When it comes to power drills, have you ever wondered what role torque plays? Well, let’s uncover the mystery together! So, what is torque in a power drill? In simple terms, torque refers to the twisting force that a power drill generates to drive screws or drill holes. It determines the drill’s strength and ability to tackle different materials. But there’s more to it, so let’s dive deeper and understand how torque impacts your drilling experience!

Imagine this: you’re working on a DIY project or fixing something around the house, and you need a power drill that can handle the job efficiently. That’s where torque comes into play. Torque in a power drill determines its ability to overcome resistance and deliver the necessary power. It’s like having a superhero strength that helps you conquer any drilling task effortlessly!

Now, let’s get into the technical aspect. Torque is measured in pounds per inch (lb-in) or Newton meters (Nm). The higher the torque value, the more force the drill can exert. This means you can effortlessly drive screws into tough materials like hardwood or bore holes in solid surfaces. So, when you’re choosing a power drill, make sure to consider the torque rating to ensure it matches your drilling needs. With the right torque, you’ll be unstoppable in your DIY adventures!

So, now we know that torque in a power drill is the force that gives it the power to drill and drive screws effectively. It’s like the engine that propels your drill to tackle various tasks. Understanding torque is essential for choosing the right power drill for your projects. So, are you ready to unleash the power of torque and take your drilling skills to the next level? Let’s dive in and explore this fascinating aspect of power tools!

What is Torque in a Power Drill?

When it comes to power tools, one term that you often hear is “torque.” But what exactly is torque in a power drill? How does it affect the performance and functionality of the tool? In this comprehensive guide, we will delve into the intricacies of torque and its significance in power drills. Whether you are a DIY enthusiast or a professional, understanding torque will empower you to make informed choices and get the job done efficiently.

Understanding the Basics: What is Torque?

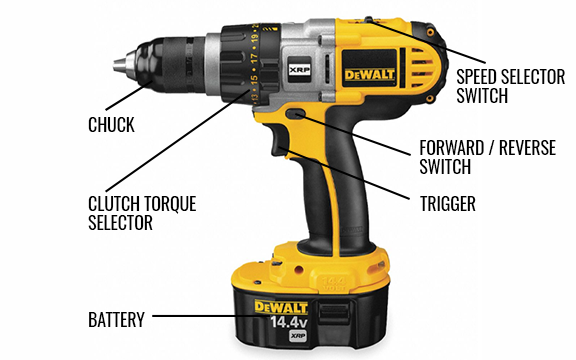

Before delving into the specific role of torque in power drills, it’s essential to understand what torque means in general. Torque refers to the rotational force or the turning effect produced by a power tool, such as a power drill. It is a crucial characteristic that determines the tool’s ability to drive fasteners into different materials. When you apply torque to a power drill, it rotates the chuck and, in turn, the drill bit. The greater the torque, the more force the drill can exert on the material being drilled or fastened.

How Torque is Measured in Power Drills

Torque is measured in units of force multiplied by distance, typically given in inch-pounds (in-lb) or newton-meters (Nm). These measurements indicate the amount of force the drill can exert on a fastener or the resistance it can overcome. When selecting a power drill, you’ll often come across the term “maximum torque” or “torque settings.” These specifications indicate the drill’s maximum rotational force, allowing you to adjust it based on the application or material being worked on. Higher torque settings are suitable for heavy-duty tasks, while lower settings are ideal for delicate materials.

The Importance of Torque in Power Drills

Torque plays a crucial role in the performance and versatility of power drills. Here are some key reasons why torque is essential:

- Driving Power: Torque determines the strength with which a power drill can drive fasteners into various materials. The higher the torque, the easier it is to tackle challenging tasks.

- Efficiency: Greater torque allows the drill to work through materials more efficiently, reducing the time and effort required to complete a task.

- Control: Torque settings allow you to adjust the amount of force applied by the drill, giving you better control over the tool and preventing damage to delicate materials.

- Adaptability: Different materials require different levels of torque. Having a drill with adjustable torque settings ensures you can adapt to various tasks and materials.

Choosing the Right Torque for Your Needs

When selecting a power drill, it’s important to consider the torque requirements of your intended applications. If you primarily work with lightweight materials or engage in precision tasks, a drill with lower torque settings may suffice. However, if you frequently work with dense materials or need the power to drive large screws or bolts, opting for a drill with higher torque capabilities is recommended. Furthermore, be sure to consider the available torque settings to have more control over the tool’s performance.

Tips for Maximizing Torque Efficiency

Here are some tips to ensure you make the most of the torque capabilities of your power drill:

- Use the appropriate torque setting for the material and task at hand.

- Ensure the drill bit or driver bit is properly secured in the chuck to maximize torque transfer.

- Apply steady and consistent pressure to maintain a consistent torque output.

- Keep the drill and chuck well-lubricated to minimize friction and maximize torque efficiency.

- Regularly clean and maintain your power drill to ensure optimal torque performance.

Conclusion

Understanding torque is essential for anyone working with power drills. It determines the tool’s driving power, efficiency, and versatility. By selecting the right torque settings and following the tips mentioned above, you can maximize the performance of your power drill and achieve excellent results in your projects. So, next time you pick up a power drill, remember the torque and its significance in getting the job done effectively and efficiently.

Key Takeaways: What is Torque in a Power Drill?

- Torque is the rotational force or power generated by a power drill.

- It determines the drill’s ability to drive or remove screws, bolts, and other fasteners.

- Higher torque means the drill can handle tougher materials and larger fasteners.

- Choosing the right torque setting ensures proper control and prevents overdriving or stripping screws.

- Understanding torque helps in selecting the right power drill for different applications.

Frequently Asked Questions

In this section, we will explore some common questions related to torque in a power drill.

How does torque affect a power drill’s performance?

Torque is a measure of the twisting force that a power drill can generate. In simple terms, the higher the torque, the more strength the drill has to overcome resistance. This means that a power drill with higher torque will be more efficient at drilling through tough materials like wood or metal, and can handle larger drill bits without losing power. On the other hand, a power drill with lower torque may struggle with demanding tasks or stall easily.

Choosing a power drill with the appropriate torque for your needs is important. For light tasks, like assembling furniture or drilling small holes in soft materials, a lower torque drill may be sufficient. However, for heavy-duty or professional use, such as drilling large holes or driving screws into dense materials, a drill with higher torque would be more suitable.

Can torque be adjusted on a power drill?

Yes, many power drills offer adjustable torque settings. These settings allow you to control the amount of force applied by the drill, which can be useful for different tasks. For example, when using a drill to drive screws into delicate materials, you can adjust the torque to a lower setting to prevent overtightening or damaging the material. Conversely, when drilling into tough materials, you can increase the torque to ensure efficient drilling.

Adjustable torque settings are typically found in cordless power drills, where the motor can generate different levels of torque. This feature provides versatility and allows you to adapt the drill’s performance to suit various applications.

Is higher torque always better in a power drill?

While higher torque may seem advantageous, it is not always necessary or better in every situation. Opting for a power drill with excessive torque may result in additional weight, bulkiness, and increased power consumption. For lighter tasks that do not require significant force, a drill with lower torque can be more practical and easier to handle.

It’s important to consider the specific tasks you will be performing and select a power drill with torque that matches your needs. For most household DIY projects, a power drill with moderate torque should be sufficient. However, for heavy-duty construction or professional use, a higher torque drill would be more suitable.

Are there any risks associated with high torque in a power drill?

Using a power drill with high torque can pose certain risks if not handled properly. One risk is the possibility of the drill bit getting stuck or binding if the torque exceeds the drill bit’s capabilities or encounters resistance from the material being drilled. This can result in the drill jerking or spinning out of control, potentially causing injury.

To minimize these risks, it is important to always use the correct drill bit for the task at hand and ensure that it is securely tightened. Additionally, maintaining a firm grip on the drill and using proper drilling techniques, such as applying steady pressure and keeping the drill aligned, can help prevent accidents. It is also essential to wear appropriate personal protective equipment, such as safety glasses or gloves, when operating a power drill.

Can torque affect the battery life of a cordless power drill?

Yes, the torque setting on a cordless power drill can impact its battery life. Higher torque settings require the drill to exert more power, which in turn consumes more energy from the battery. This means that using a power drill with higher torque settings may result in shorter battery life, requiring more frequent recharging or replacement of the battery.

If battery life is a concern, it is advisable to use the appropriate torque setting for the task at hand. As mentioned earlier, lighter tasks may not require maximum torque, so adjusting the setting to a lower level can help conserve battery power. Additionally, using a high-capacity battery or carrying an extra battery can be beneficial, especially when working on projects that demand extended running time.

Summary

To sum it up, torque is the twisting force that helps a power drill do its job. It determines how well the drill can spin and apply force to screws or drills. Higher torque means more power.

Torque is important because it affects the drill’s ability to handle different tasks. Low torque is good for delicate work, while high torque is needed for tougher jobs. It’s important to match the drill’s torque to the job at hand to ensure efficient and effective drilling.