Welcome, young reader! Are you curious to know what a lathe turret is? Well, let me take you on an exciting journey of discovery.

Imagine you have a magical machine that can shape and form metal with incredible precision. This machine is called a lathe, and it has a special superpower known as a turret.

So, what exactly is a lathe turret, you may ask? Well, think of it as a revolving carousel of tools that the lathe can use to perform various tasks. It’s like having a box of different tools all in one place, ready to be used at a moment’s notice.

Intrigued? Let’s dive deeper into the world of lathe turrets and uncover the wonders they hold.

A lathe turret is a key component of a lathe machine that holds multiple tools and allows for quick tool changes during the machining process. It is a rotating tool holder with several tool positions, eliminating the need for manual tool changes. With a lathe turret, operators can efficiently perform various operations without interrupting the workpiece setup. This enhances productivity and reduces machining time, making lathe turrets invaluable in precision manufacturing industries.

What is a Lathe Turret? Exploring the Versatile Machine Attachment

A lathe turret is an essential attachment found on many lathe machines, offering a range of benefits and versatility for machining operations. It is a tooling system that holds multiple cutting tools, allowing for quick and efficient tool changes to perform various machining operations. This article aims to provide a comprehensive understanding of a lathe turret, its components, advantages, and applications in the manufacturing industry.

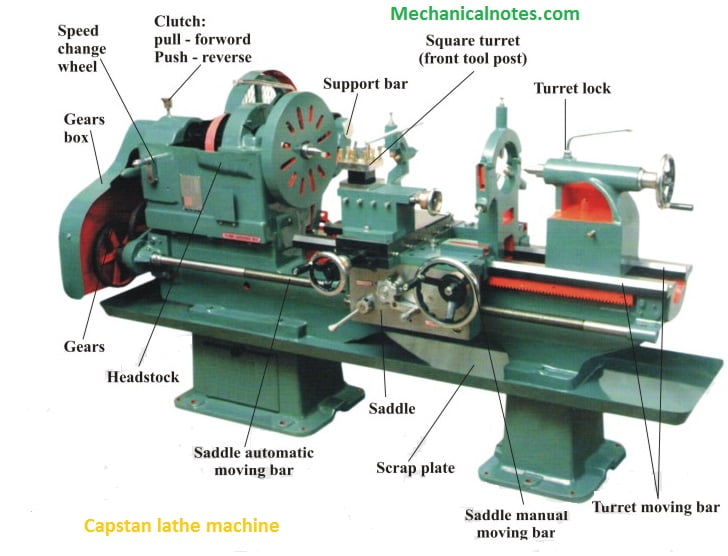

The Components of a Lathe Turret

A lathe turret consists of several key components that work together to ensure smooth tool changes and precise machining operations. The primary components of a lathe turret include:

- Turret Base: The turret base is the foundation of the turret and is mounted on the lathe’s compound rest or directly on the lathe’s bed.

- Turret Body: The turret body houses the tool holders and rotates to bring the desired tool into position for machining. It is typically equipped with an indexing mechanism for precise tool indexing.

- Tool Holders: Tool holders are mounted on the turret body and hold the cutting tools securely in place. They allow for quick tool changes and provide stability during machining operations.

- Indexing Mechanism: The indexing mechanism ensures accurate positioning of the turret body and tool holders. It allows for indexing the turret in fixed increments, typically in degrees, to position the desired tool for machining.

- Tooling Accessories: Various tooling accessories, such as boring bars, drills, and inserts, can be attached to the tool holders to perform specific machining operations.

A well-designed lathe turret offers easy accessibility, precise indexing, and reliable tool holding mechanisms to enhance machining efficiency and productivity.

The Benefits of Using a Lathe Turret

Utilizing a lathe turret in machining operations provides several advantages that contribute to increased productivity and accuracy. Here are some notable benefits:

- Quick Tool Changes: With a lathe turret, tool changes can be performed rapidly, reducing downtime and increasing machining efficiency. The ability to switch between different tools on the turret significantly speeds up the overall machining process.

- Versatility: A lathe turret allows for the use of multiple tooling accessories, enabling a wide range of operations like turning, facing, chamfering, threading, knurling, and grooving. This versatility eliminates the need for manual tool changes, saving time and effort.

- Precision and Consistency: The indexing mechanism on a lathe turret ensures precise tool positioning, resulting in consistent machining accuracy. This feature is especially crucial for complex parts that require multiple machining operations.

- Reduced Operator Fatigue: By eliminating the need for manual tool changes, a lathe turret reduces operator fatigue, allowing them to focus on other critical aspects of the machining process. It also minimizes the chances of human errors associated with manual tool changes.

The benefits of a lathe turret make it an indispensable tool for industries such as automotive, aerospace, manufacturing, and general engineering, where high precision and efficiency are crucial.

Applications of Lathe Turrets

Lathe turrets find application in a wide range of machining operations across various industries. Some common applications include:

1. Turning and Facing:

A lathe turret is frequently used in turning and facing operations, where the cutting tool removes material from the workpiece to achieve the desired shape and dimensions. The ability to switch between different cutting tools on the turret facilitates the production of complex geometries with high precision.

2. Threading:

Threading is another common application for a lathe turret, involving the creation of external or internal threads on a workpiece. The turret’s rotational capability and precise indexing allow for the efficient production of threads with various thread pitches and profiles.

3. Boring and Drilling:

Lathe turrets are often used for boring and drilling operations, where the machining process involves enlarging existing holes or creating new holes in the workpiece. The ability to mount boring bars and drills on the turret allows for efficient and accurate hole-making operations.

4. Grooving and Parting:

Grooving and parting are operations that involve cutting a groove or separating a workpiece into multiple components. A lathe turret’s quick tool change capability enables the use of dedicated cutting tools for grooving and parting, ensuring precise and efficient machining.

5. Taper Turning:

Lathe turrets also find application in taper turning, where the machinist needs to create tapered surfaces on a workpiece. By indexing the turret at specific angles, the desired taper can be achieved, allowing for the production of components such as cones and other tapered shapes.

The versatility and efficiency offered by a lathe turret make it an invaluable tool for a wide range of machining operations, enabling manufacturers to produce complex components with high precision and productivity.

The Future of Lathe Turrets: Innovations and Advancements

As technology continues to advance, lathe turrets are also evolving to meet the demands of modern machining processes. Here are three key areas where innovation is shaping the future of lathe turrets:

1. Computer Numerical Control (CNC)

The integration of lathe turrets with Computer Numerical Control (CNC) systems is revolutionizing the machining industry. CNC-controlled lathe turrets allow for automated tool changes, tool path optimization, and enhanced precision through advanced algorithms. This technology enables manufacturers to achieve higher productivity and quality.

2. Multitasking Machining

In response to the demand for increased efficiency, lathe turrets are being incorporated into multitasking machining centers. These centers combine various machining operations, such as turning, milling, and drilling, into a single machine. Lathe turrets play a vital role in these systems by providing the necessary tooling flexibility for complex component production.

3. Advanced Tooling Materials and Coatings

The development of new tooling materials and coatings is driving the advancement of lathe turrets. Harder and more durable materials, such as carbide and ceramic inserts, along with advanced coatings, improve the tool life and performance of lathe turret cutting tools. These innovations result in longer tool life, reduced downtime, and higher machining speeds.

In conclusion, a lathe turret is a versatile tooling system that enhances the efficiency and precision of machining operations. With quick tool changes, a wide range of applications, and ongoing technological advancements, lathe turrets are poised to play a significant role in shaping the future of manufacturing.

Key Takeaways:

- A lathe turret is a rotating tool holder used in lathe machines.

- It holds multiple cutting tools, allowing for quick tool changes.

- The turret can be manually or automatically rotated to select the desired tool.

- Lathe turrets improve efficiency by reducing downtime during tool changes.

- They enable the machining of complex parts with different cutting operations.

Frequently Asked Questions

What is a lathe turret?

-

How does a lathe turret work?

-

What are the advantages of using a lathe turret?

-

Can a lathe turret hold different types of tools?

-

Is a lathe turret only used in industrial settings?

-

How can I maintain a lathe turret?

A lathe turret is a tool-holding device that allows for the automatic indexing and rotation of different cutting tools during machining operations on a lathe. The turret is mounted on the lathe’s cross-slide and can hold multiple tools, which can be quickly and accurately positioned to perform various operations.

Inside the lathe turret, there is a drum or disk that can revolve, holding tool holders or tool posts. These holders securely grip the cutting tools. By rotating the turret, different tools can be brought into position for precise machining without the need for manual tool changes. This significantly reduces setup time, increases productivity, and allows for complex and efficient machining operations on the lathe.

The use of a lathe turret offers several advantages:

1. Efficiency and Productivity: The automatic indexing and rotation of tools in a lathe turret eliminate the need for manual tool changes. This leads to quicker machining operations, improved efficiency, and increased productivity.

2. Precise and Repeatable Tool Positioning: The lathe turret allows for precise and repeatable positioning of tools, ensuring consistent machining results. This is especially important for complex operations that require multiple tool changes.

3. Reduced Setup Time: With a lathe turret, setup time is significantly reduced as there is no need to manually change and align tools. This saves valuable time during machining operations, allowing for faster production runs.

Yes, a lathe turret can hold different types of tools depending on the machining requirements. The turret allows for the use of turning tools, boring tools, thread cutting tools, parting tools, grooving tools, and more.

The tool holders or tool posts in the turret are designed to securely grip different tools, allowing for versatility in machining operations. This enables the lathe to perform a wide range of tasks without the need for manual tool changes, providing efficiency and flexibility in production.

No, a lathe turret is not limited to industrial settings. While it is widely used in industries such as metalworking, automotive, and aerospace, it can also be found in smaller workshops and even hobbyist setups.

The lathe turret offers benefits in terms of efficiency, productivity, and accuracy, making it a valuable tool in various machining applications. Whether it’s for large-scale production or small-scale projects, the lathe turret provides a reliable and efficient solution for automating tool changes and optimizing machining processes.

To maintain a lathe turret, regular cleaning and lubrication are essential. Remove any chips, debris, or coolant from the turret and its components. Inspect and clean the tool holders or tool posts, ensuring they are free from dirt and properly secured.

Additionally, check the turret’s rotating mechanism for any signs of wear or damage. Lubricate all moving parts as per the manufacturer’s recommendations. Preventive maintenance, such as monitoring the turret’s performance and addressing any issues promptly, will help ensure optimal functionality and extend the life of the lathe turret.

Summary

So, what is a lathe turret? A lathe turret is an important part of a lathe machine that holds and indexes tools. It allows for quick and efficient tool changes, making processes like drilling and cutting easier.

With a lathe turret, different tools can be loaded into the turret, and the machine can automatically rotate and position them for use. This saves time and increases productivity. Turrets can have multiple tool positions, allowing for a variety of operations to be performed without the need for manual tool changes.

In conclusion, a lathe turret is a handy device that simplifies tool changes, making lathes more versatile and efficient. By using a turret, operators can perform different operations without wasting time on manual tool swaps.