Are you curious about the function of a quick-change gearbox on an engine lathe? Well, let me break it down for you in a way that’s easy to understand!

Imagine you’re just starting your woodworking or metalworking journey, and you’ve got an engine lathe in front of you. But here’s the thing: you need to change the gears inside the machine to adjust the speed for different tasks. That’s where the quick-change gearbox comes into play!

You see, the function of a quick-change gearbox is to make your life easier by allowing you to switch between different speeds effortlessly. No more fumbling around with individual gears and wasting precious time. With this ingenious device, you can swiftly adjust the speed to match the specific task at hand with just a few simple adjustments.

So, whether you’re turning metal or shaping wood, the quick-change gearbox ensures that you have the right speed setting for optimal results. With this nifty feature, you can tackle various projects efficiently and unleash your creativity without any unnecessary hassle. So, let’s dive deeper into how this gearbox works and why it’s so essential in the world of lathes!

What is the Function of a Quick-Change Gearbox on an Engine Lathe?

Introduction:

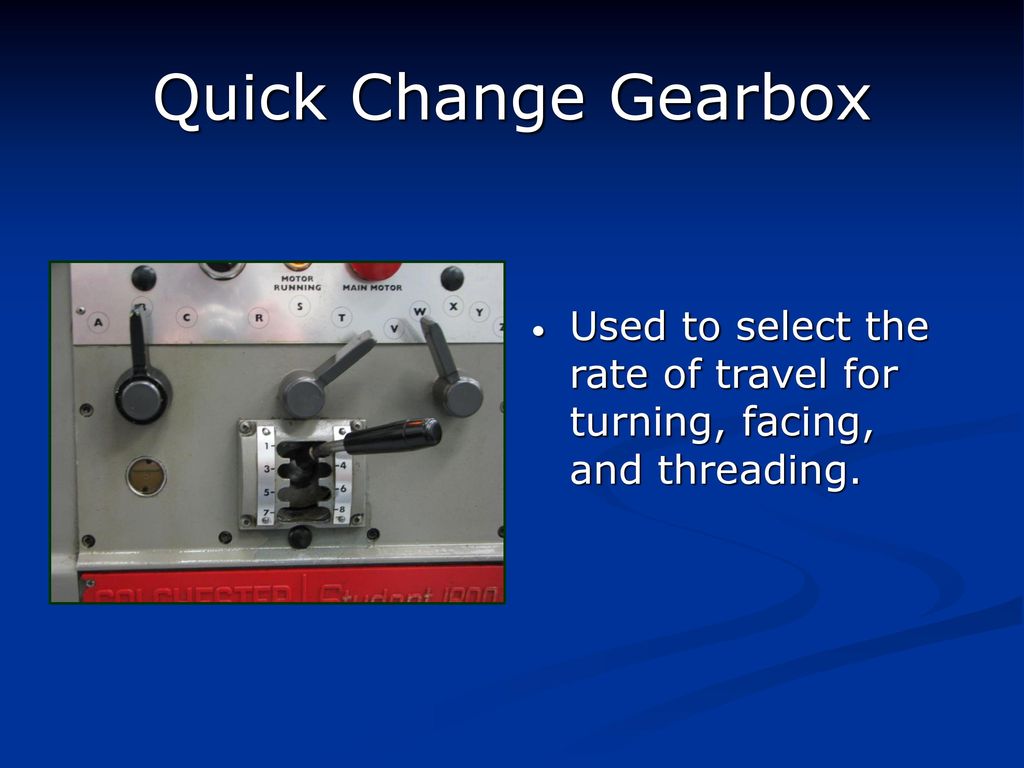

A quick-change gearbox is an essential component of an engine lathe that allows for rapid and accurate changes in the rotational speed of the workpiece. This versatile mechanism optimizes the lathe’s performance, facilitating the machining process by providing a convenient way to adjust the cutting speed, thread pitches, and feed rates. In this article, we will delve into the details of the function and importance of a quick-change gearbox on an engine lathe, exploring its benefits, features, and tips for optimal use.

The Importance of a Quick-Change Gearbox

Introduction:

The quick-change gearbox is a vital aspect of an engine lathe, enabling the operator to change the rotational speed of the workpiece quickly and easily. By offering multiple gear ratios in a single device, it eliminates the need for time-consuming manual gear changes, allowing for more efficient and precise machining operations. Let’s dive into the reasons why the quick-change gearbox is indispensable in an engine lathe.

Enhanced Efficiency and Productivity

Paragraph 1:

One of the primary functions of a quick-change gearbox is to optimize the cutting speed of the workpiece in relation to the material being machined. Different materials require varying cutting speeds to achieve the desired surface finish and prevent tool wear. With a quick-change gearbox, an operator can quickly adjust the gear ratio to select the appropriate cutting speed for the specific material, reducing the time spent on manual gear changes and increasing overall efficiency.

Paragraph 2:

Moreover, a quick-change gearbox allows for the easy selection of various thread pitches. This is especially crucial when machining threads on workpieces. By simply adjusting the gear ratio within the gearbox, an operator can quickly switch between different thread pitches without the need for complex calculations or time-consuming manual adjustments. This feature significantly enhances productivity, especially when dealing with large-scale production runs or frequent thread changes.

Paragraph 3:

Furthermore, the quick-change gearbox facilitates the adjustment of feed rates. When machining complex shapes or profiles, it is essential to control the rate at which the cutting tool advances across the workpiece. With a quick-change gearbox, an operator can modify the feed rate quickly and accurately to achieve the desired precision and surface finish. This flexibility allows for better control over the machining process, resulting in improved productivity and higher-quality workpieces.

Precision and Accuracy

Paragraph 1:

Another crucial function of a quick-change gearbox is to provide precise and accurate speed changes. By incorporating a robust and well-calibrated mechanism, the gearbox ensures consistent and reliable speed adjustments, eliminating any fluctuations in the rotational speed of the workpiece. This precision is vital, as it directly affects the dimensional accuracy, surface finish, and overall quality of the machined part.

Paragraph 2:

The quick-change gearbox minimizes the potential for human error during manual gear changes. With predefined gear ratios and clear indicators, an operator can easily and quickly select the desired speed setting without the risk of inaccurate calculations or misalignments. This eliminates the chances of costly mistakes and ensures that the lathe operates at the correct speed for every machining operation.

Paragraph 3:

Furthermore, the quick-change gearbox plays a significant role in achieving consistent thread pitches. By offering various gear ratios specifically designed for threading operations, it ensures precise thread profiles and accurate thread pitch measurements. This level of accuracy is critical, especially in applications where threaded components need to fit together precisely or meet certain industry standards.

Convenience and Versatility

Paragraph 1:

The quick-change gearbox adds a level of convenience and versatility to an engine lathe that significantly enhances its performance. By eliminating the need for manual gear changes, operators can save valuable time and effort, allowing for more efficient machining processes. This is particularly advantageous in a production environment where reducing setup time and increasing throughput are essential.

Paragraph 2:

Additionally, the quick-change gearbox enables rapid adjustments to different machining operations. It provides a range of gear ratios for specific applications such as facing, turning, threading, or knurling, allowing for quick and seamless transitions between different machining processes. This versatility ensures that the engine lathe can handle a wide range of workpiece materials, shapes, and sizes without the need for complex and time-consuming gear changes.

Paragraph 3:

Moreover, some quick-change gearboxes offer additional features such as tapers and metric to imperial conversions. These added functionalities provide even more flexibility for the operator, enabling them to tackle a broader range of machining tasks and work with various international standards. This convenience and versatility make the quick-change gearbox a valuable asset in any machine shop.

Additional H2 Headings:

Benefits of Using a Quick-Change Gearbox on an Engine Lathe

Quick-Change Gearbox vs. Manual Gear Change: A Comparison

Tips for Optimizing the Use of a Quick-Change Gearbox

Key Takeaways: The Function of a Quick-Change Gearbox on an Engine Lathe

- A quick-change gearbox on an engine lathe allows for easy and efficient gear shifting.

- It enables operators to quickly adjust the rotational speed of the lathe to suit different machining tasks.

- The gearbox eliminates the need to manually change gears, saving time and effort.

- With a quick-change gearbox, operators can switch between various speed settings without interrupting the machining process.

- This feature is especially useful for turning operations that require different cutting speeds for different materials or workpiece sizes.

Frequently Asked Questions

Welcome to our Frequently Asked Questions section, where we’ll explore the function of a quick-change gearbox on an engine lathe. Discover how this essential component improves efficiency and flexibility in metalworking processes.

1. How does a quick-change gearbox benefit an engine lathe?

The function of a quick-change gearbox on an engine lathe is to provide the operator with a convenient way to adjust the rotational speed of the workpiece. With a traditional gearbox, changing the gears manually would require considerable time and effort. However, a quick-change gearbox allows for easy and swift gear changes, saving valuable production time and enhancing overall productivity.

By providing a wide range of gear ratios, the quick-change gearbox enables the operator to select the appropriate speed for various machining operations. This flexibility allows for precise control, ensuring optimal cutting conditions, improved accuracy, and reduced wear on cutting tools. The convenience and versatility of a quick-change gearbox greatly enhance the efficiency of an engine lathe.

2. Can you explain how a quick-change gearbox works on an engine lathe?

A quick-change gearbox works by employing a system of gears and gears trains to transmit power from the lathe’s motor to the spindle. The gears in the gearbox have different numbers of teeth, which determines the speed at which the workpiece rotates. The operator can select the desired gear ratio by engaging specific gears in the gearbox.

Unlike a traditional gearbox, where changing gears would involve manually swapping gears on a shaft, a quick-change gearbox simplifies the process. It typically features a mechanism that allows the operator to engage or disengage gears quickly and effortlessly. This efficient gear changing mechanism reduces downtime and enables the operator to adapt the lathe to various machining tasks swiftly.

3. What are the advantages of using a quick-change gearbox on an engine lathe?

Using a quick-change gearbox on an engine lathe offers several advantages. Firstly, it saves time, as the operator can quickly switch between gear ratios without needing to disassemble or reassemble various parts of the lathe. This time-saving feature increases the overall efficiency of the machining process, allowing for faster production times.

Furthermore, a quick-change gearbox enhances precision by offering a wide range of selectable gear ratios. This enables the operator to precisely control the rotational speed, resulting in better surface finishes and improved dimensional accuracy. The flexibility provided by the quick-change gearbox also allows for experimentation and optimization of cutting parameters, leading to improved machining outcomes.

4. Can a quick-change gearbox be retrofitted onto an existing engine lathe?

In some cases, it is possible to retrofit a quick-change gearbox onto an existing engine lathe. However, it is essential to consider the design and compatibility of the specific lathe model. Retrofitting a quick-change gearbox may require modifications to the lathe’s structure and components, which can be a complex and time-consuming process.

Before proceeding with a retrofit, it is advisable to consult with a qualified technician or the lathe manufacturer to ensure compatibility and feasibility. They can assess the lathe’s design, inspect any potential challenges, and recommend the most suitable approach. Retrofitting a quick-change gearbox can breathe new life into an older lathe, providing increased functionality and efficiency.

5. Are there different types of quick-change gearboxes available for engine lathes?

Yes, there are different types of quick-change gearboxes available for engine lathes, each with its own set of features and advantages. Some common types include lever-action gearboxes, sliding gearboxes, and self-indexing gearboxes. These gearboxes offer varying degrees of ease and speed when it comes to changing gears, allowing operators to choose the option that best suits their specific needs and preferences.

It’s important to note that the availability of different types of quick-change gearboxes may vary depending on the specific lathe manufacturer and model. It’s always recommended to consult the lathe’s user manual or reach out to the manufacturer for information on compatible quick-change gearbox options.

A quick-change gearbox on an engine lathe is a handy tool that helps make our work easier. It allows us to quickly switch between different cutting speeds and feeds. This means we can work on various materials without wasting time changing gears manually. The gearbox also helps protect the lathe’s gears, extending its lifespan. With the right gear selection, we can achieve smooth and precise cuts, making our projects turn out great!

In addition to its speed and versatility, a quick-change gearbox improves safety by reducing the risk of accidents and injuries. By eliminating the need to manually change gears, we can focus more on our work and less on the mechanics. This allows us to maintain better control and avoid mistakes. So, next time we see a lathe with a quick-change gearbox, we’ll know it’s an essential part that keeps things running smoothly and helps us create amazing things!