Do you ever wonder what exactly shuttering plywood is? Well, you’re in luck because I’m here to tell you all about it! Shuttering plywood is a type of plywood that’s commonly used in construction projects. It’s specially designed to create temporary structures like formwork, which is used to shape concrete during the pouring and setting process. So, if you’re curious about this versatile material, keep reading to find out more!

Now, you might be wondering why it’s called “shuttering” plywood. Well, the term “shuttering” comes from the process of creating wooden shutters, which were traditionally made using this type of plywood. But don’t worry, we’re not talking about shutters for windows here! Instead, shuttering plywood is used to build molds and frameworks that hold concrete in place until it hardens. It’s a crucial component in construction projects, providing support and structure during the concrete pouring process.

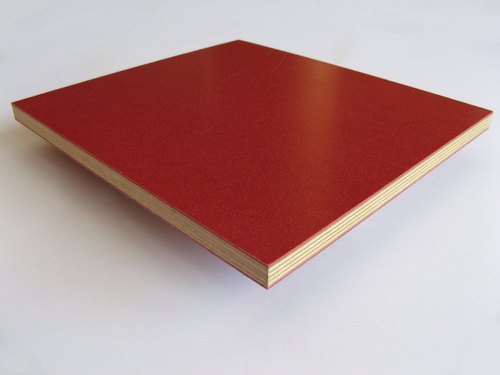

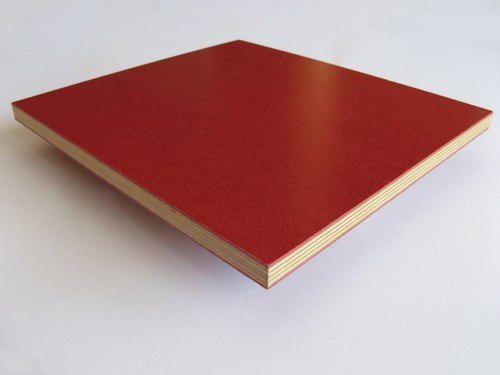

So, what makes shuttering plywood so special? Well, it’s all about the quality and durability. Shuttering plywood is made with high-quality layers of wood veneers that are bonded together with strong adhesives. This construction gives the plywood excellent strength and stability when subjected to the weight and pressure of wet concrete. Plus, the smooth surface of shuttering plywood ensures a clean finish on the concrete structure. Whether you’re working on a small DIY project or a large-scale construction site, shuttering plywood is the go-to material for temporary structures.

And there you have it! Shuttering plywood is an essential material in the world of construction. Its strength, durability, and versatility make it an ideal choice for creating temporary structures during the concrete pouring process. So, the next time you see a construction site, you can impress your friends with your knowledge of shuttering plywood and its role in building those impressive structures!

**

What is Shuttering Plywood? A Comprehensive Guide

**

Shuttering plywood is a type of plywood that is commonly used in construction projects. It is specifically designed to create formwork or molds for pouring concrete in reinforced concrete structures. In simple terms, it serves as a temporary support structure that holds the concrete in place until it hardens and gains enough strength to support itself.

Shuttering plywood is typically made from high-quality hardwood veneers that are bonded together with a strong adhesive. This makes it durable, resistant to warping, and capable of withstanding the pressure exerted by wet concrete. Unlike regular plywood, shuttering plywood is specifically engineered with a smooth surface finish to ensure easy release of the concrete once it has set.

While there are various grades of shuttering plywood available, the most commonly used grade is birch plywood. Birch plywood is known for its stiffness, stability, and high strength-to-weight ratio, making it ideal for structural applications. The thickness of shuttering plywood ranges from 12mm to 25mm, with thicker panels being used for heavy-duty projects that require additional strength.

**

The Benefits of Shuttering Plywood in Construction

**

Shuttering plywood offers several benefits that make it a popular choice in construction projects. Firstly, its smooth surface finish ensures a clean and high-quality concrete finish, free from any surface imperfections. This is particularly important in projects where appearance is a priority, such as architectural concrete elements.

Secondly, shuttering plywood is highly durable and can withstand the immense pressure exerted by wet concrete. Its strong construction and resistance to warping ensure that the formwork remains intact throughout the concrete pouring process, resulting in a structurally sound final product.

Another advantage of shuttering plywood is its versatility. It can be easily cut, drilled, and shaped, allowing for customization to fit specific project requirements. Additionally, because it is made from high-quality hardwood veneers, shuttering plywood has excellent screw-holding capacity, making it easy to secure to the supporting framework.

**

Shuttering Plywood vs. Other Formwork Materials

**

When it comes to choosing the right material for formwork in construction projects, several options are available. However, shuttering plywood has distinct advantages over other commonly used materials.

One popular alternative to shuttering plywood is steel formwork. While steel formwork offers excellent durability and reusability, it can be more expensive and time-consuming to install and dismantle. Shuttering plywood, on the other hand, is cost-effective and easy to handle, making it a preferred choice for smaller-scale projects or projects with tight deadlines.

Another alternative is plastic formwork, which is lightweight and requires little maintenance. However, plastic formwork may not be suitable for heavy-duty projects that require high load-bearing capacity. Shuttering plywood, with its superior strength and stability, is better suited for such applications.

**

Tips for Working with Shuttering Plywood

**

Now that we understand the importance and benefits of shuttering plywood, let’s delve into some useful tips for working with this material in construction projects.

1. **Ensure Proper Storage**: Shuttering plywood should be stored in a dry and well-ventilated area to prevent warping or moisture damage. It should be stacked flat and supported evenly to maintain its shape.

2. **Apply Release Agent**: To facilitate the easy release of concrete, it is advisable to apply a release agent on the surface of the shuttering plywood before pouring. This will prevent the concrete from sticking to the formwork.

3. **Use Proper Fasteners**: When securing shuttering plywood to the supporting framework, it is important to use appropriate fasteners, such as screws or nails, at regular intervals. This will ensure that the formwork remains securely in place during concrete pouring.

4. **Minimize Joints**: To achieve a smooth and seamless finish, it is recommended to minimize the number of joints in the shuttering plywood. This can be achieved by using larger panel sizes or by using tongue and groove connections.

5. **Regular Inspection**: Throughout the construction process, it is essential to regularly inspect the shuttering plywood for any signs of damage or wear. Damaged panels should be replaced promptly to maintain the structural integrity of the formwork.

In conclusion, shuttering plywood is a crucial component in construction projects, providing support and structure for poured concrete. Its smooth surface finish, durability, and versatility make it an ideal choice for a wide range of applications. By following proper storage practices and employing useful tips for working with shuttering plywood, construction professionals can ensure the success and quality of their concrete projects.

Key Takeaways: What is Shuttering Plywood?

- Shuttering plywood is a type of plywood that is commonly used in construction projects.

- It is specifically designed for use in making molds or frames for concrete structures.

- The plywood is known for its strength and durability, making it ideal for use in construction.

- Its smooth surface allows for easy removal of the mold after the concrete has cured.

- Shuttering plywood is available in different sizes and thicknesses, depending on the specific needs of the project.

Frequently Asked Questions

Are you curious about shuttering plywood? Here are some common questions and answers to help you understand more about this construction material.

1. What are the characteristics of shuttering plywood?

Shuttering plywood, also known as sheathing plywood or formwork plywood, is specifically designed for use in concrete formwork. It is made from high-quality, durable wood veneers that are bonded together with adhesives. Shuttering plywood is known for its strength, stability, and resistance to moisture and impact.

The plywood sheets have a smooth surface, ensuring a clean finish on the concrete. They are also capable of withstanding the pressure exerted by the wet concrete, preventing bulging or warping. Additionally, shuttering plywood is reusable, making it a cost-effective choice for construction projects.

2. How is shuttering plywood different from regular plywood?

Shuttering plywood differs from regular plywood in its construction and purpose. While regular plywood is primarily used for general woodworking and furniture making, shuttering plywood is specifically designed to be used as formwork in concrete construction.

The quality of the wood veneers used in shuttering plywood is also different. Shuttering plywood is typically made from hardwood veneers that provide enhanced strength and durability compared to regular softwood plywood. It is engineered to withstand the pressure and weight of wet concrete without compromising its structural integrity.

3. What are the applications of shuttering plywood?

Shuttering plywood is extensively used in the construction industry for various applications. Its primary use is in concrete formwork, where it is used to create molds or frameworks into which concrete is poured. These molds help shape and support the concrete until it hardens, ensuring the desired structure is achieved.

Aside from formwork, shuttering plywood can also be used for other temporary structures like scaffolding, site fencing, hoarding, and construction support systems. Its versatility makes it an essential material in the building process, providing temporary structural support and ensuring the quality of concrete structures.

4. Can shuttering plywood be reused?

Yes, one of the notable advantages of shuttering plywood is its reusability. After the concrete has hardened and the formwork is removed, the plywood sheets can be carefully dismantled and used again for future construction projects. This not only saves costs but also minimizes waste and promotes sustainable construction practices.

To maximize the lifespan and reuse potential of shuttering plywood, it is essential to handle and store it properly. Avoid excessive moisture exposure, clean and remove any concrete residue after each use, and store it in a dry and well-ventilated area. By taking these precautions, you can extend the life of the shuttering plywood and make the most out of its reusability.

5. How can I maintain and care for shuttering plywood?

To ensure the longevity and optimal performance of shuttering plywood, proper maintenance and care are crucial. Here are some essential tips:

First, handle the plywood with care during transportation and installation to prevent damage. Avoid dragging or dropping the sheets, as it can lead to cracks or breakages. Second, protect the wood surface from excessive moisture by applying appropriate coatings or sealants. This helps prevent swelling, warping, and delamination.

After each use, clean the plywood by removing any concrete residue or dirt. Inspect the sheets for any damage, such as cracks or excessive wear, and repair or replace them if necessary. Proper storage is also vital to protect the plywood from moisture and damage. Store it in a dry, elevated area away from direct sunlight. By following these maintenance practices, you can prolong the lifespan of the shuttering plywood and ensure its continued usability.

Summary:

Shuttering plywood is a type of wood used in construction to make temporary molds or frameworks. It is strong, versatile, and easy to work with. Shuttering plywood helps create the shape of concrete structures like walls and foundations. It is also durable and can withstand concrete’s pressure and weight.

Using shuttering plywood saves time and money because it can be reused multiple times. It is important to choose high-quality plywood to ensure the safety and stability of the construction project. Shuttering plywood is an essential material for builders and plays a crucial role in the construction industry.