Have you ever wondered what racking in woodworking is all about? Well, let me tell you, it’s a fascinating technique that can take your woodworking skills to the next level. But what exactly is racking? Let’s dive in and find out!

Imagine this: you’re working on a project, carefully aligning and assembling the pieces of wood. Suddenly, you notice that something is off. The whole structure is tilting or leaning to one side. That’s when racking comes into play. Racking is the term used to describe the unintentional twisting or misalignment of wood while working on a project.

Now, you might be thinking, “Why does racking happen, and how can I prevent it?” Great questions! Racking can occur due to various factors such as uneven pressure, inadequate bracing, or improper connections between wood pieces. However, fear not! There are techniques and precautions you can take to minimize the risk of racking and ensure a sturdy and well-constructed final product.

So, if you’re ready to enhance your woodworking skills and create beautiful, durable pieces, understanding racking is essential. In the following sections, we’ll delve deeper into the causes of racking and explore effective strategies to prevent it from wreaking havoc on your woodworking projects. Let’s get started!

In woodworking, “racking” refers to the undesirable shifting or misalignment of wooden components. It can occur when the wood is subjected to changes in moisture content or when boards are not properly secured. To prevent racking, follow these steps:

Preventing Racking in Woodworking:

– Use kiln-dried wood for stability.

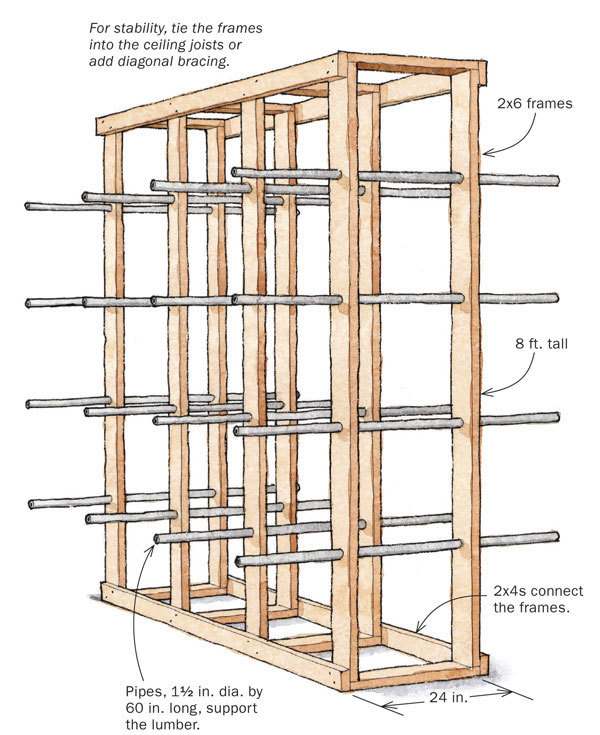

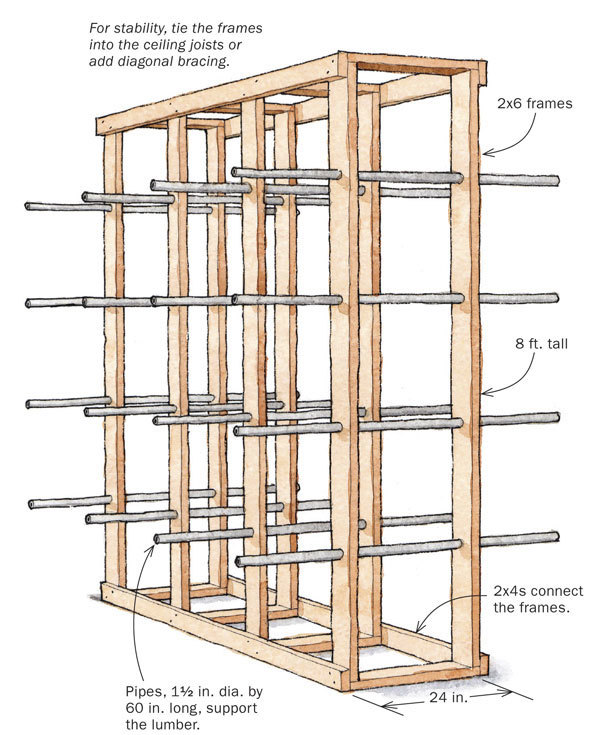

– Install diagonal bracing or corner blocks.

– Properly secure joints with screws or nails.

– Apply a finish or sealant to protect against moisture.

– Regularly check for signs of racking and make adjustments as needed.

What is Racking in Woodworking?

Woodworking is a versatile craft that allows for the creation of beautiful and functional items using wood. While the process of woodworking may seem straightforward, it involves various techniques and skills to achieve the desired results. One essential aspect of woodworking is understanding and addressing issues like racking. Racking refers to the distortion or misalignment of wood pieces, particularly in the construction of cabinets, bookshelves, and other furniture. In this article, we will explore the concept of racking in woodworking, its causes, and how to prevent or fix it.

Understanding Racking in Woodworking

When working with wood, it is crucial to ensure that the project remains stable and structurally sound. Racking occurs when the corners of a wooden structure twist or become misaligned, resulting in a weakened and unstable piece. It commonly happens in projects involving large panels or cabinets with tall dimensions, as these structures are more prone to movement and stress. Racking can make doors and drawers stick or not function properly, compromising the functionality and aesthetics of the final piece.

Several factors contribute to racking, including wood moisture content, construction methods, and the overall design of the piece. Understanding these factors and implementing appropriate techniques can help prevent racking and ensure the longevity of your woodworking projects.

Causes of Racking in Woodworking

There are several causes of racking in woodworking, and each must be taken into consideration to avoid potential issues. One significant factor is wood moisture content. Wood is a hygroscopic material, meaning it absorbs and releases moisture based on its environment. Changes in humidity and temperature can cause the wood to expand and contract, leading to dimensional changes and potential racking. It is always essential to work with properly seasoned and stable wood to minimize the risk of racking.

The construction methods used in woodworking projects can also contribute to racking. For example, the joinery techniques employed and the type of fasteners used can impact the stability of the structure. Insufficient or improper joinery can result in weak connections that might shift or twist over time, leading to racking. Additionally, inadequate bracing or reinforcement can cause a wooden piece to be more susceptible to racking.

Lastly, the design and proportions of a project play a crucial role in preventing racking. Tall and narrow structures are more prone to racking due to the increased leverage on the corners. Properly designing the piece with appropriate dimensions, support, and bracing can minimize the risk of racking and ensure the overall stability of the structure.

Preventing and Fixing Racking

Preventing racking is crucial in woodworking, as it ensures the longevity and functionality of the final piece. Here are some tips to help you prevent and fix racking:

- Choose stable wood: Work with properly seasoned wood that has reached an equilibrium moisture content to minimize dimensional changes.

- Use proper construction techniques: Employ suitable joinery methods and use high-quality fasteners to create strong and durable connections.

- Add reinforcement: Incorporate appropriate bracing or reinforcements to enhance the stability and structural integrity of the piece.

- Consider the design: Opt for proportionate dimensions and add support where required, especially for tall and narrow structures.

- Monitor and acclimate: Allow the wood to acclimate to the environment in which it will be used, and regularly monitor and adjust for any changes in humidity or temperature.

- Fixing racking: If a piece has already experienced racking, it can often be fixed by carefully realigning the corners and reinforcing the structure. This may involve disassembling and reassembling parts, adding bracing or supports, or employing advanced woodworking techniques.

The Importance of Addressing Racking

Addressing racking is crucial to ensure the stability, functionality, and longevity of your woodworking projects. Ignoring or neglecting racking issues can lead to structural failure, compromised aesthetics, and potential safety risks. By understanding the causes of racking, implementing preventive measures, and addressing any issues that arise, you can create beautiful and durable woodworking pieces that stand the test of time.

Benefits of Addressing Racking in Woodworking

Addressing the issue of racking in woodworking offers several key benefits:

- Improved stability: By preventing or fixing racking, woodworking projects become more stable and resistant to distortion, allowing for smoother operation of doors, drawers, and other moving parts.

- Enhanced functionality: Racking can compromise the functionality of a piece, resulting in doors and drawers that don’t align or operate properly. Addressing and preventing racking ensures that all components function as intended, improving overall usability.

- Longevity: A stable and structurally sound piece is more likely to withstand the test of time. By addressing racking, you increase the lifespan of your woodworking projects, ensuring that they can be enjoyed for years to come.

- Aesthetics: Racking can cause visible misalignments and distortions, negatively impacting the overall appearance of the piece. Properly addressing racking ensures that the final piece looks visually appealing and well-crafted.

- Safety: Racking can compromise the structural integrity of a woodworking project, posing safety hazards. By preventing or fixing racking, you create a safer environment for both users and the piece itself.

Conclusion

Racking is a common issue faced in woodworking, particularly in projects involving large panels or tall structures. Understanding the causes of racking, such as wood moisture content, construction methods, and design considerations, is crucial for preventing and addressing this problem. By implementing preventive measures, using stable wood, employing proper construction techniques, and making design considerations, woodworkers can tackle racking effectively. Addressing racking not only ensures stability and functionality but also enhances the longevity and aesthetics of woodworking projects.

Key Takeaways: What is Racking in Woodworking?

- Racking in woodworking refers to the tendency of assembled furniture or structures to lean or distort under stress.

- It can occur when the construction of a project is not structurally sound or when it lacks proper bracing or support.

- Woodworkers must ensure that their projects are built with strong joints and reinforcements to prevent racking.

- Addition of diagonal braces or corner blocks is a common technique to resist racking and improve stability.

- Understanding and implementing proper racking prevention is essential to create durable and long-lasting woodworking projects.

Frequently Asked Questions

Here are some common questions people have about the concept of “racking” in woodworking. Read on to gain a better understanding of this technique.

How does racking apply to woodworking?

Racking is a term used to describe the process of aligning and positioning items, such as shelves or walls, at an angle instead of straight. In woodworking, racking refers to joining two or more pieces of wood together diagonally rather than horizontally or vertically. This technique is commonly used to create sturdy structures and prevent the wood from warping or twisting over time.

By incorporating racking in woodworking projects, it adds stability and strength to the overall structure. It ensures that the load is distributed evenly across the wood pieces, enhancing the durability of the final product. Racking can be particularly useful in projects like bookshelves, cabinets, or even in the construction of a wine rack.

What are the benefits of racking in woodworking?

Racking offers several benefits in woodworking. Firstly, it helps to prevent warping and twisting of the wood, ensuring the longevity of the structure. By joining the wood pieces diagonally, racking enhances the stability and strength of the project. This is especially important when dealing with heavy items that need to be supported.

Secondly, racking can add an interesting visual aspect to the woodworking project. Instead of the traditional straight lines, the diagonal placement of the wood pieces can create a unique and eye-catching design. This can be especially appealing for individuals looking to create unique furniture pieces or artistic installations.

Can racking be applied to any woodworking project?

Racking can be applied to various woodworking projects, but it may not be suitable for every situation. The decision to use racking depends on factors such as the design of the project, the intended use, and the specific type of wood being used. Some projects may require greater structural stability, making racking a favorable option.

However, it’s essential to consider the limitations and potential drawbacks of racking. In some cases, racking may weaken the overall structure if not executed properly, especially if the wood used is not suitable for this technique. It’s best to assess each project individually and consult with a woodworking professional to determine if racking is the right choice.

Are there any alternatives to racking in woodworking?

Yes, there are alternative methods to achieve structural stability in woodworking projects. One common alternative is using reinforcing elements such as braces or corner blocks. These additional pieces of wood can be placed at certain angles to provide extra support and prevent any potential warping or twisting.

Another alternative is utilizing advanced joinery techniques, such as dovetail or mortise and tenon joints, which provide excellent strength and stability. These techniques involve intricate cuts and fittings that create a strong bond between wood pieces without the need for racking.

Is racking only applicable to woodworking projects?

No, racking is not limited to woodworking projects. The concept of racking is used in various other industries and fields. For example, in furniture assembly, racking can be applied to ensure the stability of cabinets or shelves. It can also be utilized in construction to align and secure walls or other structural elements at an angle.

Furthermore, in industries such as logistics or warehousing, racking systems are commonly used to store and organize goods. These systems are designed with diagonal beams that provide additional support and prevent any shifting or collapsing of the stored items. So, while racking is commonly associated with woodworking, its applications extend far beyond the craft.

Summary

Woodworking can be a fun and creative hobby, but sometimes we face a problem called racking. Racking happens when a piece of wood warps or twists, causing it to be uneven or unstable. To avoid racking, it’s important to choose the right type of wood, use proper techniques, and take care of the wood’s moisture content. Staying mindful of these important steps will help you create beautiful and sturdy woodworking projects without any racking issues.

Remember, when working with wood, it’s crucial to understand racking and how to prevent it. By selecting the right wood, using proper techniques, and taking care of moisture levels, you can ensure that your woodworking projects will be strong and stable. So keep practicing, stay cautious, and have fun with your woodworking adventures!