What is the gullet on a bandsaw blade? Well, let’s dig in and find out! 🕵️♂️

Imagine a bandsaw blade as a superhero slicing through wood, metal, or any material it encounters. The gullet is like the blade’s trusty sidekick, providing the space for chips and debris to escape. 🦸♂️💨

This little indentation between the teeth of the blade might seem insignificant, but it plays a vital role in ensuring smooth and efficient cutting. So, buckle up and let’s explore the fascinating world of the gullet on a bandsaw blade! 🚀

What is the Gullet on a Bandsaw Blade?

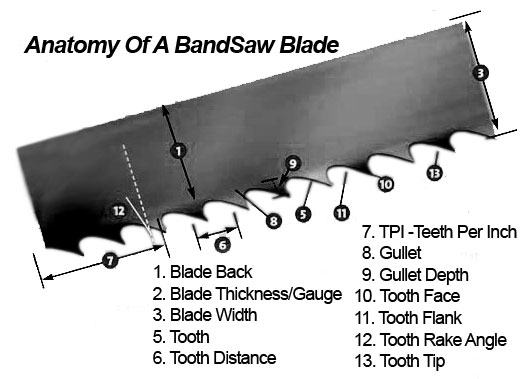

The gullet on a bandsaw blade is an integral part of the blade that plays a crucial role in its cutting performance. Located between the teeth, the gullet is the space or void that allows for the efficient removal of the material being cut. It acts as a channel for chip evacuation during the cutting process.

The gullet shape and size are essential factors that impact the blade’s cutting ability. In most bandsaw blades, the gullet is curved or rounded at the bottom, resembling a concave shape. This design allows for efficient chip evacuation and prevents clogging. The depth and width of the gullet can vary depending on the type of material being cut and the specific application of the bandsaw blade.

The gullet’s primary function is to carry the chips or waste material away from the cutting area to prevent the blade from binding or getting stuck. By providing ample space for chip evacuation, the gullet ensures that the blade remains unobstructed during the cutting process, allowing for smooth and efficient cutting.

Importance of Gullet Design

The design of the gullet greatly influences the performance of the bandsaw blade. The size and shape of the gullet impact the blade’s ability to cut different materials effectively. For example, when cutting hard or dense materials, a deeper and wider gullet allows for efficient chip removal and prevents the blade from getting overloaded.

On the other hand, when cutting softer materials, a shallower gullet can be sufficient as the chips produced are smaller and easier to evacuate. The precise design of the gullet geometry depends on the specific cutting application, whether it is ripping, cross-cutting, or resawing.

In addition to chip evacuation, the gullet design also affects the blade’s ability to dissipate heat generated during the cutting process. A well-designed gullet can help prevent heat build-up, which can reduce blade life and affect cutting accuracy. Adequate space in the gullet allows for better air circulation and cooling, leading to improved cutting performance and blade longevity.

Factors Affecting Gullet Design

Several factors need to be considered when determining the optimal gullet design for a bandsaw blade:

1. Material Type: Different materials have varying chip formations and properties. Harder materials require a larger gullet to accommodate larger chips, while softer materials can have smaller gullets.

2. Blade Width: Wider blades generally have larger gullets to allow for efficient chip evacuation. Narrower blades may have smaller gullets to maintain stability and prevent fatigue.

3. Tooth Set: The tooth set refers to the alternating bending of the teeth left and right. The gullet design should be compatible with the tooth set to ensure smooth chip removal.

4. Feed Rate: The feed rate at which the material is pushed into the bandsaw blade affects the chip formation and evacuation. The gullet design should accommodate the appropriate feed rate for optimal performance.

5. Blade Tension: Proper blade tension is crucial for the gullet to function effectively. Insufficient tension can cause the blade to lose its cutting ability and limit chip removal.

In conclusion, the gullet on a bandsaw blade is a critical feature that facilitates efficient chip evacuation during the cutting process. Its design, including shape, depth, and width, must be carefully considered to optimize the blade’s performance for different cutting applications and materials. By ensuring proper chip removal and heat dissipation, the gullet contributes to precise cuts, prolonged blade life, and enhanced overall cutting performance.

Key Takeaways: What is the Gullet on a Bandsaw Blade?

- The gullet is the curved space between the teeth on a bandsaw blade.

- Its main purpose is to carry away the sawdust and chips generated during the cutting process.

- The size and shape of the gullet affect the blade’s ability to remove debris efficiently.

- A larger gullet can handle larger debris and prevent clogging, making the cutting process smoother.

- The gullet depth should be balanced with the width and pitch of the teeth for optimal performance.

Frequently Asked Questions

Welcome to our FAQ section all about bandsaw blades! In this section, we will dive into the world of bandsaw blades and explore the gullet, an essential part of these blades. Read on to learn more!

1. What is the purpose of the gullet on a bandsaw blade?

The gullet on a bandsaw blade plays a crucial role in the cutting process. It is the space between the teeth of the blade that helps remove the excess material while cutting. When the blade makes contact with the material, the gullet allows space for the chips and sawdust to escape, preventing clogging and ensuring a smooth and efficient cut. Think of the gullet as the “highway” that carries away the debris generated during cutting.

Additionally, the size and shape of the gullet influence the blade’s performance. The gullet’s design allows for efficient chip removal, reduces heat buildup, and minimizes the chance of the blade getting stuck or breaking during cutting. It is a critical part of the bandsaw blade that contributes to its overall cutting effectiveness.

2. How does the gullet size affect the bandsaw blade’s performance?

The size of the gullet on a bandsaw blade has a direct impact on its performance. Generally, blades with larger gullets can remove more material and are better suited for aggressive cutting tasks. They are particularly useful when cutting thick or dense materials since they can quickly clear out the chips and sawdust.

On the other hand, blades with smaller gullets are better suited for more intricate or delicate cutting operations. These blades excel at making precise cuts and are commonly used when working with thinner materials. The smaller gullets allow for a smoother cutting experience and reduce the risk of damaging the material being cut.

3. How can I determine the right gullet size for my bandsaw blade?

Choosing the right gullet size for your bandsaw blade depends on various factors, including the type of material you’ll be cutting and the desired cutting speed. As a general guideline, for heavy and tough materials, opt for blades with larger gullets.

Consult the manufacturer’s recommendations for your bandsaw machine, as they often provide guidance on the ideal gullet size for different applications. Additionally, considering the thickness and density of the material can help you determine whether a larger or smaller gullet will be more suitable for the job.

4. Can gullet design affect the quality of the cut?

Yes, the gullet design can indeed impact the quality of the cut. Different gullet designs are optimized for specific cutting tasks and materials. For example, blades with deep and angled gullets are better equipped to handle aggressive cuts in thick and dense materials, resulting in faster and more efficient cutting.

Blades with shallow gullets, on the other hand, are often preferred for making smoother cuts in thinner materials, as they provide better chip clearance and reduce the risk of overheating. It’s essential to choose a gullet design that matches your specific cutting needs to achieve optimal cutting performance and the desired quality of the cut.

5. How should I maintain the gullet on my bandsaw blade?

Maintaining the gullet on your bandsaw blade is crucial to ensure its longevity and cutting performance. Regular cleaning is essential to prevent buildup of debris and sawdust in the gullets, which can negatively impact the blade’s effectiveness.

After each use, inspect the gullets and remove any accumulated residue using a soft brush or compressed air. This will help keep the gullets clear and prevent clogging during future cuts. Additionally, following the manufacturer’s guidelines for proper blade maintenance and usage will contribute to the overall care and longevity of the gullets on your bandsaw blade.

Summary

So, to sum it up, the gullet on a bandsaw blade is the space between the teeth. It helps with chip removal and allows for smoother cutting. The shape and size of the gullet can affect how well the blade performs. It’s important to choose the right blade for your specific cutting needs. Taking care of the gullet, by cleaning it and using proper cutting techniques, will help prolong the life of your bandsaw blade.