Are you wondering what is the best circular saw blade for plywood? Well, you’ve come to the right place! Finding the right saw blade can make all the difference in your woodworking projects, especially when it comes to cutting plywood. So let’s dive in and explore the top options out there!

When it comes to working with plywood, having the right circular saw blade is key. It can help you achieve smoother and cleaner cuts, reducing splintering and tear-out. But with so many options available, it can be overwhelming to choose the best one. Don’t worry, I’ve got your back! In this guide, we’ll discuss the top circular saw blades specifically designed for cutting plywood.

Whether you’re a beginner woodworker or a seasoned pro, finding the perfect saw blade for your plywood projects is crucial. So, let’s uncover the best blades on the market that will make your plywood-cutting tasks a breeze. Get ready to take your woodworking skills to the next level!

The Best Circular Saw Blade for Plywood: A Comprehensive Guide

When it comes to cutting plywood with a circular saw, using the right blade is crucial for achieving clean and precise cuts. With so many options available, it can be challenging to determine which circular saw blade is best suited for plywood. In this comprehensive guide, we will explore the key factors to consider and recommend some of the top circular saw blades that excel in cutting plywood. Whether you are a professional carpenter or a DIY enthusiast, this article will help you make an informed decision and ensure outstanding results.

Understanding Circular Saw Blades for Plywood: A Quick Overview

Before we dive into the specifics of the best circular saw blades for plywood, it is essential to understand the different types and features of these blades. Circular saw blades consist of several components, including the teeth, body, and arbor hole. The number of teeth, tooth configuration, and tooth material have a significant impact on the performance of the blade. Additionally, the blade’s diameter and thickness should match the size and thickness of the plywood you are cutting.

The Importance of Tooth Count and Configuration

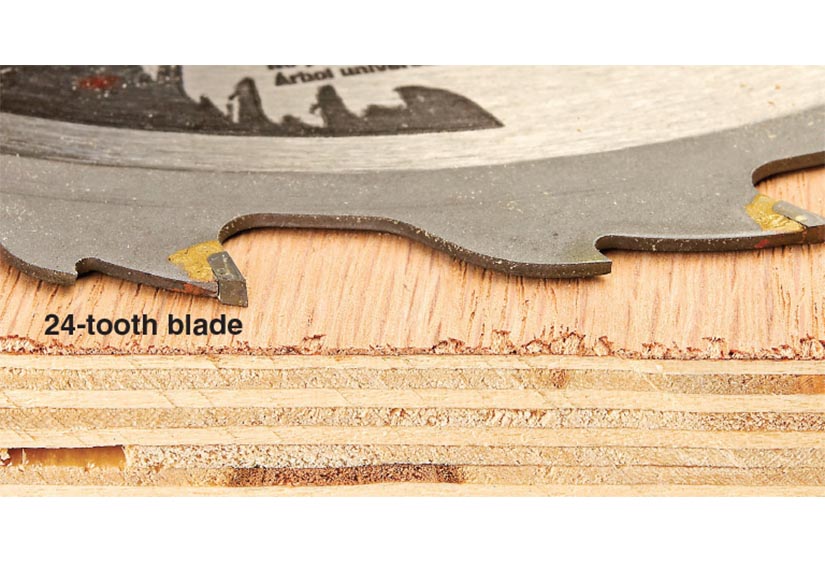

When it comes to cutting plywood, the tooth count and configuration of the circular saw blade play a crucial role. Blades with a higher tooth count tend to leave a smoother finish on the cut edges of the plywood. However, they may also cut slower. On the other hand, blades with a lower tooth count are more suitable for faster cutting but may result in slightly rougher edges. The tooth configuration, such as alternate top bevel (ATB) or triple-chip grind (TCG), is also important to consider. ATB blades are ideal for cross-cutting plywood, while TCG blades are better suited for rip cuts.

When selecting a circular saw blade for plywood, it is important to strike a balance between the tooth count and configuration based on the desired finish and cutting speed. This will help you achieve the best results and minimize any potential tear-out or chipping.

Top Circular Saw Blades for Plywood: Recommendations

There are numerous circular saw blades available in the market, each with its own unique features and specifications. To help you navigate through the options, we have curated a list of some of the best circular saw blades specifically designed for cutting plywood:

- Bosch DCB1060 Daredevil 10-Inch 60-Tooth Fine Finish Circular Saw Blade

- Freud D12100X 100 Tooth Diablo Ultra Fine Circular Saw Blade

- DEWALT DW3196 7-1/4-Inch 60T Precision Finishing Circular Saw Blade

- IRWIN Tools MARATHON Carbide Cordless Circular Saw Blade

- Diablo D0724A 7-1/4″ 24T Diablo Circular Saw Framing Blade

These circular saw blades are renowned for their exceptional performance in cutting plywood, offering smooth cuts, durability, and excellent value for money. However, it is important to choose a blade that aligns with your specific cutting needs and the type of plywood you are working with.

Tips for Choosing and Using Circular Saw Blades for Plywood

Here are some additional tips to help you choose and use the best circular saw blade for plywood:

- Select a blade with the appropriate diameter and thickness for your circular saw to ensure compatibility and achieve optimal cutting performance.

- Consider the type of plywood you are working with and choose a blade that is specifically designed for cutting that material. Different blades are optimized for cutting hardwood plywood, softwood plywood, or both.

- Always follow the manufacturer’s instructions and guidelines for blade installation, usage, and maintenance.

- Use a straight edge or guide to ensure straight and accurate cuts.

- Wear appropriate safety gear, including safety glasses and hearing protection, when operating a circular saw.

Conclusion

Choosing the best circular saw blade for plywood is essential for achieving clean, precise cuts and a professional finish. By considering factors such as tooth count, configuration, and blade diameter, you can select a blade that meets your specific cutting needs. The recommended circular saw blades mentioned in this guide offer outstanding performance and are highly regarded in the industry. Remember to follow the tips provided for selecting and using circular saw blades effectively and safely. Now armed with this information, you can confidently tackle any plywood cutting project with ease.

Additional Considerations for Circular Saw Blades

While the focus of this guide has been on selecting the best circular saw blade for cutting plywood, it is worth mentioning that circular saw blades can be used for various other materials and applications. Here are a few additional considerations to keep in mind:

Choosing the Right Blade for Different Materials

Circular saw blades are available in different configurations and tooth designs to accommodate various materials. For example, there are blades specifically designed for cutting hardwood, softwood, laminate flooring, metal, and even masonry. Ensure you select the appropriate blade for the material you are working with to achieve the best results and prolong the life of your blade.

The Importance of Blade Maintenance

To keep your circular saw blades performing at their best, regular maintenance is key. Cleaning the blade after each use and removing any resin or pitch buildup will prevent it from becoming clogged, reducing its cutting efficiency. Additionally, periodic sharpening or replacing of the blade’s teeth will ensure optimal cutting performance and prolong its lifespan.

Invest in Quality Blades

While it can be tempting to opt for cheaper circular saw blades, investing in quality blades is essential for achieving superior results. High-quality blades are made from premium materials and undergo rigorous manufacturing processes, resulting in improved performance, durability, and longevity. Spending a little more on a quality blade will save you time and money in the long run.

Summary

Choosing the right circular saw blade for your specific cutting needs is crucial for achieving accurate, clean, and efficient cuts. Consider factors such as tooth count, tooth configuration, and blade diameter when selecting a blade. Investing in high-quality blades and practicing proper blade maintenance will ensure optimal performance and prolong the life of your blades. By following these considerations and our recommendations, you can confidently tackle any cutting task with your circular saw.

Key Takeaways: What is the Best Circular Saw Blade for Plywood?

- Choosing the right circular saw blade for plywood is important for clean and accurate cuts.

- A high tooth count blade with a thin kerf is ideal for cutting plywood.

- Look for a blade specifically designed for plywood to prevent splintering.

- Carbide-tipped blades are durable and long-lasting, providing smooth cuts in plywood.

- Consider the blade diameter and arbor size to ensure compatibility with your circular saw.

Frequently Asked Questions

Are you looking for the best circular saw blade for plywood? Here are some common questions and answers to help you choose the right blade for your woodworking needs.

1. What factors should I consider when choosing a circular saw blade for cutting plywood?

When selecting a circular saw blade for plywood, consider the number of teeth, the tooth shape, and the blade diameter. Blades with a higher tooth count (typically 60 to 80) provide smoother cuts, while blades with a lower tooth count (around 24 to 40) cut faster but may leave rougher edges. For plywood, a blade with a high tooth count is recommended to achieve clean cuts.

Opt for blades with carbide or titanium carbide-tipped teeth, as they offer better durability and can withstand the abrasive nature of plywood. Additionally, choose a blade with a thin kerf (the width of the cut) to minimize material waste and reduce the strain on your saw. Overall, a combination of high tooth count, carbide-tipped teeth, and a thin kerf will give you the best results when cutting plywood.

2. Can I use a general-purpose blade for plywood cutting?

While you can use a general-purpose blade for cutting plywood, it might not give you the best results. General-purpose blades are designed to handle a variety of materials, but they may not provide the smoothest cuts in plywood. These blades typically have a lower tooth count and are better suited for rip cuts on lumber. If you regularly work with plywood, it’s worth investing in a specialized plywood blade for cleaner and more precise cuts.

A specialized plywood blade will have a higher tooth count and special tooth geometry designed to minimize chip-out and tear-out in plywood. It will also have a thinner kerf to reduce material waste. By using a dedicated plywood blade, you’ll achieve better results with less splintering and smoother edges.

3. Do I need a different blade for crosscuts and rip cuts in plywood?

While you can use the same blade for both crosscuts and rip cuts in plywood, there are blades specifically designed for each type of cut. Crosscut blades typically have a higher tooth count and a finer tooth geometry, which helps in producing smooth, splinter-free cuts across the grain of the plywood. These blades are ideal for cutting plywood sheets into smaller, more manageable pieces.

Rip cut blades, on the other hand, have a lower tooth count and a more aggressive tooth geometry. They are designed to quickly and efficiently cut along the length of the plywood, with the grain. These blades are suitable for cutting plywood into narrower strips or planks. While you can use a general-purpose blade for both types of cuts, using specialized crosscut and rip cut blades will give you cleaner and more efficient results.

4. How often should I sharpen or replace my circular saw blade for cutting plywood?

The frequency of sharpening or replacing your circular saw blade for plywood depends on several factors, including how often you use it and the type of plywood you are cutting. As a general rule of thumb, it’s recommended to sharpen the blade after approximately 10 hours of use. However, this can vary based on the hardness of the plywood and the amount of cutting you do.

If you notice that the blade is becoming dull, producing rough cuts, or causing excessive heat, it’s a good indication that it’s time for sharpening or replacement. Regular maintenance and cleaning of the blade, such as removing pitch and resin build-up, can help prolong its lifespan. Remember that a sharp blade not only improves the quality of your cuts but also reduces the risk of kickback and strain on your saw.

5. Are there any safety precautions I should take when using a circular saw blade for plywood?

Yes, there are some safety precautions you should follow when using a circular saw blade for plywood. Always wear appropriate safety gear, including safety glasses or goggles and hearing protection. Make sure the saw is properly maintained and the blade is securely attached. Before cutting, ensure that the plywood is properly supported and clamped to prevent it from moving during the cutting process.

When making the cut, maintain a steady grip on the saw and guide it along the cut line. Avoid forcing the blade through the plywood, as this can lead to kickback. Take your time and let the blade do the work. After completing the cut, wait for the blade to come to a complete stop before removing the plywood or making any adjustments. By following these safety precautions, you can minimize the risk of accidents and ensure a safe cutting experience.

Summary

Looking for the best circular saw blade for plywood? Consider these key points:

1. Choose a blade with a high tooth count, like 80 or 100, for cleaner cuts.

2. Look for a blade with carbide tips for durability and long-lasting performance.

3. Blades with thin kerfs are ideal for reducing waste and making smoother cuts.

4. Consider getting a blade with anti-kickback features for added safety.

5. Remember to match the diameter of the blade to your circular saw for proper fit.

Remember, when it comes to plywood, the right blade can make a big difference in your cutting results.