Have you ever wondered, “What is a lathe spindle bore?” Well, let me break it down for you.

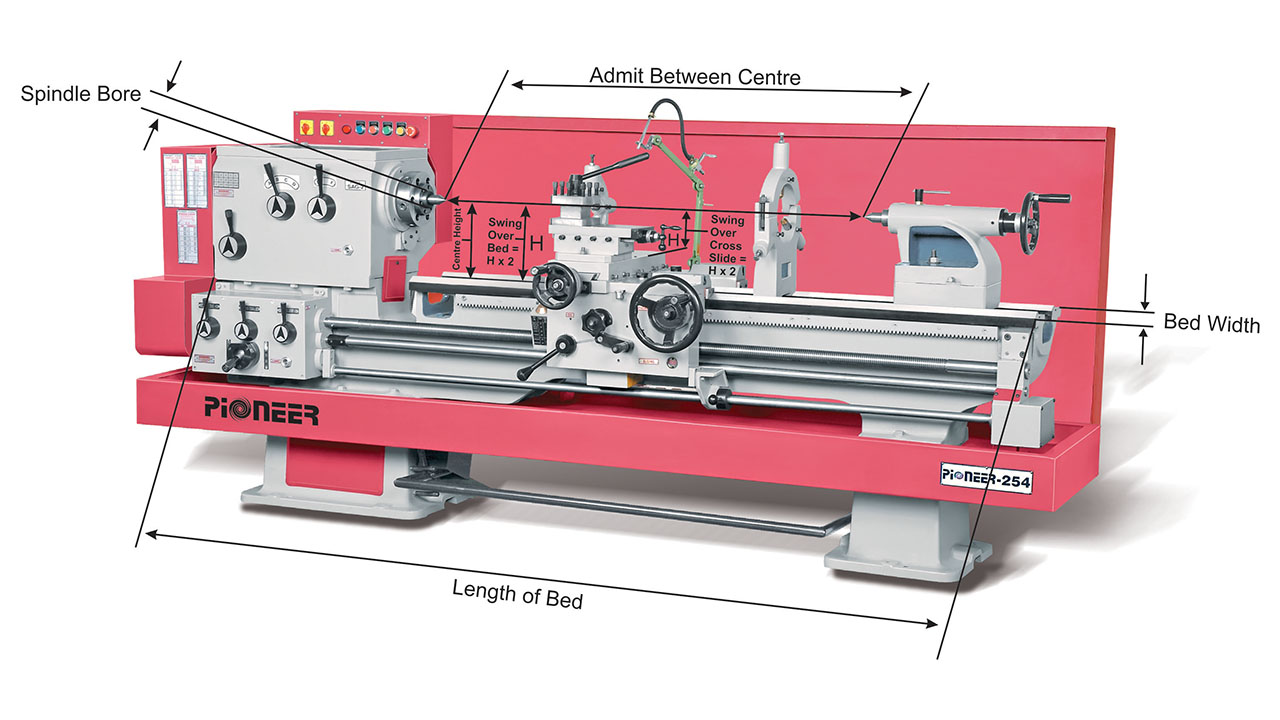

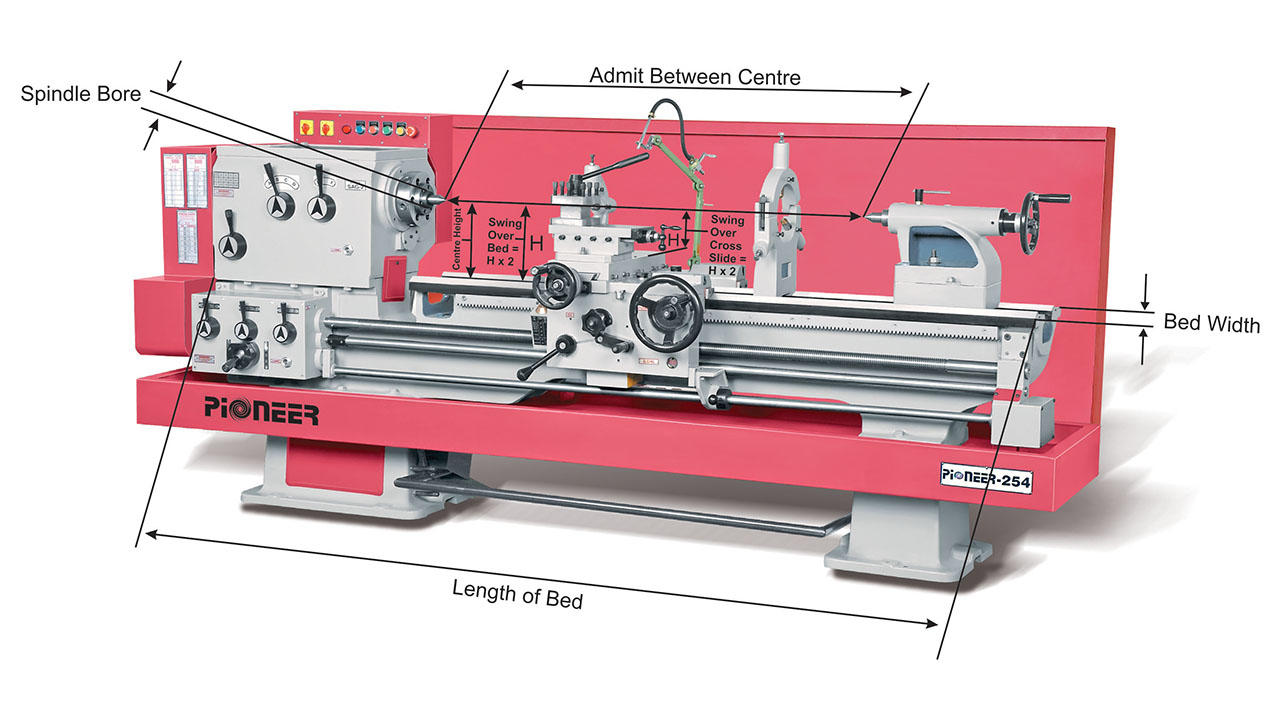

Imagine you have a lathe, a machine used for shaping metal or wood into desired shapes. The spindle bore is the opening in the center of the lathe’s headstock where the workpiece gets mounted.

This opening allows the lathe to hold and rotate different-sized materials, enabling precise cutting and shaping. So, the size of the spindle bore determines the maximum diameter of the workpiece that the lathe can handle.

Now that you have a basic understanding of the lathe spindle bore, let’s explore further and discover its importance in various machining operations.

What is Lathe Spindle Bore? A Comprehensive Guide

In the world of machining and metalworking, lathes play a crucial role. These versatile machines are used for shaping, turning, and cutting various materials. One important component of a lathe is the spindle bore. In this comprehensive guide, we will explore the concept of a lathe spindle bore, its importance, and how it affects the performance and capabilities of a lathe.

Understanding the Basics of a Lathe Spindle Bore

A lathe spindle bore refers to the opening or hollow space in the headstock of a lathe machine. It is through this bore that the workpiece is fed into the machine for machining operations. The spindle bore size determines the maximum diameter of the workpiece that can be accommodated by the lathe.

In simpler terms, the lathe spindle bore is like the “throat” or “mouth” of the lathe. The larger the spindle bore size, the larger the workpieces the lathe can handle. Spindle bore sizes can vary widely, ranging from small diameters of a few inches to larger diameters that can accommodate substantial workpieces.

Lathe machines with a smaller spindle bore size are often used for lighter tasks and smaller workpieces, while those with larger spindle bore sizes are capable of handling heavy-duty applications and larger workpieces.

The Importance of Spindle Bore Size in Lathe Machines

The spindle bore size has a significant impact on the capabilities and versatility of a lathe machine. Here are a few key reasons why the spindle bore size is important:

1. Workpiece Size

One of the primary factors influencing the choice of a lathe machine is the size of the workpieces to be machined. The spindle bore size determines the maximum diameter of the workpiece that can be passed through the headstock and machined on the lathe. Therefore, it is crucial to select a lathe with a spindle bore size that can accommodate the desired workpiece size.

2. Versatility and Flexibility

A larger spindle bore size allows for greater flexibility in terms of the range of workpieces that can be machined on a lathe. With a larger spindle bore, you can work on projects that require machining larger, bulkier materials. This versatility can be invaluable in industries such as automotive, aerospace, and construction where varying workpiece sizes are common.

3. Cutting Tool Selection

The spindle bore size also influences the selection and use of cutting tools. When working with larger workpieces, larger cutting tools may be required to accommodate the size of the workpiece and achieve the desired machining outcomes. Having a lathe with a larger spindle bore allows for the use of a wider variety of cutting tools.

Choosing the Right Spindle Bore Size for Your Needs

When selecting a lathe for your machining needs, it is essential to consider the spindle bore size that best suits your requirements. Here are a few factors to consider when choosing the right spindle bore size:

1. Workpiece Size and Project Requirements

Assess the size of the workpieces you regularly work with or plan to work with in the future. Determine the maximum diameter that you need the lathe to accommodate and select a spindle bore size that meets or exceeds that requirement.

2. Future Expansion and Versatility

If you anticipate working on larger projects or a wider range of workpiece sizes in the future, it may be wise to invest in a lathe with a larger spindle bore. This will allow for flexibility and future-proof your machining capabilities.

3. Budget and Cost Considerations

It is important to balance your budget with your machining needs. Larger spindle bore sizes generally come at a higher cost. Assess your budget and priorities to find the best balance between the spindle bore size and the overall capabilities and features of the lathe.

The Benefits of a Large Spindle Bore

When it comes to lathe machines, having a large spindle bore size offers several benefits and advantages:

1. Increased Machining Opportunities

A larger spindle bore size enables you to take on a wider range of projects. Whether you’re working on large-scale industrial parts or simply need the flexibility to machine larger and more challenging workpieces, a lathe with a large spindle bore allows for increased machining opportunities.

2. Versatility in Material Selection

With a large spindle bore, you’re not limited to working with smaller materials. You can handle larger materials such as solid bars, pipes, and shafts, expanding your options for material selection. This versatility can be particularly beneficial in industries that require machining of various materials, such as aerospace or oil and gas.

3. Enhanced Precision and Accuracy

A larger spindle bore offers more space for the workpiece, reducing the chances of interference between the workpiece and the lathe components. This enhanced space allows for smoother machining operations, leading to improved precision and accuracy in your work.

Additional Factors to Consider

When evaluating a lathe machine beyond spindle bore size, there are some other factors to take into account:

1. Horsepower and Motor Strength

The horsepower rating of a lathe’s motor is crucial, as it determines the power and speed at which the machine can operate. Consider the type of materials you’ll be machining and the level of power needed to ensure efficient cutting and shaping.

2. Bed Length and Swing

Bed length and swing are important measurements that determine the size of workpieces you can accommodate. The bed length determines the maximum length of a workpiece, while the swing refers to the maximum diameter that can be turned on the lathe.

3. Speed Ranges and Controls

Check if the lathe offers multiple speed ranges and if it has easy-to-use speed controls. Different materials and machining operations require specific speeds for optimal results, so having a range of speed options is beneficial.

By considering these additional factors in conjunction with the spindle bore size, you can select the right lathe machine that suits your specific needs.

Conclusion

A lathe spindle bore is a critical component that significantly affects the performance and capabilities of a lathe machine. Choosing the right spindle bore size is essential for accommodating the size of your workpieces, ensuring versatility, and expanding your machining opportunities. By understanding the basics of a lathe spindle bore and considering other factors such as horsepower, bed length, and speed controls, you can make an informed decision when purchasing a lathe that meets your needs and enhances your machining capabilities.

Key Takeaways: What is Lathe Spindle Bore?

- A lathe spindle bore refers to the hole in the center of the lathe spindle where the workpiece is held.

- It is important to choose a lathe with a spindle bore size that can accommodate the diameter of the workpiece you plan to turn.

- The spindle bore size affects the maximum diameter of the workpiece that can be turned on the lathe.

- A larger spindle bore allows for the turning of larger diameter workpieces.

- Choosing the right spindle bore size is crucial for successfully completing your lathe projects.

Frequently Asked Questions

Welcome to our FAQ section on the topic of lathe spindle bore. Here, we will answer some common questions related to this topic. Whether you’re a beginner or someone looking to expand their knowledge, we’ve got you covered! Let’s dive in.

1. What is a lathe spindle bore and why is it important?

A lathe spindle bore refers to the hole through the center of the lathe spindle. It is used to hold the material or workpiece being turned or machined. The size of the spindle bore determines the maximum diameter of material that can be accommodated by the lathe.

Understanding the spindle bore is crucial because it determines what size material you can work with. If the spindle bore is too small, you won’t be able to fit larger pieces. On the other hand, if the spindle bore is large, you have the flexibility to work with various sizes of material, which allows for greater versatility in your projects.

2. How does the lathe spindle bore diameter affect my turning operations?

The diameter of the lathe spindle bore directly impacts the size of the material you can work with. If the spindle bore is too small, you won’t be able to fit larger pieces through it. This limits the size and scope of your turning operations.

However, if the spindle bore diameter is large, you have the ability to work with larger pieces of material, thereby expanding the possibilities for your turning projects. It is important to choose a lathe with a spindle bore diameter that can accommodate the size of material you typically work with.

3. Can the spindle bore on a lathe be changed or modified?

In most cases, the spindle bore on a lathe cannot be easily changed or modified. The spindle bore is an integral part of the lathe design and is typically fixed. It is important to choose a lathe with a spindle bore diameter that suits your needs, as retrofitting or modifying the spindle bore can be a complex and costly task.

There are specialized lathes available with adjustable spindle bore sizes, but they are not as common as standard fixed-spindle lathes. If you anticipate needing to work with materials of varying sizes, it is advisable to invest in a lathe with a larger spindle bore diameter to provide flexibility in your future projects.

4. Are there any alternatives if the lathe’s spindle bore is too small for my project?

If the spindle bore on your lathe is too small for your project, there are a few alternative options you can consider. One option is to use a collet chuck system, which allows you to hold the material externally using collets of different sizes.

Another option is to use a spindle adapter or reducer sleeve, which can reduce the diameter of your lathe spindle bore to fit smaller workpieces. However, it is important to note that using a reducer sleeve may affect the rigidity and stability of the workpiece setup, so caution should be exercised.

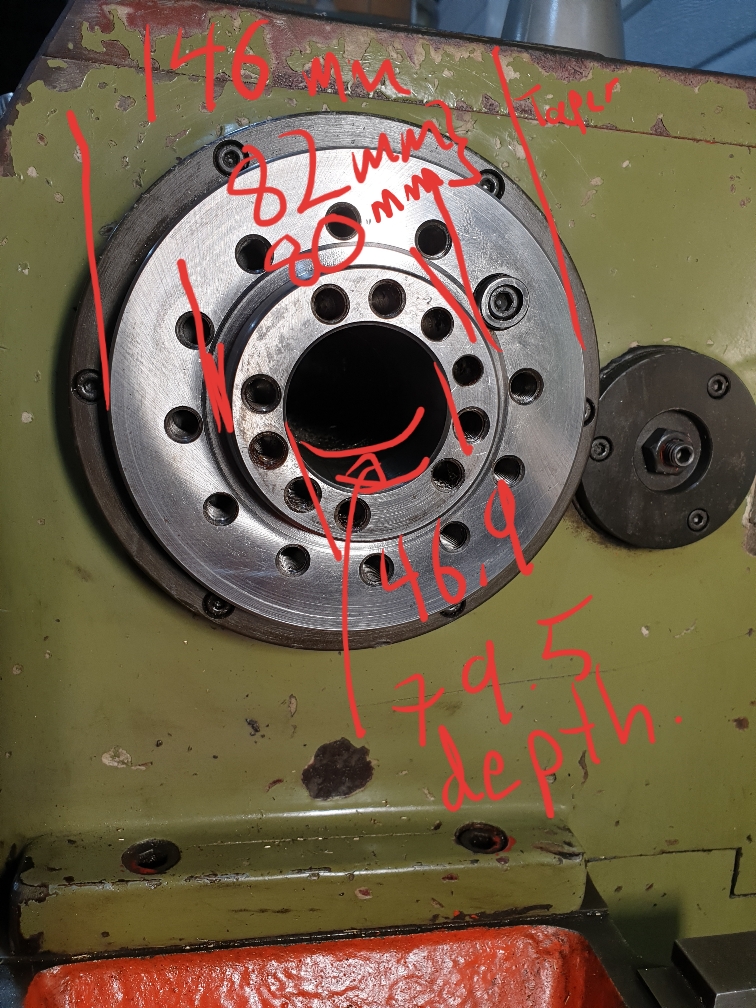

5. How do I determine the size of the lathe spindle bore?

To determine the size of the lathe spindle bore, you can refer to the lathe’s specifications or user manual. The bore size is usually listed as a measurement in inches or millimeters. Alternatively, you can physically measure the diameter of the spindle bore using calipers or a micrometer.

When considering the size of the lathe spindle bore, it is important to also account for the size of the material you plan to work with. The material diameter should be smaller than the spindle bore diameter to ensure a proper fit and safe operation of the lathe.

Summary

A lathe spindle bore is the hole in the center of a lathe’s headstock. It allows the workpiece to pass through the spindle and rotate freely. The size of the spindle bore determines the maximum diameter of the workpiece that can be accommodated. A larger spindle bore gives more flexibility in working with larger materials.

In addition to the size, the type of spindle bore is also important. There are two common types: through-hole and non-through-hole. A through-hole spindle bore allows the workpiece to be longer than the length of the lathe bed, while a non-through-hole spindle bore does not. The spindle bore is a critical factor to consider when choosing a lathe, as it determines the maximum size and type of workpiece that can be machined.