Are you curious about what the foundation of a lathe is called? Well, look no further! In this article, we’ll unravel the mystery and reveal the name of the foundation upon which a lathe is built. So, let’s dive in and discover this exciting piece of information!

Now, you might be wondering why it’s important to know the name of the foundation. Understanding the foundation is like knowing the backbone of a lathe. It provides stability, support, and balance to the machine, ensuring precision and accuracy in its operations.

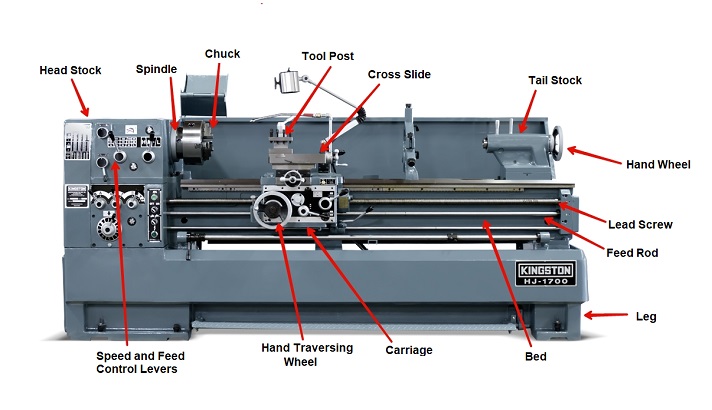

So, what is the name of the foundation upon which a lathe is built? It’s called the “bed.” Just like we have beds to sleep on and relax, a lathe has a bed that serves as its base. The bed is typically a long, horizontal structure made of cast iron or steel, designed to withstand the heavy weight and vibrations of the lathe’s various components.

Now that we know the foundation of a lathe is called the bed, we can appreciate the vital role it plays in the machine’s performance. So, remember this term the next time you come across a lathe and impress your friends with your newfound knowledge!

Understanding the Foundation of a Lathe: A Comprehensive Guide

Introduction:

When it comes to the construction of a lathe, one essential component is the foundation upon which it is built. This foundation provides stability and support to the lathe, ensuring its accurate operation and longevity. In this article, we will delve into the details of this crucial element, exploring its purpose, materials used, and best practices for constructing a solid lathe foundation. Whether you are a professional machinist or a hobbyist with a passion for turning, understanding the importance of a well-built lathe foundation is vital for achieving optimal results.

The Importance of a Stable Lathe Foundation

Paragraph 1:

The foundation of a lathe plays a critical role in its overall performance and accuracy. A stable foundation is essential for minimizing vibrations, which can negatively impact the precision of the lathe’s operations. Vibrations can result in poor surface finishes, inaccuracies in dimensions, and even tool chatter, leading to subpar workpieces. By providing a solid base, the foundation absorbs and dampens vibrations, allowing for smoother and more precise machining.

Paragraph 2:

Additionally, a stable foundation ensures the safety of the operator and the surrounding environment. Lathes can generate considerable forces and torque during operation. Without a sturdy foundation, these forces can cause the lathe to move or tip over, posing a significant risk to anyone in close proximity. By securely anchoring the lathe to a well-designed foundation, potential accidents can be prevented, creating a safer working environment.

Paragraph 3:

Moreover, a stable foundation promotes the longevity of the lathe itself. The structural integrity of the lathe is reliant on a solid base that can handle the weight and forces exerted during operation. Without a strong foundation, the lathe may experience premature wear and tear, leading to frequent breakdowns and the need for repairs or replacements. Investing time and effort into constructing a robust foundation will ultimately save time and money in the long run.

Materials and Construction of a Lathe Foundation

Paragraph 1:

When it comes to choosing the materials for a lathe foundation, several factors need to be considered. The foundation should be made of materials that can provide stability, rigidity, and excellent vibration dampening properties. Common materials used for lathe foundations include reinforced concrete and heavy-duty steel. Reinforced concrete offers durability and can effectively absorb vibrations. On the other hand, heavy-duty steel provides excellent rigidity and strength while reducing potential vibrations.

Paragraph 2:

The construction process of a lathe foundation requires careful planning and execution. Before construction begins, it is crucial to determine the dimensions and weight of the lathe that will be placed on the foundation. This information will help in determining the size, depth, and reinforcement needed for the foundation. It is recommended to consult the manufacturer’s guidelines or seek professional advice to ensure that the foundation meets the specific requirements of the lathe.

Paragraph 3:

Once the dimensions and specifications are determined, the construction of the foundation can begin. The area where the lathe will be installed needs to be prepared by clearing any debris and leveling the ground. The excavation for the foundation should be done to the appropriate depth, allowing for sufficient thickness of concrete or steel reinforcement. After the foundation is poured or installed, it should be properly cured or set before placing the lathe on top. Proper curing ensures maximum strength and stability of the foundation.

Best Practices for Constructing a Lathe Foundation

Paragraph 1:

To ensure the best possible foundation for your lathe, it is important to adhere to certain guidelines and best practices. First and foremost, the foundation should be designed to evenly distribute the weight of the lathe across its surface, avoiding concentrated stress points. This can be achieved by using appropriate reinforcement techniques such as steel bars or fibers within the concrete or reinforcing steel beams for steel foundations.

Paragraph 2:

Additionally, attention should be given to the leveling and alignment of the foundation. The surface of the foundation should be accurately leveled to prevent any tilting or misalignment of the lathe. This can be achieved by using leveling tools and shims during the installation process. Alignment is equally important, as it ensures that the lathe’s components are properly positioned for optimal performance and accuracy.

Paragraph 3:

Lastly, regular inspection and maintenance of the lathe foundation are crucial for its longevity and effectiveness. Inspect the foundation periodically to check for any signs of damage or deterioration, such as cracks or excessive wear. Address any issues promptly to prevent further damage and ensure the continued stability and performance of the lathe. Regularly clean and remove any debris from the foundation area to maintain a safe and clean working environment.

Extra Relevant Information:

Comparing Different Foundation Materials for Lathes

Reinforced Concrete Foundations

Steel Foundations

The Benefits of Using a Well-Constructed Lathe Foundation

Lathe Foundation vs. Mounting on a Bench

Tips for Maintaining a Lathe Foundation

Signs of a Damaged or Inadequate Lathe Foundation

Common Mistakes to Avoid When Building a Lathe Foundation

Key Takeaways: What is the Name of the Foundation upon which a Lathe is Built?

- The foundation upon which a lathe is built is called a lathe bed.

- The lathe bed provides a sturdy and stable base for the lathe machine.

- It is typically made of cast iron for its strength and durability.

- The lathe bed has a flat surface where the other components of the lathe, such as the headstock and tailstock, are mounted.

- A level and properly aligned lathe bed is essential for accurate and precise machining.

Frequently Asked Questions

Are you curious about the foundation upon which a lathe is built? We’ve got you covered with answers to some common questions.

1. How important is the foundation for a lathe?

The foundation is crucial for a lathe. It provides stability and support to ensure smooth and accurate operations. A solid foundation minimizes vibrations that can affect the precision of the lathe’s performance. It also helps reduce the risk of accidents by keeping the machine secure.

When a lathe is installed on a proper foundation, it allows for heavier workpieces and higher cutting forces, expanding the capabilities of the machine. Additionally, a well-built foundation extends the lifespan of the lathe by preventing structural strain and wear due to improper alignment or excessive vibrations.

2. What is the typical material used for the foundation of a lathe?

The most commonly used material for a lathe foundation is concrete. Concrete provides excellent stability and dampens vibrations effectively. Reinforced concrete is often used to handle the weight and forces generated during lathe operations. The amount and type of reinforcement may vary based on the size and weight of the lathe.

Concrete foundations are preferred due to their durability and ability to distribute the weight and vibrations evenly. The foundation needs to be correctly dimensioned, allowing for proper weight distribution and load-bearing capacity to sustain the lathe’s operations and maintain its stability.

3. Can a lathe be placed on any surface without a dedicated foundation?

While it may be tempting to place a lathe on any available surface, it is highly discouraged. Operating a lathe without a dedicated foundation can lead to several issues. Without a proper foundation, vibrations from the machine can be transmitted to the surrounding area, potentially causing damage to nearby structures or affecting the quality of workpieces being machined.

Furthermore, a lathe without a dedicated foundation may experience increased levels of vibrations, resulting in poor machining accuracy and decreased tool life. It is essential to invest in a solid foundation to ensure the lathe’s stability and optimize its performance and longevity.

4. Are there any specific requirements for constructing a lathe foundation?

Yes, there are specific requirements to consider when constructing a lathe foundation. The foundation should be leveled and accurately aligned with the lathe’s axis to ensure proper operation. It should also have sufficient load-bearing capacity, taking into account the weight of the lathe and any additional accessories or workpieces.

The foundation should be free from cracks, voids, or other structural defects. It should be composed of high-quality materials and properly cured to attain maximum strength. It is also crucial to follow the manufacturer’s guidelines for foundation dimensions, reinforcing elements, and the installation process to ensure optimal performance and safety.

5. Can a lathe foundation be modified or repaired if needed?

Modifying or repairing a lathe foundation is possible, but it requires careful planning and execution. Any modifications or repairs should be carried out by professionals experienced in working with lathe foundations. Proper assessment and analysis should be conducted to identify the specific issues and determine the best course of action.

Common repairs may include patching and sealing cracks, reinforcing weaker sections, or leveling the foundation to address any misalignment. Modifications might be needed to accommodate changes in lathe size or additional equipment. It is crucial to consult with experts to ensure that any modifications or repairs are done correctly to maintain the integrity and functionality of the lathe foundation.

Summary

A lathe is built upon a foundation called a lathe bed. The lathe bed provides stability and support for the machine. It is usually made of strong and heavy materials like cast iron or steel. The foundation ensures that the lathe operates smoothly and accurately.

The lathe bed is an essential component of a lathe as it determines the machine’s overall rigidity and stability. It plays a crucial role in preventing vibrations and maintaining precision during machining operations. The lathe bed is carefully designed and manufactured to ensure the lathe’s durability and accuracy. So, the next time you see a lathe, remember that it’s the trusty lathe bed that supports the entire machine!