Hey there! Are you wondering about the correct shutdown procedure for the drill press? Well, you’ve come to the right place! Let’s dive in and learn how to properly shut down this powerful tool.

When it comes to operating the drill press, it’s crucial to know the correct shutdown procedure. This ensures not only your safety but also the longevity of the machine. So, what steps should you follow to shut down the drill press properly?

Firstly, after you’ve finished using the drill press, make sure to turn off the power switch. You’ll typically find it on the front or side of the machine. This simple step prevents any accidental starts and keeps you safe.

Next, release the quill lock. This handy feature locks the drill bit in place during operation but needs to be released before shutting down the machine. Just locate the quill lock knob, usually located near the handle, and twist it counterclockwise to unlock.

Lastly, give the drill press a final inspection. Look for any loose tools or debris around the machine and make sure nothing is obstructing the moving parts. Keep your work area clean and tidy for a safer and more organized workspace.

Now you know the correct shutdown procedure for the drill press! By following these steps, you’ll ensure your safety and keep the machine in tip-top shape. So, let’s review: turn off the power, release the quill lock, and give the drill press a final inspection. Happy drilling!

To safely shut down a drill press, follow these steps:

- Release the power switch to turn off the drill press.

- Wait for the drill bit to completely stop spinning before removing your workpiece.

- Raise the drill bit to its highest position using the handle or lever.

- Unplug the drill press from the power source.

- Clean the work area and remove any debris or scraps.

Remember to follow these steps every time you finish using the drill press for a safe and efficient shutdown process.

The Correct Shutdown Procedure for the Drill Press: A Comprehensive Guide

Drill presses are powerful tools used in woodworking and metalworking to create precise and clean holes. While it’s essential to know how to operate a drill press safely, it is equally important to understand the correct shutdown procedure. A proper shutdown ensures the longevity of the machine and minimizes the risk of accidents or damage. In this article, we will discuss the step-by-step process to shut down a drill press safely and efficiently.

1) Turning Off the Power

The first step in the shutdown procedure for a drill press is to turn off the power. Locate the power switch, usually located near the front or side of the machine. Flip the switch to the “Off” position. Some drill presses may have a direct power plug instead of a switch, in which case you need to unplug the machine from the electrical outlet. It’s important to ensure that the machine is completely powered off to prevent any accidental starts while performing maintenance tasks.

Next, check if there is a magnetic switch or circuit breaker on the drill press. If so, make sure it is in the “Off” position. This additional safety measure helps protect against unexpected power surges or accidental starts. Once the power is completely off, you can proceed with the remaining steps of the shutdown procedure.

2) Lowering the Drill Bit

After turning off the power, it’s essential to lower the drill bit to its lowest position. Begin by adjusting the table height or the quill feed handle to lower the bit until it is as close to the work surface as possible. This step prevents any potential accidents or injuries by ensuring that the drill bit is not in a raised position where it could contact the operator or other objects accidentally.

Once the drill bit is lowered, double-check its position to ensure that it is at the lowest point possible. This step also makes it easier to clean the work area and prevents any potential damage to the drill bit or other parts of the machine due to accidental contact.

3) Removing the Workpiece

After lowering the drill bit, it’s crucial to remove the workpiece from the machine. Carefully and slowly lift the workpiece off the table, making sure not to damage the surface or get your fingers caught between the workpiece and the table. If clamps were used to secure the workpiece, release them before removing it from the machine.

Inspect your work area to ensure that no debris or remnants of the workpiece are left behind. Clearing the work area after each use helps maintain a clean and safe working environment and prevents any potential hazards or interference during the next operation.

4) Cleaning and Maintenance

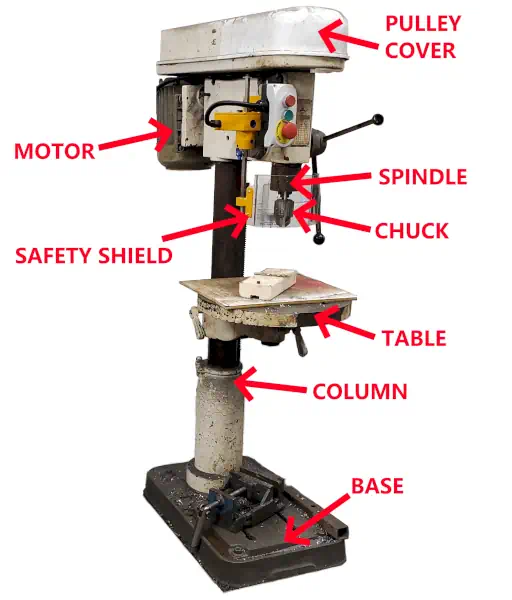

Once the drill press is clear of the workpiece, it’s time to clean and perform any necessary maintenance tasks. Use a brush or compressed air to remove any dust, wood shavings, or metal chips from the drill press table, column, and other surfaces. Pay close attention to the chuck and the area around it, as debris can affect the proper operation of the machine.

If required, apply a few drops of lubricating oil to the drill bit and the chuck to keep them in optimal condition. Refer to the manufacturer’s guidelines for specific maintenance instructions and recommendations.

Additionally, inspect the power cord for any signs of damage, such as fraying or exposed wires. If you notice any issues, it’s crucial to address them before using the drill press again. Regular maintenance and cleaning not only extend the lifespan of the drill press but also promote safe and efficient operation.

5) Storing and Securing the Drill Press

Once the drill press has been cleaned and maintained, it’s time to store it properly. If you have a dedicated workshop, return the drill press to its designated location, making sure it is secured and stable. Avoid placing it near edges or in high-traffic areas where it may accidentally be knocked over or interfered with.

If you work in a shared space or need to store the machine temporarily, consider covering it with a protective cloth or tarp to prevent dust or other debris from settling on it. This step helps maintain the drill press’s performance and prevents any potential damage.

6) Following Manufacturer’s Guidelines

It’s important to note that the specific shutdown procedure may vary depending on the make and model of the drill press. Always consult the manufacturer’s guidelines and follow their instructions for the correct shutdown procedure. They may include additional steps or specific recommendations based on the machine’s design and features. Adhering to the manufacturer’s guidelines ensures that you are using the drill press safely and correctly.

Additional Tips for Safe Drill Press Shutdown

Now that we have covered the correct shutdown procedure for a drill press, let’s discuss some additional tips to ensure your safety and the machine’s longevity:

1) Wear Appropriate Personal Protective Equipment (PPE)

Prior to operating or shutting down a drill press, always wear the necessary personal protective equipment. This may include safety goggles, ear protection, and gloves. PPE helps prevent injuries and keeps you safe while using the machine.

2) Familiarize Yourself with the Drill Press Controls

Before using a drill press, take the time to familiarize yourself with the machine’s controls. Read the user manual, watch instructional videos, or seek guidance from experienced users. Understanding the controls and their functions ensures safe operation and shutdown.

3) Regularly Inspect the Drill Press Components

Perform regular inspections of the drill press components, such as belts, pulleys, and fasteners. Look for any signs of wear, damage, or loose parts. Address any issues promptly to prevent accidents and maintain the machine’s efficiency.

4) Keep the Work Area Clean and Organized

Maintain a clean and organized work area around the drill press. Clear away any unnecessary tools, materials, or debris. This promotes safety and prevents any interference during operation or shutdown.

5) Monitor the Drill Press Operation

While operating the drill press, pay close attention to any unusual sounds, vibrations, or performance issues. Address these immediately before shutting down the machine to prevent further damage or complications.

Conclusion

Knowing the correct shutdown procedure for a drill press is just as important as understanding how to use the machine safely. By following the steps outlined in this guide, you can ensure that the drill press is turned off properly, the drill bit is lowered, the work area is cleaned, and the machine is securely stored. Remember to consult the manufacturer’s guidelines for specific instructions pertaining to your drill press. By practicing proper shutdown procedures and adhering to safety guidelines, you can ensure a longer lifespan for your drill press and a safer working environment for yourself.

Key Takeaways: What is the Correct Shut Down Procedure for the Drill Press?

- Always wear safety goggles when operating the drill press.

- Turn off the drill press by flipping the power switch to the “off” position.

- Wait for the drill press to come to a complete stop before leaving it unattended.

- Unplug the drill press from the power outlet after shutting it down.

- Clean the drill press and remove any debris to maintain its performance and longevity.

Frequently Asked Questions

Welcome to our FAQ section on the correct shut down procedure for the drill press. Below, you’ll find answers to common questions, ensuring the safe and proper usage of this powerful tool.

1. What are the key steps to shut down the drill press safely?

To safely shut down a drill press, follow these steps:

Firstly, turn off the power switch and unplug the drill press from the power source. Next, ensure the drill bit has completely stopped rotating before removing any workpiece or adjusting the table or other components. Finally, clean the drill press and the surrounding area of any debris or excess material, keeping it tidy for the next use.

2. Should I wear any personal protective equipment when shutting down the drill press?

Yes, it’s important to prioritize safety and wear the necessary personal protective equipment (PPE) when using and shutting down the drill press. This includes safety glasses or goggles to protect your eyes from any flying debris, and sturdy gloves to safeguard your hands from potential injuries when handling the machine or removing materials.

Additionally, if you’re using the drill press in a particularly noisy environment, consider wearing ear protection to prevent any hearing damage. Remember, safety should always be the top priority!

3. Is there anything I should check or inspect before shutting down the drill press?

Before shutting down the drill press, it’s important to perform a quick visual inspection and check for any issues or abnormalities. Look for any loose or damaged parts, frayed cords, or signs of excessive wear. Ensure all components are in their proper place and functioning correctly.

If you notice any problems during the inspection, do not attempt to use the drill press. Instead, contact a qualified professional for repairs or maintenance. It’s always better to be safe than sorry!

4. Can I leave the drill press unattended after shutting it down?

No, it is highly recommended to never leave the drill press unattended after shutting it down. It’s best practice to unplug the machine completely and store it in a secure location. Leaving the drill press unattended poses a safety risk, especially if there are curious individuals, children, or pets nearby who may accidentally start the machine or injure themselves on its moving parts.

Always remember to prioritize safety and take the necessary precautions when using and storing the drill press.

5. How often should I clean and maintain the drill press?

Regular cleaning and maintenance are vital to keep your drill press in good working condition. It is recommended to clean the drill press after each use to remove any dust, debris, or metal shavings that may have accumulated.

Aside from the regular cleaning, you should also periodically lubricate the moving parts of the drill press, such as the chuck and the quill. This will help ensure smooth operation and prevent any unnecessary strain or damage to the machine.

Moreover, it’s a good idea to refer to the manufacturer’s guidelines for any specific maintenance recommendations or schedules. Following these guidelines will help prolong the lifespan of your drill press and keep it operating at its best.

Summary

When shutting down a drill press, it’s important to follow the correct procedure to ensure safety and proper maintenance. First, turn off the power switch and wait for the drill bit to completely stop spinning. Then, gently raise the drill bit up and release any pressure on the material. Finally, clean the drill press and return any accessories to their proper place for the next use. Remember, safety comes first!

Key Points

To shut down a drill press correctly:

– Turn off the power switch and allow the drill bit to stop spinning.

– Raise the drill bit up and release any pressure on the material.

– Clean the drill press and put accessories back where they belong.

– Always prioritize safety by following the correct procedure.