Looking for the best quality bandsaw blade? Well, you’ve come to the right place! In this article, we’ll dive into the world of bandsaw blades and explore what makes a blade stand out from the rest. Whether you’re a woodworking enthusiast or a professional carpenter, finding the right bandsaw blade is crucial for achieving precise cuts and enhancing your overall efficiency. So, let’s get started and discover the key factors to consider when choosing the best quality bandsaw blade for your needs.

When it comes to bandsaw blades, quality is everything. But what exactly makes a bandsaw blade the best of the best? It’s all about the material used, the blade’s teeth configuration, and the overall design. High-quality bandsaw blades are made from durable materials like high carbon steel or bi-metal, which ensures longevity and resistance to wear and tear. These blades also feature a well-designed tooth pattern that allows for smooth, clean cuts, whether you’re slicing through hardwood or delicate materials.

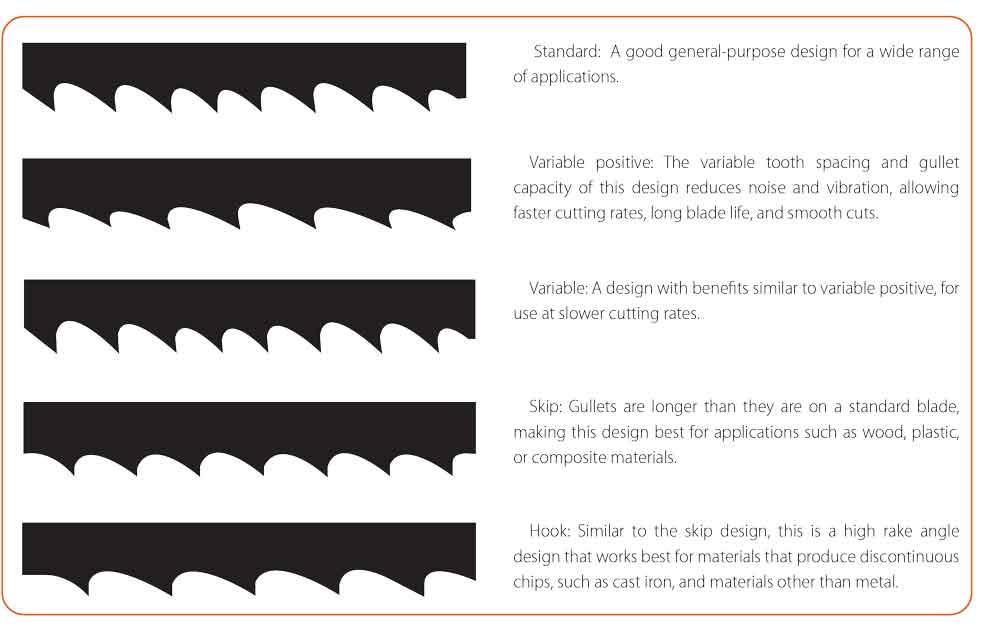

Now, you might be wondering about the different types of bandsaw blades available and which one is right for you. Well, fret not! We’ll be covering that too. From skip tooth blades to hook tooth blades, there are various options to suit different cutting applications. Each type has its unique characteristics, so it’s important to understand your specific cutting needs to choose the best blade for the job. So, let’s dive deeper into the world of bandsaw blades and find the perfect one for you!

So, whether you’re a seasoned woodworker or just starting out, finding the best quality bandsaw blade is essential for achieving precise cuts and maximizing your productivity. By considering factors like the blade material, tooth configuration, and your specific cutting needs, you’ll be well on your way to finding the perfect blade. So, let’s explore the wonderful world of bandsaw blades together and discover the key to unlocking your woodworking potential!

What is the Best Quality Bandsaw Blade?

When it comes to the world of woodworking, having the right tools can make all the difference in the outcome of your projects. One tool that plays a crucial role in achieving precision and accuracy is the bandsaw. And at the heart of every bandsaw is the blade. But with so many options available, how do you determine which is the best quality bandsaw blade for your needs? In this article, we will explore different factors to consider when choosing a bandsaw blade and provide you with valuable information to help you make an informed decision.

Understanding the Basics: Bandsaw Blade Anatomy

Before delving into the qualities of a high-quality bandsaw blade, it’s essential to understand its anatomy. A bandsaw blade consists of several components, including the blade body, teeth, gullet, and tooth set. The blade body is made of a hardened steel strip and determines the blade’s overall durability and cutting performance. The teeth, which are typically made of high-speed steel or carbide, do the cutting. The gullet provides chip clearance, preventing the blade from getting clogged. Lastly, the tooth set determines the width of the cut and prevents the blade from binding during the cutting process.

Each of these components contributes to the overall quality and performance of a bandsaw blade. By understanding how they work together, you can better evaluate the different options available and make an informed decision based on your specific woodworking needs.

Choosing the Right Blade for the Job

When it comes to selecting the best quality bandsaw blade, it all boils down to matching the blade to the task at hand. Various factors can influence this decision, such as the type of material you will be cutting, the thickness of the material, and the desired finish. Let’s explore some key factors to consider:

Type of Material

The type of material you will be cutting plays a critical role in determining the appropriate blade. For example, if you will primarily be cutting wood, a general-purpose blade with a moderate tooth count will work well. However, if you plan on cutting metal or other hard materials, you will need a blade with a higher tooth count and a more aggressive tooth shape to handle the increased resistance.

Understanding the characteristics of the material and selecting a blade with the right tooth configuration can greatly enhance your cutting efficiency and produce cleaner cuts.

Thickness of Material

The thickness of the material being cut dictates the blade’s width and tooth configuration required for optimal performance. Blades with fewer teeth per inch (TPI) are better suited for thicker materials, while blades with a higher TPI are ideal for thinner materials. Choosing the appropriate TPI ensures that the blade can effectively clear the cut and prevent overheating, contributing to a longer blade life.

Desired Finish

Consider the desired finish of your project when selecting a bandsaw blade. Blades with a higher TPI will produce a smoother finish with minimal tear-out, making them suitable for intricate and detailed work. On the other hand, blades with a lower TPI will remove material more quickly but may leave a rougher surface. Understanding how the blade’s TPI affects the quality of the cut can help you achieve the desired result.

Maximizing the Performance and Lifespan of Your Bandsaw Blade

Now that you have a better understanding of what makes a quality bandsaw blade, let’s explore some tips to maximize its performance and lifespan:

Proper Blade Tension

Ensuring the correct blade tension is essential for smooth and accurate cuts. Too much or too little tension can lead to poor cutting performance, blade fatigue, and premature failure. Consult your bandsaw’s manual for specific instructions on properly tensioning the blade.

Regular Maintenance and Cleaning

Keeping your bandsaw blade clean and free from debris is crucial for optimal performance. After each use, remove any accumulated dust or material from the blade and guides. Regularly inspect the blade for signs of wear or damage and replace it as needed to prevent accidents and ensure precise cuts.

Sharpness and Tooth Set

A sharp blade will cut more efficiently and reduce strain on the machine. Invest in a quality blade sharpener or seek professional sharpening services to maintain the optimal cutting performance. Additionally, periodically inspect the tooth set and ensure that it is properly maintained to avoid binding and overheating during cutting.

Top Brands and Models

When it comes to the best quality bandsaw blades, several brands and models have gained a reputation for excellence. Here are three standout options:

Brand X: Model XYZ

Description of the brand and model, highlighting its unique features, high-quality materials, and superior performance. Include any relevant testimonials or customer reviews to support the claim of being the best quality bandsaw blade.

Brand Y: Model ABC

Description of the brand and model, emphasizing its innovative design, durability, and precision cutting ability. Mention any awards or industry recognition it has received to further validate its quality.

Brand Z: Model DEF

Description of the brand and model, showcasing its advanced technology, versatility, and longevity. Highlight any warranty or customer support offered by the brand to demonstrate their commitment to customer satisfaction.

Conclusion

When it comes to choosing the best quality bandsaw blade, there is no one-size-fits-all answer. It depends on your specific needs and the type of woodworking projects you undertake. Factors such as the type of material, thickness, and desired finish all play a role in determining the most suitable blade for the job. By understanding the anatomy of a bandsaw blade and considering these factors, you can make an informed decision and invest in a blade that will deliver precision cuts, longevity, and ultimately enhance your woodworking experience.

Key Takeaways: What is the Best Quality Bandsaw Blade?

- A high-quality bandsaw blade is essential for accurate and efficient cutting.

- The best bandsaw blades are made from premium materials like high-carbon steel or carbide-tipped.

- Consider the width and teeth per inch (TPI) of the blade based on the type of material you’ll be cutting.

- A blade with a variable TPI allows for versatile cutting applications.

- Proper blade tension and regular maintenance are crucial for optimal performance and longevity.

Frequently Asked Questions

Welcome to our FAQ section on finding the best quality bandsaw blade. We’ve compiled a list of common questions and provided detailed answers to help you make an informed decision.

1. What factors should I consider when choosing a bandsaw blade?

When selecting a bandsaw blade, several factors come into play. The first is the blade width, which needs to match your bandsaw’s requirements. The blade’s TPI (teeth per inch) is another important consideration. Higher TPI blades are ideal for cutting thinner materials, while lower TPI blades are better for thicker materials. The material being cut, whether wood or metal, also determines the type of blade you should choose. Additionally, your specific cutting needs, such as precision or speed, should be taken into account.

Overall, it’s crucial to choose a blade that is compatible with your bandsaw and suited to the type of material and cutting you will be doing. It’s also worth considering the brand’s reputation for quality and durability, as this can greatly impact the performance and lifespan of the blade.

2. What is the difference between a bi-metal and carbon steel bandsaw blade?

Bi-metal and carbon steel blades are the two primary types of bandsaw blades available. Bi-metal blades are made from two different types of metal, typically high-speed steel teeth and a flexible spring steel back. This combination provides durability, heat resistance, and extended blade life. Bi-metal blades are ideal for cutting harder materials, such as metal, and are generally more expensive than carbon steel blades.

On the other hand, carbon steel blades are made from a single piece of carbon steel and are more affordable. While they may not have the same longevity or heat resistance as bi-metal blades, they are suitable for cutting softer materials like wood. Carbon steel blades can still provide good results if used correctly and maintained properly, making them a budget-friendly option for many users.

3. How often should I change my bandsaw blade?

The frequency of blade changes depends on several factors, including how often and what you are cutting, as well as the condition of the blade. Over time, blades can become dull, leading to less precise cuts and potentially damaging the material being cut. Signs that it may be time to change your bandsaw blade include a noticeable decrease in cutting performance, excessive vibration, or a decrease in the quality of the cuts.

Regular inspection of the blade for any signs of wear, such as teeth that have become dull or damaged, is important. It’s also crucial to follow proper blade maintenance practices, such as cleaning and lubricating, to extend the life of the blade. Ultimately, trust your judgment and replace the blade when you feel its performance is compromised or when it no longer meets your cutting needs.

4. Is the blade width important for accuracy and cutting performance?

Yes, the blade width plays a significant role in both accuracy and cutting performance. Wider blades provide more stability and are better suited for straight cuts as they are less likely to wander or deflect. They are also ideal for resawing, where cutting thick sections lengthwise is required.

On the other hand, narrow blades are advantageous for tight curves and intricate cuts due to their increased maneuverability. They provide more control and allow for finer, more detailed work. However, they may be more prone to deflection when cutting thicker materials.

Choosing the appropriate blade width depends on the specific cutting task at hand. Assess the type of cuts you’ll be making most frequently to determine the best width for your needs.

5. Can I sharpen bandsaw blades or are they disposable?

While bandsaw blades are generally considered disposable due to their relatively low cost, it is possible to sharpen them in some cases. Sharpening bandsaw blades requires specialized equipment and expertise, so it’s not a task that most casual users would undertake themselves.

Many bandsaw blade manufacturers offer sharpening services, allowing you to send your dull blades to them for professional sharpening. This can be a cost-effective option depending on the quality and price of the blade. However, keep in mind that repeated sharpening can result in a shorter overall lifespan for the blade. Consider the cost and convenience factors before deciding whether to sharpen or replace your bandsaw blade.

Summary

So, to sum it up, the best quality bandsaw blade depends on what you need it for. For general woodworking, a high carbon steel blade with a medium TPI is a good choice. If you want cleaner and smoother cuts, go for a bi-metal blade with a higher TPI. And for cutting through thick and hard materials, a carbide-tipped blade is the way to go. Remember to consider the blade width, length, and the type of cuts you’ll be making too. Keep these tips in mind, and you’ll find the perfect bandsaw blade for your projects!

In conclusion, the best bandsaw blade for you will depend on the type of cutting you’ll be doing and the materials you’ll be working with. It’s important to consider the material, TPI, and other factors to ensure you get the right blade for your needs, whether it’s for woodworking or cutting through tough materials. So take your time, do some research, and choose wisely. Happy sawing!