If you’ve ever wondered about the lathe tool that’s used to enlarge a hole, you’re in the right place! Let’s dive into this fascinating topic and discover the answer together.

Imagine you have a hole that needs to be made bigger on a piece of wood or metal. What tool would you reach for? Well, in the world of lathes, there’s a specific tool designed just for this purpose.

So, what exactly is this magical tool called, and how does it work? Stick around as we explore the ins and outs of the lathe tool used to enlarge a hole. Get ready for some fascinating insights!

What Lathe Tool is Used to Enlarge a Hole?

Lathe tools are essential for various machining operations, including enlarging holes. When it comes to increasing the diameter of a hole in a workpiece, there are several lathe tools available. Each tool has its specific purpose and advantages. In this article, we will explore the different lathe tools used to enlarge holes, their features, and how they are used. So, let’s dive in and discover the world of hole-enlarging lathe tools!

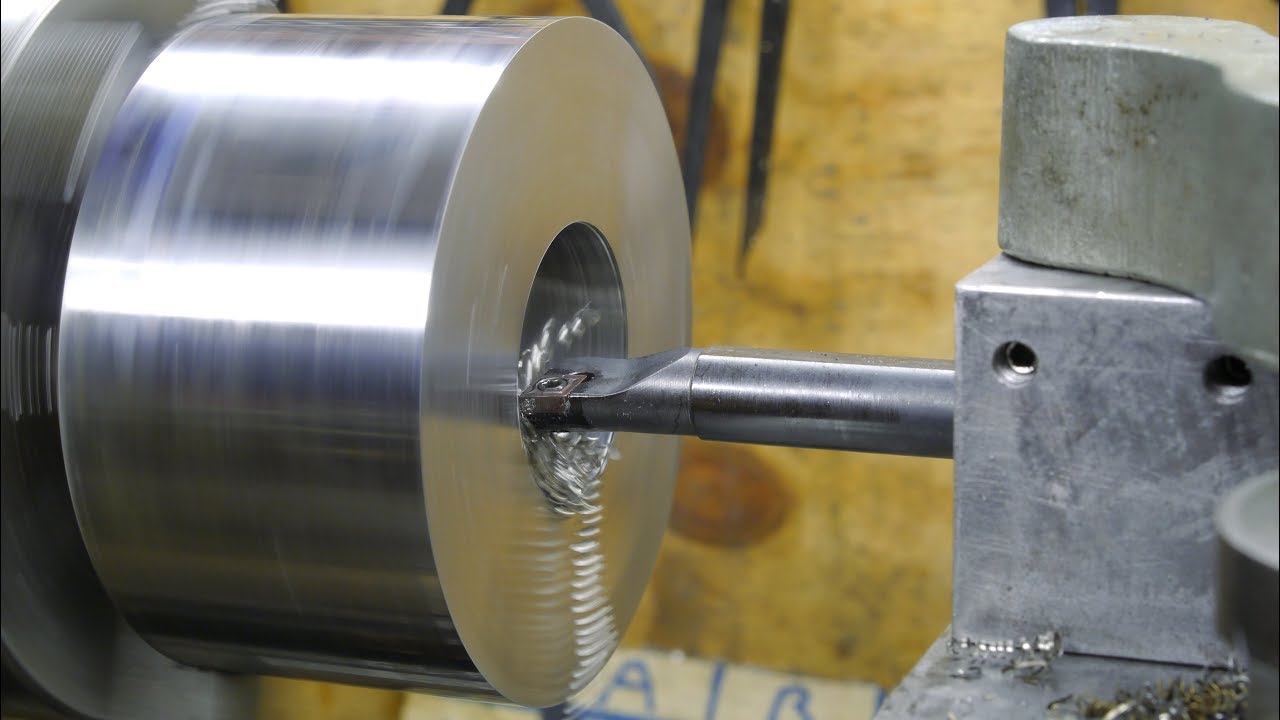

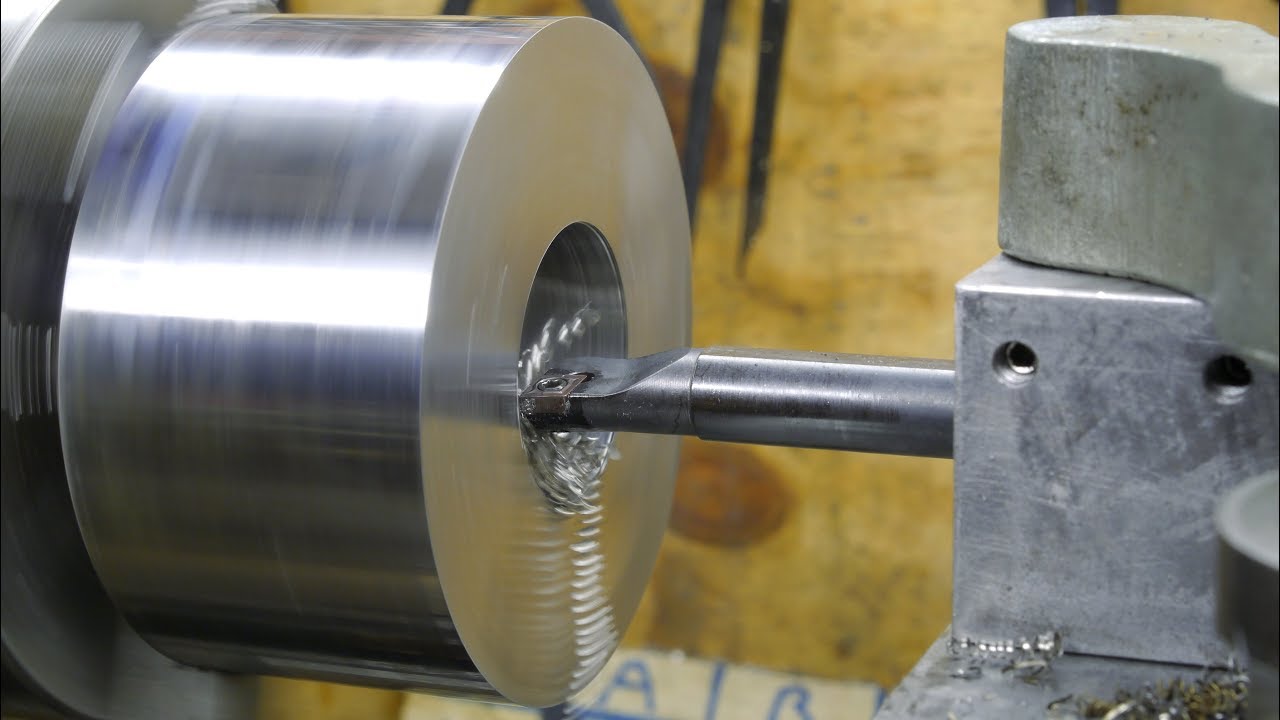

1. Boring Bar

A boring bar is a versatile lathe tool commonly used to enlarge holes with precision. It consists of a solid bar with a cutting tip attached at one end. The bar is held securely in the lathe’s tool holder, while the cutting tip enters the hole to remove material, gradually enlarging it. Boring bars come in various shapes, such as straight, offset, or angled, allowing for flexibility in accessing different hole positions.

Using a boring bar involves careful setup and calculation of the required diameter increase. The cutting tip is adjusted to the desired position and depth, and the lathe is carefully operated to remove material incrementally. Boring bars are particularly useful for creating precise, large-diameter holes, as they allow for minimal deflection and excellent control over the process.

2. Reamer

Another popular tool used to enlarge holes is a reamer. Reamers consist of a cylindrical body with a series of cutting edges along its length. They are designed to align and enlarge existing holes with high precision. Reamers are commonly used when a high level of accuracy and surface finish is required. They come in various types, including hand reamers, machine reamers, and adjustable reamers.

To use a reamer, the workpiece is securely clamped in the lathe, and the tool is positioned at the entrance of the hole. The reamer is then rotated and slowly fed into the hole while removing small amounts of material. Reamers are ideal for achieving smooth, concentric holes with tight tolerances, making them a popular choice in industries like aerospace and automotive manufacturing.

3. Counterbore

A counterbore is a lathe tool specifically designed to enlarge the opening of a hole to accommodate a bolt head or a similar component. It consists of a cylindrical body with a flat cutting surface at the end and a pilot guide. Counterbores are commonly used when a recessed section is needed below the surface of the workpiece.

Using a counterbore is straightforward. The tool’s pilot guide is positioned in the existing hole, ensuring alignment, and the counterbore is then rotated to enlarge the opening. Counterbores are particularly useful in applications where precise depth and diameter control are crucial, such as in the assembly of mechanical components.

4. Drill Bit

While drill bits are primarily used to create holes, they can also be utilized to enlarge existing holes to a certain extent. Drill bits come in various sizes and types, such as twist drills, step drills, and tapered drills. When using a drill bit to enlarge a hole, it is essential to choose the appropriate size and type to achieve the desired diameter increase.

To enlarge a hole with a drill bit, the bit is aligned with the existing hole and rotated while applying moderate pressure. Care must be taken to avoid excessive material removal or creating an uneven, oversized hole. Drill bits are commonly used for enlarging smaller-diameter holes or when only a slight increase in diameter is required.

5. Expanding Mandrel

An expanding mandrel is a specialized lathe tool used to enlarge holes with exceptional accuracy and control. It consists of a tapered mandrel and a set of expanding fingers that grip the inner wall of the hole, evenly applying outward pressure. Expanding mandrels are particularly useful when working with delicate or thin-walled materials that may be prone to distortion or damage.

To use an expanding mandrel, the mandrel is inserted into the existing hole, and the fingers are carefully expanded to grip the inner wall. The workpiece and mandrel are then securely held in the lathe, and the hole is enlarged by applying rotational force while the expanding fingers evenly push against the hole’s interior. Expanding mandrels are often used in the precision machining of cylindrical parts.

6. Adjustable Reamer

Similar to regular reamers, adjustable reamers are designed to enlarge existing holes with precise accuracy. However, what sets adjustable reamers apart is their unique feature of adjustable blades. These blades can be expanded or contracted to achieve different hole diameters.

To use an adjustable reamer, it is necessary to set the blades to the desired diameter and secure them in place. The reamer is then inserted into the existing hole and rotated while applying moderate pressure. The adjustable blades remove excess material, enlarging and aligning the hole with precision. Adjustable reamers are highly versatile and allow for a wide range of diameter adjustments, making them ideal for various applications.

7. Step Drill Bit

Step drill bits are designed with multiple steps of increasing diameters on a single tool. They are primarily used for creating holes with different sizes in materials of various thicknesses. However, step drill bits can also be used to enlarge existing holes by selecting the appropriate step size.

To enlarge a hole using a step drill bit, the bit is positioned at the entrance of the hole, aligning it with the existing diameter. The next step size is chosen, and the drill is slowly rotated while applying moderate pressure. As the drill progresses, it removes material and incrementally enlarges the hole. Step drill bits are convenient for quickly and precisely enlarging holes with a smooth finish.

Benefits of Using the Right Lathe Tool for Enlarging Holes

Using the correct lathe tool for enlarging a hole brings several benefits. Firstly, it ensures accurate and precise results, which is crucial in industries such as manufacturing, engineering, and metalworking. Achieving the intended hole diameter and maintaining tight tolerances can prevent potential issues in assembly or operation.

Secondly, using the appropriate tool minimizes the risk of damaging the workpiece or distorting the material. Some tools, like expanding mandrels, counterbores, and adjustable reamers, provide better control and reduce the chances of overcutting or deflection, especially when working with delicate or thin-walled materials.

Moreover, using the right lathe tool can enhance productivity and efficiency. Each tool is designed to optimize the enlargement process for specific purposes. Boring bars, reamers, and step drill bits, for example, can efficiently remove material and enlarge holes at a controlled and consistent rate, saving time and effort.

Lastly, utilizing the proper lathe tool ensures a smooth finish and improves the overall aesthetics of the workpiece. Whether it is a hole for functional purposes or visual appeal, having a clean, concentric, and properly aligned enlarged hole can significantly enhance the final product’s quality and appearance.

Additional H2 headings:

Factors to Consider When Choosing a Lathe Tool for Enlarging Holes

Tips for Properly Using Lathe Tools to Enlarge Holes

Common Mistakes to Avoid When Enlarging Holes with Lathe Tools

The Importance of Proper Maintenance for Lathe Tools

Factors to Consider When Choosing a Lathe Tool for Enlarging Holes

When selecting a lathe tool for enlarging holes, several factors should be taken into consideration to ensure optimal results. Here are some essential factors to consider:

1. Material Compatibility: Different lathe tools are designed for different materials. Consider the characteristics of the workpiece material, such as hardness and toughness, to choose a tool that can effectively remove material without excessive tool wear or workpiece damage.

2. Desired Hole Diameter: Determine the required diameter increase for the hole. Some tools, like adjustable reamers and step drill bits, offer flexibility in achieving various diameter sizes.

3. Tolerance Requirements: Assess the level of accuracy and precision needed for the enlarged hole. Depending on the application, tight tolerances may be necessary, requiring tools like reamers or expanding mandrels.

4. Workpiece Stability: Consider the stability of the workpiece during the enlargement process. Delicate or thin-walled materials may require tools that minimize deflection and provide better control, such as expanding mandrels or counterbores.

5. Surface Finish: Evaluate the desired surface finish of the enlarged hole. If a smooth and polished finish is required, tools like reamers or boring bars can deliver excellent results.

Tips for Properly Using Lathe Tools to Enlarge Holes

To ensure the best possible results when using lathe tools to enlarge holes, follow these tips:

1. Secure the Workpiece: Properly clamp or secure the workpiece to prevent movement or vibrations that can affect hole accuracy. Use workpiece-supporting devices when necessary.

2. Precise Measurements: Take accurate measurements of the existing hole to determine the size of enlargement required. Double-check the measurements before selecting the lathe tool.

3. Gradual Enlargement: When using tools like reamers or boring bars, remove material gradually in small increments. This helps maintain control over the process and ensures precise and accurate results.

4. Lubrication: Use appropriate cutting fluids or lubricants to reduce friction and heat generation during the enlargement process. This helps prolong tool life and improves surface finish.

5. Monitoring and Adjustments: Regularly inspect the workpiece and the tool during the enlargement process. Make necessary adjustments to the tool’s position, depth, or cutting speed to ensure optimal results.

Common Mistakes to Avoid When Enlarging Holes with Lathe Tools

While using lathe tools to enlarge holes, it’s important to avoid the following common mistakes:

1. Overcutting: Removing excessive material beyond the desired diameter can lead to oversized and misshapen holes. Take precise measurements and carefully control the material removal process.

2. Insufficient Support: Neglecting to properly support the workpiece can result in vibration, unwanted movement, or workpiece damage. Use appropriate fixtures, supports, or steady rests to ensure stability.

3. Incorrect Tool Selection: Choosing the wrong lathe tool for the specific enlargement task can lead to inaccurate results or tool damage. Take into account the material, hole diameter, and required tolerance before selecting the tool.

4. Improper Tool Setup: Failing to set up the lathe tool correctly can compromise the integrity of the hole-enlarging process. Ensure the tool is properly aligned, tightened, and set to the appropriate cutting depth.

5. Lack of Maintenance: Neglecting regular maintenance of lathe tools, such as sharpening or replacing dull blades, can result in poor performance, reduced accuracy, and shorter tool life. Follow proper maintenance procedures recommended by the tool manufacturer.

The Importance of Proper Maintenance for Lathe Tools

Proper maintenance of lathe tools used for enlarging holes is essential to ensure their longevity and optimal performance. Regular maintenance helps maintain cutting accuracy, prolongs tool life, and reduces the risk of accidents or tool failure. Here are some key maintenance practices to keep in mind:

1. Cleaning: After each use, clean lathe tools thoroughly to remove chips, debris, and coolant residue. This prevents buildup that may affect cutting performance and accuracy.

2. Sharpening: Regularly inspect and sharpen lathe tools to maintain their cutting edges. Dull or worn-out tools can result in poor quality holes, excessive material removal, or increased cutting forces.

3. Lubrication: Apply appropriate lubricants or cutting fluids during the enlargement process to reduce friction, heat, and tool wear. Refer to the tool manufacturer’s recommendations for the correct lubrication.

4. Storage: Store lathe tools in a clean and dry environment, away from extreme temperatures or humidity. Proper storage prevents corrosion and preserves the tool’s cutting integrity.

5. Replacement: Monitor the condition of lathe tools and replace them when necessary. Signs of wear, damage, or reduced cutting performance may indicate the need for replacement to ensure accurate hole enlargement.

As with any machinery or tool, following the manufacturer’s guidelines for maintenance and safety is crucial to maximize the lifespan and performance of lathe tools. Regular inspection, sharpening, and cleaning procedures should become routine practices in any workshop or machining environment.

In summary, various lathe tools can be used to enlarge holes, each with its own advantages and specific applications. Boring bars, reamers, counterbores, drill bits, expanding mandrels, adjustable reamers, and step drill bits offer different functionalities and accuracy levels. Choosing the appropriate tool depends on factors like material compatibility, desired diameter, tolerance requirements, workpiece stability, and surface finish. By following proper usage techniques, avoiding common mistakes, and practicing regular maintenance, you can achieve accurate and precise hole enlargement, enhancing the quality and functionality of your workpieces.

Key Takeaways: What Lathe Tool is Used to Enlarge a Hole?

- A boring bar is a lathe tool commonly used to enlarge a hole.

- It is a long, slender metal rod with a cutting tip at one end.

- The cutting tip is made of hard material, such as tungsten carbide or high-speed steel.

- Boring bars are used by mounting them on the lathe’s tool post and rotating them into the existing hole.

- As the bar spins, the cutting tip removes material and gradually enlarges the hole to the desired size.

Frequently Asked Questions

Are you curious about the tools used in a lathe to enlarge holes? Look no further! Below are some common questions and answers to satisfy your curiosity.

1. What tool is used in a lathe to enlarge a hole?

The tool used in a lathe to enlarge a hole is called a boring bar. It is a cylindrical metal rod with sharp cutting edges at one end. Boring bars come in different sizes and shapes to accommodate various hole sizes and shapes. They are designed to remove material from the inside of a hole, enlarging it to a desired diameter.

When using a boring bar, the operator mounts it securely in the lathe’s tool post and adjusts its position and height accurately to match the desired hole dimensions. As the lathe spins, the boring bar is fed into the hole, gradually removing material and enlarging the hole. This process is often used in machining applications to achieve precise hole sizes for components and parts.

2. How does a boring bar enlarge a hole in a lathe?

A boring bar enlarges a hole in a lathe through a cutting action. The cutting edges on the end of the boring bar remove material as it rotates and moves further into the hole. The depth and diameter of the hole can be adjusted by controlling the feed rate and the rotation speed of the lathe.

As the boring bar cuts into the material, it creates chips and swarf, which are small pieces of removed metal. These chips are guided away from the cutting area to maintain a clean environment and prevent damage to the tool and workpiece. By gradually moving the boring bar deeper into the hole and adjusting the feed rate, the hole can be enlarged with precision and accuracy.

3. Are there different types of boring bars for enlarging holes in a lathe?

Yes, there are different types of boring bars for enlarging holes in a lathe. The choice of boring bar depends on factors such as the size of the hole, the material being machined, and the desired level of precision. Common types of boring bars include solid boring bars, indexable insert boring bars, and carbide tip boring bars.

Solid boring bars are made from a single piece of metal and often used for general-purpose hole enlarging. Indexable insert boring bars have replaceable cutting inserts, which allow for easy and quick tool changes. They are suitable for high-speed machining and offer excellent cutting performance. Carbide tip boring bars feature a carbide insert at the cutting end, providing increased durability and cutting efficiency.

4. Can a lathe tool other than a boring bar be used to enlarge a hole?

Yes, besides a boring bar, a lathe tool called a reamer can also be used to enlarge a hole. A reamer is a cutting tool specifically designed to ensure accurate and smooth hole enlargement. It features multiple cutting edges and is typically used for finishing operations to achieve precise hole dimensions.

Reamers come in various sizes and types, including hand reamers, machine reamers, and adjustable reamers. They can be used in a lathe or by hand, depending on the specific application. When using a reamer in a lathe, it is essential to securely hold the workpiece and carefully feed the reamer into the hole at the appropriate speed to prevent damage and achieve the desired hole size.

5. What are some precautions to take when using a boring bar or reamer to enlarge a hole in a lathe?

When using a boring bar or reamer to enlarge a hole in a lathe, it is essential to take certain precautions to ensure safety and achieve accurate results. Here are some important precautions to keep in mind:

1. Securely mount the boring bar or reamer in the lathe’s tool post, ensuring it is tight and properly aligned.

2. Use appropriate safety gear, such as safety glasses and gloves, to protect yourself from debris or sharp edges.

3. Adjust the lathe’s speed and feed rate according to the type of material being machined and the size of the hole.

4. Take light cuts and avoid excessive pressure to prevent tool breakage or damage to the workpiece.

5. Properly lubricate the boring bar or reamer to reduce friction and extend tool life.

By following these precautions, you can safely and effectively enlarge holes in a lathe using a boring bar or reamer.

Summary

If you want to make a hole bigger in woodworking, you can use a tool called a reamer. It’s shaped like a cone and smoothens the sides of the hole. Reamers are great, but be careful not to use them on hard materials like metal. If you’re working with metal, you’ll need a different tool called a boring bar. It scrapes away the material and makes the hole larger. Remember to always use safety gear when working with any tools!

So, if you need to enlarge a hole, use a reamer for wood and a boring bar for metal. Stay safe and have fun woodworking!