Are you curious about the difference between capstan and turret lathe? Well, you’ve come to the right place! In this article, we’ll explore these two types of lathes and highlight their unique features. If you’ve ever wondered how these machines work and what sets them apart, keep reading!

Lathes are fascinating tools used in machining and manufacturing processes. They play a crucial role in shaping and cutting materials like metal. Capstan and turret lathes are two popular variations, each offering distinct advantages. Whether you’re a budding engineer or simply an inquisitive mind, understanding the differences between these lathes will expand your knowledge of machining technology.

So, buckle up and get ready to dive into the world of capstan and turret lathes. By the end of this article, you’ll have a clear understanding of how they work, what they’re used for, and the key distinctions that make them unique. Let’s get started!

The Difference Between Capstan and Turret Lathe: An In-Depth Comparison

When it comes to machining, two types of lathes that often come up in discussions are capstan and turret lathes. While they may seem similar at first glance, there are distinct differences between the two. In this article, we will dive deep into the world of machining and explore the variances between capstan and turret lathes, their functionalities, applications, and advantages. Let’s explore the fascinating world of these precision machines.

What is a Capstan Lathe? An Insight into its Features and Capabilities

A capstan lathe is a type of lathe machine that is primarily used for repetitive production of small to medium-sized workpieces. It is designed to enable rapid and efficient machining of intricate parts with high precision. Capstan lathes typically feature a headstock with a collet chuck that holds the workpiece firmly, while the tool moves longitudinally to perform various operations such as turning, grooving, threading, and more.

One of the key features of a capstan lathe is its turret, which holds a series of toolholders. The turret can revolve around the collet chuck, allowing for quick tool changes and reducing the time required for setup. This feature makes a capstan lathe highly efficient for mass production, as it eliminates the need for manual tool changes after each operation.

In addition to the turret, capstan lathes often incorporate a power feed mechanism that enables automatic advance of the tool along the workpiece. This feature, coupled with the rapid tool changes, drastically improves productivity and reduces cycle times. Capstan lathes are commonly used in industries such as automotive, aerospace, and electronics, where high-volume production of intricate components is required.

What is a Turret Lathe? Exploring its Functions and Advantages

A turret lathe, on the other hand, is a versatile machine that is widely used in various manufacturing industries. It is designed to handle both short-run and long-run production of medium to large-sized workpieces. Turret lathes are known for their ability to perform multiple operations on a workpiece without the need for manual intervention.

The defining feature of a turret lathe is its turret, which houses a variety of toolholders. These toolholders can be rotated into position, allowing for the execution of different operations such as turning, drilling, boring, and milling. The turret can be indexed to bring the desired tool into position, providing quick and efficient tool changes.

Turret lathes often feature automatic feed mechanisms that enable the tool to move longitudinally or transversely along the workpiece. This automation, coupled with the versatility of the turret, makes turret lathes ideal for complex machining tasks that require multiple operations. Industries such as automotive, defense, and heavy machinery rely on turret lathes for their ability to handle diverse workpieces and produce high-quality components with precision.

Capstan Lathe vs. Turret Lathe: A Detailed Comparison

Now that we have explored the individual features and functionalities of capstan and turret lathes, let’s delve deeper into the key differences between the two:

1. Design and Configuration:

A capstan lathe typically has a simpler design with a single turret and collet chuck, allowing for rapid tool changes and efficient production of small to medium-sized components. In contrast, a turret lathe has a larger and more complex structure, often featuring multiple turrets, providing versatility and the ability to handle larger workpieces.

While capstan lathes are designed for high-speed turning and limited range of operations, turret lathes offer a wider range of machining capabilities, including drilling, milling, and boring, in addition to turning.

Table: A comparison of design and configuration between capstan and turret lathes:

| Feature | Capstan Lathe | Turret Lathe |

|---|---|---|

| Number of Turrets | Single turret | Multiple turrets |

| Operation | High-speed turning | Turning, drilling, milling, boring |

2. Size and Workpiece Capacity:

Capstan lathes are designed for smaller workpieces and are well-suited for high-volume production. They excel at machining components that require precision and repeatability, such as connectors, bolts, and small shafts. In contrast, turret lathes can handle both small and large workpieces with greater flexibility, making them suitable for diverse machining tasks.

Table: A comparison of size and workpiece capacity between capstan and turret lathes:

| Feature | Capstan Lathe | Turret Lathe |

|---|---|---|

| Workpiece Size | Small to medium-sized | Small to large-sized |

| Workpiece Capacity | High-volume production | Short-run to long-run production |

3. Speed and Accuracy:

Capstan lathes are designed for high-speed operations, allowing for faster machining and increased productivity. They are particularly efficient in repetitive production, where the same operation is performed on multiple workpieces. Turret lathes, on the other hand, offer greater versatility and can perform various operations with high accuracy and precision.

Table: A comparison of speed and accuracy between capstan and turret lathes:

| Feature | Capstan Lathe | Turret Lathe |

|---|---|---|

| Speed | High-speed operations | Varies based on operation |

| Accuracy | High precision | High precision |

4. Applications:

Capstan lathes find their applications in industries such as automotive, aerospace, electronics, and telecommunications, where high precision and rapid production are required. They are well-suited for manufacturing small components, such as screws, fasteners, and connectors.

Turret lathes, on the other hand, are widely used in industries such as automotive, defense, heavy machinery, and general machining. They can handle diverse workpieces and perform a wide range of operations, making them a versatile choice for various manufacturing applications.

Table: A comparison of applications between capstan and turret lathes:

| Feature | Capstan Lathe | Turret Lathe |

|---|---|---|

| Applications | Precision components | General machining, defense, heavy machinery |

Pros and Cons of Capstan and Turret Lathes

As with any machinery, both capstan and turret lathes have their own set of advantages and disadvantages. Let’s take a closer look:

Capstan Lathe:

- Pros: High-speed operations, rapid tool changes, efficient for high-volume production, well-suited for precision components.

- Cons: Limited range of operations, smaller workpiece capacity.

Turret Lathe:

- Pros: Versatile, handles both small and large workpieces, performs multiple operations, high accuracy and precision.

- Cons: Larger and more complex structure, slower tool changes compared to capstan lathe.

In conclusion, both capstan and turret lathes have their unique features and capabilities that cater to different manufacturing needs. Capstan lathes excel in high-speed production of precision components, while turret lathes offer versatility and the ability to handle diverse workpieces. Understanding the key differences between these two types of lathes allows manufacturers to choose the right machine for their specific requirements and optimize their production processes.

Key Takeaways: What is the Difference Between Capstan and Turret Lathe?

- A capstan lathe is designed for smaller, precise work, while a turret lathe is used for larger, heavier work.

- The capstan lathe typically has a single spindle, while the turret lathe has multiple spindles.

- A capstan lathe is operated manually, while a turret lathe can be operated manually or automatically.

- In a capstan lathe, the tool is held in a tool post that moves along the length of the workpiece. In a turret lathe, the tool is fixed in a rotating turret.

- A capstan lathe is more suitable for mass production of small parts, while a turret lathe is better for larger, more complex workpieces.

Frequently Asked Questions

In this section, we will explore the differences between capstan and turret lathes.

1. What are capstan and turret lathes, and how do they differ?

A capstan lathe is a type of lathe machine that primarily focuses on automatic and semi-automatic production. It is commonly used for manufacturing small turned parts in high quantities. Capstan lathes are equipped with a collet closer and are designed for quick changes of workpieces. On the other hand, a turret lathe is a versatile machine that allows for the machining of many different types of parts. It comes with a turret tool post that holds multiple tools, enabling the operator to change tools quickly and efficiently during the machining process. Turret lathes are often used for both medium and large-scale production.

In summary, the main difference lies in their purpose and versatility. Capstan lathes are primarily designed for high-speed mass production of small parts, while turret lathes offer greater versatility and can handle a wider range of workpieces.

2. What are the advantages of capstan lathes?

Capstan lathes offer several advantages in high-speed production environments. Firstly, their collet closer allows for quick and easy workpiece changes, maximizing efficiency. Secondly, capstan lathes have a higher spindle speed, resulting in faster cutting speeds. This makes them ideal for machining small parts that require a high level of precision. Additionally, the automatic and semi-automatic features of capstan lathes reduce the need for manual intervention, further increasing productivity.

In conclusion, the advantages of capstan lathes include rapid workpiece changes, high spindle speeds for faster cutting, and automated processes that streamline production.

3. What are the advantages of turret lathes?

Turret lathes offer several advantages that make them popular in medium to large-scale production settings. The most significant advantage is their versatility. With a turret tool post, it is easy to switch between various tools during the machining process, allowing for a wide range of operations and part designs. Moreover, turret lathes are robust and can handle heavy-duty machining, making them suitable for larger workpieces. They also have a large swing over bed, enabling the machining of longer and larger parts.

In summary, the advantages of turret lathes include their versatility, ability to handle heavy-duty machining, and the capability to handle larger and longer workpieces.

4. Can capstan and turret lathes be used interchangeably?

While both capstan and turret lathes serve different purposes and offer distinct advantages, there may be situations where they can be used interchangeably. For example, if a specific operation requires high-speed production of small parts, a capstan lathe would be the most suitable choice. However, if the same operation requires more versatility or the machining of larger parts, a turret lathe could be used instead.

Ultimately, the decision to use either a capstan or turret lathe depends on the specific requirements of the machining operation.

5. Are there any limitations to using capstan or turret lathes?

While both capstan and turret lathes are versatile machines, they do have certain limitations. Capstan lathes are primarily designed for high-speed mass production of small parts. If you have a requirement for larger workpieces or a wider range of machining operations, a capstan lathe may not be suitable. On the other hand, turret lathes, while more versatile, may not achieve the same level of high-speed production as capstan lathes for small parts.

It’s important to assess your specific machining requirements and consult with experts to determine which type of lathe will best meet your needs.

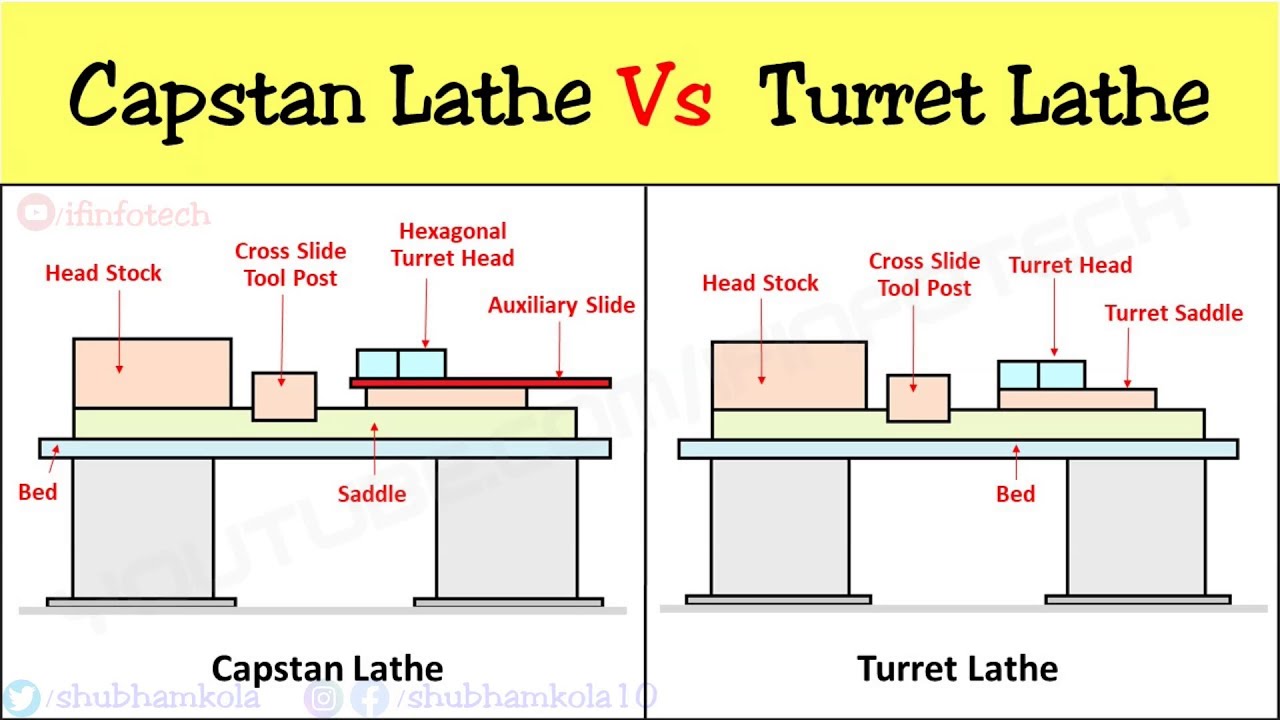

Difference between Capstan and Turret Lathe Machine over Engine Lathe [Diagram]

Summary

So, to sum it up for you, the difference between a capstan and turret lathe is that a capstan lathe is mainly used for small, repetitive jobs, while a turret lathe is designed for larger and more complex tasks. Capstan lathes have a hexagonal turret with multiple tool positions, allowing for quick tool changes and efficient production. On the other hand, turret lathes have a circular turret with even more tool positions, making them ideal for turning longer and heavier materials. So, the key difference lies in their size and capacity for different types of work.

In conclusion, capstan and turret lathes may sound similar, but they have distinct features and purposes. Capstan lathes handle small, repetitive jobs, while turret lathes are better suited for larger and more complex tasks. Remember, the important thing is to choose the right lathe for the specific job you need to get done!