Hey there! Have you ever wondered what “swing over bed” means in the context of a lathe? Well, let’s delve into it and find out!

In the world of lathes, “swing over bed” refers to the maximum diameter of the workpiece that can be accommodated by the machine. It’s like the amount of space a lathe has to play with!

Picture this: if you have a lathe with a swing over bed measurement of 12 inches, it means it can handle workpieces with a diameter of up to 12 inches. Pretty cool, right? So, the swing over bed tells you how big of a chunk of material you can turn on your lathe.

Now that you have a grasp on what swing over bed means, let’s dive deeper into how it affects your projects and what to consider when choosing a lathe.

What is Swing Over Bed in Lathe?

Lathe machines are essential tools in the field of machining and metalworking. One of the key measurements that determine the capability and capacity of a lathe machine is the swing over bed. The swing over bed refers to the maximum diameter of a workpiece that can be accommodated on the lathe’s bed. It is an important specification to consider when selecting a lathe as it determines the size of workpieces that can be turned. In this article, we will explore the concept of swing over bed in detail, its significance, and how it affects the functionality of a lathe machine.

The Importance of Swing Over Bed in Lathe Selection

When choosing a lathe machine, understanding the swing over bed is crucial as it directly influences the size of workpieces that can be worked on. The swing over bed measurement determines the maximum diameter of the workpiece that can be rotated on the lathe without any obstruction or damage. It is essential to select a lathe with a swing over bed capacity that suits the desired applications.

1. Determining the Size of Workpieces

The swing over bed measurement provides a clear indication of the maximum diameter of the workpiece that can be accommodated. This measurement is usually taken from the bed’s center to the furthest point across the lathe’s bed. By knowing the swing over bed, machinists can determine the maximum size of workpieces they can turn on a lathe machine. It is essential to consider the swing over bed when working on large-scale projects that require a specific turning diameter.

2. Compatibility with Workpiece Mounting

Swing over bed not only affects the diameter of the workpiece but also determines the space available for mounting the workpiece. Larger swing over bed measurements provide more space to secure and position the workpiece securely on the lathe. This ensures stability during the turning process, preventing any vibrations or inaccuracies. When selecting a lathe, it is important to consider the desired workpiece mounting method and ensure that the swing over bed is sufficient to accommodate the chosen technique.

3. Flexibility and Versatility

A larger swing over bed measurement offers increased flexibility and versatility in turning various sizes of workpieces. It allows machinists to handle a wide range of projects, from small intricate parts to large-scale components, without needing to invest in multiple machines. By choosing a lathe with an appropriate swing over bed capacity, machinists can maximize their productivity and expand their machining capabilities.

Swing Over Bed and Lathe Design

1. Bed Length and Stability

The swing over bed measurement is closely related to the lathe’s bed length. A longer bed allows for a larger swing over bed, accommodating more massive workpieces. It is important to note that as the swing over bed increases, the bed’s stability becomes crucial to handle the increased weight and cetering forces. The bed needs to be rigid and robust to ensure accuracy and precision during the turning process.

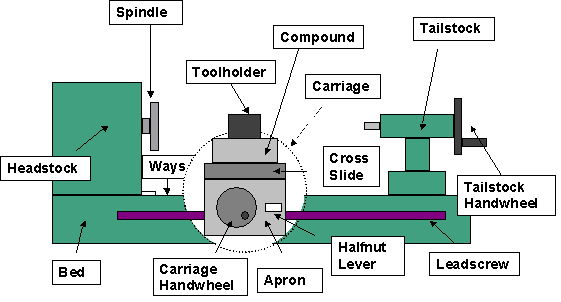

2. Headstock and Spindle Capacity

The swing over bed also affects the design and capacity of the lathe’s headstock and spindle assembly. The headstock houses the main spindle, which rotates the workpiece. A larger swing over bed requires a more powerful headstock and a larger diameter spindle to ensure optimal performance and stability. The headstock design and construction should align with the swing over bed capacity to prevent any limitations in turning larger workpieces.

3. Tool Rest Positioning and Tool Clearance

The swing over bed measurement also influences the positioning of the tool rest and the clearance for cutting tools. As the swing over bed increases, there is more distance between the bed and the rotating workpiece. This allows for better clearance, facilitating the use of various turning tools and tool rest configurations. It is essential to ensure that the chosen lathe provides ample clearance for the desired turning operations and tooling setup.

Conclusion

The swing over bed is a critical specification in lathe machines that determines the size of workpieces that can be accommodated. It plays a vital role in machine selection, workpiece compatibility, and overall versatility. Understanding the swing over bed measurement and its impact on lathe design and functionality is essential for machinists and metalworkers. By considering the swing over bed, one can select the right lathe machine that meets the specific needs and requirements of their projects, ultimately leading to efficient and precise turning operations.

Key Takeaways for “What is Swing over Bed in Lathe?”

- The swing over bed in a lathe refers to the largest diameter of a workpiece that can be accommodated by the machine.

- It determines the size and capacity of the lathe, allowing for larger or smaller workpieces to be turned.

- A larger swing over bed provides more versatility and allows for bigger projects to be undertaken.

- It is important to consider the swing over bed when selecting a lathe, as it should match the size of the workpieces you will be working on.

- Understanding the swing over bed is crucial for determining the limitations and capabilities of a lathe.

Frequently Asked Questions

When it comes to lathes, understanding the concept of “swing over bed” is essential. Below are some commonly asked questions to help you grasp the concept better:

1. How is swing over bed measured in a lathe?

The swing over bed in a lathe is the maximum diameter of a workpiece that can be rotated on the lathe without any restrictions. To measure it, you need to find the distance from the lathe bed’s surface to the centerline of the lathe’s spindle.

This distance represents the radius of the largest workpiece that can fit between the lathe’s bed and the spindle. Once you have this measurement, double it to find the swing over bed value.

2. Why is the swing over bed important in a lathe?

The swing over bed measurement is crucial because it determines the maximum size of the workpiece you can work on using the lathe. If you have a larger swing over bed value, you’ll be able to work with larger and longer components.

On the other hand, if the swing over bed is smaller, you’ll be limited to working with smaller workpieces. It’s important to consider the swing over bed measurement when selecting a lathe, as it directly impacts the size of projects you can undertake.

3. Does the swing over bed measurement affect the precision of the lathe?

No, the swing over bed measurement doesn’t directly affect the precision of the lathe. It refers solely to the maximum workpiece size that can be accommodated. The precision of a lathe depends on factors such as the quality of construction, the accuracy of the spindle, and the skill of the operator.

However, it’s worth noting that larger swing over bed measurements in lathes often indicate robust and heavy-duty machines, which can contribute to overall stability and accuracy during machining operations.

4. Can the swing over bed be increased on a lathe?

No, the swing over bed measurement of a lathe cannot be increased once the lathe is manufactured and assembled. It is a fixed specification that is defined by the design and construction of the lathe.

If you require a larger swing over bed capacity, you would need to purchase a new lathe with a larger swing over bed measurement that meets your specific requirements.

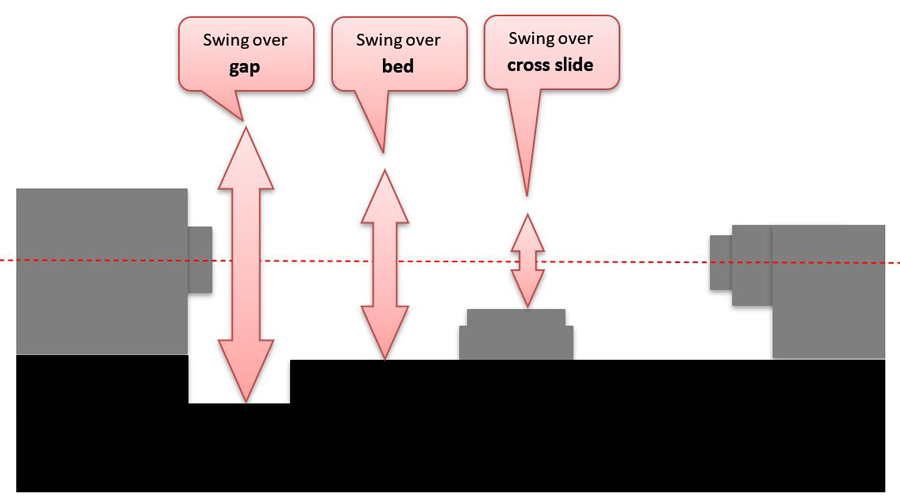

5. How does swing over bed differ from swing over cross slide?

While swing over bed refers to the maximum diameter of a workpiece that can be accommodated without restrictions, swing over cross slide refers to the maximum diameter of a workpiece that can be turned when the cutting tool is positioned on the cross slide.

In other words, swing over cross slide takes into account the limitations imposed by the presence of the tool post and the cross slide, which reduces the available diameter for turning. Typically, the swing over bed measurement is greater than the swing over cross slide measurement.

Summary

When it comes to lathes, swing over bed is how big of a piece it can hold. It’s like a circle. The swing over bed tells you the biggest circle that will fit in the lathe. So, if you have a lathe with a 10 inch swing over bed, you can put a piece up to 10 inches in diameter on it. But remember, the swing over bed is only one measurement. There are other things to consider when choosing a lathe, like the distance between centers and the horsepower of the motor.