Welcome to the fascinating world of lathes! Wondering what lathe speed to use for your projects? You’ve come to the right place.

Whether you’re a budding DIY enthusiast or an experienced woodworker, understanding the optimal lathe speed is key to achieving precision and quality.

In this article, we’ll delve into the factors that influence lathe speed and offer practical tips to help you determine the perfect speed for your turning needs. So let’s get spinning and explore the exciting world of lathe speeds together!

The Art of Choosing the Right Lathe Speed: A Guide for Woodworkers

When it comes to woodworking, one of the key factors that determines the success of your project is using the right lathe speed. The speed at which the lathe rotates can greatly impact the quality of your work, the efficiency of your cuts, and the overall safety of the process. However, with a wide range of lathe speed options available, it can be challenging to know which one to choose for each specific task. In this comprehensive guide, we will explore the factors that influence your choice of lathe speed and provide you with practical tips to help you make informed decisions.

Understanding Lathe Speed: The Basics

To understand how to choose the right lathe speed, it is important to have a basic understanding of how it works. The speed of a lathe is measured in revolutions per minute (RPM) and refers to how fast the workpiece rotates. Most lathes allow you to adjust the speed within a certain range, giving you flexibility to adapt to different types of wood, tools, and cuts.

When determining the ideal lathe speed, several factors come into play. These include the diameter and length of the workpiece, the type of wood being used, the type and size of the lathe tools, and the desired outcome of the project. By understanding these factors and considering them in combination, you can find the optimal speed for your specific woodworking needs.

One important thing to note is that different lathe operations require different lathe speeds. For example, roughing out a block of wood requires a different speed than creating intricate details on a finished piece. This is why knowing how to adjust and set the lathe speed is crucial for achieving desired results.

Determining the Right Speed for Your Woodworking Projects

Now that you have a basic understanding of lathe speed, let’s dive deeper into how to determine the correct speed for your woodworking projects. Keep in mind that while there are general guidelines, it is important to experiment, practice, and fine-tune the speed based on your own experience and specific project requirements.

1. Consider the Diameter and Length of the Workpiece: The size of the workpiece has a direct impact on the ideal lathe speed. As a general rule, larger diameters require slower speeds, while smaller diameters can handle faster speeds. Longer workpieces may also require slower speeds to ensure stability and prevent vibrations.

2. Know Your Wood: Different types of wood have different characteristics, such as density and hardness. These factors affect how the wood responds to cutting and shaping. Softer woods generally require higher speeds, while harder woods may require slower speeds to achieve clean cuts and minimize tear-out.

3. Adapt to the Tool and Desired Outcome: The type and size of the lathe tool you are using will also influence the speed you should set. Larger tools and roughing gouges can handle higher speeds for efficient stock removal, while smaller detail tools require slower speeds for precision cuts. Additionally, the desired outcome of your project, whether it’s rough shaping or fine detailing, will influence the speed you choose.

Tips for Enhancing Your Woodworking Experience

Now that you have a solid foundation on how to choose the right lathe speed, here are some additional tips to enhance your woodworking experience:

- Practice on scrap wood before working on your final piece to get a feel for how different speeds affect the wood and your tools.

- Invest in a lathe with variable speed settings, offering you more flexibility to adapt to different projects and materials.

- Always wear appropriate safety gear, such as safety glasses and a face shield, when working with a lathe to protect yourself from wood chips and debris.

- Regularly maintain and clean your lathe to ensure it operates smoothly and accurately.

- Seek advice and guidance from experienced woodworkers, either through online forums, woodworking clubs, or in-person classes.

Conclusion

Choosing the right lathe speed is a crucial aspect of woodworking that significantly impacts the outcome of your projects. By understanding the basics of lathe speed, considering factors like workpiece size and wood type, and experimenting with different speeds, you can achieve precise cuts, minimize tear-out, and enhance your overall woodworking experience. Remember, practice makes perfect, so don’t be afraid to try different speeds and techniques to find what works best for you. Happy woodworking!

Key Takeaways: What Lathe Speed to Use?

- Choosing the right lathe speed depends on the material you are working with.

- For harder materials like metal, slower lathe speeds are recommended.

- Softer materials like wood require faster lathe speeds for efficient cutting.

- Experimentation is key to finding the optimal lathe speed for different materials.

- Always prioritize safety and start with lower speeds before increasing gradually.

Frequently Asked Questions

When it comes to using a lathe, understanding the right speed to use is crucial for achieving the desired results. Here are some frequently asked questions about lathe speed and their answers:

1. How do I determine the right speed to use on my lathe?

Choosing the correct lathe speed depends on various factors, such as the material you’re working with, the diameter of the workpiece, and the type of tooling. In general, larger workpieces require slower speeds, while smaller ones can be turned at higher speeds. Some materials, like plastics, may require slower speeds, while metals can be turned at higher speeds. It’s essential to consult the manufacturer’s guidelines for specific recommendations and experiment with different speeds to find what works best for your project.

Keep in mind that the speed you choose also affects the finish and quality of your work. Lower speeds provide better control and cleaner cuts, while higher speeds may result in a rougher finish. Ultimately, it’s a balance between the material, workpiece size, and desired outcome.

2. What happens if I use the wrong speed on my lathe?

Using the wrong speed on your lathe can have several consequences. If you use a speed that is too high, it can cause the workpiece to vibrate or even break, leading to an unsafe working environment. High speeds can also result in poor surface finish, increased tool wear, and potential overheating of the material.

On the other hand, using a speed that is too slow can lead to inadequate cutting performance, causing the tool to chatter, burn the material, or get jammed. Additionally, slow speeds may result in inefficient material removal, prolonged machining time, and inconsistent accuracy.

To avoid these issues, it’s crucial to understand the characteristics of the material and workpiece you’re using and select an appropriate speed range within the manufacturer’s recommendations or based on your past experiences with similar projects.

3. Are there any general guidelines for lathe speeds?

While there are no one-size-fits-all rules for lathe speeds, you can follow some general guidelines. For turning wood, start with a medium speed and make adjustments as needed based on the project requirements and the wood’s hardness. For turning metal, begin with a slower speed and increase it gradually until you achieve satisfactory results.

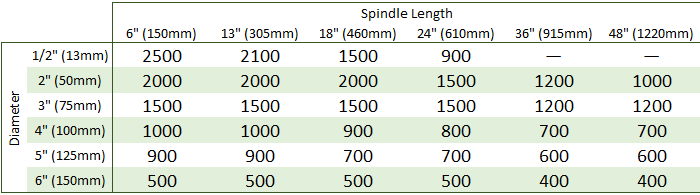

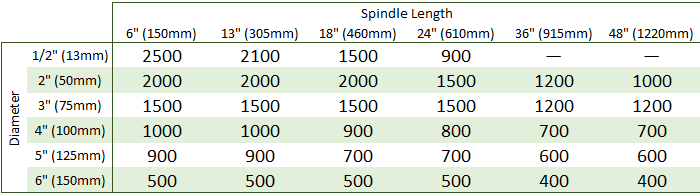

You can also refer to speed charts provided by lathe manufacturers or online resources that offer suggested speed ranges for specific materials and workpiece dimensions. However, it’s essential to remember that these charts serve as starting points, and some adjustments may be required based on individual factors and personal preferences.

4. How can I adjust the speed on my lathe?

The method for adjusting the speed on a lathe depends on the specific type and model you are using. Some lathes have a manual speed control where you can change the belt position on different pulley settings. Others have electronic variable speed controls that allow you to adjust the speed using a dial or buttons. Refer to the lathe’s user manual or consult the manufacturer’s instructions to learn how to adjust the speed on your specific lathe.

For lathes with variable speed controls, it’s important to make speed adjustments while the lathe is turned off to prevent any accidents or damage. Take your time to understand how your lathe operates and practice changing speeds before attempting any projects.

5. Can I use the same speed for all lathe operations?

While it may be tempting to use the same speed for all lathe operations to simplify things, it’s generally not recommended. Different cutting tasks, materials, and workpiece sizes require different speeds to achieve optimal results. For example, roughing cuts may require faster speeds to remove material quickly, while finishing cuts often require slower speeds for precision and a smooth surface finish.

By adjusting the speed to match the specific operation and material, you can enhance safety, improve the quality of your work, and prolong the life of your lathe tools. It’s best to experiment and find the optimal speed for each operation based on your experience and the desired outcome.

Summary

To determine the appropriate lathe speed, consider the type of material being worked on. Softer materials like wood require faster speeds, while harder materials like metal require slower speeds. It’s important to match the speed with the material for best results.

Additionally, the size of the workpiece is crucial in setting the lathe speed. Larger workpieces need slower speeds, while smaller ones can handle faster speeds. By considering the material and size, you can ensure optimal lathe speed for a successful turning process.