If you’ve ever wondered what the “y axis” on a lathe is, you’re in the right place! But before we delve into the details, let’s start with the basics. A lathe is a machine used to shape and cut various materials like wood, metal, or plastic. It’s an essential tool for craftsmen and engineers alike. Now, let’s explore what the y axis specifically refers to in the context of a lathe.

When it comes to a lathe, the y axis is one of the axes that allows for movement and precision. Think of it as the vertical or up-and-down motion of the lathe’s cutting tool. With the y axis, you can control the depth and height of the cuts you make, giving you the ability to create intricate and precise designs. It’s like having another dimension of control right at your fingertips!

Having a y axis on a lathe opens up a world of possibilities in terms of design and functionality. It allows craftsmen to create complex shapes and contours, bringing their ideas to life. Whether you’re turning a simple bowl or crafting intricate patterns, the y axis gives you the flexibility to unleash your creativity and achieve the desired results.

Now that you have a better understanding of what the y axis on a lathe is, let’s dive deeper into its functions, how it works, and some practical tips for using it effectively. Get ready to take your lathe skills to the next level as we explore the fascinating world of the y axis!

Exploring the Y-Axis on a Lathe: A Guide for Beginners

When it comes to machining, precision and accuracy are of utmost importance. One of the key features that enable this level of precision is the Y-axis on a lathe. In this guide, we will delve into what the Y-axis is, its significance, and how it is used in the world of machining. Whether you are a novice machinist or simply curious about the inner workings of a lathe, this article will provide you with a comprehensive understanding of the Y-axis and its role in the machining process.

Understanding the Basics of a Lathe

Before diving into the details of the Y-axis, let’s first discuss the basic components of a lathe. A lathe is a machine tool that rotates a workpiece on its axis, allowing for various operations such as cutting, drilling, and shaping. It consists of several key components, including the bed, headstock, tailstock, and carriage. The bed serves as the foundation of the lathe, providing rigidity and support to the other components. The headstock contains the main spindle that rotates the workpiece, while the tailstock is used for additional support. The carriage, on the other hand, holds the cutting tool and facilitates its movement along the lathe bed.

Now that we have a basic understanding of a lathe, let’s turn our attention to the Y-axis, one of the integral axes of a lathe.

The Role of the Y-Axis in a Lathe

The Y-axis, also known as the radial axis, is one of the primary axes in a lathe. It is responsible for the vertical movement of the cutting tool during machining operations. While the X-axis (longitudinal axis) controls the horizontal movement of the cutting tool along the lathe bed, the Y-axis allows for movement perpendicular to the workpiece’s axis. This enables machinists to perform operations such as facing, grooving, and tapering with precision.

By utilizing the Y-axis, machinists can create complex shapes and contours on a workpiece. It provides the freedom to move the cutting tool in multiple directions, resulting in intricate and precise cuts. The Y-axis is particularly crucial when working on cylindrical objects or when machining curved surfaces. Without the Y-axis, achieving such intricate designs would be challenging, if not impossible.

In addition to its role in shaping and cutting operations, the Y-axis also contributes to the overall efficiency and productivity of the machining process. By utilizing the Y-axis along with the other axes of a lathe, machinists can perform multiple operations simultaneously, reducing the time required to complete a job. This enables them to optimize their workflow and deliver high-quality results in a shorter timeframe.

The Mechanism and Control of the Y-Axis

The Y-axis movement in a lathe is controlled by the lead screw and the cross slide. The cross slide is an integral part of the carriage and holds the cutting tool. It can be moved vertically along the Y-axis by the rotation of the lead screw. The lead screw, which is connected to the cross slide, converts the rotational motion of the spindle into linear motion. This allows for precise positioning of the cutting tool along the Y-axis.

In modern lathes, the Y-axis movement is usually controlled through computer numerical control (CNC). CNC lathes utilize motors and servo systems to accurately position the cross slide along the Y-axis. This advanced control system enables machinists to program complex tool paths, ensuring precise and repeatable movements along the Y-axis. CNC lathes have revolutionized the machining industry, providing increased accuracy, efficiency, and ease of use.

In conclusion, the Y-axis plays a vital role in the functionality of a lathe. It enables machinists to perform a wide range of operations with precision and efficiency. By understanding the intricacies of the Y-axis, machinists can unlock the full potential of a lathe and achieve remarkable results in their machining endeavors.

The Advantages of Using the Y-Axis on a Lathe

When it comes to machining on a lathe, the use of the Y-axis brings numerous advantages that contribute to the overall efficiency and precision of the process. In this section, we will explore the benefits of utilizing the Y-axis, highlighting its impact on various machining operations. Whether you are a seasoned machinist looking to enhance your skills or a beginner eager to learn, understanding the advantages of the Y-axis is essential for achieving optimal results in lathe machining.

Improved Versatility and Flexibility

One of the key advantages of the Y-axis on a lathe is the increased versatility and flexibility it offers. With the ability to move the cutting tool vertically, machinists have the freedom to create intricate shapes and contours on a workpiece. This opens up a world of possibilities, allowing for the production of complex parts with precision and ease. From creating grooves and tapers to shaping curved surfaces, the Y-axis enables machinists to tackle a wide range of projects and fulfill diverse customer requirements.

Moreover, the Y-axis facilitates the implementation of multi-axis machining. By combining the Y-axis movement with the X-axis (longitudinal) and Z-axis (cross-slide), machinists can perform complex operations simultaneously. This significantly reduces production time, as multiple cuts can be made in a single pass. The ability to leverage the Y-axis in conjunction with other axes provides machinists with enhanced flexibility and efficiency in their machining endeavors.

Enhanced Accuracy and Precision

Precision is paramount in the world of machining, and the Y-axis plays a significant role in achieving accurate results. By utilizing the Y-axis, machinists can position the cutting tool precisely along the vertical axis, ensuring precise depths of cut and consistent tolerances. This level of control is particularly crucial for operations such as facing and grooving, where accurate positioning of the cutting tool is essential.

In addition, the Y-axis enables the creation of smooth and even curved surfaces. Machinists can manipulate the vertical movement of the cutting tool to gradually shape the workpiece, resulting in a seamless and aesthetically pleasing finish. Whether it’s the production of decorative parts or components that require a high degree of accuracy, the Y-axis plays a crucial role in achieving exceptional results.

Increased Efficiency and Productivity

Time is of the essence in the machining industry, and the Y-axis allows machinists to optimize their workflow and increase overall efficiency. By moving the cutting tool vertically, machinists can perform multiple operations simultaneously, reducing the number of passes required to complete a job. This not only saves time but also minimizes the wear and tear on the cutting tool, prolonging its lifespan.

Furthermore, the Y-axis facilitates the implementation of automated machining processes. With the advancements in CNC technology, machinists can program complex tool paths that incorporate precise movements along the Y-axis. This eliminates the need for manual adjustments and streamlines the machining process, resulting in increased productivity and reduced human error.

In conclusion, the utilization of the Y-axis on a lathe brings a multitude of advantages to the world of machining. From improved versatility and flexibility to enhanced accuracy and increased efficiency, the Y-axis empowers machinists to achieve remarkable results in their lathe machining endeavors. By harnessing the full potential of the Y-axis, machinists can elevate their skills and deliver high-quality products that meet the demands of their customers.

Tips for Maximizing the Potential of the Y-Axis

The Y-axis on a lathe is a powerful tool that can greatly enhance the capabilities of a machinist. To fully utilize its potential and achieve optimal results, it is essential to employ proper techniques and strategies. In this section, we will provide some valuable tips for maximizing the potential of the Y-axis, ensuring that you can leverage this axis to its fullest extent and take your lathe machining skills to new heights.

Invest in Proper Tooling

When working with the Y-axis, having the right tooling is crucial. Invest in high-quality cutting tools that are specifically designed for lathe machining. Consider the material you will be working with and choose the appropriate tooling inserts for optimal performance. Keeping your tools sharp and properly maintained is also essential for achieving precise cuts along the Y-axis.

Master the Art of Multi-Axis Machining

The Y-axis is most effective when used in conjunction with the other axes on a lathe. Mastering the art of multi-axis machining is key to unlocking the full potential of the Y-axis. Take the time to understand how the different axes interact and experiment with various tool paths to achieve the desired results. Practice and experimentation will help you develop the skills needed to utilize the Y-axis effectively in your machining projects.

Utilize CNC and CAD/CAM Software

Embrace technology to streamline your machining process. Invest in CNC lathes that offer precise control over the Y-axis movement. Additionally, utilize CAD/CAM software to design and program complex tool paths. These software tools enable you to visualize and simulate the machining process before actually cutting the workpiece. This helps eliminate errors and ensures accurate movements along the Y-axis.

By following these tips and techniques, you can harness the full potential of the Y-axis on a lathe. From choosing the right tooling to mastering multi-axis machining and leveraging technology, these strategies will help you achieve exceptional results and elevate your lathe machining skills.

Exploring Advanced Y-Axis Features on Modern Lathes

In recent years, advancements in lathe technology have introduced new features and capabilities that enhance the functionality of the Y-axis. In this section, we will explore some of the advanced Y-axis features found in modern lathes, highlighting their benefits and impact on the machining process. Whether you are a seasoned machinist looking to stay up-to-date with the latest trends or a beginner eager to explore the possibilities, understanding these advanced features will broaden your horizons in the world of lathe machining.

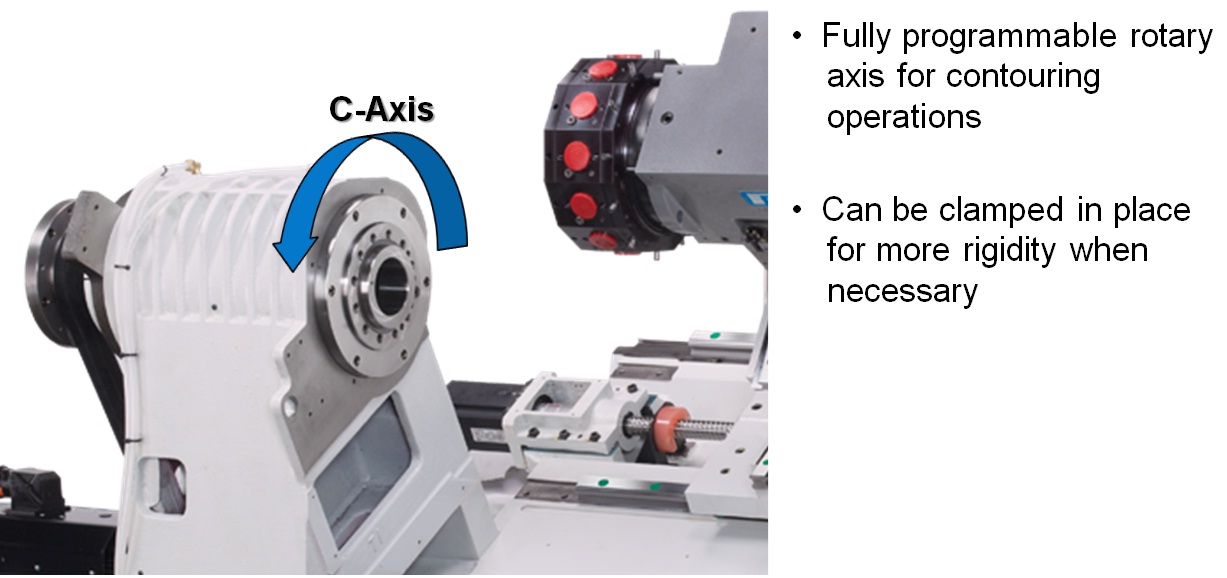

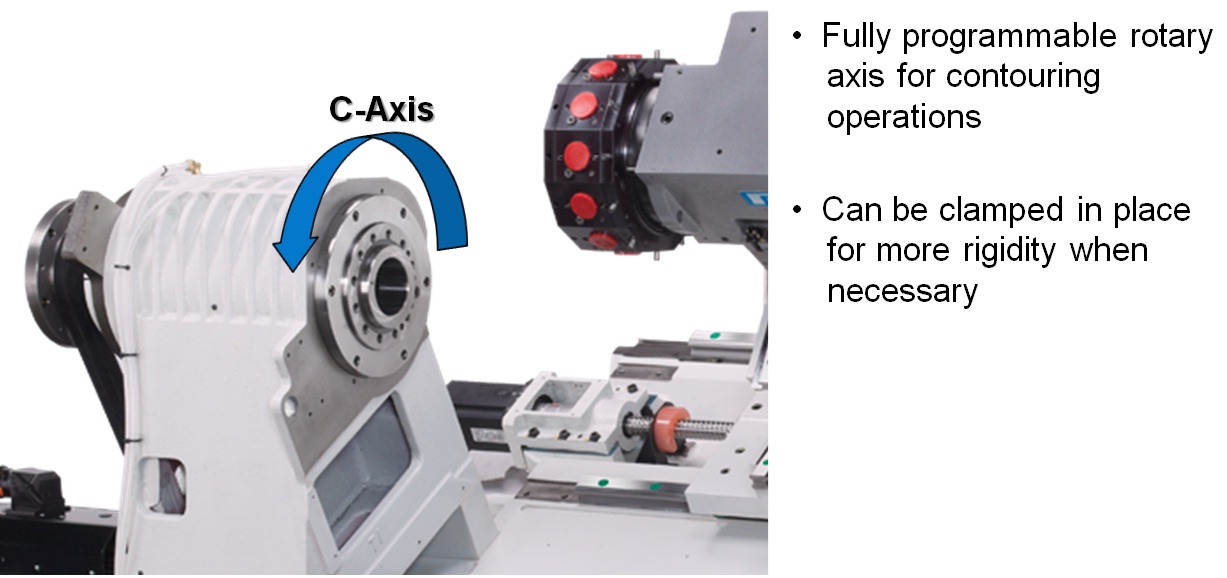

Live Tooling

Live tooling is a feature that enables machining operations to be performed on the Y-axis while the workpiece is spinning. This capability adds a new dimension of functionality to the Y-axis, allowing for milling, drilling, and tapping operations to be performed directly on the workpiece. Live tooling eliminates the need for secondary operations and reduces production time significantly.

By combining the capabilities of the Y-axis with live tooling, machinists can achieve remarkable levels of complexity and versatility. They can create features such as holes, slots, and threads directly on the workpiece, eliminating the need for additional setups and reducing the risk of errors associated with repositioning the workpiece.

Sub-Spindles and Y-Axis Movements

Sub-spindles are additional spindles that allow for simultaneous machining on both ends of the workpiece. When combined with Y-axis movements, this feature opens up a wealth of possibilities for complex machining operations. Machinists can perform a variety of operations such as turning, milling, drilling, and tapping simultaneously on different parts of the workpiece.

Sub-spindles with Y-axis movements enable the production of intricate parts and components that would otherwise be time-consuming or even impossible to manufacture. With the ability to work on multiple sides of the workpiece simultaneously, machinists can reduce cycle times and enhance overall productivity.

Hybrid Y-Axis and B-Axis Movements

Some modern lathes offer hybrid Y-axis and B-axis movements, also known as angular or tilted machining. This feature allows for the Y-axis to be tilted at an angle, expanding the range of machining possibilities. By combining the functionalities of the Y-axis and the B-axis (tilt), machinists can machine complex contours, angled surfaces, and intricate profiles.

This advanced capability is particularly useful in industries such as aerospace and automotive, where complex geometries are common. The hybrid Y-axis and B-axis movements enable machinists to produce parts with intricate angles and transition areas, ensuring a perfect fit and optimal performance.

In conclusion, modern lathe technology has introduced advanced features that amplify the capabilities of the Y-axis. Live tooling, sub-spindles with Y-axis movements, and hybrid Y-axis and B-axis movements have revolutionized the machining industry, providing machinists with unprecedented levels of complexity and flexibility. By leveraging these advanced features, machinists can push the boundaries of their creativity and deliver remarkable results in their lathe machining endeavors.

Troubleshooting Tips for Y-Axis Issues

While the Y-axis on a lathe is a powerful tool, issues may arise that can hinder its performance. In this section, we will discuss common troubleshooting tips for addressing Y-axis issues, ensuring smooth operation and optimal results. Whether you are experiencing inaccuracies in Y-axis movements or facing difficulties with Y-axis programming, these tips will help you identify and resolve the problem, getting you back on track with your lathe machining projects.

Check for Mechanical Issues

If you encounter issues with the Y-axis movements, the first step is to check for any mechanical problems that may be affecting its performance. Inspect the lead screw, cross slide, and associated components for any signs of wear or damage. Ensure that the lead screw is properly lubricated and free from debris. Additionally, check that the slides and gibs are appropriately adjusted to minimize friction and backlash.

If you notice any abnormalities or suspect mechanical issues, consult the lathe’s user manual or contact the manufacturer for guidance. They will be able to provide specific troubleshooting steps based on the make and model of your lathe.

Calibrate Y-Axis Positioning

Poor positioning accuracy along the Y-axis can lead to inaccuracies in your machining operations. It is important to ensure that the Y-axis is properly calibrated to achieve precise movements. Consult your lathe’s user manual for instructions on calibrating the Y-axis positioning. Follow the provided steps and verify that the Y-axis is moving the desired distance consistently.

In some cases, recalibrating the Y-axis may require the assistance of a professional technician. If you are unsure or unable to perform the calibration yourself, it is best to seek professional help to ensure accurate and reliable Y-axis movements.

Review Y-Axis Programming

If you are encountering difficulties with Y-axis programming, thoroughly review your program to identify any errors or inconsistencies. Pay close attention to the Y-axis commands and verify that they are correctly inputted. Ensure that the units of measurement (e.g., inches or millimeters) are consistent throughout the program. Mistakes in programming can lead to unexpected movements or inaccurate positioning along the Y-axis.

If you are new to CNC programming or unsure about a specific command, consult the programming manual or reach out to the manufacturer for assistance. They will be able to provide guidance on programming best practices and troubleshooting steps for Y-axis programming issues.

In conclusion, troubleshooting Y-axis issues on a lathe requires a systematic approach. By checking for mechanical issues, calibrating Y-axis positioning, and reviewing the programming, you can identify and resolve common problems that may arise. However, if the issue persists or is beyond your expertise, do not hesitate to seek assistance from professionals who specialize in lathe maintenance and repair.

Key Takeaways – What is the Y-Axis on a Lathe?

- The Y-axis on a lathe refers to the vertical or up-down movement of the cutting tool.

- It allows for precision in machining cylindrical or round-shaped objects.

- The Y-axis movements are controlled by the lathe’s computer numerical control (CNC) system.

- By adjusting the Y-axis, different depths and shapes can be achieved in the workpiece.

- Understanding the Y-axis is important for operating a lathe and creating accurate cuts.

Frequently Asked Questions

Welcome to our FAQ section where we answer common questions about the y-axis on a lathe. If you’re curious about the role and function of the y-axis on this machine, you’ve come to the right place. Read on to find answers to some of the most frequently asked questions about the y-axis on a lathe.

Q: How does the y-axis work on a lathe?

The y-axis on a lathe is an essential component that allows for precise movement of the cutting tool along the vertical plane. It controls the up and down movement of the tool turret, which enables operators to create complex shapes and contours on the workpiece. By adjusting the y-axis, you can position the tool at different heights, thereby controlling the depth of the cut or the thickness of the material being removed during the machining process. This axis adds versatility to a lathe’s capabilities and enhances its precision and efficiency.

When the y-axis is activated, the cutting tool moves along the vertical plane, allowing for operations such as facing, grooving, drilling, and threading. This axis is particularly useful for tasks that require varied depths or complex profiles. By adjusting the y-axis, operators can create intricate designs and achieve desired levels of precision in their work.

Q: What are the advantages of the y-axis on a lathe?

The y-axis on a lathe offers several advantages that enhance the machining process. First and foremost, it adds flexibility and versatility to the machine’s capabilities. With the ability to move the cutting tool up and down, operators can create complex shapes and contours that wouldn’t be possible with just x and z-axis movements. This axis also allows for greater precision in the machining process, as it enables operators to make small adjustments to the tool’s height to achieve the desired thickness or depth of cut.

Additionally, the y-axis improves efficiency by reducing the need for multiple setups or repositioning of the workpiece. With the y-axis, operators can perform multiple operations without having to manually adjust the height of the cutting tool. This saves time and effort, making the machining process more efficient. The y-axis is a valuable feature for lathe operators looking to produce intricate and precise workpieces in a streamlined manner.

Q: Do all lathes have a y-axis?

No, not all lathes have a y-axis. The presence of a y-axis depends on the type and configuration of the lathe machine. Basic lathes typically have only x and z-axis movements, which provide horizontal and longitudinal motion, respectively. However, more advanced lathes, such as CNC lathes or multi-axis lathes, often incorporate a y-axis to enhance their machining capabilities.

CNC lathes, in particular, commonly feature a y-axis to enable precise and complex machining operations. This axis can be controlled automatically with computer programming, allowing for the creation of intricate designs with ease. It’s worth noting that the availability of a y-axis may vary depending on the specific model and manufacturer of the lathe machine.

Q: Can the y-axis be used for turning operations on a lathe?

While the y-axis primarily controls vertical movement, it can also be used for certain turning operations on a lathe. Turning operations involve rotating the workpiece against a stationary cutting tool to create cylindrical shapes or remove material. While the x-axis is primarily responsible for the lateral movement of the tool for turning operations, the y-axis can be utilized to adjust the position of the tool vertically, allowing for variations in the diameter or taper of the workpiece.

By adjusting the y-axis during turning operations, operators can achieve specific profiles or contours on the workpiece, creating more intricate and complex shapes. However, it’s important to note that the y-axis’s role in turning operations may vary depending on the specific lathe machine and the desired outcome of the turning process.

Q: How does the y-axis contribute to precision machining on a lathe?

Precision machining requires meticulous control over the tool’s movements, and the y-axis plays a crucial role in achieving that precision on a lathe. By allowing for vertical movement of the cutting tool, the y-axis enables operators to make precise adjustments to the tool’s height, controlling the depth of cut or the thickness of the material being removed. This precise control ensures that the desired dimensions and tolerances are achieved in the workpiece.

In addition to controlling the depth of cut, the y-axis also facilitates the creation of intricate profiles and contours. By precisely positioning the tool at different heights, operators can shape the workpiece with precision, achieving complex designs and detailed features. The y-axis’s contribution to precision machining on a lathe cannot be overstated, as it allows for accurate control and execution of various machining operations.

Summary

So, what is the y-axis on a lathe? The y-axis is the vertical axis that controls the up and down movement of the cutting tool. It helps to create different shapes and contours on the workpiece. By adjusting the y-axis, you can make precise cuts and create intricate designs. It’s an essential component of a lathe machine that enables you to shape and transform materials into various forms.

In conclusion, the y-axis on a lathe is responsible for the vertical movement of the cutting tool. It plays a crucial role in shaping and cutting materials. So, the next time you see a lathe machine, you’ll know what that y-axis is all about!