Welcome, young minds, to the exciting world of lathes! Have you ever wondered, “What is lathe swing?” Well, get ready for a journey through the mechanics of this fascinating machine.

Picture this: you’re in a workshop, surrounded by tools and materials. Suddenly, you see a massive machine with a spinning metal rod. That, my friend, is a lathe. But what sets it apart from other machines? That’s where the concept of “lathe swing” comes in.

Imagine swinging a ball on a string. The distance from the center of the swing to the ball is the swing radius. In the world of lathes, swing refers to the maximum diameter of a workpiece that can be rotated on the machine. It’s like the size limit of what the lathe can handle.

So, to wrap it up, the lathe swing determines the largest diameter of material that can be turned on the machine. Now that you understand the basics, let’s delve deeper into the fascinating world of lathes and explore their amazing capabilities! So, tighten your safety goggles and brace yourselves for an awesome adventure!

Discovering the Lathe Swing: Unleashing the Power of Precision and Control

If you’re curious about the lathe swing, you’re in for a treat. The lathe swing refers to the maximum diameter of a workpiece that a lathe machine can accommodate. It’s a crucial measurement that determines the size of projects you can tackle. Understanding the lathe swing opens up a world of possibilities for woodturning, metalwork, and more. Dive deep into the realm of lathe swing and unleash your creativity!

What is Lathe Swing? A Deep Dive into the World of Lathe Turning

Welcome to the world of lathe turning, where precision and craftsmanship meet to create beautiful and functional objects. If you’re new to the world of machining or woodworking, you may be wondering what exactly is meant by the term “lathe swing”. In this article, we’ll explore the meaning and importance of lathe swing, as well as delve into the various aspects that contribute to a lathe’s performance. From the basics to advanced techniques, we’ll cover it all, so grab your safety goggles and let’s dive in!

The Basics of Lathe Swing: Understanding the Fundamentals

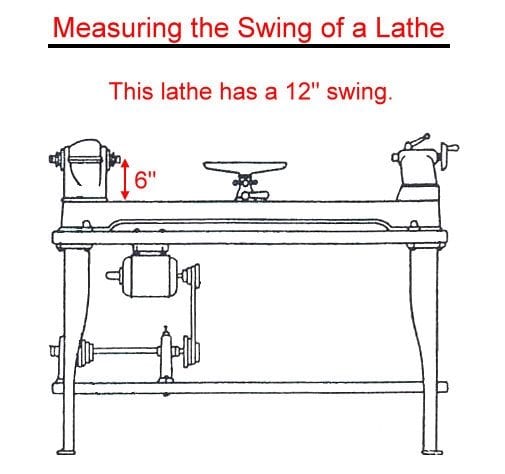

Lathe swing refers to the maximum diameter of workpiece that can be accommodated on a lathe. It is determined by measuring the distance from the center of the lathe spindle to the bed, and then doubling that measurement. This measurement is crucial as it determines the size of the projects that can be turned on a lathe.

When selecting a lathe, it’s important to consider the desired lathe swing based on the types of projects you plan to undertake. A larger lathe swing allows for the turning of larger diameter workpieces, providing more versatility and flexibility in your woodworking or machining endeavors. Conversely, a smaller lathe swing may limit the size of projects you can undertake. It’s important to strike a balance between your budget, available space, and the intended use of the lathe.

Lathe swing is typically specified in inches, with common sizes ranging from 10 inches to 24 inches or more. However, it’s worth noting that the stated lathe swing does not necessarily mean that you can turn a workpiece of that exact diameter. It’s important to consider factors such as tool clearance, protruding features, and other constraints that may affect the maximum diameter of workpiece that can be turned on a specific lathe.

The Importance of Lathe Swing in Woodworking

Woodworking enthusiasts understand the significance of lathe swing when it comes to turning out beautiful pieces. With a larger lathe swing, you have the ability to turn bigger bowls, platters, and other projects, allowing for more creativity in your designs. Additionally, a larger lathe swing also improves stability and reduces vibrations, resulting in smoother cuts and a higher quality finished product.

On the other hand, a smaller lathe swing is more suitable for delicate and intricate work, such as pen turning or spindle turning. A smaller lathe swing offers better maneuverability and control, allowing for precise detailing and fine craftsmanship in smaller pieces.

Ultimately, the choice of lathe swing depends on your personal preferences, the types of projects you plan to undertake, and the space and budget available to you. Whether you opt for a larger or smaller lathe swing, remember that practice and skill are essential in achieving excellent results, regardless of the size of your lathe.

Factors Affecting Lathe Swing: Beyond the Basics

While the lathe swing is a fundamental specification to consider, there are several other factors that can affect the performance and capabilities of your lathe. Let’s take a closer look at some of these factors:

1. Bed Length:

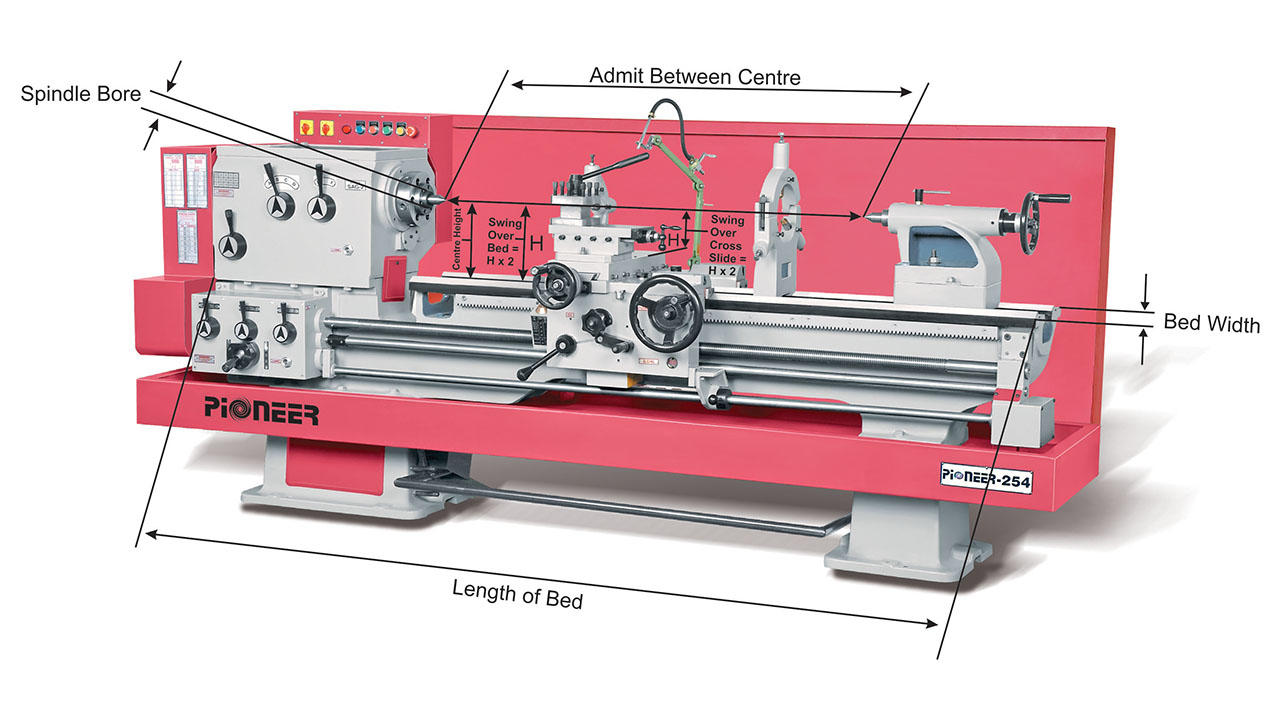

The length of the lathe bed determines the maximum length of workpiece that can be turned. Consider the types of projects you plan to undertake and ensure that the lathe bed is long enough to accommodate them.

2. Motor Power:

The motor power of the lathe is another crucial factor to consider. A more powerful motor can handle larger and denser workpieces, allowing for more versatile turning capabilities.

3. Headstock and Tailstock:

The design and construction of the headstock and tailstock also play a role in the overall performance of the lathe. Look for features such as adjustable tailstocks and indexing capabilities, which can enhance precision and control in your turning projects.

4. Tool Rest and Tool Support:

The tool rest and tool support system on a lathe are essential for stability and safety during turning. Look for a lathe that offers a sturdy and adjustable tool rest, as well as a reliable tool support system that can accommodate a variety of turning tools.

5. Variable Speed Control:

Having the ability to control the speed of the lathe is crucial for achieving optimal results with different types of wood and projects. Look for a lathe with a variable speed control feature, allowing you to adjust the speed to match the specific requirements of your project.

By considering these additional factors alongside the lathe swing, you can make an informed decision when selecting a lathe that meets your specific needs and preferences.

Choosing the Right Lathe Swing for You: Tips and Considerations

Now that you have a better understanding of lathe swing and its importance, let’s explore some tips and considerations to help you choose the right lathe swing for your needs:

1. Assess Your Project Requirements:

Determine the types and sizes of projects you plan to undertake. This will give you a clearer idea of the lathe swing that will best suit your needs.

2. Consider Available Space:

Measure the space you have available for your lathe. Ensure that the lathe swing you choose will fit comfortably in your workshop or designated area.

3. Budget Appropriately:

Set a realistic budget for your lathe purchase. Remember to consider not only the cost of the lathe itself but also the necessary accessories and tools.

4. Research and Compare:

Take the time to research and compare different lathe models and brands. Read reviews, seek recommendations, and consider the reputation and reliability of the manufacturer.

5. Test Before You Buy:

If possible, try out different lathes before making a final decision. This will give you a hands-on experience and help you gauge the performance and usability of the lathe.

6. Seek Guidance and Advice:

Don’t hesitate to reach out to experienced woodturners or machinists for guidance and advice. They can provide valuable insights and tips based on their own experiences.

By following these tips and considering your specific needs and requirements, you can confidently choose a lathe swing that will allow you to embark on your lathe turning journey with precision and success.

Advanced Techniques and Tips for Lathe Turning Excellence

Now that you have a solid understanding of lathe swing and the factors to consider when choosing a lathe, let’s explore some advanced techniques and tips to help you achieve excellence in your lathe turning projects.

Key Takeaways: What is Lathe Swing?

- Lathe swing refers to the maximum diameter of workpiece that can fit on a lathe.

- It is determined by the distance from the centerline of the lathe to the bed, multiplied by 2.

- Lathe swing is important when choosing a lathe for specific machining tasks.

- A larger lathe swing allows for machining larger workpieces.

- Knowing the lathe swing is crucial for ensuring the right size of lathe is used for a project.

Frequently Asked Questions

Are you curious about the concept of lathe swing? Look no further! Here are some questions and answers to help you understand this topic better.

1. What is the swing of a lathe?

The swing of a lathe refers to the maximum diameter of workpiece that can be turned on the lathe without any obstructions. It is measured by determining the distance from the centerline of the lathe spindle to the bed, and doubling that value. In simpler terms, it is the largest diameter piece that can fit on the lathe.

The swing of a lathe is an important specification, as it determines the size of work that can be accommodated by the machine. A larger swing allows for the turning of bigger and longer pieces.

2. How is lathe swing different from lathe distance between centers?

While lathe swing refers to the maximum diameter of workpiece that can fit on the lathe without any obstructions, the distance between centers refers to the length of the workpiece that can be supported and turned on the lathe. It is the distance between the lathe spindle and the tailstock, which determines the maximum length of the workpiece that can be turned.

In summary, the swing of a lathe focuses on the width of the workpiece, while the distance between centers considers the length. Both are important specifications to consider when selecting a lathe for a specific project.

3. Why is lathe swing an important factor to consider?

The lathe swing is an important factor to consider because it determines the size of work that can be turned on the lathe. If you frequently work with larger diameter pieces, you would need a lathe with a larger swing to accommodate those projects. However, if you primarily work on smaller items, a smaller swing might be sufficient.

By considering the lathe swing, you ensure that the machine can handle the size of work you plan to turn. It allows you to avoid any limitations or restrictions when selecting a lathe for your projects.

4. Can the lathe swing be increased?

The lathe swing cannot be increased once the lathe is built or manufactured. The swing is determined by the design and construction of the lathe, specifically the distance from the centerline of the spindle to the bed. This means that if you require a larger swing, you would need to invest in a lathe with a bigger swing capacity.

It is essential to choose a lathe with a swing that matches your project needs, as trying to exceed the machine’s swing capacity can result in damage to the lathe or poor-quality turning.

5. What are the implications of exceeding the lathe swing?

Exceeding the lathe swing can lead to various issues. Firstly, there may be physical limitations preventing the work from fitting properly on the lathe, resulting in obstructions or collisions. Secondly, attempting to turn a workpiece with a diameter larger than the lathe swing can strain the lathe’s motor and components, potentially causing damage.

Moreover, exceeding the lathe swing can negatively impact the quality of your turning. The workpiece may vibrate or wobble excessively, leading to imprecise cuts and an overall poor turning experience. Therefore, it is crucial to select a lathe with an appropriate swing capacity for the work you plan to undertake.

Summary

If you’ve ever wondered what “lathe swing” means, it’s actually quite simple. Lathe swing refers to the maximum diameter of a workpiece that can fit on a lathe without hitting the bed or other parts. It’s kind of like how big of a circle you can draw on a lathe. The swing is an important measurement because it determines the size of objects that can be turned on the lathe.

A lathe is a machine that spins a workpiece while a cutting tool shapes it. The swing on a lathe can vary depending on the size and design of the machine. Larger lathes typically have a bigger swing, meaning they can handle larger workpieces. So, if you’re interested in turning big objects, you’ll need a lathe with a large swing. Understanding the concept of lathe swing can help you choose the right lathe for your projects and ensure that your workpieces fit properly.