So, you want to know what a drill press is all about? Well, you’ve come to the right place! In this article, we’ll dive into the description of a drill press, giving you all the information you need in a simple and easy-to-understand way. Let’s get started, shall we?

First things first, a drill press is a handy tool that every DIY enthusiast and professional woodworker should have in their arsenal. It’s like a superpowered version of a handheld drill! With a drill press, you can accomplish precise and accurate drilling tasks with ease.

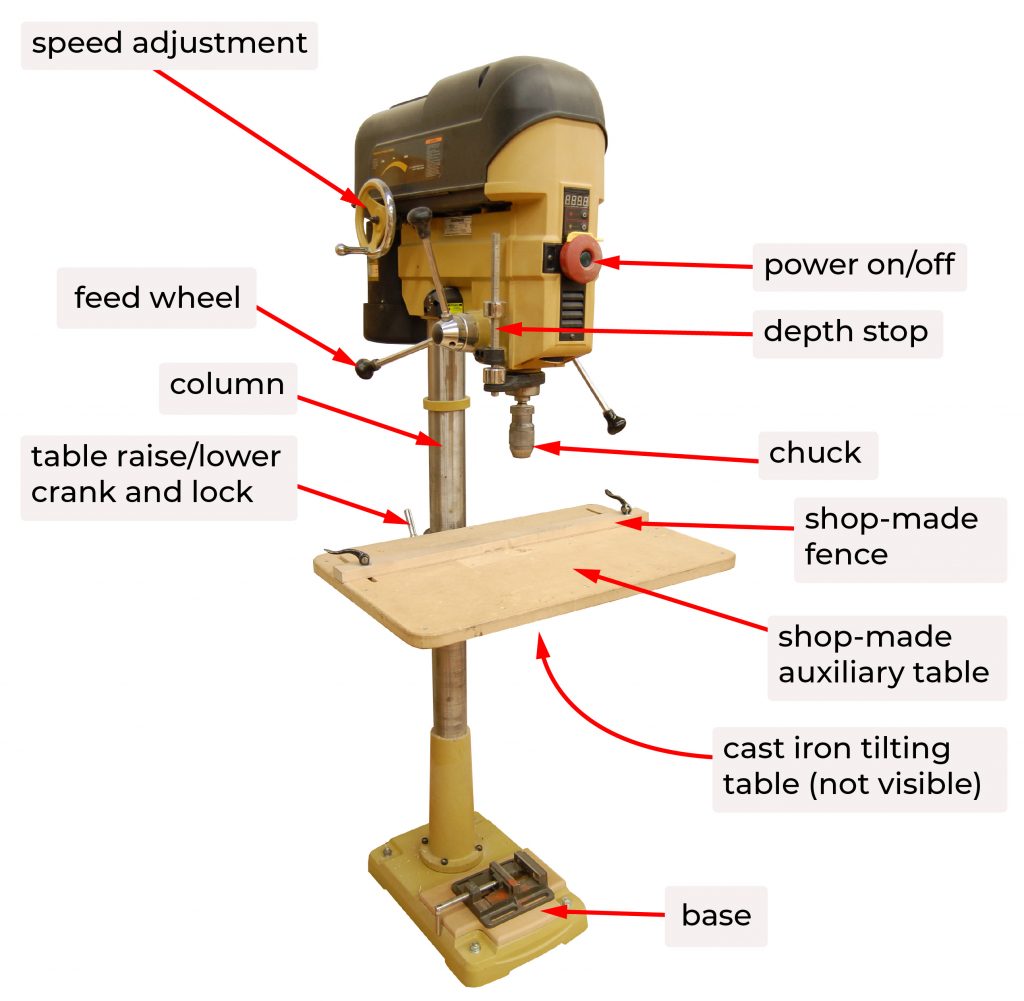

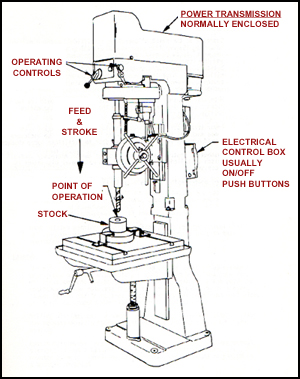

Now, imagine a sturdy machine standing on your workbench, ready to take on any drilling challenge. The drill press consists of a base, a column, a spindle, and a drill head. These components work together to provide stability, control, and power while drilling.

Stay tuned as we delve deeper into the description of a drill press. We’ll explore its various features, functions, and benefits that make it an indispensable tool. So, whether you’re a beginner or a seasoned pro, you’ll find all the information you need right here. Let’s explore the fascinating world of drill presses together!

What is the Description of a Drill Press?

A drill press is a versatile power tool used for various drilling applications. It is also known as a bench drill or a pedestal drill. The drill press is designed to provide accuracy, stability, and power in drilling holes in different materials such as wood, metal, and plastic. It consists of a base, a column, a worktable, a spindle, and a drill chuck. The drill chuck holds the drill bit, and the spindle rotates the bit to create holes of different sizes and depths.

With its adjustable depth stop, the drill press allows you to control the depth of the hole, ensuring consistency and precision. It also offers variable speed options, allowing you to adjust the speed of the spindle according to the material being drilled. Some drill presses even come with built-in laser guides or digital depth indicators to further enhance accuracy.

Benefits of Using a Drill Press

1. Precision: One of the main benefits of a drill press is its ability to provide precise drilling. The drill press offers a stable platform, reducing the risk of wobbling or deviation during drilling. This allows for accurate placement and consistent depth control, making it ideal for tasks that require precision, such as woodworking or metalworking.

2. Power: Compared to handheld drills, drill presses are more powerful and can handle larger drill bits and tougher materials. The motor of a drill press is specifically designed to provide high torque, enabling you to drill through materials with ease.

3. Safety: Drill presses come with safety features such as built-in depth stops and safety guards to protect the user from accidental injuries. The drill press also eliminates the need for excessive manual force, reducing the risk of slippage or strain.

Types of Drill Presses

1. Benchtop Drill Press: This type of drill press is compact and designed to be placed on a workbench. It is suitable for small-scale projects and workshops with limited space. They are lightweight and portable, making them easy to move around when needed.

2. Floor Standing Drill Press: Floor standing drill presses are larger and sturdier than benchtop models. They are designed to be placed directly on the floor and offer increased stability and power. Floor standing drill presses are commonly used in professional settings and workshops where heavy-duty drilling is required.

3. Magnetic Drill Press: Magnetic drill presses are specifically designed for drilling through steel and other magnetic materials. They use an electromagnetic base to secure the drill press to the workpiece. This type of drill press is commonly used in metalworking industries and construction sites.

Tips for Using a Drill Press

1. Wear Safety Gear: Always wear appropriate safety gear, including safety glasses and ear protection, when using a drill press. This will protect you from flying debris and loud noises.

2. Secure the Workpiece: Ensure that the workpiece is securely clamped or held in place before drilling. This will prevent any movement or shifting during the drilling process.

3. Start with a Pilot Hole: When drilling large holes, start with a smaller pilot hole to guide the larger drill bit. This will prevent the drill bit from wandering and ensure accuracy.

4. Adjust Speed and Depth: Depending on the material being drilled, adjust the speed and depth settings accordingly. Higher speeds are generally used for softer materials, while slower speeds are required for harder materials.

5. Clean and Maintain: Regularly clean and maintain your drill press to ensure its longevity and optimal performance. Lubricate the moving parts and check for any loose or damaged components.

Conclusion

A drill press is an essential tool for accurate and precise drilling. Its sturdy construction, adjustable features, and power make it suitable for a wide range of drilling applications. Whether you are a DIY enthusiast or a professional, a drill press can greatly enhance your drilling experience and improve the quality of your work.

Remember to prioritize safety when using a drill press and follow the manufacturer’s instructions for proper usage and maintenance. With the right techniques and precautions, your drill press can be a valuable tool in your workshop.

Key Takeaways: What is the Description of Drill Press?

- A drill press is a tool used for making precise and accurate holes in different materials.

- It consists of a base, a column, a drill head, a spindle, and a table.

- The drill press is operated by lowering the drill bit onto the material and using the handle to apply pressure.

- It offers various speed settings to accommodate different types of materials and drilling tasks.

- A drill press is commonly used in woodworking, metalworking, and other DIY projects.

Frequently Asked Questions

Are you curious about the description of a drill press? Look no further! We’ve got you covered with the answers to some of the most commonly asked questions about this handy tool.

What is a drill press and how does it work?

A drill press is a stationary power tool used for precision drilling in various materials. It consists of a base, a column or pillar that supports the drill head, and an adjustable table. The drill head houses a motor, a chuck to hold drill bits, and a spindle that rotates the drill bit. To operate a drill press, you simply lower the drill bit onto the material using the lever or handle, and the rotational force of the spindle drills a hole with accuracy and precision.

Drill presses are commonly used in woodworking, metalworking, and other applications that require precise and repetitive drilling. They offer better control, accuracy, and stability compared to handheld drills, making them a popular choice in workshops and factories.

What are the main features of a drill press?

A drill press typically has several key features that enhance its functionality and user experience. These include:

1. Adjustable table: The table can be moved up, down, and tilted to accommodate different workpieces and drilling angles.

2. Depth stop: This allows you to set the desired depth of the hole, ensuring consistent drilling depth across multiple workpieces.

3. Speed control: Most drill presses come with adjustable speed settings, allowing you to choose the optimal speed for different materials and drill bit sizes.

4. Laser or LED guide: Some drill presses have built-in laser or LED lights that help you align the drill bit accurately on the desired drilling spot.

5. Safety features: Many drill presses include safety features like emergency stop switches and transparent guards to protect the operator from potential hazards.

What are the advantages of using a drill press?

Using a drill press offers several advantages over handheld drills. Firstly, it provides greater accuracy and precision, allowing you to drill straight and consistent holes. The adjustable depth stop ensures you achieve the same drilling depth every time, which is crucial for certain applications.

Another advantage is the stability provided by a drill press. Unlike handheld drills that rely on your grip, a drill press is securely mounted and minimizes the risk of the workpiece moving or shifting during drilling. This stability also helps prevent accidents and improves safety in the workshop.

What are the different types of drill presses?

Drill presses come in various types to cater to different needs. The most common types include:

1. Benchtop drill presses: These compact and portable drill presses are designed to sit on a workbench. They are lightweight and suitable for small to medium-sized projects.

2. Floor drill presses: Floor models are larger and more powerful than benchtop drill presses. They are generally used in professional workshops and industrial settings.

3. Magnetic drill presses: These specialized drill presses use a powerful magnet to secure the tool to metal surfaces. They are ideal for drilling holes in steel or other ferrous materials.

4. Radial arm drill presses: This type of drill press features an arm that can be rotated and positioned horizontally. It offers more flexibility for drilling holes in larger workpieces.

Can a drill press be used for other tasks besides drilling?

While the primary purpose of a drill press is drilling, it can be used for other tasks with the help of additional accessories. For example, you can attach sanding drums, buffing wheels, or mortising attachments to transform your drill press into a versatile tool. However, it’s important to remember that drill presses are primarily designed for drilling, and using them for other tasks may require careful adjustments and safety considerations.

Before attempting any non-drilling tasks, make sure to consult the drill press manual and follow the manufacturer’s guidelines for compatibility and safety. Using the right accessories and taking proper precautions can help you extend the functionality of your drill press.

Summary

A drill press is a tool used for making precise holes in materials like wood or metal. It has a motor that powers a rotating drill bit, which is lowered onto the workpiece using a handle or lever. The drill press provides more control and accuracy compared to handheld drills.

Drill presses come in different sizes and have adjustable features like speed and depth. They are commonly used in woodworking, metalworking, and other fields that require precise drilling. Safety precautions like wearing goggles and securing the workpiece are important when using a drill press.