Have you ever wondered what “lathe height” means? Well, you’re in the right place! In this article, we’ll uncover the mystery behind this term and explore its significance in the world of machining. So, fasten your seat belts and join me on this exciting journey of discovery!

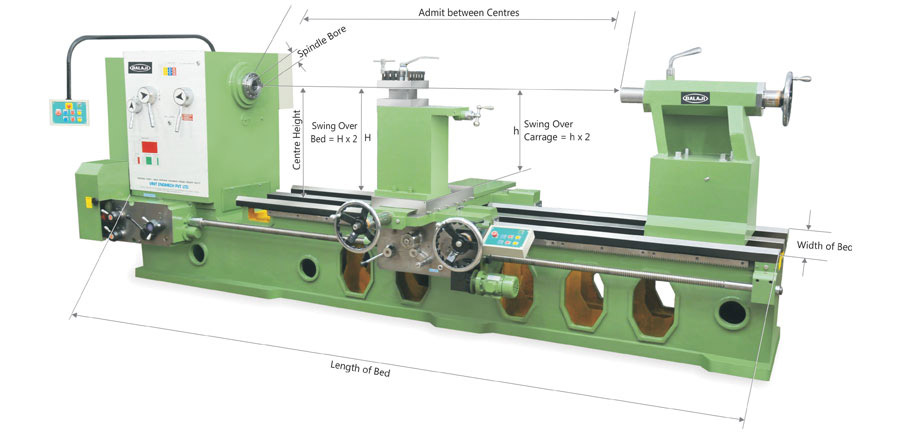

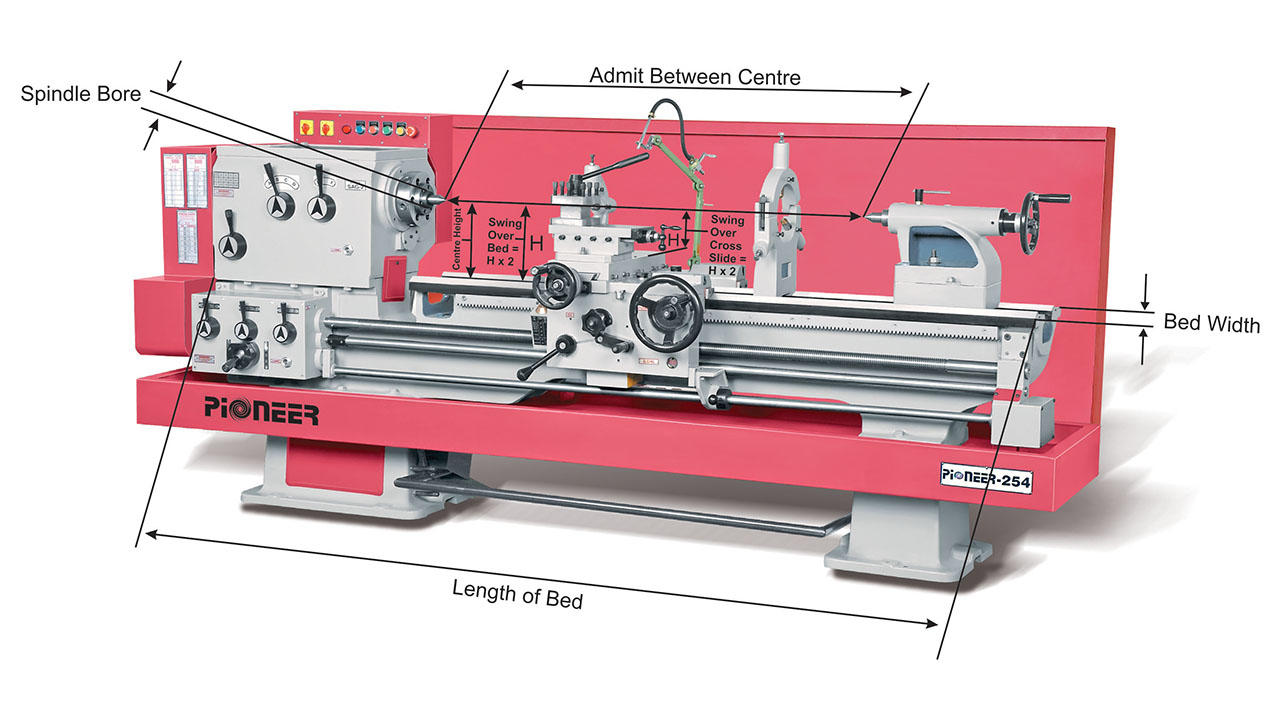

Imagine you have a lathe machine, a powerful tool used to shape and cut materials with precision. Now, picture the distance between the lathe’s bed and the centerline of its spindle – that’s what we call the “lathe height.” It may seem like a simple measurement, but it plays a vital role in achieving accurate and consistent results.

But why is lathe height so important? Well, let me tell you, my curious friend! By setting the lathe height correctly, you ensure that your workpiece aligns perfectly with the tool’s cutting edge. This alignment ensures smooth and precise cuts, reducing errors and improving overall machining quality. So, mastering the concept of lathe height is essential for any aspiring machinist.

Ready to dive deeper into this fascinating world of machining? Stick around as we explore the ins and outs of lathe height, its impact on machining operations, and how to determine and optimize it for a flawless cutting experience. Get ready for an exciting adventure in the world of precision engineering!

What is Lathe Height?

Lathe height is a critical measurement in the field of machining. It refers to the distance between the centerline of the lathe spindle and the lathe bed. This measurement is essential because it determines the maximum size of the workpiece that can be turned on the lathe. Understanding lathe height and its significance is crucial for machinists and anyone involved in metalworking or woodworking. In this article, we will explore the concept of lathe height in detail, its importance, and how it affects the machining process.

The Importance of Lathe Height

Lathe height plays a crucial role in determining the work envelope of a lathe, which refers to the maximum size of the workpiece that can be accommodated by the machine. The lathe height limits the diameter of the workpiece that can be turned without interference between the rotating workpiece and the lathe bed. This measurement is especially critical for precision machining, as any interference or misalignment can result in poor surface finish, inaccuracies, or damage to the workpiece and the machine.

Additionally, lathe height affects the stability and rigidity of the machine during operation. Ideally, the lathe bed should be at a height that allows the machinist to work comfortably, maintaining proper posture and control. Working with a lathe bed that is too high or too low can lead to fatigue, reduced accuracy, and even safety risks. Hence, understanding the optimal lathe height for a particular operator is essential for ensuring efficient and safe machining operations.

The Impact of Lathe Height on Machining

1. Tool Geometry and Cutting Dynamics:

The lathe height affects the geometry of the tool in relation to the workpiece. When the lathe height is set incorrectly, the tool may not engage the workpiece at the desired angle, resulting in inefficient cutting, poor surface finish, and increased tool wear. Proper alignment between the lathe height, tool geometry, and workpiece is crucial for achieving desired cutting dynamics and producing high-quality machined parts.

2. Cutting Forces and Vibrations:

Incorrect lathe height can affect the balance and stability of the machine, leading to excessive vibrations and unwanted chatter during cutting operations. These vibrations can cause poor surface finish, dimensional inaccuracies, and even damage the cutting tool. Achieving the correct lathe height minimizes vibrations, optimizes cutting forces, and promotes smooth and efficient machining processes.

3. Chip Evacuation:

Proper lathe height ensures effective chip evacuation, which is critical to maintaining good cutting performance and preventing chip clogging. If the lathe height is set too high or too low, the chips may not be effectively removed from the cutting zone, leading to chip recutting, poor surface finish, and overheating. The correct lathe height allows for the smooth flow and evacuation of chips, ensuring optimal cutting conditions and reducing the risk of tool damage and workpiece defects.

Factors Affecting Lathe Height

1. Type of Lathe:

The type of lathe being used can influence the optimal lathe height. Different lathes have varying bed heights, and each operator needs to adjust their lathe to suit their body mechanics and comfort level for efficient and safe operation.

2. Machinist’s Body Mechanics:

The physical stature, height, and the preferred working stance of the machinist are crucial factors in determining the ideal lathe height. A machinist should work with a lathe height that allows comfortable hand placement and proper body posture to minimize fatigue and ensure optimal control and accuracy.

3. Size of the Workpiece:

Since the lathe height determines the maximum size of the workpiece that can be turned, the size of the workpiece is a key factor in setting the lathe height. The machinist needs to consider the required clearance and alignment between the workpiece and the lathe bed to avoid any interference during the turning process.

Choosing the Correct Lathe Height

To determine the correct lathe height, follow these steps:

- Stand in front of the lathe and adjust the height of the lathe bed so that it aligns with the center of your body.

- Bend your elbows at a comfortable angle, approximately 90 degrees, and ensure that your hands can rest comfortably on the lathe controls.

- Check that your posture is upright, with your back straight and your feet firmly planted on the ground.

- Once you have set the lathe height, perform a test run by turning a small workpiece to ensure that you have an appropriate level of control and comfort while machining.

Conclusion

Understanding the concept of lathe height and its significance is crucial for machinists and individuals involved in metalworking or woodworking projects. It directly impacts the maximum size of the workpiece that can be turned on a lathe, as well as the stability, rigidity, cutting dynamics, vibrations, and chip evacuation during the machining process. By choosing the correct lathe height based on factors such as the type of lathe, body mechanics, and the size of the workpiece, machinists can ensure efficient, accurate, and safe machining operations. Maintaining the correct lathe height is essential for achieving high-quality machined parts and optimizing productivity in the workshop.

Key Takeaways: What is Lathe Height?

- Lathe height refers to the vertical distance between the lathe bed and the lathe centerline.

- It is an important measurement as it determines the maximum diameter of workpieces that can be turned on the lathe.

- A higher lathe height allows for larger workpieces, while a lower height limits the size.

- Lathe height can be adjusted using leveling feet or shimming to ensure proper alignment.

- It is crucial to set the lathe height correctly for precise and efficient turning operations.

Frequently Asked Questions

Welcome to our frequently asked questions section on the topic of lathe height. Here, we’ve compiled a list of common queries to help you better understand this concept. Explore the questions below to gain a deeper insight into “what is lathe height?”

1. How does lathe height affect precision in machining?

Lathe height refers to the distance between the lathe’s worktable and the cutting tool. It is a critical factor in machining precision. When the lathe height is properly set, it ensures that the workpiece is centered accurately. This alignment minimizes errors and allows for precise cutting, resulting in high-quality finished products. The correct lathe height also contributes to better chip control and smoother cutting, enhancing overall machining accuracy.

However, if the lathe height is improperly set, it can lead to issues such as tool chatter, inaccurate cutting, and poor surface finish. Therefore, maintaining the correct lathe height is crucial for achieving precision in machining operations.

2. What factors should be considered when determining the lathe height?

Several factors need consideration when determining the lathe height:

– Tool height: The height of the cutting tool affects the lathe height as it needs to align with the workpiece for accurate cutting.

– Workpiece dimensions: The size and shape of the workpiece influence the lathe height determination. It’s essential to choose a height that allows for proper tool clearance and effective cutting.

– Tool type: Different types of tools have varying dimensions, which can impact the ideal lathe height. Each tool must be appropriately accommodated to ensure precise machining.

By considering these factors, you can determine the optimal lathe height for your specific machining requirements.

3. Can lathe height be adjusted during machining?

Yes, lathe height can be adjusted during machining to ensure optimal performance. Typically, lathes are equipped with mechanisms that allow for height adjustments. These mechanisms may include adjustable feet, shims, or leveling screws, which can be manipulated to fine-tune the lathe height.

Being able to adjust the lathe height is particularly useful when switching between different workpieces or tooling setups. It allows for quick and precise alignment to maintain the desired cutting accuracy. However, it is essential to follow the manufacturer’s guidelines and best practices when adjusting the lathe height to avoid damaging the machine or compromising the machining process.

4. How does lathe height affect operator safety?

While lathe height primarily impacts machining precision, it also plays a role in operator safety. When the lathe height is too high or too low, it can cause ergonomic issues for the operator, resulting in discomfort or potential injuries. Maintaining the correct lathe height ensures that the operator can comfortably reach the controls, handle the workpiece, and observe the machining operation without straining or assuming awkward positions.

Moreover, the proper lathe height contributes to a safer working environment by reducing the risk of tool slippages, unexpected tool movements, and workpiece ejections. By prioritizing operator safety through the appropriate lathe height, machining operations can be conducted more efficiently and effectively.

5. Are there any guidelines for setting the lathe height?

Setting the lathe height should be done methodically to achieve optimal results. Here are some guidelines to follow:

– Consult the lathe manufacturer’s documentation: Start by referring to the lathe’s manual or guidelines provided by the manufacturer. They often include specific instructions for determining the ideal lathe height.

– Perform trial cuts and measurements: Make initial test cuts on a sample workpiece while varying the lathe height. Measure the resulting dimensions and surface finish to identify the height that yields the best results.

– Fine-tune using operator feedback: Seek feedback from the operator who works with the lathe regularly. They can provide insights into comfort levels, ergonomic considerations, and any issues they may have encountered during previous operations.

By following these guidelines, you can effectively set the lathe height to optimize machining precision and operator safety.

Summary

Lathe height is the distance between the lathe’s bed and the centerline of the spindle. It is important because it affects the accuracy of the workpiece and the ease of cutting. Having the correct lathe height is crucial for achieving precise and consistent results in machining.

A lathe with the wrong height can cause the workpiece to vibrate, resulting in inaccuracies and poor surface finishes. By adjusting the lathe height, you can ensure that the cutting tool aligns perfectly with the workpiece, leading to better cutting performance and improved quality of the final product. Remember, finding the right lathe height may require some trial and error, but it is worth the effort for excellent machining outcomes.