Have you ever wondered why there’s something called “crowning” on the cutting edge of a chisel? Well, you’re in the right place to find out! In this guide, we’ll explore the purpose of crowning and why it’s an essential feature on a chisel’s cutting edge. So, let’s dive in and discover the fascinating world of woodworking tools!

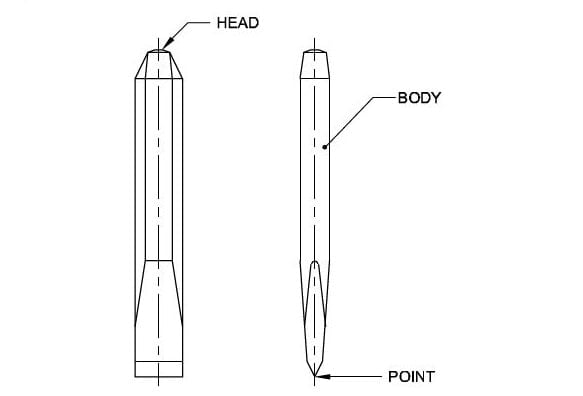

When it comes to woodworking, precision is key, and chisels play a vital role in achieving that. Crowning is a special design feature on the cutting edge of a chisel that sets it apart from other tools. It refers to the slight curvature or convex shape that can be found on the chisel’s bevel. But why is this seemingly small detail so important? Let’s find out!

The purpose of crowning on the cutting edge of a chisel is to ensure better contact with the material being worked on. When you press the chisel against the wood, the crowning allows more concentrated force to be applied to the middle of the cutting edge. This helps prevent the corners of the chisel from digging in too deeply, reducing the risk of gouging or chipping the wood. By distributing the force evenly, crowning helps create cleaner and more precise cuts, making your woodworking projects look professional and polished. So now you know why the crowning on a chisel is a game-changer for woodworkers!

The Purpose of Crowning on the Cutting Edge of Chisel

Introduction: Chisels are widely used tools in woodworking and metalworking, and their cutting performance is crucial for achieving clean and precise results. One important aspect of a chisel’s cutting edge is its crowning. Crowning refers to the intentional convex shape given to the cutting edge of a chisel. This article will explore the purpose of crowning on the cutting edge of chisels, its benefits, and how it affects the tool’s performance.

Why is Crowning Important?

When chiseling, the crowning on the cutting edge of a chisel plays a significant role in its functionality. The convex shape provides several key benefits that contribute to the overall performance of the tool.

1. Improved Control

By adding a slight curvature to the cutting edge, crowning helps distribute the force exerted during a chiseling motion more evenly. This allows for better control and maneuverability, especially when working with intricate or delicate materials. The curved shape also prevents the corners of the chisel from digging too deeply into the surface, reducing the risk of unintended damage.

Additionally, the crowning reduces the contact area between the cutting edge and the material being worked on, resulting in less friction. This reduced friction enables the chisel to glide smoothly through the material, further improving control and precision.

2. Enhanced Durability

The crowning on the cutting edge of a chisel helps to distribute the impact force over a larger area, reducing the stress on any one particular point. This promotes longevity by minimizing the risk of chipping or fracturing the blade’s edge. The curved profile also helps prevent the cutting edge from rolling or becoming dull prematurely, ensuring a longer lifespan for the tool.

Furthermore, crowning allows for effective resharpening. When a chisel is resharpened, the convex shape facilitates the process by guiding the sharpening stone or honing guide across the edge more smoothly and consistently, contributing to the chisel’s durability.

3. Better Chip Removal

The crowning on the cutting edge of a chisel aids in the removal of chips or waste material during the chiseling process. The convex shape helps guide the chips away from the cutting edge, preventing them from getting caught or impeding progress. This ensures that the cutting action remains efficient and minimizes the risk of clogging, which can adversely affect the quality of the workpiece and slow down the chiseling process.

4. Reduced Friction and Easier Entry

The curved cutting edge reduces the contact area between the chisel and the material, resulting in less friction during entry. This allows for smoother and easier penetration into the material being worked on, enhancing user experience and overall efficiency.

In conclusion, the purpose of crowning on the cutting edge of a chisel is to improve control, enhance durability, facilitate chip removal, and reduce friction during entry. These benefits make a chisel with a crowned cutting edge a valuable tool for anyone working with wood, metal, or other materials that require precise and controlled cutting.

Tips for Maintaining and Using Chisels with Crowning

Now that you understand the importance of crowning on the cutting edge of a chisel, here are some tips to help you maintain and make the most out of your chisels:

1. Regular Sharpening

Sharpen your chisels regularly to maintain their cutting performance. The convex shape of the cutting edge may require specialized sharpening techniques, so be sure to research and follow the appropriate methods for sharpening chisels with crowning.

2. Proper Storage

Store your chisels in a dedicated case or rack to protect the cutting edge and prevent accidental damage. Avoid placing them in a way that may cause the crowning to flatten or deform over time, such as storing them with heavy objects pressing down on the cutting edges.

3. Choose the Right Chisel for the Job

When working on a project, select a chisel with the appropriate size, shape, and type of crowning for the task at hand. Different chisels may have varying degrees of crowning, and some may be more suitable for specific applications or materials.

4. Practice and Safety

As with any tool, practice using chisels with crowning to become comfortable and proficient. Always prioritize safety by wearing appropriate protective gear, such as safety glasses or goggles, and be mindful of your hand placement and technique to avoid accidental injuries.

By following these tips, you can ensure the longevity and optimal performance of your chisels with crowning, allowing you to create high-quality woodworking or metalworking projects.

Key Takeaways: What is the purpose of crowning on the cutting edge of a chisel?

- Crowning on the cutting edge of a chisel helps to prevent the tool from digging into the wood too deeply.

- It promotes better control and accuracy when using the chisel for woodworking tasks.

- The crowned cutting edge disperses force more evenly, reducing the risk of chipping or splintering the wood.

- It allows for smoother and cleaner cuts by preventing the chisel from grabbing or catching on the surface.

- Crowning also extends the lifespan of the chisel by reducing wear and tear on the cutting edge.

Frequently Asked Questions

When it comes to the cutting edge of a chisel, crowning plays a crucial role. Let’s explore the purpose of crowning and how it benefits the cutting process.

1. Why is crowning important on the cutting edge of a chisel?

Crowning refers to the slight arc-shaped curve on the cutting edge of a chisel. This design feature is essential for two main reasons. Firstly, it helps to prevent the corners of the cutting edge from digging into the material being worked on. This prevents the chisel from getting stuck or causing damage to the surface. Secondly, the crowning allows for more control over the cutting action by providing a smaller contact area with the material. This helps in making precise and controlled cuts.

Overall, crowning improves the performance and usability of a chisel by enhancing cutting efficiency, reducing the chances of getting stuck, and enabling better control over the cutting process.

2. Can crowning on the cutting edge affect the strength of the chisel?

No, crowning on the cutting edge does not significantly affect the overall strength of the chisel. The curve on the cutting edge is deliberately designed to be subtle and minimal. This means that the structural integrity of the chisel remains intact, allowing it to withstand the forces and pressures associated with cutting or shaping materials.

The crowning is carefully balanced to provide the desired benefits without compromising the strength and durability of the chisel. Manufacturers consider factors like the type of material the chisel will be used on, the intended cutting action, and the expected forces during use. Therefore, you can trust that a properly designed crowning will not compromise the strength of the chisel.

3. Are there different degrees of crowning on chisels?

Yes, there can be variations in the degree of crowning on chisels, depending on the intended application and cutting requirements. Some chisels may have a more pronounced curve on the cutting edge, while others may have a shallower curve. The specific degree of crowning is determined by factors such as the type of material being worked on, the desired cutting action, and the user’s preference.

Deeper crowning may be used for softer materials or when a more aggressive cutting action is required. On the other hand, shallower crowning may be preferred for harder materials or when more control and precision are needed. Ultimately, the degree of crowning can be customized to suit specific cutting needs and achieve optimal results.

4. Do all chisels require crowning on their cutting edges?

No, not all chisels require crowning on their cutting edges. The need for crowning depends on the specific application and the material being worked on. Some chisels, such as carving chisels, may benefit more from crowning due to the need for controlled and precise cuts. However, other types of chisels, like those used for heavy-duty woodworking or construction tasks, may have straight cutting edges without any crowning.

The decision to incorporate crowning on a chisel depends on factors like the desired cutting action, the material properties, and the user’s preferences. It’s important to choose the right type of chisel for the task at hand, considering whether or not crowning is necessary for the specific cutting requirements.

5. Can I modify or add crowning to a chisel myself?

Modifying or adding crowning to a chisel is generally not recommended for most users. Crowning requires careful consideration of various factors, including the material, cutting action, and overall structural integrity of the chisel. It is best left to experienced professionals or manufacturers who can ensure the modification is done accurately and safely.

Furthermore, modifying a chisel without proper knowledge and expertise can lead to negative consequences, such as weakening the chisel, affecting its performance, or causing damage to the material being worked on. If you feel that a specific chisel requires crowning or modification, it is advisable to consult a professional or contact the chisel manufacturer for guidance.

Crown Cryo Colwin Way Signature Skew Chisels – Overview and Projects

Summary

The purpose of crowning on the cutting edge of a chisel is to provide stability and durability. Crowning helps to prevent the chisel from getting damaged or dull too quickly.

When a chisel has a crowned cutting edge, it means that the center of the edge is slightly higher than the edges on the sides. This design distributes the cutting force evenly across the edge, reducing the risk of the chisel breaking or chipping.

Crowning also helps to maintain sharpness for longer periods. By evenly distributing the pressure, the chisel does not wear down as quickly, allowing it to stay sharp and effective for longer.

In summary, crowning on the cutting edge of a chisel is important for stability, durability, and maintaining sharpness. It helps the chisel last longer and perform better, making it an essential feature in woodworking tools.