Are you curious about the formula for calculating RPM on a lathe? Well, you’ve come to the right place! In this article, we’ll explore the ins and outs of RPM and how it applies to lathe operations. So, buckle up and get ready to uncover the secret behind this essential formula.

Now, you might be wondering, what exactly is RPM? RPM stands for “revolutions per minute” and it refers to the number of full revolutions a lathe spindle makes in one minute. Understanding how to calculate RPM is crucial for achieving optimal performance and safety while using a lathe.

So, how do you determine the RPM on a lathe? Don’t worry, it’s not as complicated as it sounds! By using a simple formula that takes into account the cutting speed and the diameter of the workpiece, you can easily calculate the ideal RPM for your lathe. Keep reading to discover the step-by-step process and unlock the key to successful lathe operations.

What is the Formula for RPM on a Lathe?

In the world of machining, lathes play a crucial role in turning raw materials into finished products. Determining the correct RPM (Revolutions Per Minute) is essential for achieving precise and efficient results. Whether you are a beginner or an experienced machinist, understanding the formula for RPM on a lathe is a fundamental skill that you must possess. In this comprehensive guide, we will delve into the details of this formula and equip you with the knowledge to optimize your lathe operations.

Understanding RPM on a Lathe

Before we dive into the formula, let’s take a moment to understand the significance of RPM on a lathe. RPM refers to the rotational speed of the workpiece or the cutting tool. It plays a crucial role in determining the quality of the finished product. By selecting the appropriate RPM, you can control parameters such as cutting speed and surface finish. Furthermore, using the correct RPM can minimize tool wear, prolonging the life of your cutting tools.

Calculating RPM on a Lathe: The Formula

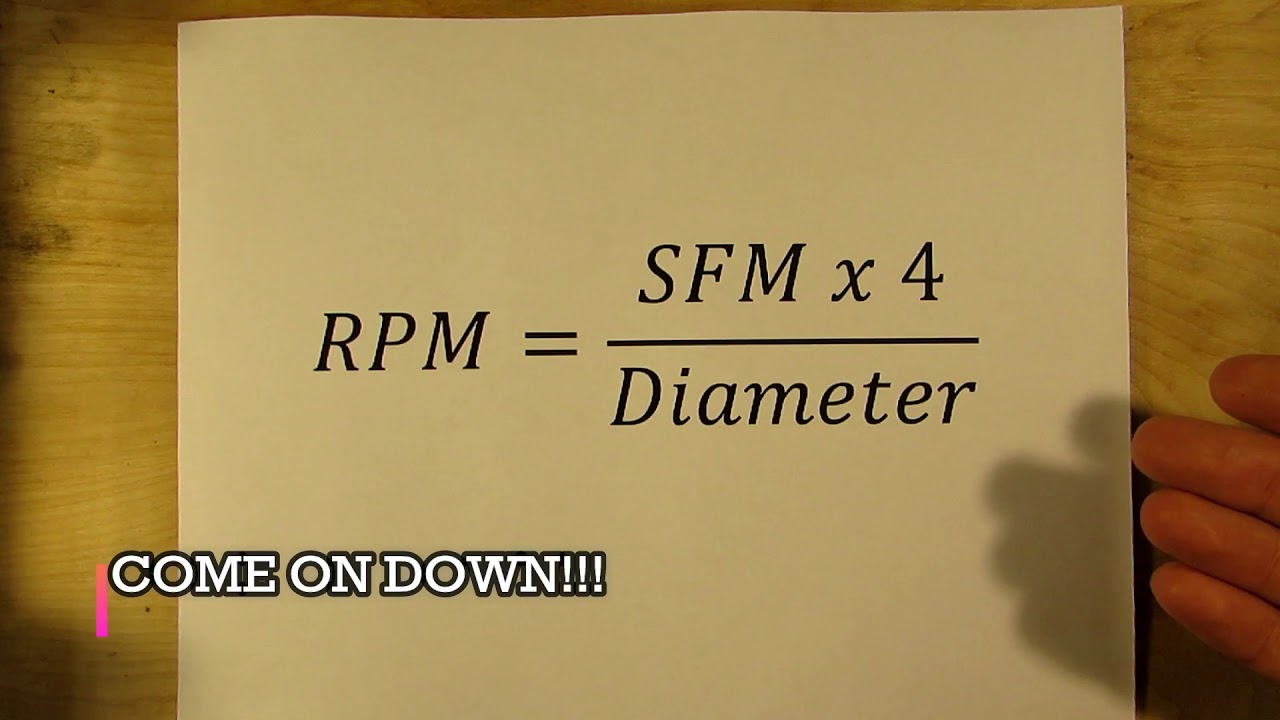

The formula for calculating RPM on a lathe is straightforward:

RPM = (CS x 4) / D

- RPM: Revolutions Per Minute

- CS: Cutting Speed (in feet per minute)

- D: Diameter of the workpiece or the cutting tool (in inches)

By plugging in the values for the cutting speed and the diameter into this formula, you can determine the optimal RPM for your lathe. It is crucial to note that the cutting speed is dependent on factors such as the material being machined, the type of cutting tool, and the desired surface finish.

Factors Influencing RPM on a Lathe

While the formula provides a general guideline for calculating RPM on a lathe, several factors can influence the actual speed required. Let’s explore some of these factors:

Material:

The type of material being machined greatly affects the RPM. Harder materials require lower RPM to prevent excessive tool wear, while softer materials can tolerate higher RPM.

Cutting Tool Type:

Different cutting tools have varying optimal RPM ranges. Carbide tools, for example, can handle higher speeds compared to high-speed steel tools.

Desired Surface Finish:

If a smooth surface finish is desired, lower RPM may be necessary to minimize vibrations that can lead to surface imperfections.

Workpiece Diameter:

The diameter of the workpiece or the cutting tool affects the cutting speed and, consequently, the optimal RPM. Larger diameters require lower RPM to maintain an appropriate cutting speed.

Tips for Optimizing RPM on a Lathe

Now that you understand the formula and the factors influencing RPM on a lathe, let’s explore some tips for optimizing this parameter:

- Refer to the manufacturer’s guidelines or cutting tool catalogs for recommended RPM ranges based on the material and cutting tool type.

- Start with conservative RPM settings and gradually increase or decrease the speed based on the surface finish and tool wear.

- Monitor the cutting process for any signs of excessive vibrations, poor surface finish, or tool chatter. Adjust the RPM accordingly to optimize the results.

- Consider using RPM calculators or mobile apps to simplify the calculation process and ensure accuracy.

- Keep your lathe and cutting tools well-maintained to maximize their performance and longevity.

Conclusion

Mastering the formula for RPM on a lathe is a vital skill for any machinist. Understanding the relationship between cutting speed, workpiece diameter, and RPM enables you to achieve precise results and prolong the life of your tools. By considering the material being machined, the cutting tool type, and the desired surface finish, you can further optimize the RPM for your specific application. Remember to rely on manufacturer guidelines, experiment with conservative settings, and monitor the cutting process for best results. So, the next time you step in front of your lathe, you can confidently calculate the RPM and create impeccable machined parts.

Key Takeaways: What Is the Formula for RPM on a Lathe?

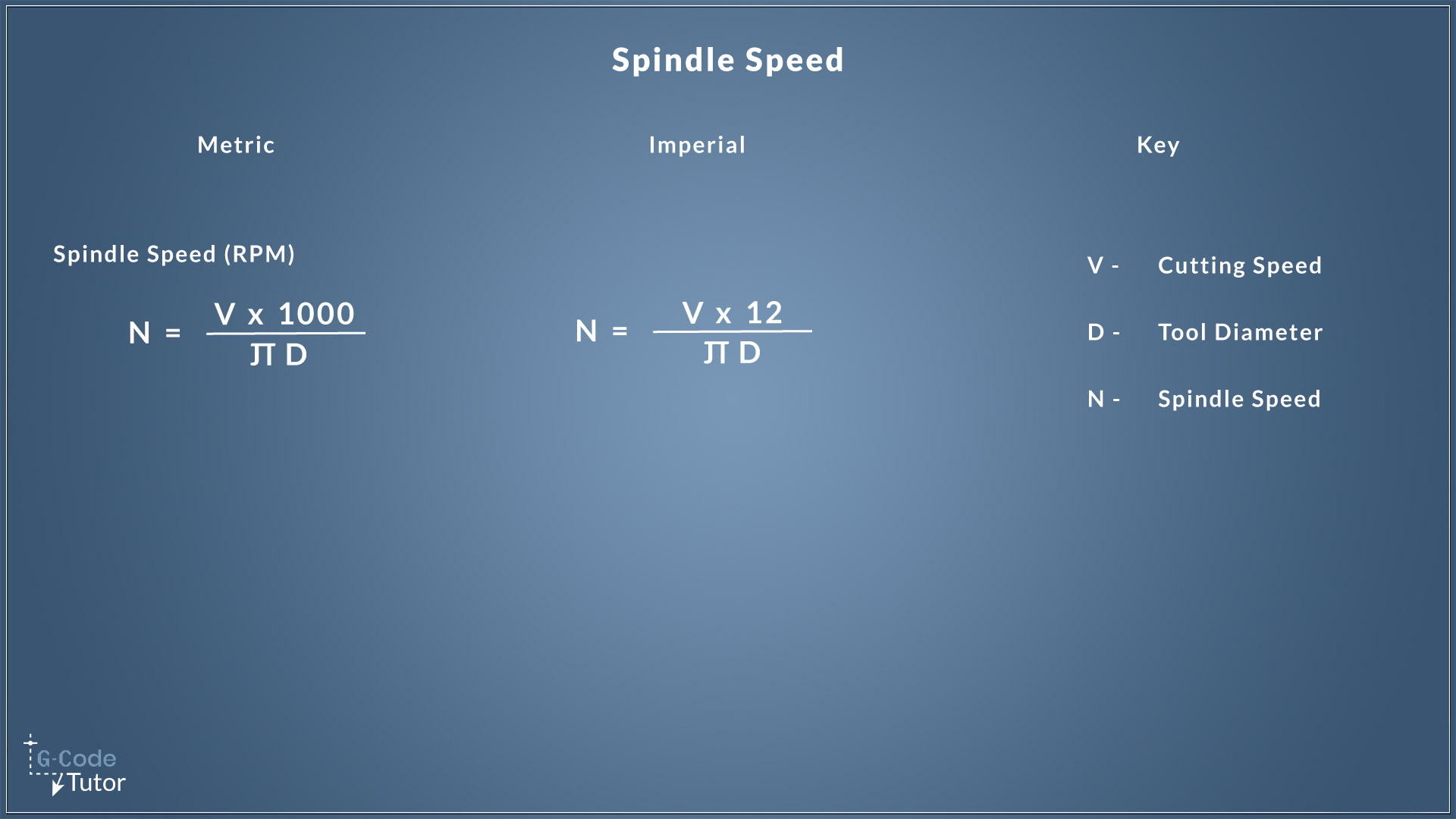

- The formula for calculating RPM (Rotations Per Minute) on a lathe is: RPM = (Cutting Speed * 12) / (Pi * Diameter)

- Cutting speed refers to how fast the material moves past the cutting tool.

- Diameter is the measurement across the lathe workpiece.

- The formula helps determine the ideal RPM for achieving the desired cutting speed and precision.

- Understanding the formula for RPM on a lathe is important for optimizing the machining process and achieving quality results.

Frequently Asked Questions

In this section, we will answer some commonly asked questions about calculating RPM on a lathe.

Question 1: How do you calculate RPM on a lathe?

Calculating RPM (Revolutions Per Minute) on a lathe is done using a simple formula. You need to divide the cutting speed by the circumference of the workpiece. The formula is:

RPM = (Cutting Speed / (π x Diameter)) x 12

Where the cutting speed is measured in surface feet per minute, the diameter is the diameter of the workpiece or the effective diameter, and π is a mathematical constant approximately equal to 3.14159.

Question 2: What is the cutting speed on a lathe?

The cutting speed on a lathe refers to the speed at which the workpiece moves in relation to the cutting tool. It is usually measured in surface feet per minute (SFM). The cutting speed depends on various factors like the material being machined and the type of tool being used. To determine the cutting speed, you can consult reference tables or use cutting speed calculators that are readily available online or in machining handbooks.

Remember that the cutting speed should be appropriate for the material being machined to ensure efficient and accurate results. Using the correct cutting speed helps in achieving the desired surface finish and prolongs the tool’s lifespan.

Question 3: What factors should you consider when calculating RPM on a lathe?

When calculating RPM on a lathe, there are a few factors you need to consider. First, you need to know the cutting speed, which is determined by factors like the material being machined and the tool being used. You also need to know the diameter of the workpiece or the effective diameter if you are using special tools or inserts.

Additionally, it’s important to consider the desired surface finish, the type of lathe being used, and any manufacturer recommendations or guidelines. The RPM calculation may vary based on the specific lathe and its capabilities.

Question 4: Why is calculating RPM important in lathe operations?

Calculating RPM is crucial in lathe operations because it helps determine the speed at which the workpiece should rotate. Choosing the correct RPM is essential for achieving desired and precise results. If the RPM is too low, it may result in a poor surface finish or cause the cutting tool to rub instead of cutting. On the other hand, if the RPM is too high, it may cause the tool to wear out quickly or result in unwanted vibrations.

By calculating the RPM, you can ensure that the lathe is operating at the optimal speed, promoting smooth cutting, prolonging tool life, and achieving high-quality results.

Question 5: Are there any online resources available to help calculate RPM on a lathe?

Yes, there are various online resources available to help calculate RPM on a lathe. Many machining websites, tool manufacturers, and online forums provide RPM calculators that take into account different variables like cutting speed, material, and diameter. These calculators simplify the process by automatically applying the appropriate formula and generating RPM values based on the inputs provided.

Additionally, you can find machining handbooks and reference tables that offer recommended cutting speeds and RPM values for different materials and tools. These resources serve as valuable references, providing a wealth of information for machining operations.

Summary

Calculating the RPM on a lathe is important for controlling the speed of rotation. The formula for RPM is simple: divide the cutting speed by the circumference of the workpiece.

To find the cutting speed, multiply the spindle speed by the circumference’s diameter. Then, divide this value by the desired surface footage. Remember, the surface footage is the speed at which the material moves past the tool. By using this formula, you can adjust the RPM to ensure safe and efficient machining on a lathe.