When it comes to woodworking, one question that often arises is, “What is the best size for a woodworking shop?” It’s a great question because having the right size of a woodworking shop can make a significant difference in your projects. So, let’s dive in and explore the answer to this important question.

Finding the perfect size for a woodworking shop depends on various factors like the available space, your budget, and the type of woodworking projects you plan to undertake. By striking the right balance, you can create a functional and efficient workspace that suits your needs and allows for creativity to flourish.

In this article, we’ll walk you through the considerations for determining the ideal size for your woodworking shop. From space requirements to layout design, we’ll provide you with insights and tips to help you make informed decisions. So, let’s embark on this journey together and discover the best size for your woodworking haven.

If you’re wondering about the ideal size for a woodworking shop, there are a few factors to consider. Firstly, the available space and budget will play a crucial role. However, a general rule of thumb is to aim for a minimum of 200 square feet for small projects and around 500 square feet for larger projects. This will provide enough room for workbenches, tools, and storage. Ultimately, the best size for a woodworking shop will depend on your specific needs and preferences.

The Best Size for a Woodworking Shop: A Guide to Optimal Space

Woodworking is a popular hobby and profession that requires a dedicated space to work on projects. Whether you’re a beginner or an experienced woodworker, having the right size for your woodworking shop is essential for efficiency, organization, and safety. In this article, we will explore the factors to consider when determining the best size for a woodworking shop, the benefits of different shop sizes, and practical tips for optimizing your workspace.

Factors to Consider When Determining the Best Size for a Woodworking Shop

Before diving into the specific dimensions, it’s important to consider a few key factors that will influence the size of your woodworking shop. These factors include the available space, budget, the type of projects you typically work on, and your personal preferences. Let’s explore each of these factors in detail:

1. Available Space

The amount of space you have available will be the primary factor in determining the size of your woodworking shop. Take stock of the area where you plan to set up your shop and measure the dimensions. Consider any constraints such as low ceilings, obstructions, or the need to share the space with other activities. It’s important to have enough room to move around freely and accommodate your tools and work surface.

Keep in mind that woodworking involves handling large pieces of lumber and maneuvering heavy equipment, so having ample space for these activities is crucial for safety and convenience. You’ll need enough clearance to operate your tools comfortably without restrictions. Additionally, consider the storage space needed for materials, supplies, and finished projects.

2. Budget

Your budget will also play a role in determining the size of your woodworking shop. A larger space will generally require more investment for construction, insulation, lighting, and heating or cooling systems. It’s important to strike a balance between your budget and the space you need. Consider whether you can afford the initial setup costs and any ongoing expenses, such as utility bills and maintenance.

Remember, however, that your woodworking shop is an investment that will ultimately contribute to the quality and efficiency of your work. While it’s important to be mindful of your budget, compromising too much on space may limit your ability to work on larger projects or grow your woodworking business in the future.

3. Type of Projects

The type of woodworking projects you typically work on will also influence the size of your shop. If you primarily work on small, precise pieces like crafting jewelry boxes or intricate carvings, you may not require a large workshop. On the other hand, if you frequently build furniture or cabinets, you’ll need more space to accommodate larger pieces of lumber and maneuver them effectively.

Consider the workflow of your projects and how much space is needed for different stages, such as cutting, sanding, and assembly. If you frequently work on multiple projects simultaneously, having enough space to set up separate workstations can significantly improve your productivity.

The Benefits of Different Woodworking Shop Sizes

Now that we’ve discussed the factors to consider when determining the size of your woodworking shop, let’s explore the benefits of different shop sizes:

1. Small Woodworking Shop

A small woodworking shop can be an excellent choice for hobbyists or those with limited space and budget. Despite having less room to work with, a small shop can still be highly functional and productive. Some benefits of a small woodworking shop include:

- Cost-effective: Setting up a small shop requires fewer materials and may involve lower utility bills.

- Easier to maintain: Cleaning and organizing a smaller space is generally quicker and more manageable.

- Cozier atmosphere: A smaller shop can create a more intimate and focused working environment.

- Less time wasted: With a smaller shop, tools and materials are within closer reach, reducing the time spent moving between workstations.

However, it’s important to note that a small woodworking shop may limit the size of projects you can work on and may require more thoughtful organization to maximize efficiency.

2. Medium Woodworking Shop

A medium-sized woodworking shop strikes a balance between space and functionality, offering more versatility and room for expansion. Here are some benefits of a medium woodworking shop:

- Greater flexibility: In a medium-sized shop, you’ll have more freedom to work on a variety of projects, both small and large.

- Improved workflow: With more space, you can separate your workstations, ensuring a smoother flow from one task to another.

- Accommodates growth: A medium-sized shop allows for future growth, whether you plan to take on larger projects or expand your woodworking business.

- Enhanced storage options: Having more space means you can dedicate areas for organized storage of tools, materials, and finished projects.

A medium-sized shop is an ideal choice for dedicated hobbyists and emerging professionals who want more room to work comfortably and accommodate a broader range of projects.

3. Large Woodworking Shop

A large woodworking shop offers the most expansive workspace, providing maximum flexibility and potential for professional woodworkers. Here are the benefits of a larger shop:

- Room for large-scale projects: With ample space, you can comfortably handle and assemble significant pieces of furniture, cabinetry, or even boat building.

- Multiple workstations: A large shop allows for the setup of multiple workstations, making it easier to work on different projects simultaneously or collaborate with others.

- Enhanced equipment organization: You’ll have plenty of room to store and display your tools, ensuring easy access and efficient workflow.

- Potential for expanding your business: If you plan to turn your woodworking hobby into a full-time profession, a large shop can accommodate the space needed for increased production and additional employees.

However, it’s important to note that a large woodworking shop requires a significant investment and ongoing maintenance. It may be more suitable for seasoned professionals or those with established woodworking businesses.

Practical Tips for Optimizing Your Woodworking Shop

Regardless of the size of your woodworking shop, optimizing the layout and organization can greatly improve your efficiency and enjoyment. Here are some practical tips:

1. Plan your layout:

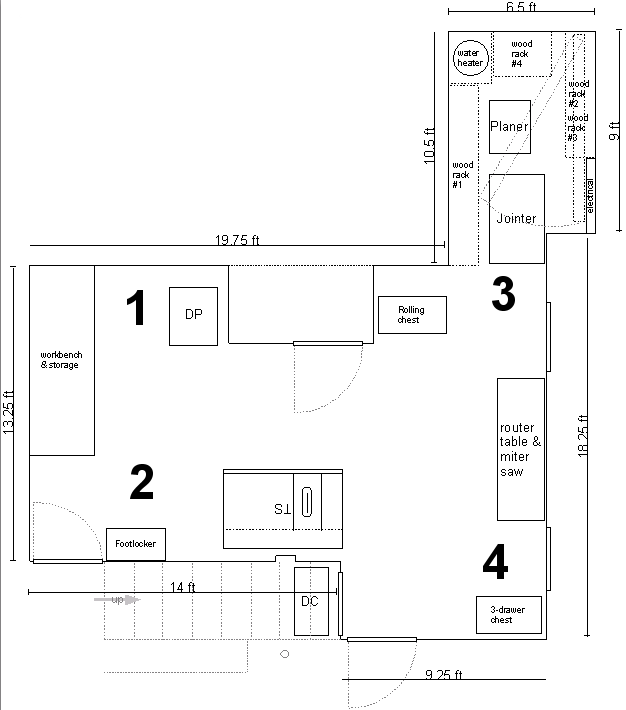

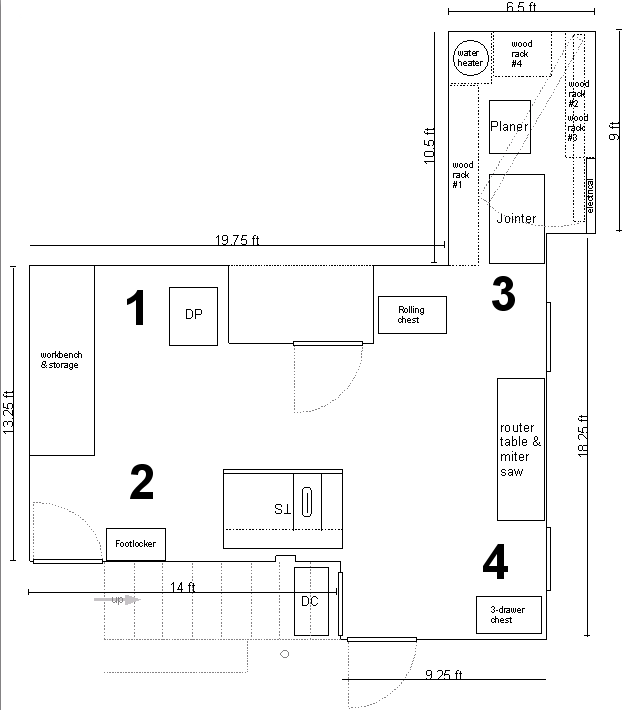

Before setting up your shop, create a detailed floor plan that considers the workflow of your projects. Map out where each tool, workbench, and storage area will be located to minimize unnecessary movement and maximize productivity.

2. Invest in versatile storage solutions:

Effective storage is essential in a woodworking shop. Invest in shelves, cabinets, pegboards, and drawers to keep your tools and materials organized and easily accessible. Consider vertical storage options to make the most of your available space.

3. Maximize natural and artificial lighting:

Good lighting is crucial for accurate woodworking. Maximize natural light by positioning your workbenches near windows, and supplement it with artificial lighting, including task lighting for specific work areas.

4. Use mobile workstations:

If you have limited space or frequently work in different areas of your shop, consider using mobile workstations or tool carts. These portable solutions allow you to move equipment and materials as needed.

5. Consider dust collection and ventilation:

Woodworking generates a significant amount of dust, which can be detrimental to your health and affect the quality of your work. Install an effective dust collection system and ensure proper ventilation for a cleaner and healthier work environment.

6. Create a dedicated finishing area:

Designate a specific area in your shop for finishing tasks to prevent dust contamination on your projects. This area should be well-ventilated and separate from other workstations.

7. Regularly declutter and maintain your shop:

To keep your shop organized and efficient, make it a habit to regularly declutter and clean your workspace. Remove any unnecessary tools or materials, and ensure everything has a designated place.

In conclusion, the best size for a woodworking shop depends on various factors, including available space, budget, the type of projects you work on, and personal preferences. Whether you opt for a small, medium, or large shop, careful planning and organization are key to creating a functional and efficient workspace. Consider your needs, future growth potential, and prioritize safety and convenience. By optimizing your woodworking shop’s size and layout, you’ll set yourself up for success and enjoy your woodworking journey to the fullest.

Key Takeaways: What is the Best Size for a Woodworking Shop?

Frequently Asked Questions

Welcome to our Frequently Asked Questions section, where we’ll answer some common queries about the best size for a woodworking shop. Whether you’re a beginner or a seasoned woodworker, finding the right size for your shop is crucial to ensure comfort, efficiency, and productivity. Let’s dive into the questions!

1. How do I determine the ideal size for my woodworking shop?

When determining the ideal size for your woodworking shop, consider the space you have available and the types of projects you usually work on. Start by measuring the dimensions of your space to get an accurate idea of the area you can allocate to your shop. Next, think about the tools and equipment you’ll need: table saw, workbench, lumber storage, etc. Create a floor plan and imagine how you’ll arrange everything to optimize workflow and movement within the shop. It’s also important to account for future growth, allowing for expansion and the addition of new tools.

Additionally, think about the types of projects you typically undertake. If you focus on small-scale woodworking, a compact shop may suffice. However, if you tackle larger projects like furniture-making or cabinetry, a larger shop would be beneficial. Remember, it’s crucial to find a balance between workspace and storage so that you have enough room for both your tools and your projects.

2. Should I prioritize the size of my woodworking shop over other factors?

The size of your woodworking shop is undoubtedly important but should be considered alongside other factors. While having ample space is beneficial, it’s equally crucial to focus on organization, lighting, ventilation, and safety measures. A small, well-organized shop can be just as effective as a larger one if you utilize the space efficiently.

Take time to plan the layout of your shop to ensure tools, equipment, and workstations are easily accessible. Incorporate proper lighting to reduce eye strain and enhance visibility. Ventilation is critical for maintaining good air quality, as woodworking can produce dust and fumes. Lastly, prioritize safety by implementing measures such as fire extinguishers, first aid kits, and clear walking paths. By considering these factors in conjunction with the size of your shop, you’ll create a functional and safe working environment.

3. Are there any common mistakes to avoid when determining the size of a woodworking shop?

Yes, there are a few common mistakes to avoid when determining the size of a woodworking shop. One mistake is underestimating the amount of space you’ll need for storage. Woodworking involves acquiring various materials, tools, and supplies, so having sufficient storage is crucial. Failing to allocate enough space for storage can lead to a cluttered and disorganized shop, hindering productivity.

Another common mistake is not leaving enough room for maneuvering between workstations and equipment. It’s essential to have adequate space to move around comfortably, especially when dealing with large pieces of wood or operating heavy machinery. Lack of maneuverability can impact your safety and overall workflow in the shop.

4. Can I optimize a small woodworking shop for maximum efficiency?

Absolutely! Even with limited space, you can optimize your small woodworking shop for maximum efficiency. One approach is to invest in versatile tools that can fulfill multiple functions. For example, a combination machine that combines a table saw, jointer, and planer into one device can save precious space.

Another way to maximize efficiency is through smart organization. Utilize wall space by installing shelves, pegboards, and magnetic strips to keep your tools organized and easily accessible. Consider using mobile workstations or foldable tables that can be stored away when not in use. By utilizing every inch of your small shop effectively, you can create a functional and efficient workspace.

5. What are some additional considerations when designing the layout of a woodworking shop?

When designing the layout of your woodworking shop, there are a few additional considerations to keep in mind. One important aspect is workflow optimization. Place workstations and tools in a logical order to minimize unnecessary movement and optimize productivity. For example, position your workbench close to your table saw for easy access when cutting materials.

Another consideration is noise control. Woodworking can generate loud noises from power tools, which can be distracting or disruptive. To minimize noise, separate noisy machinery from quieter workstations or create dedicated enclosures or sound-absorbing panels. Additionally, think about electrical outlets and install them strategically, ensuring convenient access to power without the need for long extension cords.

Summary:

So, what’s the best size for a woodworking shop? Well, it depends on a few things. First, think about the tools and equipment you’ll need. Make sure you have enough space to work comfortably and store everything. Next, consider the types of projects you want to do. If you plan on building large furniture pieces, a bigger shop might be necessary. Lastly, don’t forget about safety. Make sure there’s enough room to move around and avoid accidents. Overall, the best size for your woodworking shop is the one that fits your needs and allows you to work efficiently.

In conclusion, remember to prioritize functionality and comfort when determining the size of your woodworking shop. Take into account your tools, projects, and safety, and choose a size that suits your needs. Happy woodworking!