Are you curious about the cutting depth of a circular saw? Well, you’ve come to the right place! In this article, we’ll unravel the mystery behind this essential feature of a circular saw. So, hang tight and get ready to explore the depths of cutting with your trusty tool!

When it comes to woodworking, it’s crucial to understand the cutting depth of a circular saw. This measurement determines how deep the blade can penetrate into the material you’re working with. With the right knowledge, you can make precise cuts without going too shallow or too deep.

Now, you might be wondering, “Why is cutting depth important?” Well, my young woodworking enthusiast, knowing the cutting depth allows you to plan your project effectively. Whether you’re building a bookshelf or creating a wooden masterpiece, understanding this feature will help you achieve desired outcomes effortlessly. So, let’s dive into the world of cutting depths and take your woodworking skills to new heights!

Understanding the Cutting Depth of a Circular Saw

A circular saw is a versatile tool commonly used in woodworking and construction projects. One important factor to consider when using a circular saw is the cutting depth. The cutting depth refers to the maximum thickness or depth at which the saw can cut through a material. Knowing the cutting depth of your circular saw is crucial for achieving accurate and efficient cuts. In this article, we will explore what the cutting depth of a circular saw is, how it affects your projects, and some important considerations for using a circular saw.

The Anatomy of a Circular Saw

Before diving into the cutting depth, let’s take a moment to understand the basic components of a circular saw. A circular saw consists of a motor, a circular blade, and a base plate, also known as a shoe. The motor powers the rotation of the blade, while the base plate provides stability and guidance during cuts. The cutting depth is determined by the distance between the base plate and the lowest point of the blade’s teeth. Now that we have a basic understanding of the circular saw’s anatomy, let’s explore the cutting depth in more detail.

The Definition and Importance of Cutting Depth

The cutting depth of a circular saw refers to the maximum thickness of material the saw can cut through in a single pass. This measurement is essential as it determines the types of projects you can tackle and the efficiency of your cuts. When using a circular saw, it is crucial to choose the correct blade diameter and adjust the cutting depth accordingly. Failure to do so may result in incomplete cuts, damaged materials, or even accidents.

The cutting depth of a circular saw can usually be adjusted by adjusting the position of the base plate. Different saw models offer different cutting depths, so it is important to consult the manufacturer’s guidelines or the user manual to determine the specific cutting depth range of your saw. It is also important to note that the cutting depth may vary depending on the diameter of the blade being used. Now that we understand the definition and importance of cutting depth, let’s explore some factors to consider when using a circular saw.

Factors Affecting Cutting Depth

Several factors can affect the cutting depth of a circular saw. Understanding these factors will help you make informed decisions when using this versatile tool:

- Blade Diameter: The diameter of the blade plays a significant role in determining the cutting depth. Larger blades typically have a greater cutting depth than smaller blades.

- Maximum Blade Extension: The maximum extension of the blade from the base plate also affects the cutting depth. Adjusting the blade extension allows you to control the cutting depth according to your project requirements.

- Material Type: Different materials have varying densities, which can impact the cutting depth. Harder materials may require multiple passes or specialized blades to achieve the desired depth.

- Motor Power: The power of the circular saw’s motor can influence the cutting depth. More powerful motors can handle thicker materials and maintain consistent cutting performance.

- Base Plate Tilt: The tilt of the base plate can affect the cutting depth, especially when making bevel cuts. Be sure to adjust the base plate tilt accordingly to achieve accurate and desired cutting depths.

Tips for Using a Circular Saw Safely and Efficiently

Now that we have covered the basics of cutting depth and its importance, let’s go over some tips for using a circular saw safely and efficiently:

- Read the Manual: Always read and understand the manufacturer’s instructions and safety guidelines before operating a circular saw.

- Wear Protective Gear: Use appropriate safety gear such as safety goggles, ear protection, and gloves to protect yourself from potential hazards.

- Secure the Material: Ensure the material you are cutting is firmly secured to prevent movement during the cutting process, which can affect the accuracy of the cut.

- Measure Twice, Cut Once: Take accurate measurements and mark your cut lines before starting to ensure precision and minimize mistakes.

- Go Slow and Steady: Apply gentle pressure and let the saw do the work. Avoid forcing the saw through the material, as this can lead to kickback or blade damage.

The Benefits of Using a Circular Saw

Now that we have explored the cutting depth and important considerations for using a circular saw, let’s briefly discuss the benefits of using this versatile tool:

- Versatility: Circular saws can handle a wide range of materials, making them suitable for various projects, including woodworking, construction, and home improvement.

- Portability: Unlike larger stationary saws, circular saws are compact and easy to transport, allowing you to work on projects in different locations.

- Precision Cutting: When used correctly, circular saws can produce accurate and clean cuts, making them ideal for both professional and DIY projects.

- Speed and Efficiency: With the right blade and technique, circular saws can cut through materials quickly, increasing productivity and saving time.

Choosing the Right Circular Saw for Your Projects

Now that we’ve covered the cutting depth, important considerations, and benefits of using a circular saw, let’s briefly touch on choosing the right circular saw for your projects. When selecting a circular saw, consider factors such as blade diameter, motor power, ergonomic features, and brand reputation. Research customer reviews and consult experts to ensure you choose a saw that meets your specific requirements and offers reliable performance.

Maintaining Your Circular Saw for Longevity

Lastly, it’s important to maintain your circular saw to ensure its longevity and optimal performance. Some basic maintenance tips include regularly cleaning the saw, inspecting and replacing worn-out parts, lubricating moving components, and storing the saw properly in a dry and secure location. Regular maintenance will not only extend the lifespan of your circular saw but also help prevent accidents and ensure consistent cutting performance.

In conclusion, understanding the cutting depth of a circular saw is crucial for achieving accurate and efficient cuts in your woodworking and construction projects. By knowing the factors that affect the cutting depth and following safety guidelines, you can use a circular saw safely and efficiently. Remember to choose the right saw for your projects and maintain it properly for long-lasting performance. Happy cutting!

Key Takeaways: What is the Cutting Depth of a Circular Saw?

2. It is an important specification to consider when choosing a circular saw for your projects.

3. Circular saws typically have adjustable cutting depths, allowing you to customize the depth according to your needs.

4. The cutting depth is determined by the size of the saw blade and the design of the saw’s housing.

5. It is essential to follow the manufacturer’s guidelines and safety precautions when using a circular saw to ensure proper cutting depth and avoid accidents.

Frequently Asked Questions

When it comes to using a circular saw, understanding its cutting depth is crucial. Here are some common questions about the cutting depth of a circular saw and their answers.

1. How can I determine the cutting depth of a circular saw?

To determine the cutting depth of a circular saw, you need to look at the blade and consider its diameter. The cutting depth is generally half an inch less than the blade’s diameter. For example, if the circular saw has a 7 ¼-inch blade, the cutting depth will be around 6 ¾ inches. However, it’s important to note that the actual cutting depth may vary depending on the specific model and settings.

It’s recommended to refer to the manufacturer’s instructions or the saw’s user manual to find the exact cutting depth for your circular saw. Additionally, some circular saws have an adjustable cutting depth feature that allows you to customize it according to your needs.

2. Can I adjust the cutting depth of a circular saw?

Many circular saws come with an adjustable cutting depth feature, which allows you to modify the depth according to the requirements of your project. With this feature, you can easily increase or decrease the cutting depth as needed. By adjusting the cutting depth, you can achieve shallower cuts for thin materials or deeper cuts for thicker materials.

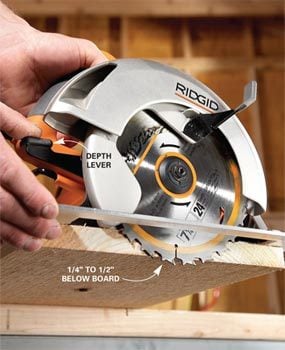

To adjust the cutting depth, look for the depth adjustment lever or knob on your circular saw. Consult the user manual or the manufacturer’s instructions to understand how to use this feature correctly. Remember to make adjustments while the saw is unplugged and turned off to ensure safety.

3. What factors can affect the cutting depth of a circular saw?

Several factors can affect the cutting depth of a circular saw. Firstly, the diameter of the blade plays a significant role. As mentioned earlier, the cutting depth is generally half an inch less than the blade’s diameter. Additionally, the power and RPM (revolutions per minute) of the circular saw can impact the cutting depth. Higher-powered saws with higher RPMs tend to have greater cutting depths.

The type of material being cut is another important factor. Softer materials, such as plywood, may allow for deeper cuts, while harder materials, like hardwood, may require shallower cuts. It’s also worth considering the condition and sharpness of the blade. A dull blade can reduce the cutting depth, while a sharp blade can enhance it.

4. Are there any safety precautions to consider when adjusting the cutting depth?

When adjusting the cutting depth of a circular saw, it’s essential to prioritize safety. Before making any adjustments, ensure that the saw is unplugged and turned off. This eliminates the risk of accidental starts. Additionally, use personal protective equipment (PPE) such as safety goggles and gloves to protect yourself from any debris or sharp edges.

Once you’ve made the necessary adjustments to the cutting depth, double-check that everything is securely locked in place before turning on the saw. It’s crucial to follow the manufacturer’s instructions and guidelines for adjusting the cutting depth to ensure the safe and proper use of the circular saw.

5. Can I use a circular saw with a limited cutting depth for thicker materials?

Using a circular saw with a limited cutting depth for thicker materials can be challenging and may not yield satisfactory results. If you’re working with thicker materials, it’s recommended to use a circular saw with a deeper cutting depth or consider using alternative tools such as a jigsaw or a table saw.

However, if you only have a circular saw with a limited cutting depth, you can make multiple passes on the material to achieve the desired depth. This process requires patience and precision to ensure accurate and clean cuts. Make sure to align each subsequent cut accurately with the previous one to maintain consistency and avoid any accidents or inconsistencies in the final outcome.

Adjusting circular saw depth.

Summary

So, to sum it all up, the cutting depth of a circular saw refers to how deep it can cut into a material. This is important to know because it determines the thickness of the material that can be cut. The cutting depth can be adjusted on most circular saws, allowing for different thicknesses of materials to be cut. It’s important to always check the cutting depth of a circular saw before using it to make sure it is set correctly for your project.