Welcome, curious minds! Have you ever wondered about the angle marked ‘x’ on a chisel? Well, you’re in the right place because today we’re going to dive into the fascinating world of carpentry and explore the name of that elusive angle.

Now, picture this: you’re in a workshop, holding a chisel, and there it is, that mysterious angle labeled ‘x’ on the chisel’s blade. What on earth is it called? Let’s find out together!

In this article, we’ll uncover the name of that angle and delve into its importance in the world of woodworking. So, grab your tool belt and let’s embark on this exciting journey of discovery!

The Angle Marked ‘X’ on a Chisel: What Is It?

Chisels are versatile tools used in various woodworking and metalworking applications. They come in different shapes and sizes, each designed for specific tasks. One notable feature on many chisels is the angle marked ‘X.’ But what exactly is this angle called, and why is it important? In this article, we will explore the name of the angle marked ‘X’ on a chisel and delve into its significance in achieving precise and clean cuts.

The Bevel Angle: Understanding the ‘X’ Marking

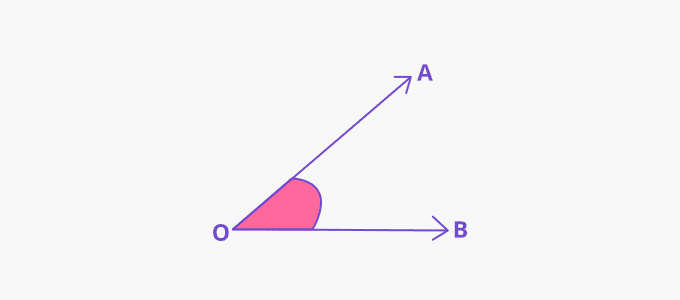

The angle marked ‘X’ on a chisel refers to the bevel angle of the blade. The bevel angle is the angle formed between the chisel’s cutting edge and a reference surface when the tool is laid flat. This angle determines the sharpness of the blade and plays a crucial role in the chisel’s performance.

When you examine a chisel, you will notice that one side of the blade is flat, while the other side is beveled. The flat side, also called the back or the reference surface, is placed against the workpiece during a chiseling operation. The beveled side contains the cutting edge, where the actual cutting action occurs. It is this beveled side that has the angle marked ‘X.’

The angle marked ‘X’ can vary depending on the type of chisel and its intended use. Woodworking chisels usually have bevel angles between 20 and 35 degrees, while chisels used in metalworking often have steeper angles. The angle chosen for the bevel also depends on the type of wood or material being worked on and the desired level of precision and control.

The Importance of the Bevel Angle

The bevel angle plays a significant role in the performance of a chisel. Here are a few reasons why the angle marked ‘X’ is crucial:

- Sharpness: The bevel angle determines the sharpness of the blade. A steeper angle creates a narrower and sharper cutting edge, allowing for finer and more precise cuts. On the other hand, a shallower angle creates a wider cutting edge, which is more durable but may sacrifice some level of precision.

- Control and Maneuverability: The bevel angle affects the chisel’s control and maneuverability. A lower angle offers more control and allows for delicate and precise work, such as creating intricate details or cutting across challenging grain patterns. A higher angle, on the other hand, provides more strength and stability, making it suitable for heavy-duty tasks or working with tougher materials.

- Durability: The bevel angle also influences the chisel’s durability. A higher angle creates a stronger bevel, which can withstand more force and is less likely to chip or break. However, it may require frequent sharpening to maintain optimal performance. A lower angle, while providing excellent cutting performance, may be more susceptible to damage if used improperly or subjected to excessive force.

Choosing the Right Bevel Angle

When choosing the appropriate bevel angle for a chisel, several factors need to be considered:

- Material: The type of material being worked on is an essential factor. Softer woods may require a lower bevel angle for clean and precise cuts, while harder woods may benefit from a higher angle for increased durability.

- Task: The specific task at hand also influences the bevel angle selection. Finer tasks, such as detailed carving or joinery work, often require lower angles for optimal control. Conversely, heavier tasks like heavy-duty chopping or mortising may require higher angles for added strength and stability.

- Experience: The level of experience and skill of the user can also impact the bevel angle choice. Beginners may find it easier to control a chisel with a higher bevel angle, while experienced woodworkers or craftsmen may prefer the precision provided by lower angles.

- Personal Preference: Ultimately, personal preference plays a role in the bevel angle selection. Woodworkers develop their own techniques and preferences over time, and it’s essential to experiment and find what works best for each individual’s style and comfort.

Common Chisel Types and Their Bevel Angles

Now that we have explored the importance of the bevel angle and its impact on chisel performance, let’s take a look at some common chisel types and their typical bevel angles:

Bench Chisels

Bench chisels, commonly used for general woodworking tasks, typically have bevel angles ranging from 25 to 30 degrees. This angle provides a good balance between sharpness and durability, making bench chisels versatile for various applications.

Mortise Chisels

Mortise chisels, designed specifically for cutting mortise joints, often have higher bevel angles, typically between 30 and 35 degrees. The steeper angle provides increased strength and durability, allowing the chisel to withstand the heavy pounding necessary for mortising.

Paring Chisels

Paring chisels, used for delicate and precise tasks such as trimming or fitting joints, usually have lower bevel angles. A bevel angle of around 20 degrees is common for paring chisels, as it provides excellent control and maneuverability when working with tricky grain patterns and intricate details.

Japanese Chisels

Japanese chisels, known for their exceptional sharpness and precision, have unique variations in their bevel angles. Some Japanese chisels have a two-level bevel, with a primary bevel angle ranging from 20 to 30 degrees and a smaller secondary bevel angle between 5 and 10 degrees. This construction allows for quick and easy sharpening, as only the secondary bevel needs to be honed.

Conclusion

The angle marked ‘X’ on a chisel refers to the bevel angle, which plays a vital role in the chisel’s performance, sharpness, control, and durability. The choice of bevel angle depends on factors such as the material being worked on, the specific task, the user’s experience, and personal preference. Understanding the different bevel angles for various chisel types can help woodworkers and craftsmen select the most suitable tool for their projects and achieve the desired results.

Key Takeaways: What is the Name of the Angle Marked ‘x’ of the Chisel?

2. The cutting bevel is the slanted edge of the chisel that comes into contact with the material being cut.

3. The angle of the cutting bevel affects the chisel’s performance and cutting ability.

4. The name ‘x’ is used to represent the angle, and it varies depending on the specific chisel.

5. Understanding the name and purpose of the angle marked ‘x’ helps in using the chisel effectively.

Frequently Asked Questions

In this section, we’ll tackle some common questions related to the angle marked ‘x’ on a chisel.

1. What is the purpose of the angle marked ‘x’ on a chisel?

The angle marked ‘x’ on a chisel, also known as the bevel angle, plays a crucial role in its functionality. This angle determines the cutting performance and the type of material the chisel is best suited for. A sharper bevel angle, such as 20 degrees, is ideal for softer materials like pine or fir. On the other hand, a more obtuse angle, like 30 degrees, will provide better performance on harder woods or metals. Essentially, the bevel angle helps optimize the chisel’s cutting ability for specific applications.

It’s essential to choose the right bevel angle based on the material you’ll be working with. Using the appropriate angle not only enhances the chisel’s efficiency but also minimizes the risk of damaging the tool or the workpiece.

2. How does the angle marked ‘x’ affect the chisel’s cutting edge?

The angle marked ‘x’ on a chisel influences the cutting edge’s performance and durability. A steeper bevel angle, such as 25 degrees or higher, results in a thinner cutting edge. This thin edge excels at slicing through materials cleanly and with less resistance. On the other hand, a shallower bevel angle, around 20 degrees or lower, creates a thicker cutting edge that can withstand more force and is less prone to chipping or breaking.

Choosing the appropriate angle marked ‘x’ depends on the intended application and the material you’ll be working with. For delicate cuts and finer woodworking tasks, a sharper angle may be preferable, while heavy-duty applications may benefit from a more robust cutting edge with a less acute bevel angle.

3. Can I sharpen the angle marked ‘x’ on a chisel?

Yes, you can sharpen the angle marked ‘x’ on a chisel. In fact, regular sharpening is essential for maintaining the chisel’s cutting performance and prolonging its lifespan. When sharpening, it’s crucial to maintain the original bevel angle to ensure optimal cutting efficiency.

Sharpening can be done using various methods, such as sharpening stones, honing guides, or sharpening jigs. Whichever method you choose, it’s important to follow the appropriate technique and maintain a consistent bevel angle across the cutting edge. Regular sharpening not only enhances the chisel’s performance but also reduces the risk of accidents and improves the overall quality of your work.

4. Can a chisel with a different bevel angle still be effective?

Yes, a chisel with a different bevel angle can still be effective, but its performance may vary depending on the application and material. While a chisel with a different angle marked ‘x’ may still cut, it may not achieve the same level of efficiency or precision as one with the recommended bevel angle.

When using a chisel with a different bevel angle, it’s important to consider the material you’re working with and make adjustments accordingly. For example, if you’re using a chisel with a shallower angle on a harder wood, you may need to apply more force or take lighter cuts to achieve the desired results. Experimentation and practice will help you understand how different bevel angles behave in various situations and allow you to adapt your technique accordingly.

5. Can I modify the angle marked ‘x’ on a chisel to suit my needs?

While it is possible to modify the angle marked ‘x’ on a chisel, it’s generally not recommended for most users. Adjusting the bevel angle requires specialized tools and expertise, and any mistakes can result in a chisel that is ineffective or unsafe to use.

If you have specific requirements or unique woodworking needs, it’s best to invest in chisels with different bevel angles, as many manufacturers offer a range of options. This way, you can use the chisel that best suits each specific task without compromising its integrity or performance. Remember, modifying the angle marked ‘x’ should only be attempted by experienced individuals with access to the necessary tools and knowledge.

Find the angles marked with letters

Summary

Alright, so let’s wrap things up and summarize what we’ve learned about the angle marked ‘x’ on the chisel. Basically, this angle helps determine the sharpness of the chisel’s blade. It’s measured by looking at the space between the two sides of the blade and finding the angle formed. The smaller the angle, the sharper the chisel will be. Remember to be safe when using chisels and always ask for help if you’re unsure!

In conclusion, the angle marked ‘x’ on the chisel is important for its sharpness. Smaller angles mean sharper blades, but it’s essential to prioritize safety and ask for guidance if needed. Keep exploring and learning, young woodworking enthusiast!