Have you ever wondered what spindle travel on a drill press is all about? Well, you’ve come to the right place! In this article, we’ll dive into the fascinating world of drill press spindle travel and why it’s an important feature to consider. So, let’s get started and unlock the secrets of this essential component!

Now, you might be thinking, “What exactly is spindle travel?” Simply put, spindle travel refers to the distance the drill bit can move up and down, or in other words, the vertical travel of the drill press spindle. It plays a crucial role in determining the depth of the holes you can drill.

But why does spindle travel matter? Well, imagine you’re working on a project that requires drilling holes of varying depths. If your drill press has limited spindle travel, you might find yourself struggling to reach the desired depth. On the other hand, a drill press with ample spindle travel allows you to tackle a wider range of projects with ease and precision.

So, whether you’re a woodworking enthusiast, a metalworking maestro, or just starting your DIY journey, understanding spindle travel on a drill press is key. Stick around as we explore the ins and outs of this important feature and how it can elevate your drilling game to new heights! Get ready to take your projects to the next level with the knowledge of spindle travel on a drill press!

What is Spindle Travel on a Drill Press?

A drill press is a versatile tool used for drilling precise holes in various materials. One key feature of a drill press is spindle travel. But what exactly is spindle travel? In this article, we will explore the concept of spindle travel, its importance, and how it impacts your drilling experience. Whether you are a professional woodworker or a hobbyist, understanding spindle travel will help you make informed decisions when choosing and using a drill press.

Understanding Spindle Travel

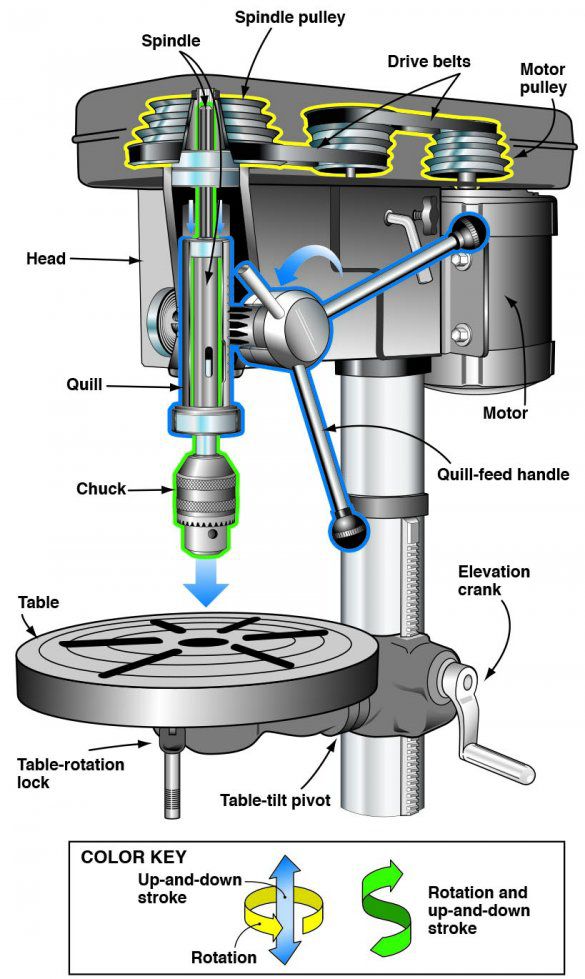

Spindle travel refers to the vertical distance the drill bit can travel while being driven by the drill press’s spindle. It is the measure of how deep you can drill a hole with a particular drill press. Typically, the spindle travel is specified in inches or millimeters, and it determines the maximum depth of the holes you can drill in a single pass.

The spindle travel is determined by the design and construction of the drill press. It is essential to know the spindle travel range of a drill press to ensure it meets your specific drilling needs. If you frequently work with materials that require deep holes, you will need a drill press with a greater spindle travel.

The Importance of Spindle Travel

The spindle travel of a drill press is crucial for several reasons. Firstly, it allows you to drill holes of varying depths without having to adjust or reposition the workpiece. This saves time and ensures precision in your drilling operations. Secondly, a greater spindle travel provides versatility, allowing you to tackle a wider range of drilling tasks. Whether you need to drill shallow holes for hardware installation or deep holes for dowels and tenons, having adequate spindle travel will enable you to complete the job efficiently.

Furthermore, the spindle travel directly affects the overall usability and functionality of the drill press. If the spindle travel is too limited, you may encounter difficulties when drilling deep holes or working with thicker materials. On the other hand, if the spindle travel is excessive and exceeds your requirements, you may end up with a larger and more expensive drill press than necessary.

Factors Influencing Spindle Travel

Several factors can influence the spindle travel of a drill press. The most significant factor is the design and engineering of the drill press itself. Different manufacturers may prioritize different aspects of the drill press, which can affect the spindle travel. Generally, larger drill presses designed for heavy-duty applications tend to have greater spindle travel.

Another factor that can impact spindle travel is the size of the drill press’s motor. A more powerful motor can drive the spindle with greater force, allowing for deeper drilling. However, it is important to note that a larger motor may also result in a bulkier and heavier drill press, which may not be desirable in certain situations.

Lastly, the physical dimensions and construction of the drill press can affect the spindle travel. Some drill presses may have a longer quill, which is the part of the drill press that holds and moves the drill bit. This longer quill allows for greater spindle travel and enables you to drill deeper holes.

Tips for Choosing the Right Spindle Travel

When selecting a drill press, it is important to consider your specific drilling needs and choose a spindle travel that aligns with those requirements. Here are a few tips to help you choose the right spindle travel:

- Assess the types of materials you regularly work with and the depths of holes you need to drill. This will give you an idea of the minimum spindle travel you should look for.

- Consider your future projects and whether they may require deeper holes. It is often beneficial to choose a drill press with slightly more spindle travel than your current needs to allow for future growth.

- Take into account the size and weight of the drill press. If you need a highly portable drill press, a smaller spindle travel may be more suitable.

- Read reviews and consider the recommendations of experienced drill press users to determine which models offer the best combination of spindle travel and overall performance.

Conclusion

Spindle travel plays a crucial role in the functionality and versatility of a drill press. Understanding what spindle travel is and its importance will help you make informed decisions when choosing a drill press that meets your specific drilling needs. Consider factors such as your typical drilling depths, the materials you work with, and the portability requirements before selecting the appropriate spindle travel. By doing so, you can ensure an optimal drilling experience and achieve accurate and precise results in your projects.

Key Takeaways: What Is Spindle Travel on a Drill Press?

- Spindle travel refers to the vertical distance the drill press spindle can move up and down.

- It is an important specification to consider when choosing a drill press as it determines the maximum depth of holes you can drill.

- Spindle travel is usually measured in inches or millimeters.

- A larger spindle travel allows you to drill deeper holes, providing more versatility for various projects.

- Make sure to choose a drill press with a spindle travel that meets your specific drilling needs.

Frequently Asked Questions

Welcome to our Frequently Asked Questions section where we answer common queries about spindle travel on a drill press. Read on to find out more!

1. How does spindle travel affect drilling depth?

Spindle travel refers to the vertical movement of the drill press’s spindle, which determines the depth of the hole you can drill. The greater the spindle travel, the deeper the holes you can create. When you lower the spindle by adjusting the depth stop, it determines how far the drill bit goes into the material being drilled. This feature is crucial for accurately controlling the depth of the holes you want to create.

By having a drill press with sufficient spindle travel, you can easily drill holes of various depths without the need for additional adjustments or multiple drilling attempts. So, if you plan on working with different materials that require holes of varying depths, consider a drill press with ample spindle travel for more versatility.

2. Do I need a drill press with a large spindle travel for all my projects?

The amount of spindle travel you need for your projects depends on the specific drilling tasks you’ll be undertaking. If you primarily work with thin materials or require drilling shallow holes, a drill press with a smaller spindle travel may suffice. However, if you frequently drill deep holes or work with thicker materials, investing in a drill press with a larger spindle travel is beneficial.

While a larger spindle travel offers more flexibility for drilling tasks, it’s important to consider the space you have available in your workshop. Larger drill presses with increased spindle travel often require more room, so ensure you have enough space before opting for a model with a greater range of vertical movement.

3. Can I adjust the spindle travel on a drill press?

The spindle travel on a drill press is typically fixed and cannot be adjusted. The range of spindle travel is determined by the design and specifications of the drill press. However, you can control the depth of the hole by adjusting the depth stop, which limits how far the spindle descends during drilling.

Some drill presses may offer the option to modify the depth stop setting, allowing you to restrict the spindle travel and drill shallower holes if needed. However, keep in mind that this will reduce the overall available spindle travel. It’s always good to check the user manual or specifications of your drill press to understand its specific capabilities in terms of spindle travel adjustment.

4. Are there any limitations to consider with spindle travel?

While spindle travel plays a crucial role in determining drilling depth, it’s important to note that other factors can also impact the effective depth you can achieve. These factors include the length of the drill bit itself, the thickness and hardness of the material being drilled, and the rigidity and stability of the drill press.

Additionally, the depth of the hole may also be influenced by the chuck capacity of the drill press. The chuck capacity refers to the maximum diameter of the drill bit that the drill press can accommodate. It’s essential to choose the appropriate drill bit size within the chuck capacity to achieve optimal results.

5. Can I increase the spindle travel of my existing drill press?

Unfortunately, it’s not possible to increase the spindle travel of a drill press without modifying its internal structure, which can be complex and potentially compromise the drill press’s performance. If you require a larger spindle travel, it’s advisable to invest in a drill press model that offers the desired range of spindle travel from the start.

Keep in mind that different drill presses are designed with specific spindle travels to cater to various drilling needs. Choosing the right drill press with the appropriate spindle travel for your projects is a more reliable option than attempting to modify an existing drill press.

Summary

The spindle travel on a drill press refers to how deep the drill bit can go into a material. It is an important factor to consider when choosing a drill press for your projects. The spindle travel determines the maximum depth of holes you can drill, so you need to make sure it meets your needs. It is usually measured in inches or millimeters.

When looking at drill press specifications, you will often see a number for the spindle travel. This tells you the maximum depth the drill bit can reach. If you need to drill deep holes, make sure to choose a drill press with a sufficient spindle travel. Additionally, keep in mind that the spindle travel can affect the overall height of the drill press, so consider the space available in your workshop. Understanding spindle travel will help you select the right drill press for your drilling needs.