When it comes to plywood, have you ever wondered what span rating means? Well, let’s dive into the fascinating world of construction materials and learn all about it! So, what is span rating for plywood, you ask? Buckle up, because we’re about to find out!

You see, span rating is a crucial factor in determining the strength and durability of plywood. It refers to the maximum distance between supports that the plywood can safely span without sagging or bending. Think of it as the ultimate test of a plywood sheet’s structural integrity. But why is this important? Well, it ensures that the plywood can bear the weight and stress exerted on it when used in various applications.

Now, you might be wondering how span ratings are determined. It’s a meticulous process that involves testing the plywood to measure its deflection under stress. Engineers subject the plywood to a range of loads and spans, evaluating its performance and determining a suitable span rating. These ratings are usually specified in the form of numbers or letters, representing the maximum span in inches or feet.

So, next time you’re working on a construction project, keep in mind the importance of span rating when choosing the right plywood. It’s a key factor that ensures the safety and stability of your structures. So, now that you have a good understanding of what span rating for plywood is, let’s explore its significance and applications in more detail. Grab your hard hat, and let’s get started!

Understanding the Span Rating for Plywood: A Comprehensive Guide

Plywood is a versatile building material used in various construction and woodworking projects. But have you ever wondered about its span rating? In this comprehensive guide, we will delve into the world of span rating for plywood. From what it means to how it is determined, we will cover all the essential aspects of this crucial specification. So, whether you are a DIY enthusiast or a professional contractor, read on to unlock the secrets of span rating and its significance in plywood applications.

What is Span Rating for Plywood?

The span rating for plywood is a measure of the maximum recommended distance between supports for a given thickness of plywood panel. In other words, it denotes the maximum unsupported span that the plywood can withstand without excessive deflection or failure. Span ratings are typically provided by the manufacturer and are important for determining the appropriate applications and load capacities of plywood panels. Let’s explore the intricacies of span rating further to understand its significance in the construction industry.

The Role of Span Rating in Plywood Quality

The span rating of plywood is a critical factor in determining its overall quality and suitability for various applications. It indicates the panel’s strength and stiffness, helping builders and designers select the right type and thickness of plywood for their specific needs. Higher span ratings denote stronger and stiffer panels, capable of spanning larger distances between supports. This ensures structural integrity and prevents sagging or buckling under heavy loads.

The span rating is determined by subjecting plywood panels to rigorous testing procedures. These tests involve loading the panels at increasing increments until they fail or deflect excessively. The results are then used to calculate the span rating, which is expressed in inches. It is important to note that span ratings may vary depending on the panel’s thickness and the intended use. Therefore, it is crucial to consult the manufacturer’s specifications to determine the appropriate span rating for your project.

Understanding Span Ratings: Plywood Application Examples

Span ratings play a vital role in determining the appropriate applications for different plywood panels. Here are some common examples:

1. Roof Decking: Plywood with a high span rating is ideal for roof decking, as it can span larger distances between rafters or trusses. This ensures the roof’s structural integrity and prevents sagging.

2. Subflooring: When used as subflooring, plywood with a suitable span rating provides a stable and level surface for finished flooring materials. It can withstand the weight of foot traffic and furniture without excessive deflection.

3. Shelving and Cabinets: Plywood with a high span rating is often used for making shelves and cabinets. The panels can support the weight of books, dishes, or other items without sagging or bending.

4. Non-Structural Wall Sheathing: Plywood panels with lower span ratings are commonly used for non-structural wall sheathing. The panels provide a solid surface for attaching siding materials while minimizing deflection.

To ensure safety and compliance with building codes, it is imperative to select plywood with the appropriate span rating for each specific application. Consulting with structural engineers or building professionals can provide valuable insights in this regard.

Benefits of Understanding Span Ratings

Understanding span ratings for plywood offers several benefits for both professionals and DIY enthusiasts.

1. Enhanced Structural Integrity: By selecting plywood with the appropriate span rating, you can ensure structural integrity in your construction projects. The panels will be able to bear the intended loads without excessive deflection or failure.

2. Optimal Use of Materials: Knowing the span rating helps in optimizing material usage. You can select the right thickness and type of plywood, reducing waste and saving costs on unnecessary materials.

3. Compliance with Building Codes: Building codes often specify the required minimum span ratings for various applications. By understanding these ratings, you can ensure compliance with regulations and avoid potential issues during inspections.

4. Increased Project Durability: Using plywood with a suitable span rating prevents premature wear and tear. It ensures that the panels can withstand the expected loads, extending the lifespan of your construction or woodworking projects.

In conclusion, span rating is a crucial aspect of plywood that determines its load-bearing capabilities and overall suitability for different applications. By understanding span ratings, you can make informed decisions about material selection and ensure the structural integrity and durability of your projects. Whether you are building a roof, installing flooring, or designing cabinets, considering the span rating of plywood will contribute to successful and long-lasting results.

Factors Affecting Span Rating for Plywood

Several factors influence the span rating of plywood. It’s essential to consider these factors when selecting plywood for specific applications. Let’s explore the key factors that can affect span ratings:

Plywood Grade and Adhesive Type

The grade of plywood refers to its visual appearance and the number of allowable defects. Higher-grade plywood typically has fewer defects and better structural integrity, resulting in higher span ratings. Additionally, the type of adhesive used in plywood manufacturing can impact the span rating. Plywood constructed with high-quality adhesive materials tends to have higher span ratings, indicating increased strength and durability.

Plywood Thickness

The thickness of plywood panels directly affects their span rating. Thicker panels offer increased strength and stiffness, allowing them to span larger unsupported distances. Therefore, when selecting plywood for a specific application, it is crucial to consider the appropriate thickness to ensure optimal load-bearing capacity.

Panel Orientation

The orientation of plywood panels can affect their span ratings. Panels installed with their long edges perpendicular to the supports typically have higher span ratings compared to panels installed with their short edges perpendicular. This is because the longer direction of the plywood offers greater structural stability and load-bearing capacity.

Support Spacing

The spacing between supports, such as floor joists or roof rafters, significantly influences the span rating of plywood. Wider support spacing requires plywood with a higher span rating to ensure structural integrity and prevent excessive deflection. Following the manufacturer’s recommendations and consulting structural engineering guidelines can help determine the appropriate support spacing for a given span rating.

Environmental Considerations

Environmental factors, such as temperature and humidity, can impact the span rating of plywood. Extreme temperature variations or high humidity levels can potentially weaken the adhesive and lead to reduced span ratings over time. It is crucial to consider the expected environmental conditions when selecting plywood to ensure the longevity and performance of the panels.

By considering these factors, builders and designers can make informed decisions about the appropriate span rating of plywood for their specific applications. Additionally, consulting with industry professionals and adhering to relevant building codes and regulations will contribute to the successful and safe completion of construction projects.

Choosing the Right Span Rating for Plywood

Selecting the right span rating for plywood is crucial to ensure structural integrity, safety, and compliance with building codes. Let’s explore some essential tips to help you choose the appropriate span rating for your plywood applications:

Identify the Application

Start by identifying the specific application or project requirements. Determine whether the plywood will be used for roofing, flooring, sheathing, or any other purpose. Different applications have varying load requirements and support spacing guidelines, which influence the required span rating.

Consult Building Codes

Consult the local building codes and regulations relevant to your construction project. These codes often specify the minimum span rating requirements for various applications. Ensuring compliance will guarantee the structural integrity and safety of your project.

Consider Load Requirements

Evaluate the anticipated load requirements for the plywood. Determine the expected weight that the panels need to support to avoid excessive deflection or failure. This will influence the appropriate span rating needed for your application.

Consult Structural Engineers

If you are unsure about the span rating requirements for your specific project, it is advisable to consult with structural engineers or other industry professionals. Their expertise and knowledge will help you make informed decisions and ensure the optimal selection of plywood.

Refer to Manufacturer’s Specifications

Always refer to the manufacturer’s specifications for the plywood panels you are considering. The manufacturer’s documentation will provide detailed information about the span ratings, including any additional requirements or recommendations for installation and usage.

By following these tips and considering the specific requirements of your project, you can confidently choose plywood with the appropriate span rating. This will result in a structurally sound and compliant construction or woodworking project, delivering long-lasting and reliable performance.

Incorporating Span Ratings in Plywood Selection: Tips and Best Practices

Now that you have a good understanding of span ratings for plywood, let’s explore some tips and best practices for incorporating them into your plywood selection process:

Understand Application-Specific Requirements

To narrow down your options, thoroughly understand the specific requirements of your application. Consider factors such as support spacing, load requirements, and any structural or building code specifications. This will help you determine the appropriate span rating needed for your project.

Factor in Safety and Compliance

Make safety a top priority when selecting plywood. Ensure compliance with relevant building codes and regulations regarding span ratings. This will ensure the structural integrity and safety of your construction or woodworking project.

Consult Manufacturer’s Recommendations

Always refer to the manufacturer’s recommendations for the plywood panels you are considering. Manufacturers often provide detailed guidelines and installation instructions specific to their products. This information will help you make accurate decisions regarding span ratings and panel suitability.

Consider Long-Term Performance

Think about the long-term performance and durability of the plywood panels. Factors such as environmental conditions and expected wear and tear should influence your choice. Opt for plywood with a span rating that can withstand the anticipated loads and environmental challenges for sustained performance.

Seek Expert Advice

When in doubt, seek expert advice from structural engineers, architects, or experienced professionals in the construction industry. Their knowledge and expertise will provide valuable insights into selecting the ideal span rating for your plywood applications.

By incorporating these tips and following best practices, you can confidently select plywood with the appropriate span rating. This will result in successful construction and woodworking projects, ensuring safety, compliance, and long-term performance.

Conclusion

In this comprehensive guide to span ratings for plywood, we explored the definition of span rating, its significance in plywood quality, and its role in various applications. We discussed the key factors affecting span ratings and provided tips for selecting the right span rating for your plywood projects.

Remember, understanding span ratings enables you to make informed decisions, ensuring structural integrity, load-bearing capabilities, and compliance with building codes. By following the tips and best practices outlined in this guide, you can confidently choose plywood with the appropriate span rating for your construction or woodworking needs. So go ahead, embrace the world of span ratings, and embark on your next successful project with confidence.

What is the Span Rating for Plywood?

Plywood span rating is a measure of its strength and ability to support weight over a certain distance without sagging or breaking.

- Plywood span rating helps determine its suitability for different applications.

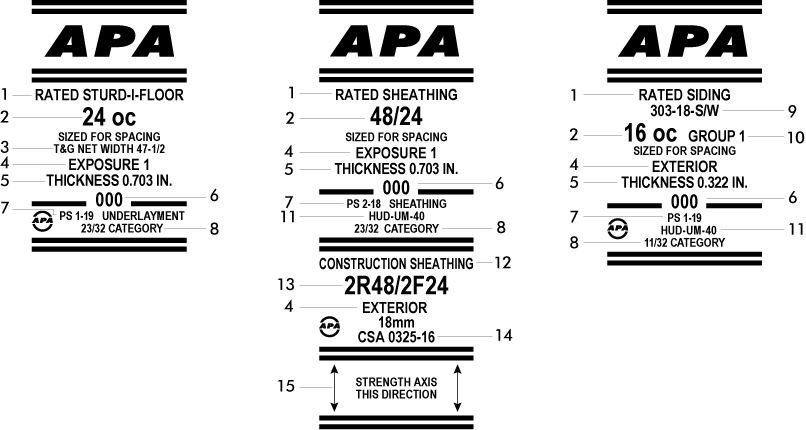

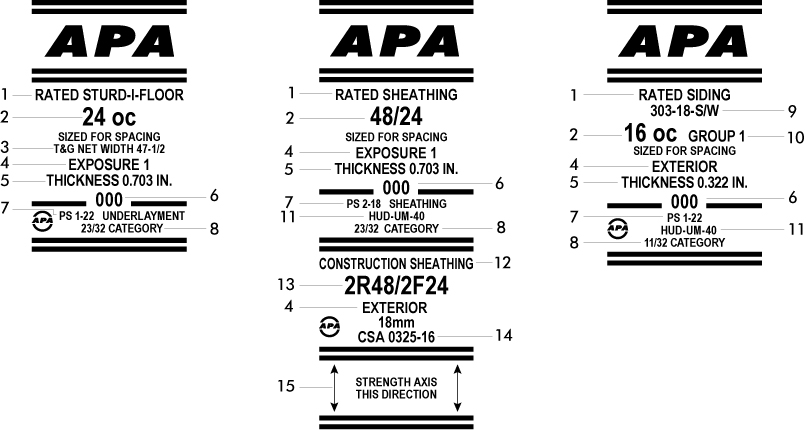

- The span rating is usually indicated by two numbers separated by a slash, such as 32/16.

- The first number represents the maximum recommended spacing between supports for a roof or floor application.

- The second number represents the maximum recommended spacing for subflooring or sheathing.

- A higher span rating indicates stronger and stiffer plywood.

Frequently Asked Questions

Want to know more about the span rating for plywood? Here are the answers to some commonly asked questions:

1. How is the span rating determined for plywood?

The span rating for plywood is determined through testing and evaluation by industry standards organizations. These organizations subject plywood panels to various loads and measure their deflection under those loads. This information is then used to assign a span rating, which indicates the maximum distance between supports that the plywood can safely span without excessive deflection.

Factors such as panel thickness, grade, and the type of wood used in the ply layers can impact the span rating. The higher the span rating, the stronger the plywood, allowing for longer spans between supports.

2. Why is the span rating important?

The span rating is important because it helps determine the appropriate use and application of plywood. By knowing the span rating, builders and engineers can ensure that they are using plywood panels that are suitable for the intended load and span requirements of a project. Using plywood with an insufficient span rating can lead to structural failures, sagging, or excessive deflection.

The span rating also plays a role in determining the spacing of supports and the spacing of fasteners when installing plywood. Adhering to the recommended span rating ensures the structural integrity and safety of the construction.

3. How do I find the span rating of a plywood panel?

The span rating of a plywood panel can usually be found on the panel itself or in the manufacturer’s documentation. It is typically indicated as a set of two numbers separated by a slash, such as 32/16 or 48/24. The first number represents the maximum recommended span for roof or floor applications, while the second number represents the maximum recommended span for sidewall or vertical applications.

It’s important to note that the span rating may vary depending on the thickness, grade, and type of plywood. Always refer to the manufacturer’s guidelines and consult with a structural engineer if you are unsure about the appropriate span rating for your specific project.

4. Can I exceed the recommended span rating for plywood?

Exceeding the recommended span rating for plywood is not recommended. The span rating is determined based on rigorous testing and engineering analysis to ensure the structural integrity of the material. Going beyond the recommended span can result in excessive deflection, sagging, or even failure of the plywood panel.

If your project requires longer spans, it’s advisable to consult with a structural engineer who can evaluate the specific requirements and recommend appropriate alternatives, such as using thicker or stronger plywood, adding additional support, or exploring other construction methods.

5. Are there different span ratings for different types of plywood?

Yes, different types of plywood can have varying span ratings. The span rating depends on factors such as the type of wood used, the number of ply layers, and the manufacturing process. For example, structural plywood designed for heavy-duty applications may have a higher span rating compared to exterior-grade or interior-grade plywood.

It’s crucial to select the appropriate type of plywood with the required span rating for your specific project to ensure its structural integrity and safety. Always consult the manufacturer’s guidelines and consider the recommendations of structural engineers or building professionals for the best results.

Summary

Plywood is a type of wood that is often used in construction and furniture-making. It comes in different ratings, including a span rating.

A span rating indicates how much weight a piece of plywood can support without sagging. The higher the span rating, the stronger the plywood.

It is important to choose plywood with the right span rating for your project to ensure it is structurally sound.

Additionally, span rating is determined by the spacing of the joists or supports that the plywood will be placed on.

So, make sure to consider the span rating along with the spacing requirements for your specific project.

In conclusion, span rating is a crucial consideration when using plywood. By understanding its meaning and choosing the right span rating, you can ensure the structural integrity of your construction or furniture piece.