When it comes to using hand-held power tools, safety should always be a top priority. You might be wondering, “What is the proper safety guard for hand-held power tools?” Well, you’ve come to the right place! In this article, we’ll explore the importance of safety guards and how they can protect you while using these powerful tools.

Using power tools can be exciting, but it’s essential to know how to use them safely. Safety guards are designed to prevent accidents and protect you from potential hazards. Whether you’re using a drill, angle grinder, or circular saw, having the appropriate safety guard can make a significant difference in your safety.

In this article, we’ll dive into different types of safety guards for hand-held power tools and how they function. So, let’s get started and uncover the world of safety guards to keep you protected during your DIY projects or professional tasks.

Understanding the Proper Safety Guard for Hand-Held Power Tools

Hand-held power tools have become essential in various industries, aiding workers in their tasks and increasing productivity. However, it is crucial to prioritize safety when using these tools to prevent accidents and injuries. One of the key safety features of hand-held power tools is the proper safety guard. In this article, we will explore the importance of safety guards, the different types available, and tips for choosing the right one for your specific tool.

The Importance of Safety Guards

Safety guards are designed to protect the user from potential hazards associated with hand-held power tools. These guards act as a barrier between the tool and the user’s body, preventing contact with sharp blades, rotating parts, or flying debris. They are particularly important in reducing the risk of cuts, amputations, and eye injuries.

Moreover, safety guards help to maintain the stability and control of the tool during operation, enhancing overall efficiency and accuracy. They also play a crucial role in keeping the work area clean and free from debris, reducing the chances of accidents caused by slipping or tripping over materials.

Types of Safety Guards

There are several types of safety guards available for hand-held power tools, each designed to cater to different needs and specific applications. Let’s explore some of the common types:

- Blade Guards: These guards are commonly found in circular saws and jigsaws. They cover the exposed portion of the blade and retract automatically when cutting, providing protection against accidental contact.

- Chip Guards: Chip guards are commonly used in routers and planers. They prevent wood chips or particles from being expelled towards the user’s face, reducing the risk of eye injuries and inhalation of hazardous dust.

- Debris Guards: As the name suggests, debris guards are commonly found in power sanders and grinders. They collect and trap debris generated during operation, preventing it from being scattered and minimizing the risk of injuries.

It is important to note that different tools may require specific safety guards. Always refer to the manufacturer’s instructions and safety guidelines to ensure proper usage and compatibility.

Tips for Choosing the Right Safety Guard

Selecting the appropriate safety guard for your hand-held power tool is crucial to ensure optimal protection. Here are a few tips to help you make the right choice:

- Consider the Application: Evaluate the specific tasks and applications you will be using the tool for. Different tasks may require different types of safety guards. Choose one that is suitable for the materials, cutting techniques, and work environment you will be working in.

- Check Compatibility: Ensure that the safety guard is compatible with your specific power tool model. Refer to the manufacturer’s instructions and consult with experts if needed.

- Inspect the Guard: Examine the safety guard for any damages or defects before use. A damaged guard may compromise its effectiveness and put you at risk.

- Easy Installation and Adjustment: Look for safety guards that are easy to install and adjust. A user-friendly design will save you time and effort during setup and make it convenient to adapt to different cutting depths or angles.

- Quality and Durability: Invest in a high-quality safety guard that will withstand regular use and provide long-lasting protection. Cheap or poorly made guards may fail to adequately protect you or wear out quickly.

By following these tips, you can ensure that you have the proper safety guard for your hand-held power tool, enhancing both your safety and productivity.

Maintaining Safety Guards for Optimal Protection

Once you have chosen the appropriate safety guard for your hand-held power tool, it is essential to properly maintain it to ensure ongoing protection. Here are some maintenance tips to keep in mind:

Regular Inspection and Cleaning

Inspect the safety guard before each use, looking for any signs of damage or wear. Make sure it is properly secured and functioning as intended. Additionally, regularly clean the guard to remove any debris or buildup that could obstruct its effectiveness.

Replace Damaged Guards

If you notice any cracks, breaks, or other forms of damage on the safety guard, immediately replace it. Using a damaged guard can compromise your safety and increase the risk of accidents or injuries.

Follow Manufacturer Guidelines

Always refer to the manufacturer’s instructions and guidelines when it comes to maintaining your safety guard. They will provide specific recommendations for cleaning, lubrication, and replacement intervals.

Conclusion

Choosing the proper safety guard for your hand-held power tool is essential in ensuring your safety while operating these tools. Consider the nature of your work, the specific application, and the compatibility of the guard with your tool. Regular inspection, cleaning, and replacement of damaged guards are crucial to maintaining optimal protection. By following these guidelines, you can ensure a safer working environment and reduce the risk of accidents or injuries.

Key Takeaways: What is the Proper Safety Guard for Hand-Held Power Tools?

- Always use a safety guard designed for the specific power tool you’re using.

- Make sure the safety guard is properly attached and secure before operating the tool.

- Regularly inspect the safety guard for any damage or wear and replace if necessary.

- Never remove or disable the safety guard, as it helps protect you from potential hazards.

- Follow the manufacturer’s instructions and guidelines for using the safety guard correctly.

Frequently Asked Questions

Welcome to our Frequently Asked Questions section, where we will address common inquiries regarding the proper safety guards for hand-held power tools. We understand the importance of safety and want to ensure you are well-informed. Read on to find answers to your questions.

1. How do safety guards on hand-held power tools protect users?

Hand-held power tools often have rotating or moving parts that can pose risks to users. Safety guards are designed to prevent accidental contact with these hazards. They act as a barrier between the user and the tool’s blades, disks, or other dangerous components. When properly installed and used, these guards reduce the likelihood of injuries and provide an extra layer of protection. Always make sure the safety guard is in place and functioning before operating a power tool.

Additionally, safety guards on hand-held power tools can help contain debris and sparks that may be generated during use. This helps prevent these hazards from potentially causing harm to the user or those nearby, improving overall safety in the workspace or job site.

2. Are safety guards required by law for hand-held power tools?

Yes, in many jurisdictions, safety guards are mandated by law when using hand-held power tools. The specific regulations may vary, so it’s important to familiarize yourself with the laws and guidelines in your location. These requirements are in place to ensure the safety of workers and minimize accidents and injuries that can occur when using power tools.

Even if not explicitly required by law, it is still highly recommended to use safety guards as a best practice. They are designed to protect users from potential hazards and reduce the risk of accidents, making them an essential safety measure in any work environment.

3. Can safety guards be removed from hand-held power tools?

Safety guards on hand-held power tools are intentionally designed to be difficult to remove. They serve an essential safety function, and removing them compromises user safety. Tampering with or removing safety guards is strongly discouraged and goes against recommended safety guidelines. Doing so increases the risk of accidents and potential injuries.

If you find that a safety guard is damaged or faulty, it is best to have it repaired or replaced by a qualified professional. It is crucial to always ensure the safety guards are in place and properly functioning before using any hand-held power tool.

4. Are there specific safety guards for different types of hand-held power tools?

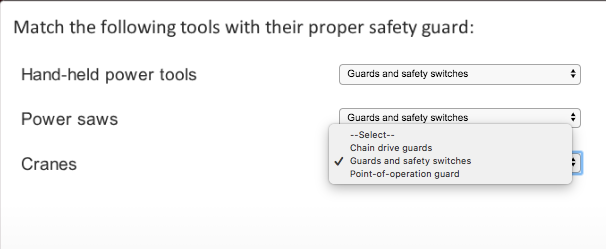

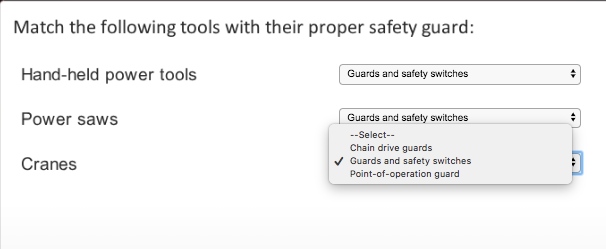

Yes, different types of hand-held power tools may require specific safety guards tailored to their design and functionality. The safety guard for a table saw, for example, will be different from the one used on a handheld circular saw. It is important to consult the manufacturer’s instructions and guidelines for each specific tool to determine the appropriate safety guard to use.

Using the correct safety guard for a particular tool is crucial for ensuring optimum protection and safety. Always follow the manufacturer’s instructions and recommendations when it comes to selecting and installing safety guards on hand-held power tools.

5. Can I modify or customize safety guards to fit my needs?

Alterations or modifications to safety guards on hand-held power tools are strongly discouraged. Safety guards are engineered and tested to provide optimal protection based on the tool’s specific design. Modifying safety guards can compromise their effectiveness and increase the risk of accidents and injuries.

If you have specific needs or concerns regarding a safety guard, it is best to consult the manufacturer or a safety professional. They can provide guidance on alternative methods or recommend suitable safety equipment that addresses your specific requirements without compromising safety.

Summary

When using hand-held power tools, safety guards are essential to prevent accidents and injuries. The type of guard needed depends on the tool being used, but some common examples include adjustable guards, eye shields, and blade guards. These guards help protect our hands and eyes from potential hazards, such as flying debris or accidental contact with moving parts.

It is important to always follow the manufacturer’s instructions for installing and using safety guards correctly. Regularly inspect the guards for any damage and replace them if needed. Remember, safety should always be our top priority when using hand-held power tools to ensure a safe and enjoyable experience.