faceplate of the lathe. It features a single, centrally located tail that extends perpendicularly to the axis of the lathe. This design allows for easy setup and provides a firm grip for turning operations.

When using a faceplate lathe dog, it is important to position the tail against the faceplate and secure it tightly for optimal grip. Regular inspection of the faceplate and tail connection is recommended to ensure safe operation and prevent any slippage during turning.

The Function of a Lathe Dog

A lathe dog serves the primary purpose of securing the workpiece to the lathe during turning operations. By gripping the workpiece, it prevents any undesirable movement or rotation, allowing the turning tool to engage the material precisely. The secure connection provided by the lathe dog enables the machinist to achieve accurate cuts, shape the workpiece according to the desired specifications, and maintain dimensional integrity.

In addition to its gripping function, the lathe dog also acts as a torque multiplier. As the workpiece rotates, the lathe dog’s tail applies force perpendicular to the axis, transmitting torque that aids in maintaining rotational stability.

Lathe dogs are typically used in conjunction with faceplates or lathe centers to ensure a secure grip on the workpiece. Proper alignment and setup of these components are crucial for effective and safe operation.

Benefits of Using a Lathe Dog

Using a lathe dog offers several benefits that make it an indispensable tool for lathe operations:

- Enhanced Precision: The firm grip provided by the lathe dog ensures minimal workpiece movement, allowing for accurate cuts and precise shaping.

- Increased Efficiency: By preventing workpiece rotation or slippage, the lathe dog enables the operator to focus on machining tasks without interruptions or readjustments.

- Versatility: Different lathe dog designs cater to various workpiece shapes and sizes, increasing the range of turning operations that can be performed.

- Cost-Effective Solution: Investing in a lathe dog is a cost-effective alternative to specialized workholding solutions for specific turning operations.

- Easy Setup: Lathe dogs are relatively simple to install and remove, making them convenient to use for both experienced machinists and beginners.

With their ability to provide a secure and reliable grip, lathe dogs are indispensable tools that enhance the precision, efficiency, and versatility of turning operations on a lathe. Whether you are shaping a cylindrical workpiece or tackling irregular shapes, the right lathe dog will ensure optimal results and a streamlined machining process.

Tips for Using a Lathe Dog

Mastering the art of using a lathe dog requires practice and attention to detail. Here are some tips to help you make the most out of this versatile tool:

1. Proper Alignment and Secure Setup:

Prior to starting the lathe, ensure that the tail of the lathe dog is firmly secured against the faceplate or chuck jaws. Proper alignment and a secure setup will prevent any rotational slippage during turning.

2. Choose the Right Lathe Dog for the Job:

Selecting the appropriate lathe dog for your specific turning operation is crucial. Consider the shape, size, and material of the workpiece to determine which type of lathe dog will provide the best grip and stability.

3. Regularly Inspect the Lathe Dog:

Inspect the lathe dog for signs of wear or damage before each use. Replace any worn-out or damaged lathe dogs to ensure safe and reliable operation.

The Future of Lathe Dogs

As advancements in machining technology continue, lathe dogs are likely to evolve further to meet the changing demands of the industry. Innovations in materials and design may lead to more ergonomic and efficient lathe dog solutions. Additionally, the integration of automation and computer numerical control (CNC) technology in lathes may influence the development of lathe dogs that can be seamlessly integrated into automated machining processes.

Conclusion

The lathe dog is a fundamental tool in the world of machining, allowing for precise turning operations and enhancing the efficiency and accuracy of the lathe. Understanding the different types of lathe dogs, their functions, and the benefits they offer is essential for both beginners and experienced machinists. By following the tips for using a lathe dog effectively, you can maximize its potential and achieve superior results in your turning operations. Embrace the power of the lathe dog and embark on a journey of precision and craftsmanship!

Key Takeaways: What is a Lathe Dog?

- A lathe dog is a device used in a lathe machine to hold and rotate cylindrical workpieces.

- It helps secure the workpiece firmly in place to prevent movement during turning operations.

- Lathe dogs have two main parts: the body and the bent tail, which engages with the workpiece.

- These devices come in various sizes and shapes to accommodate different workpiece diameters and shapes.

- Lathe dogs are commonly used in metalworking and woodworking applications.

Frequently Asked Questions

Looking to learn more about lathe dogs? You’ve come to the right place! Here are some commonly asked questions and their answers:

What is the purpose of a lathe dog?

A lathe dog is a device used in metalworking to hold a workpiece securely on a lathe. Its purpose is to grip the workpiece and rotate it along with the spindle, allowing for precision machining operations like turning, facing, and threading. The lathe dog typically consists of two parts: a body that attaches to the lathe and a flexible arm that clamps onto the workpiece. This arrangement ensures that the workpiece stays firmly in place while spinning, preventing any unwanted movement or vibrations.

Lathe dogs are especially useful when working with long or irregularly shaped workpieces that cannot be easily held by other means. By using a lathe dog, machinists can perform accurate and consistent machining operations, resulting in high-quality finished products.

What are the different types of lathe dogs?

There are several types of lathe dogs available, each designed to suit specific workpiece shapes and sizes. The most common types include face dogs, bent tail dogs, and double-headed dogs.

Face dogs are used for workpieces with a flat face, such as discs or plates. They have a V-shaped arm that bites into the material, providing a secure grip. Bent tail dogs, on the other hand, are ideal for irregularly shaped workpieces. Their arm has a bent shape, allowing for better clamping on uneven surfaces. Double-headed dogs are versatile and can hold workpieces from both ends. They consist of two arms and are useful for longer workpieces that need support at both ends.

How do I use a lathe dog?

To use a lathe dog, first, attach the body of the dog to the lathe by sliding it onto the spindle or attaching it to a faceplate. Make sure it is securely fastened. Then, position your workpiece between the dog’s arm and the body. The arm should be on the outside of the workpiece, with the clamping end touching the material.

Tighten the clamping end of the dog’s arm onto the workpiece by adjusting the screw or bolt. Ensure a firm grip, but be careful not to overtighten, as this could damage the workpiece. Turn on the lathe and initiate the desired machining operation, making sure to maintain a steady speed and feed rate. Monitor the workpiece closely to ensure it remains securely held in place by the lathe dog throughout the process.

Can a lathe dog be used with any type of lathe?

Yes, lathe dogs can be used with various types of lathes, including both manual and CNC lathes. The design of the lathe dog allows it to be attached to the lathe’s spindle or faceplate, providing a secure hold on the workpiece during rotation. Whether you are using a small benchtop lathe or a large industrial lathe, a lathe dog can be a valuable tool for holding workpieces in place.

However, it is important to consider the size and weight limitations of your specific lathe when selecting a lathe dog. Ensure that the lathe dog you choose is compatible with the maximum workpiece dimensions and weight capacity of your lathe to prevent any accidents or damage.

Are there any safety precautions to follow when using a lathe dog?

When using a lathe dog, it is essential to follow certain safety precautions to ensure a smooth and accident-free machining process. Firstly, always wear appropriate personal protective equipment (PPE) such as safety goggles and gloves to protect yourself from potential hazards.

Secondly, carefully inspect the lathe dog and the workpiece before starting the machining operation. Make sure that the dog’s arm is securely clamped onto the workpiece and that there are no defects or abnormalities that could cause the workpiece to become dislodged during rotation.

Lastly, be mindful of the cutting tools and their proximity to the lathe dog. Avoid any collisions or entanglements that could lead to tool damage or injury. By following these safety precautions, you can use a lathe dog effectively and confidently.

Summary

So, what is a lathe dog? A lathe dog is a handy tool used in machining that helps hold and rotate workpieces on a lathe machine. It has two parts: a body that clamps onto the workpiece and a pointed tail that fits into slots on the lathe’s faceplate. The lathe dog ensures that the workpiece stays secure and spins at the desired speed, allowing for precise cutting and shaping.

If you’re ever working with a lathe machine, understanding how to use a lathe dog is important for successful and accurate machining. So, now you know!