Have you ever wondered what the spindle bore on a lathe is all about? Well, you’re in the right place! In this article, we’ll explore the ins and outs of this fascinating feature of a lathe. So, buckle up and get ready for an exciting journey into the world of machining!

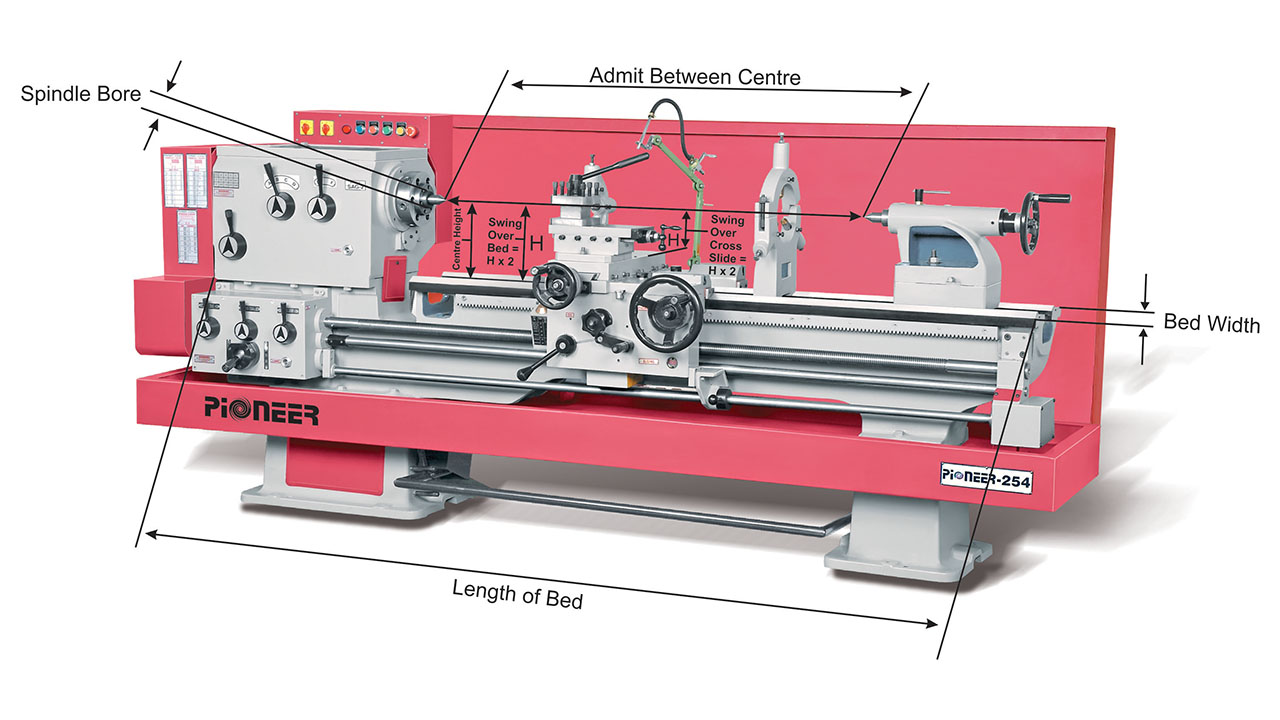

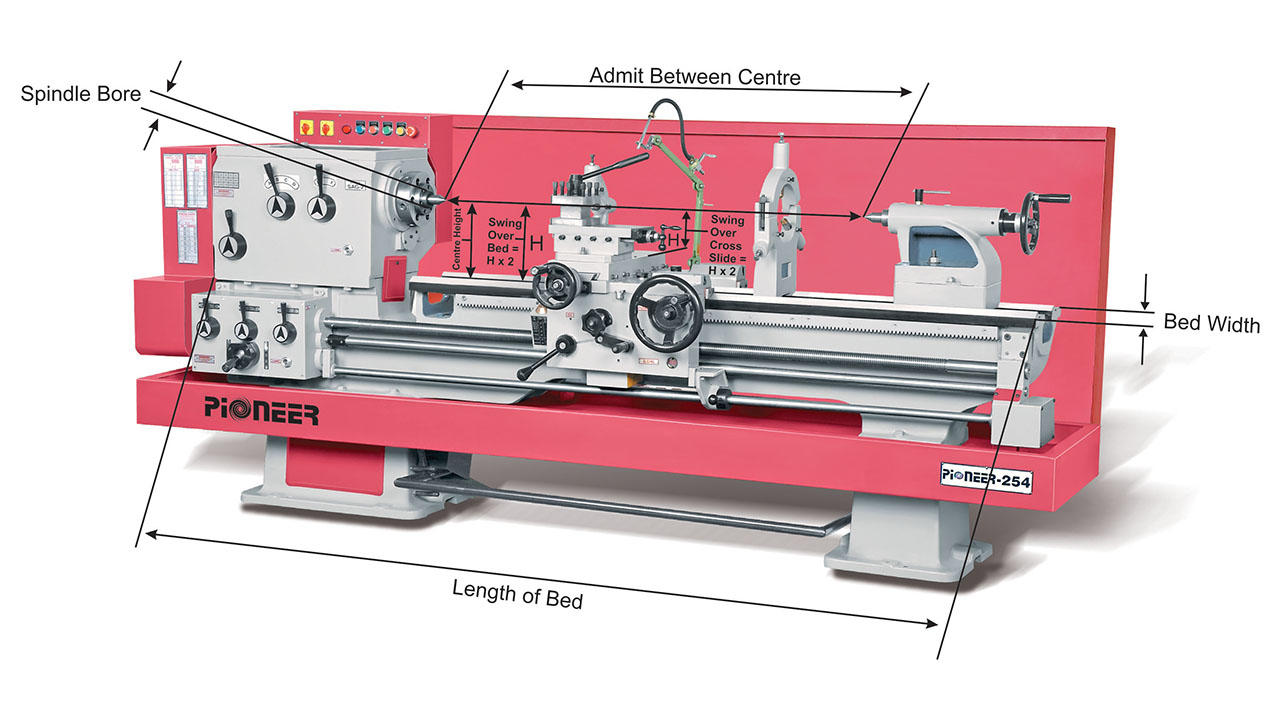

First things first, let’s answer the burning question: what is spindle bore on a lathe? Simply put, the spindle bore is the hollow passage that runs through the center of the lathe’s headstock. It’s like a tunnel that allows you to pass long workpieces through the spindle, giving you the freedom to work on larger and more complex projects.

Now, you might be wondering why the spindle bore is such an important feature. Well, here’s the deal: the size of the spindle bore determines the maximum diameter of the workpiece you can accommodate on the lathe. In other words, it sets the limit on how big your turning projects can be. So, if you want to tackle larger workpieces, a lathe with a generous spindle bore is what you need!

Get ready to dive deeper into the world of lathes as we unravel the mysteries of spindle bores and uncover their importance in the machining realm. So, stick around and let’s explore this fascinating topic together!

What is Spindle Bore on a Lathe? Explained in Detail

Spindle bore is an essential feature of a lathe machine that plays a crucial role in its functionality. In simple terms, spindle bore refers to the hollow cylindrical space in the spindle of a lathe that allows the passage of long workpieces through the machine for turning or machining operations. The size and capacity of the spindle bore determine the maximum diameter of the workpiece that can be accommodated on the lathe.

The spindle bore is typically located at the center of the headstock, which is the front part of the lathe that houses the main spindle. It is through the spindle bore that a variety of workpieces, such as rods, shafts, pipes, and other long cylindrical objects, are fed into the lathe for machining. The spindle bore is designed to have precise dimensions to ensure a proper fit and secure hold on the workpiece during the turning process.

The Importance of Spindle Bore Size

The size of the spindle bore is a critical factor to consider when choosing a lathe for a specific machining task. The larger the spindle bore, the larger the diameter of the workpiece that the lathe can accommodate. This is particularly important when working with large or oversized materials that require turning or facing operations.

Having a lathe with a significant spindle bore size allows for the efficient machining of larger workpieces, eliminating the need for additional equipment or sacrificing accuracy. It also provides the advantage of versatility, enabling the operator to tackle a wide range of turning applications, from small to large diameter components.

Choosing the Right Spindle Bore Size for Your Needs

When selecting a lathe with the appropriate spindle bore size, it is important to consider the types of workpieces you will be working with frequently. Determining the maximum diameter of the workpiece you are likely to encounter will guide you in choosing a lathe with a spindle bore that can accommodate those dimensions.

It is important to note that the spindle bore size is not the only consideration when it comes to choosing the right lathe. Other factors, such as bed length, horsepower, and speed range, also play a significant role in the lathe’s capability and suitability for your machining requirements.

Benefits of a Large Spindle Bore Size

Having a large spindle bore size offers several advantages for lathe users:

1. Increased Versatility: With a larger spindle bore, the lathe can handle a wider range of workpiece sizes, providing versatility in machining capabilities.

2. Time and Cost Savings: Eliminating the need for additional equipment or outsourcing machining jobs for larger workpieces can lead to significant time and cost savings.

3. Improved Accuracy: A larger spindle bore allows for the secure mounting of oversized workpieces, ensuring greater machining accuracy and precision.

4. Flexibility for Future Projects: Investing in a lathe with a larger spindle bore size provides flexibility for future projects that may require machining larger components.

5. Expanded Market Opportunities: With a lathe that can accommodate larger workpieces, businesses can take on larger projects, opening up new market opportunities and potential growth.

Conclusion

The spindle bore is a critical component of the lathe that determines its capacity to handle various workpiece diameters. By understanding the importance of spindle bore size and considering the specific machining requirements, operators can choose the right lathe with an appropriate spindle bore to meet their needs. A larger spindle bore size offers increased versatility, efficiency, and accuracy, providing numerous benefits to lathe users. So, whether you are a professional machinist or a hobbyist, the spindle bore size is a vital consideration when selecting a lathe for your machining projects.

Key Takeaways: What is Spindle Bore on a Lathe?

- The spindle bore on a lathe refers to the hole that runs through the center of the lathe’s spindle.

- It is important because it allows the passage of materials, such as long workpieces or drill bits, through the spindle.

- The size of the spindle bore determines the maximum diameter of the materials that can be used on the lathe.

- Having a larger spindle bore allows for more versatility and the ability to work with larger materials.

- It’s essential to consider the spindle bore size when choosing a lathe for specific projects or applications.

Frequently Asked Questions

Below are some common questions about the spindle bore on a lathe, an important feature in machining:

What is a spindle bore on a lathe and why is it important?

A spindle bore on a lathe refers to the hollow opening running through the center of the lathe’s spindle. It allows the passage of a workpiece or a bar stock through the spindle, enabling machining operations such as drilling, turning, or boring. The size of the spindle bore determines the maximum diameter of the workpiece that can be accommodated by the lathe. Therefore, having a larger spindle bore is crucial for machining larger or longer workpieces.

For example, if you need to machine a part with a larger diameter, you would need a lathe with a spindle bore large enough to enable the workpiece to pass through it. The spindle bore is a fundamental consideration when selecting a lathe for specific machining needs.

What are the advantages of a lathe with a larger spindle bore?

Having a lathe with a larger spindle bore offers several advantages. Firstly, it provides the flexibility to machine larger workpieces without the need for additional equipment or modifications. This can save time and money in the long run, especially if you frequently work with larger diameter workpieces.

Secondly, a larger spindle bore allows for the machining of longer workpieces by enabling the passage of bar stocks through the spindle. This is particularly useful when working with materials such as metal or wood, where longer stock lengths may be required.

Can the spindle bore size be changed on a lathe?

The spindle bore size of a lathe is typically fixed and cannot be easily changed without significant modifications to the lathe’s structure. The size of the spindle bore is determined during the manufacturing process and remains constant throughout the lathe’s lifespan.

If you require a lathe with a different spindle bore size, you would need to consider purchasing a lathe model that meets your specific requirements.

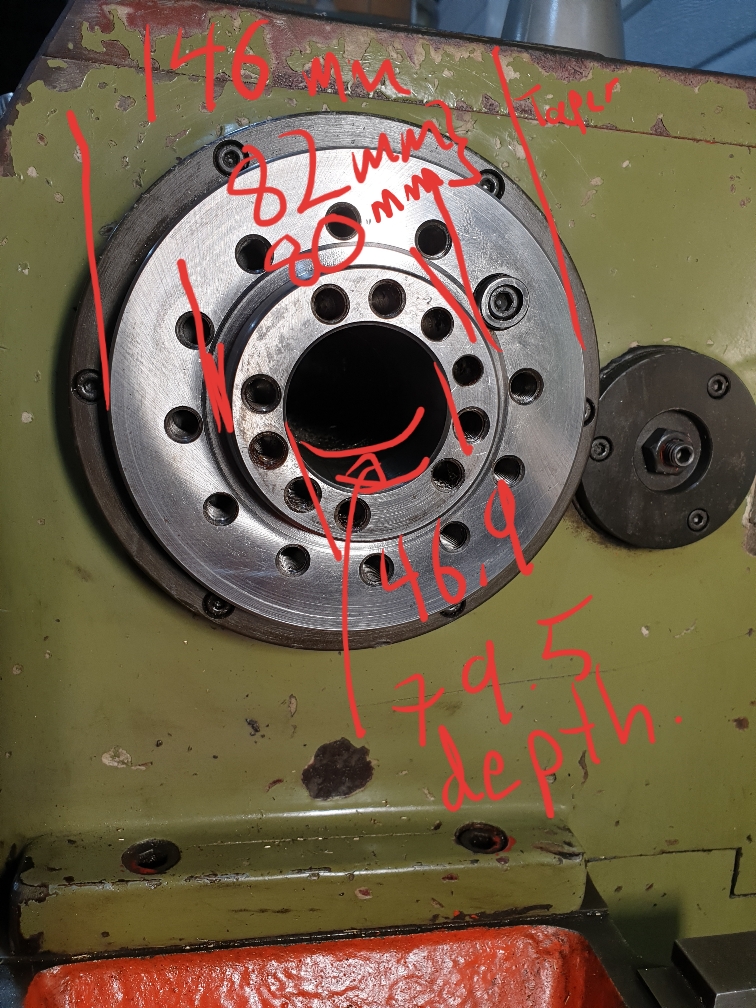

How is the spindle bore size measured on a lathe?

The spindle bore size on a lathe is often specified as the maximum diameter of the workpiece that can pass through the spindle without any obstructions. This measurement is typically taken at the narrowest point of the spindle bore, such as at the back of the chuck.

To obtain an accurate measurement, you can use tools such as calipers or bore gauges to measure the internal diameter of the spindle bore. It’s essential to have the correct measurements to ensure compatibility with the workpieces you plan to machine.

Are there any limitations to consider when using a smaller spindle bore size?

Using a lathe with a smaller spindle bore size may have limitations when it comes to machining larger workpieces. If the workpiece diameter exceeds the size of the spindle bore, it will not fit through the spindle, preventing you from performing certain operations on the workpiece.

Additionally, a smaller spindle bore may restrict the use of bar stocks, limiting the length of the workpiece that can pass through the spindle. It’s important to consider these limitations and choose a lathe with a suitable spindle bore size based on the sizes of the workpieces you plan to machine.

Spindle bore bar support for the lathe

Summary

To sum it up, the spindle bore on a lathe is the hole in the middle. It allows you to work on larger pieces by passing them through the bore. This is super handy because it saves you from having to turn down or remove the piece entirely. The size of the spindle bore varies between lathes, so make sure to check the specs before buying one. Remember, the bigger the bore, the larger the workpiece it can handle.

In addition, the spindle bore is measured in diameter, meaning the distance across the hole. It’s essential to consider the spindle bore size when selecting a lathe to ensure it meets your project needs. So, next time you hear about spindle bore, you’ll know it’s all about that hole in the middle!