Have you ever wondered what the quill on a drill press is all about? Well, you’re in luck because we’re about to dive into this fascinating topic! So, what exactly is the quill on a drill press? Let’s find out together!

The quill is a crucial component of a drill press that allows for precise and controlled drilling. It is the part of the drill press that moves up and down, guiding the drill bit into the material being worked on. Think of the quill as the arm that carries the drill bit and helps you achieve accurate drilling depths.

Now, you might be wondering how the quill works. When you turn the handle or use the lever on the drill press, it activates the mechanism that raises or lowers the quill. This movement is adjustable, allowing you to control the depth of your drill holes. It’s like having a magic wand that brings your drilling dreams to life!

So, there you have it – a brief introduction to the mysterious quill on a drill press. Get ready to explore more about how this essential part works and how it enhances your drilling experience. Let’s dive deeper into the world of drill presses and uncover all the secrets of the mighty quill! Ready? Let’s go!

What is the Quill on a Drill Press?

The quill on a drill press is an essential component that allows for precise drilling and depth control. It is a vertical shaft or spindle that holds the cutting tool and can be raised or lowered to adjust the drilling depth. The quill is typically connected to a handle or lever, allowing the user to easily maneuver and control the drilling operation. Understanding the functionality and features of the quill is crucial for achieving accurate and efficient drilling results.

The Functionality of the Quill

The main function of the quill on a drill press is to control the drilling depth. When the quill is raised or lowered, it moves the cutting tool in a vertical direction, allowing for precise and consistent drilling. The quill is equipped with a depth stop mechanism, which ensures that the cutting tool does not exceed the desired depth.

Additionally, the quill serves as a guide for the cutting tool. It helps to stabilize the tool and prevent it from drifting or moving during the drilling process. This is especially important when drilling through tough or hard materials, as any movement can lead to inaccuracies or damage to the workpiece.

Components of the Quill

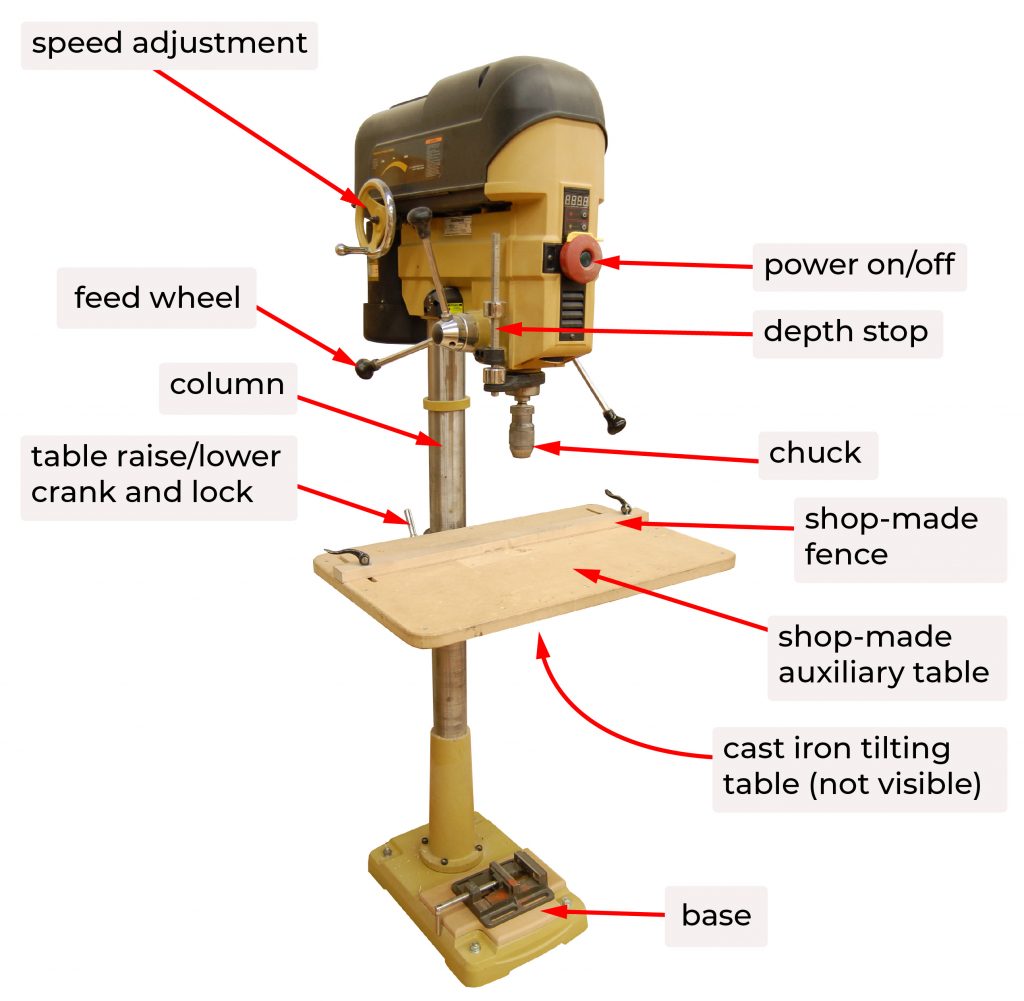

The quill consists of several components that work together to provide smooth and controlled drilling operations. These components include:

1. Spindle: The spindle is the upper part of the quill that holds the cutting tool. It is designed to securely grip the tool and ensure that it remains in place during drilling.

2. Quill Housing: The quill housing is the main body of the quill and provides support and stability to the spindle. It is usually made of durable materials such as cast iron or steel to withstand the forces generated during drilling.

3. Depth Stop: The depth stop mechanism allows the user to set a specific drilling depth and ensures that the quill does not exceed this limit. It can be adjusted using a depth stop collar or a depth stop rod, which limits the movement of the quill when the desired depth is reached.

4. Feed Handles: The feed handles are attached to the quill and allow the user to raise or lower it. They provide a comfortable grip and enable precise control over the drilling depth and speed.

Advantages of Using a Drill Press Quill

Using a drill press with a quill offers several advantages compared to other types of drilling machines or manual drilling methods. These advantages include:

1. Accuracy and Precision: The quill on a drill press allows for precise control over the drilling depth, resulting in accurate and consistent holes. This is especially important when drilling multiple holes that need to be aligned or when working with detailed projects.

2. Ease of Use: The quill’s handle or lever makes it easy to raise or lower the cutting tool, eliminating the need for manual adjustments or complex setups. This allows for quicker and more efficient drilling operations.

3. Safety: The quill’s depth stop mechanism helps prevent the drilling tool from going too deep, reducing the risk of damaging the workpiece or causing accidents. It provides an added layer of safety and control during drilling.

4. Versatility: The quill on a drill press is compatible with a wide range of cutting tools, allowing for versatility in drilling operations. It can accommodate various sizes and types of drill bits, making it suitable for different applications and materials.

In conclusion, the quill on a drill press plays a crucial role in achieving accurate and controlled drilling operations. Its functionality and features enable users to easily adjust the drilling depth and ensure precise results. Understanding the components and advantages of the quill can greatly enhance the efficiency and quality of drilling tasks. Whether you are a professional woodworker, metalworker, or a DIY enthusiast, mastering the quill on a drill press is essential for achieving excellent drilling results.

Key Takeaways: What is the Quill on a Drill Press?

- The quill on a drill press is a movable spindle that holds the drill bit.

- It allows for precise vertical movement of the drill bit.

- By adjusting the quill, you can control the drilling depth.

- The quill is operated by a handle or lever on the drill press.

- Understanding the role of the quill is important for safe and accurate drilling.

Frequently Asked Questions

Curious about the quill on a drill press? Look no further! Below, we answer some of the most common questions about this essential component of a drill press.

How does the quill on a drill press work?

The quill on a drill press is a vertically movable part that holds the cutting tool. It is connected to the spindle, which provides the rotational movement to the drill bit. When you lower the quill, it brings the drill bit down, allowing it to penetrate the material you’re working on. By lifting the quill, you can retract the drill bit from the material.

The quill is equipped with a mechanism that allows you to adjust its depth of travel and lock it in place at a specific position. This feature ensures precise drilling and makes it easier to control the depth of the holes you are creating.

What is the purpose of the quill travel on a drill press?

The quill travel on a drill press refers to the unrestricted vertical movement of the quill. It allows you to adjust the depth at which the drill bit penetrates the material. By controlling the quill travel, you can create holes of varying depths, accommodating different project requirements.

The ability to set the quill at different depths is particularly useful when drilling holes for things like dowels or screws. It ensures that the holes are the correct depth and size, preventing them from going too deep or not deep enough. The quill travel feature also helps improve overall drilling accuracy.

Can the quill on a drill press be replaced?

Yes, in most drill presses, the quill can be replaced if it becomes damaged or wears out. However, the process of replacing the quill can vary depending on the model and manufacturer. It typically involves disassembling the drill press and carefully removing the old quill before installing the new one.

If you need to replace the quill on your drill press, it’s best to consult the manufacturer’s instructions or seek guidance from a professional. They can provide you with specific steps and ensure that the replacement is done correctly, preserving the functionality of your drill press.

What are the common materials used for quills on drill presses?

Quills on drill presses are commonly made from sturdy materials such as hardened steel or cast iron. These materials provide the necessary strength, rigidity, and durability to withstand the high forces and rotational movements involved in drilling operations.

Steel quills are often preferred for their excellent resistance to wear and ability to maintain precision over time. Cast iron quills, on the other hand, offer exceptional stability and reduce vibrations during drilling, contributing to higher accuracy. The material used for the quill may vary depending on the drill press model and its intended use.

Are all drill presses equipped with a quill?

Most drill presses come equipped with a quill as an integral part of their design. The quill is essential for the vertical movement and control of the drill bit, allowing for precise drilling operations. However, there may be some specialized drill press models or variations that function without a quill. These models may be tailored for specific applications or have unique drilling mechanisms that don’t require a traditional quill setup.

When choosing a drill press for your needs, it’s important to consider whether having a quill is necessary for the types of projects you’ll be working on. For general drilling purposes, a drill press with a quill is typically the most versatile and reliable option.

Summary

The quill on a drill press is the part that holds and moves the drill bit. It allows you to control the depth of the hole you’re drilling. The quill is attached to the spindle, which rotates the drill bit to create the hole. By adjusting the quill’s position, you can drill holes at different depths. Make sure to always secure the workpiece properly before drilling to prevent accidents. Keep in mind that the quill can be adjusted up and down to accommodate different height workpieces. Always follow safety guidelines and wear protective equipment when using a drill press.