Phenolic plywood…now there’s a term you might not have heard before. But don’t worry, I’ve got you covered! So, what is phenolic plywood anyway? Well, let’s dive in and explore this fascinating topic together.

Picture this: you’re working on a project that requires durability and strength, whether it’s for construction, outdoor furniture, or even boat building. That’s where phenolic plywood comes into play. It’s a special type of plywood that’s engineered to withstand even the toughest conditions.

Think of phenolic plywood as the superhero of the wood world. It’s made by bonding layers of wood veneer together with a strong phenolic resin adhesive. This magical combination creates a plywood that’s not only water-resistant but also resistant to extreme temperatures, chemicals, and wear and tear.

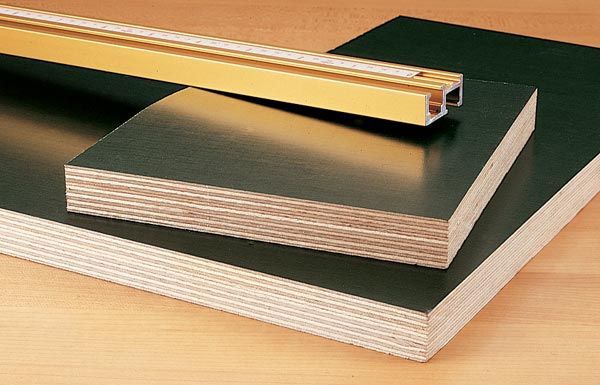

But wait, there’s more! Phenolic plywood isn’t just tough; it’s also beautiful. With its smooth surface and natural wood grain patterns, it can add a touch of elegance to your projects. Plus, it’s available in a wide range of thicknesses and sizes, making it versatile and adaptable to various applications.

So, whether you’re a DIY enthusiast or a professional builder, phenolic plywood might just be the secret ingredient that takes your projects to the next level. Get ready to unleash your creativity and let phenolic plywood revolutionize the way you work with wood. Together, we’re about to embark on a journey of durability, resilience, and endless possibilities. Are you ready? Let’s go!

What is Phenolic Plywood? A Comprehensive Guide

When it comes to choosing the right building material for a construction project, plywood is a popular choice due to its durability and versatility. One type of plywood that stands out is phenolic plywood. But what exactly is phenolic plywood? In this comprehensive guide, we will dive into the world of phenolic plywood, exploring its composition, benefits, and various applications. Whether you’re a contractor, architect, or simply curious about construction materials, this article will provide you with all the information you need to know about phenolic plywood.

Composition and Manufacturing Process of Phenolic Plywood

Phenolic plywood is manufactured using a unique process that involves bonding phenolic resin impregnated cellulose fibers with layers of wood veneers. This unique composition gives phenolic plywood its exceptional strength and durability, making it suitable for a wide range of applications. The resin used in the manufacturing process is derived from phenol and formaldehyde, which undergo a chemical reaction to form a strong and rigid material.

The manufacturing process of phenolic plywood involves several steps. Firstly, the wood veneers are coated with the phenolic resin, which is then pressed and heated under high pressure, resulting in a bonded structure. This process ensures that the resin fully impregnates the wood fibers, creating a material with superior strength and resistance to moisture, chemicals, and rot. The number of layers and thickness of the wood veneers used in the manufacturing process can vary, depending on the desired strength and application of the phenolic plywood.

The Benefits of Phenolic Plywood

Phenolic plywood offers a multitude of benefits that make it a preferred choice for various construction projects. Here are some of the key advantages:

- Exceptional Strength: Phenolic plywood is known for its remarkable strength and resistance to impact and bending. It can withstand heavy loads, making it suitable for use in structural applications.

- Water and Moisture Resistance: Thanks to the phenolic resin impregnation, phenolic plywood is highly resistant to water and moisture. This resistance makes it ideal for outdoor applications, such as marine construction or outdoor furniture.

- Chemical Resistance: Phenolic plywood is also highly resistant to chemicals, including solvents, acids, and alkalis. This makes it suitable for use in laboratories, industrial settings, and chemical processing plants.

- Durable and Long-lasting: Due to its composition and manufacturing process, phenolic plywood is incredibly durable and long-lasting. It can withstand harsh environmental conditions, making it a reliable choice for both interior and exterior applications.

- Easy to Work With: Although phenolic plywood is strong and rigid, it is still relatively easy to work with. It can be cut, drilled, and shaped using standard woodworking tools. This versatility makes it convenient for various construction projects.

Applications of Phenolic Plywood

Phenolic plywood finds a wide range of applications across various industries. Here are some of the common uses of phenolic plywood:

- Construction and Building: Phenolic plywood is widely used in the construction industry for applications such as formwork, scaffolding, flooring, and wall paneling. Its strength and moisture resistance make it a reliable choice for these purposes.

- Transportation and Automotive: Phenolic plywood is commonly used in the transportation industry for applications such as truck flooring, trailer sidewalls, and bus interiors. Its durability and resistance to wear and tear make it suitable for heavy-duty use.

- Furniture and Cabinetry: Phenolic plywood is also popular in the furniture and cabinetry industry. It is used to create durable and moisture-resistant furniture pieces, cabinets, and countertops.

- Marine Construction: Due to its exceptional water and moisture resistance, phenolic plywood is extensively used in marine construction. It is used for boat building, decking, and other marine applications.

- Industrial Applications: Phenolic plywood is highly valued in industrial settings where strength, chemical resistance, and durability are crucial. It is used in the manufacturing of storage tanks, chemical containers, and equipment panels.

The Environmental Impact of Phenolic Plywood

As with any construction material, it is essential to consider the environmental impact of phenolic plywood. Phenolic resin, which is a key component of phenolic plywood, is derived from non-renewable resources. However, many manufacturers are taking steps to minimize their environmental footprint by using sustainable and certified wood sources for their plywood veneers.

Furthermore, phenolic plywood itself is highly durable and long-lasting, reducing the need for frequent replacement and minimizing waste. It also has excellent thermal insulation properties, contributing to energy efficiency in buildings. When choosing phenolic plywood, it is advisable to look for products that comply with recognized environmental certifications, such as the Forest Stewardship Council (FSC) or the Programme for the Endorsement of Forest Certification (PEFC).

Tips for Working with Phenolic Plywood

Working with phenolic plywood requires some considerations to ensure optimal results. Here are a few tips to keep in mind:

- Use Appropriate Tools: Phenolic plywood is denser and harder than standard plywood, so it is essential to use sharp and durable tools. High-quality carbide-tipped saw blades and drill bits are recommended for cutting and drilling.

- Take Safety Precautions: When cutting or sanding phenolic plywood, wear appropriate personal protective equipment (PPE) such as safety goggles, a dust mask, and gloves to protect yourself from dust and potential splintering.

- Prevent Moisture Infiltration: While phenolic plywood is highly resistant to moisture, it is still advisable to seal the edges and any exposed areas with waterproof sealant to prevent water infiltration.

- Follow Manufacturer’s Guidelines: Each manufacturer may have specific recommendations for working with their phenolic plywood products. It is essential to read and follow their guidelines to ensure optimal performance and durability.

In Conclusion

Phenolic plywood is a durable, versatile, and reliable building material that offers numerous benefits for various construction projects. Its exceptional strength, resistance to water and chemicals, and ease of workability make it a preferred choice in industries ranging from construction to marine applications. By understanding its composition, benefits, and applications, you can make informed decisions and utilize phenolic plywood to its fullest potential. Remember to consider the environmental impact and work with this material safely and responsibly. With its outstanding properties, phenolic plywood is an excellent investment for any construction project.

Key Takeaways: What is Phenolic Plywood?

- Phenolic plywood is a type of plywood that is coated with a phenolic resin, making it durable and resistant to water, chemicals, and wear.

- It is commonly used in construction and outdoor applications, such as building facades, flooring, and marine structures.

- Phenolic plywood is known for its high strength and stability, making it suitable for heavy-duty use.

- It has a smooth surface finish, which makes it easy to clean and maintain.

- When purchasing phenolic plywood, it is important to consider the thickness, size, and quality of the plywood to ensure it meets your specific project requirements.

Frequently Asked Questions

Welcome to our FAQ section where we answer some common questions about phenolic plywood. Phenolic plywood is a type of plywood that has been treated with a phenolic resin for enhanced durability and water resistance. It is commonly used in construction and outdoor applications due to its strength and weather resistance.

1. How is phenolic plywood different from regular plywood?

Phenolic plywood differs from regular plywood in that it has been treated with a phenolic resin. This resin is infused throughout the layers of the plywood, making it highly resistant to water, moisture, and chemicals. Regular plywood, on the other hand, is more susceptible to water damage and may warp or deteriorate when exposed to moisture. Phenolic plywood is also stronger and more durable overall, making it a preferred choice for applications where strength and resistance to the elements are important factors.

2. What are some common uses for phenolic plywood?

Phenolic plywood has a wide range of uses due to its durability and weather resistance. It is commonly used in the construction industry for applications such as concrete formwork, flooring, and wall panels. It is also used in the manufacturing of furniture, cabinets, and transportation vehicles. Additionally, phenolic plywood is often utilized in outdoor settings where exposure to rain, snow, and humidity is a concern, such as for decks, boat building, and exterior cladding.

3. How does the phenolic resin enhance the properties of plywood?

The phenolic resin used in the treatment of plywood acts as a binder, providing increased strength and water resistance. It creates a protective barrier that helps repel moisture and prevents the growth of mold and mildew. The resin also improves the overall structural integrity of the plywood, making it stiffer and more resistant to warping or bending under heavy loads. This enhanced durability and resistance to the elements make phenolic plywood a reliable choice for demanding applications.

4. Is phenolic plywood more expensive than regular plywood?

Yes, phenolic plywood is generally more expensive than regular plywood due to the added cost of the phenolic resin treatment. However, when considering the long-term benefits and durability, it can be a worthwhile investment. The extended lifespan and reduced maintenance requirements of phenolic plywood may offset the initial higher cost, especially in applications where exposure to moisture or harsh conditions is a concern.

5. How should phenolic plywood be maintained?

To maintain the integrity and lifespan of phenolic plywood, it is important to keep it clean and free from excessive moisture. Regularly inspect the plywood for any signs of damage or wear, and promptly address any issues to prevent further deterioration. Avoid exposing phenolic plywood to prolonged periods of direct sunlight, as this can cause discoloration. Additionally, it is advisable to follow the manufacturer’s guidelines for cleaning and maintenance to ensure the proper care of your phenolic plywood.

Summary

Phenolic plywood is a type of plywood that is treated with a phenolic resin, adding extra durability and water-resistance. It is commonly used in construction and outdoor projects due to its strength and weather-resistant properties. This type of plywood is made by layering thin sheets of wood together with the phenolic resin, which acts as a protective barrier and prevents water damage. Phenolic plywood is a great choice for projects that require a sturdy and long-lasting material.

In addition to its water-resistance, phenolic plywood is also resistant to chemicals, making it ideal for applications where exposure to harsh substances is expected. This type of plywood is often used in the construction of concrete forms, boat building, and outdoor furniture. While it may be slightly more expensive than regular plywood, the added benefits and durability make it a worthwhile investment. Phenolic plywood is a versatile option that can withstand the test of time and various environmental conditions.