Do you ever wonder what tools are used to enlarge a hole on a lathe? Well, you’ve come to the right place! In this article, we’ll explore the answer to the question, “What lathe tool is used to enlarge a hole?” So, let’s dive in and discover the tool that makes hole enlargement a breeze!

Whether you’re a budding woodworker or a curious DIY enthusiast, knowing the right tools for the job is essential. When it comes to expanding a hole on a lathe, one tool stands out – the boring bar. This versatile tool is specifically designed to enlarge existing holes with precision and ease.

Imagine having the power to make a small hole bigger without compromising accuracy. With a boring bar in hand, you can achieve just that! So, let’s delve deeper into the workings of this magical tool and uncover its secrets. Get ready to take your lathe projects to the next level as we unravel the wonders of the boring bar!

(Please note: This task can be accomplished using either HTML or plain text, depending on your preference.)

What Lathe Tool is Used to Enlarge a Hole?

When it comes to enlarging a hole on a lathe, there are several tools that can be used depending on the size and material of the hole. Each tool has its own unique purpose and method of operation, allowing for precise and accurate hole enlargement. In this article, we will explore the different lathe tools specifically designed for enlarging holes, their uses, and the benefits they offer. Whether you are a beginner or an experienced lathe operator, understanding these tools and their capabilities will enhance your machining skills and help you achieve professional results.

Boring Bar

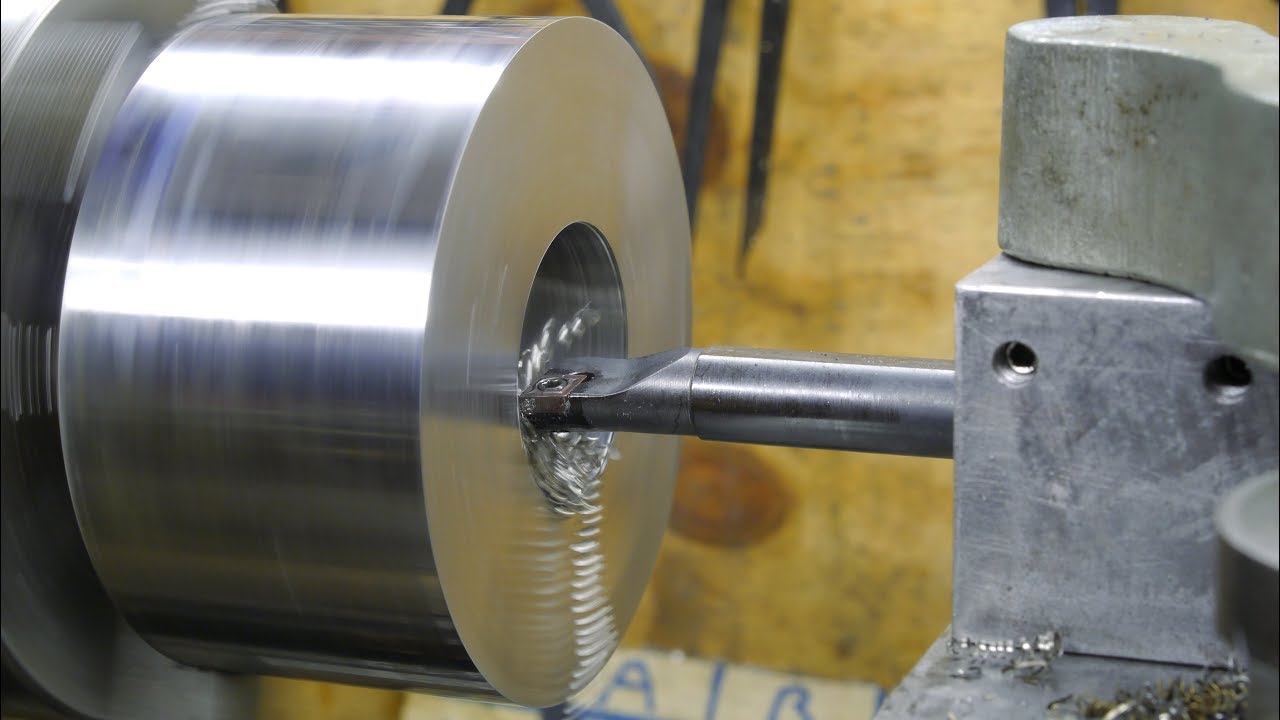

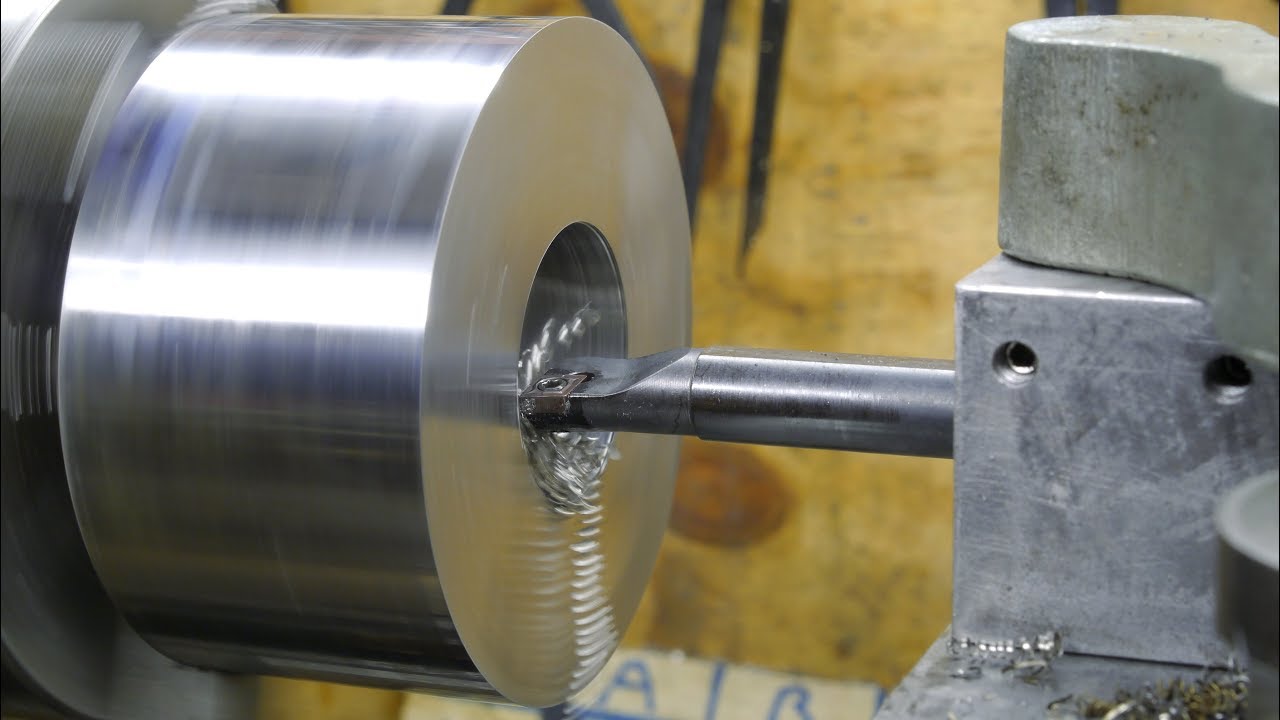

The boring bar is one of the most commonly used lathe tools for enlarging holes. It is a long, cylindrical tool with a cutting edge at the tip. Boring bars come in various sizes and shapes, allowing for versatility in different hole diameters and depths. To use a boring bar, it is clamped in a tool holder and inserted into the lathe’s spindle. The tool is then fed into the hole being enlarged, gradually removing material and increasing the hole size. Boring bars are widely used in metalworking applications, and they provide greater precision and control compared to other hole enlargement methods.

Benefits of using a boring bar:

- Precision: Boring bars allow for precise control over the hole diameter and depth, ensuring accurate results.

- Versatility: With different sizes and shapes available, boring bars can be used for various hole diameters and depths.

- Smooth Finishes: Boring bars produce smooth surfaces inside the hole, reducing the need for additional finishing operations.

- Efficiency: The cutting action of boring bars is efficient, minimizing material wastage and saving time.

Reamer

A reamer is another commonly used tool for enlarging holes on a lathe. It is a cutting tool with multiple flutes or blades that remove material as it is rotated. Reamers are available in different sizes and types, such as hand reamers, machine reamers, and adjustable reamers. To use a reamer, it is held in a chuck or inserted into a collet and then rotated while being fed into the hole. The cutting action of the reamer removes small amounts of material, gradually enlarging the hole to the desired size. Reamers are especially useful for achieving tight tolerances and smooth finishes.

Benefits of using a reamer:

- Precision: Reamers are designed to provide precise hole diameters and wall finishes, ensuring accurate and consistent results.

- Tight Tolerances: With the ability to remove small amounts of material, reamers can achieve tight tolerances for precise fits.

- Smooth Finishes: The multiple flutes or blades on a reamer produce smooth surfaces inside the hole, reducing the need for further finishing operations.

- Cost-Effective: Reamers are generally more affordable than other specialized hole enlargement tools.

Expanding Mandrel

An expanding mandrel is a useful tool for enlarging holes that require precise concentricity. It consists of a tapered sleeve or arbor and segmented clamping fingers. When inserted into a hole, the mandrel is expanded by tightening a threaded nut or collar, causing the clamping fingers to grip the inside of the hole. This securely holds the workpiece in place while allowing for controlled enlargement. Expanding mandrels are often used in applications where concentricity is crucial, such as cylindrical grinding, honing, or gear cutting.

Benefits of using an expanding mandrel:

- Concentricity: Expanding mandrels ensure precise concentricity between the original and enlarged hole, preserving accuracy in subsequent machining processes.

- Secure Grip: The clamping fingers provide a secure grip on the inside of the hole, preventing any movement during the enlargement process.

- Versatility: Expanding mandrels can be used for various hole diameters, eliminating the need for multiple tools for different sizes.

- Efficiency: Once set up, expanding mandrels offer a quick and efficient method of enlarging holes, reducing setup time and improving productivity.

Counterbore

A counterbore is a specialized tool used to enlarge the entrance of a hole while maintaining its center location. It consists of a cylindrical body with a flat cutting face and a pilot guide at the center. Counterbores are commonly used when a fastener, such as a bolt or screw, needs to be countersunk into a hole, allowing the head to be flush with or below the surface. The pilot guide ensures accurate centering, while the cutting face enlarges the entrance diameter. Counterbores come in various sizes and are often used in woodworking, metalworking, and engineering applications.

Benefits of using a counterbore:

- Accurate Centering: The pilot guide on a counterbore ensures precise centering of the enlarged hole, resulting in proper alignment for fasteners.

- Flush or Recessed Fasteners: Counterbores create a recess at the entrance of the hole, allowing fasteners to be flush with or below the surface.

- Versatility: Counterbores can be used for various hole sizes and materials, making them suitable for a range of applications.

- Efficiency: The cutting action of a counterbore is efficient, reducing the time required to enlarge the hole and counterbore the entrance.

Step Drill Bit

A step drill bit, also known as a step drill or a cone drill, is a versatile tool designed for multiple hole sizes. It is conical in shape, with stepped or graduated diameters. Step drill bits are commonly used in applications where the hole diameter needs to be increased in a stepped manner, rather than a continuous enlargement. As the drill bit advances, each step cuts a larger diameter, allowing for incremental hole enlargement. Step drill bits are popular in metalworking and woodworking for their ease of use and versatility.

Benefits of using a step drill bit:

- Versatility: Step drill bits can create multiple hole sizes with a single tool, eliminating the need for multiple drill bits or hole enlarging tools.

- Incremental Enlargement: The stepped design allows for incremental hole enlargement, providing flexibility in achieving different hole sizes.

- Smooth Finishes: Step drill bits produce clean and smooth surfaces inside the hole, reducing the need for additional finishing operations.

- User-Friendly: Step drill bits are easy to use, requiring minimal setup and providing efficient hole enlargement.

Countersink

A countersink tool is used to create a conical recess at the entrance of a hole, allowing the head of a fastener to sit flush with or below the surface. It is typically used in applications where the appearance of the fasteners is important, such as woodworking or metalworking projects. Countersinks come in various sizes and designs, including single-flute, multi-flute, or adjustable countersinks. The cutting action of a countersink removes material from the entrance, enlarging it to accommodate the fastener head while providing a clean and finished look.

Benefits of using a countersink:

- Flush or Recessed Fasteners: Countersinks create a recess at the entrance of the hole, allowing fasteners to be flush with or below the surface.

- Finishing Touch: Countersinks provide a clean and finished appearance to drilled holes, enhancing the overall aesthetics of the project.

- Versatility: Countersinks are available in various designs and sizes, making them suitable for a range of hole diameters and materials.

- Cost-Effective: Countersinks are generally affordable and offer a cost-effective solution for creating recesses in drilled holes.

Additional Information

Using Lathe Tools for Enlarging Holes

When using any of the lathe tools mentioned above for enlarging holes, it is essential to follow proper safety practices. Always wear appropriate protective equipment, such as safety goggles, gloves, and hearing protection. Ensure that the lathe machine is in good working condition and properly secured before starting any hole enlargement operations. Take your time and apply consistent pressure to achieve quality results. Remember to regularly check and maintain the cutting tools to ensure optimal performance and prolong tool life. With practice and experience, you will master the art of hole enlargement and produce professional-grade results.

Tips for Hole Enlargement on a Lathe

Here are some additional tips to consider when enlarging holes on a lathe:

- Measure Twice, Cut Once: Take accurate measurements of the original hole and plan the enlargement process accordingly.

- Use Lubrication: Apply cutting fluid or lubricant to the cutting tool to reduce friction and prolong tool life.

- Start Small: If enlarging a hole to a specific diameter, start with a slightly smaller diameter tool and gradually increase the size for better control and accuracy.

- Take Breaks: Enlarging holes can be a time-consuming process. Take breaks to avoid fatigue and maintain focus.

- Inspect and Test: Regularly inspect the hole during the enlargement process and test the fit of any components or fasteners to ensure the desired result.

Conclusion

Enlarging a hole on a lathe requires the use of specialized tools designed for this purpose. Boring bars, reamers, expanding mandrels, counterbores, step drill bits, and countersinks are some of the commonly used tools. Each tool offers unique benefits and features, allowing for precise and accurate hole enlargement. By understanding the capabilities of these tools and following proper techniques, you can achieve professional results and enhance your machining skills. Remember to prioritize safety and adhere to proper procedures when operating a lathe machine. With practice and experience, you will become proficient in hole enlargement and achieve the desired results for your projects.

Key Takeaways: What Lathe Tool is Used to Enlarge a Hole?

- The lathe tool used to enlarge a hole is called a boring bar

- Boring bars are long, slender tools that are inserted into the hole and rotate to remove material

- Boring bars come in various sizes and shapes depending on the desired hole enlargement

- Using a boring bar requires precision and careful control to ensure the hole is enlarged evenly

- Boring bars can be used on both metal and wood materials

Frequently Asked Questions

Welcome to our FAQ section on the topic of lathe tools! Here, we will address some common queries related to enlarging holes using a lathe tool.

What tool can I use on a lathe to increase the size of a hole?

When it comes to enlarging a hole on a lathe, you can use a boring bar. A boring bar is a versatile tool that helps widen or enlarge existing holes with precision. It is designed to remove material, such as metal or wood, from the inner diameter of a workpiece.

Typically, a boring bar consists of a shank, which is mounted in the lathe’s tool holder, and a cutting head that extends beyond the shank. By rotating the workpiece and guiding the boring bar, you can gradually increase the size of the hole to the desired diameter.

What are the benefits of using a boring bar to enlarge a hole?

Using a boring bar offers several advantages when it comes to enlarging holes on a lathe. Firstly, it allows you to achieve precise and accurate results, ensuring the hole is enlarged to the exact dimensions required. This is especially important when working on projects that demand tight tolerances.

Additionally, a boring bar provides excellent control over the cutting process. You can adjust the cutting speed, feed rate, and depth of cut, allowing you to gradually remove material and avoid any sudden or excessive removal that could damage the workpiece. This control also enables you to achieve a smooth and even surface finish on the newly enlarged hole.

Are there different types of boring bars for enlarging holes?

Yes, there are various types of boring bars available for different purposes. The most common types include solid boring bars, indexable insert boring bars, and carbide-tipped boring bars.

Solid boring bars are made from a single piece of high-quality steel and are ideal for smaller diameter holes. Indexable insert boring bars feature replaceable inserts, which allow for easy and cost-effective cutting edge replacement. Carbide-tipped boring bars are known for their durability and are suitable for heavy-duty machining operations.

What factors should I consider when selecting a boring bar?

When choosing a boring bar for enlarging holes, several factors should be considered. Firstly, consider the diameter range you need to work with. Ensure the boring bar is capable of accommodating the range of hole sizes you require.

Additionally, consider the material you will be working with. Different materials may require different cutting speeds and feeds, so select a boring bar that is specifically designed for the material you will be machining. Finally, consider the rigidity and stability of the boring bar to ensure it can handle the cutting forces and provide consistent and reliable performance.

What safety precautions should I take when using a boring bar?

When using a boring bar to enlarge holes on a lathe, safety should always be a top priority. Make sure to wear appropriate personal protective equipment, such as safety glasses and gloves, to protect yourself from potential hazards.

It is also crucial to secure the workpiece firmly in the lathe’s chuck or collet to prevent any movement or vibrations during the cutting process. Always double-check that the machine is properly set up and that all components are securely tightened before starting the machining operation. Lastly, take your time and work at a comfortable pace, paying close attention to the cutting process to ensure everything is going smoothly.

Summary

So, if you want to make a hole bigger on a lathe, you can use a boring tool. This tool cuts away material and enlarges the hole. Another option is using a reamer, which smooths out and trims the hole to the desired size. Both tools can help you get the right size hole without starting from scratch.

But remember, whether you’re using a boring tool or a reamer, make sure you measure carefully and take it slow. Enlarging a hole requires precision and patience to get the best results. Happy lathe turning!