Have you ever wondered what powers a tunnel boring machine? Well, you’re in for an exciting journey to the underground world! You may think it’s a superhero-like machine with lightning speed, but the truth is even more fascinating.

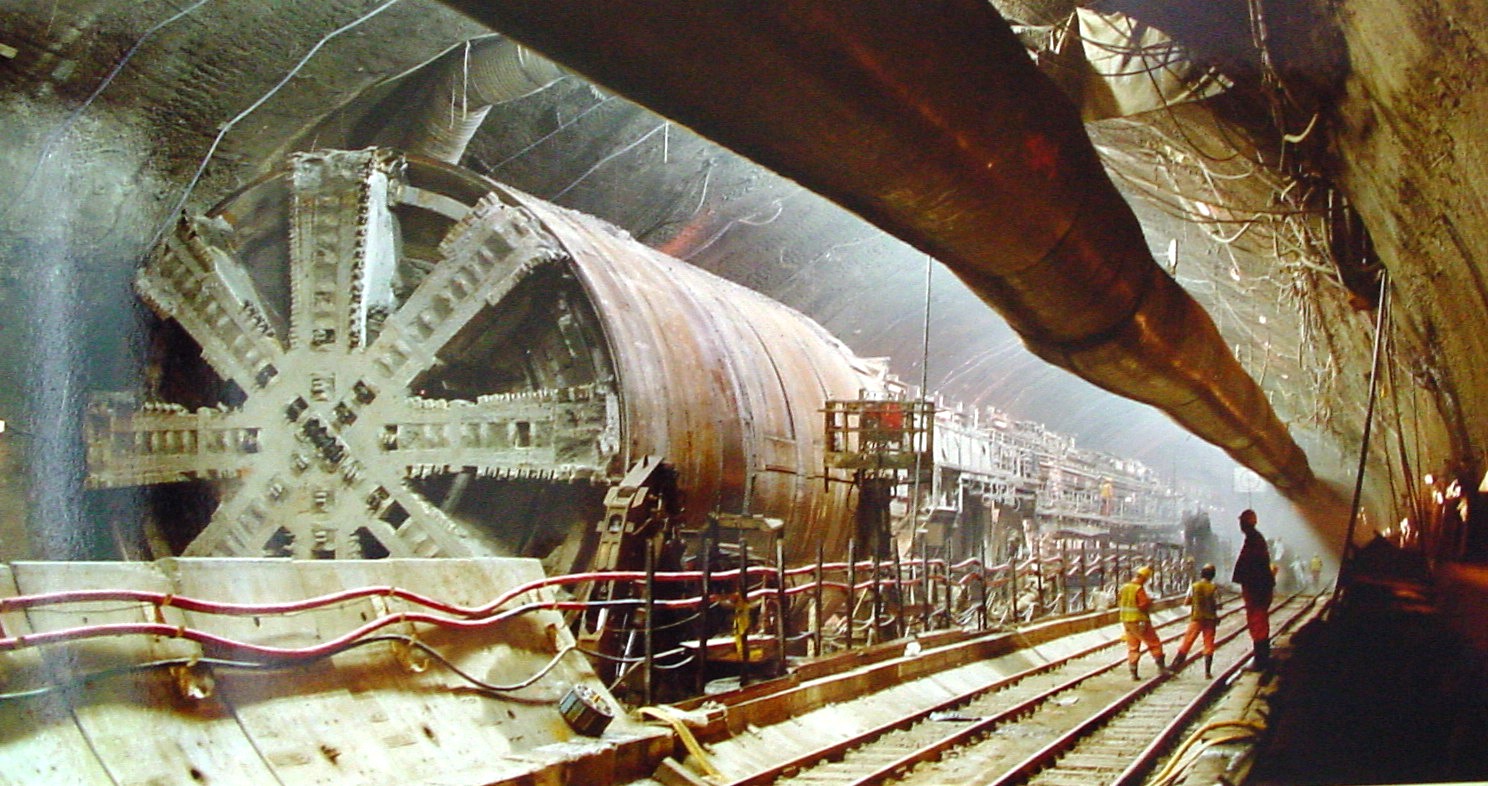

Imagine a massive creature that chews through mountains and excavates long tunnels deep beneath the Earth’s surface. It’s like a giant mechanical worm on a mission. But how does it get its power to do all this impressive work?

In this article, we will uncover the mystery and reveal what powers a tunnel boring machine. Get ready to explore the incredible machinery that brings these underground marvels to life!

What Powers a Tunnel Boring Machine?

Tunnel boring machines (TBMs) are colossal machines that are used to excavate tunnels through various types of soil and rock. They are incredibly powerful and can bore through even the toughest of terrains. But what exactly powers these impressive machines? In this article, we will delve into the inner workings of tunnel boring machines and explore the different sources of power that drive these engineering marvels.

The Main Power Source: Electricity

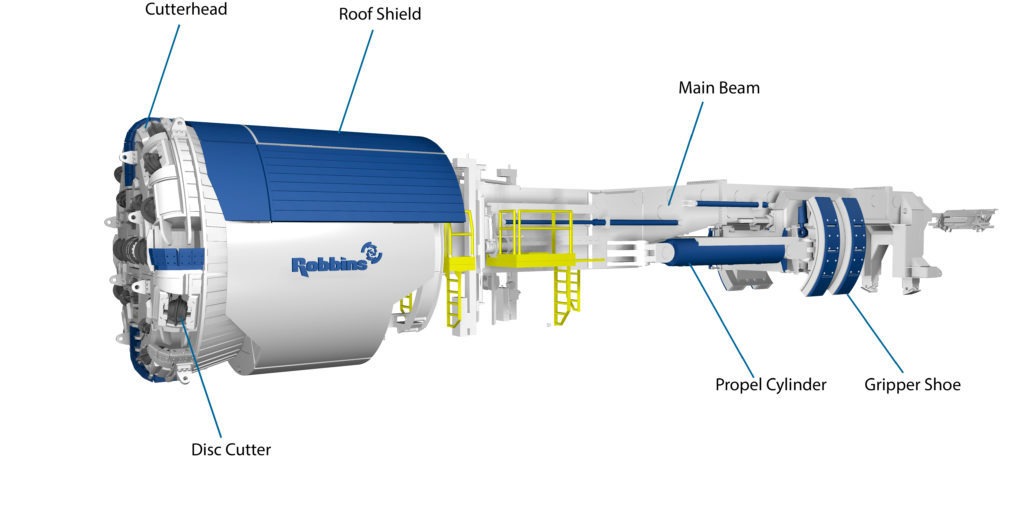

Tunnel boring machines primarily rely on electricity to operate. Large electric motors, typically powered by an external power supply, provide the necessary torque and horsepower to drive the cutterhead and propel the machine forward. This design allows for more precise control, increased efficiency, and reduced emissions compared to using traditional diesel engines for power.

The electricity for tunnel boring machines is typically supplied through high-voltage cables connected to an external power grid. These cables are fed into the tunnel through specially designed entry points and are securely fastened to ensure a continuous flow of electricity. In some cases, the tunnels themselves may have a dedicated power system to provide electricity directly to the TBM.

Auxiliary Power Systems

In addition to the main electric motors, tunnel boring machines also incorporate auxiliary power systems to operate various components and systems. These auxiliary systems are typically powered by smaller electric motors or hydraulic systems. They include:

1. Conveyor Systems: Tunnel boring machines often employ conveyor systems to remove excavated material from the tunnel. These systems are powered by electric motors and transport the debris to the surface for disposal.

2. Ventilation Systems: To maintain air quality and remove dust and fumes generated during excavation, tunnel boring machines utilize powerful ventilation systems. These systems consist of fans and blowers driven by electric motors.

3. Cooling Systems: Tunnel boring machines generate a significant amount of heat during operation. To prevent overheating and ensure optimal performance, cooling systems with fans and pumps are employed. These systems are also powered by electric motors.

4. Control Systems: Tunnel boring machines require sophisticated control systems to monitor and adjust various parameters during operation. These systems are powered by dedicated electrical circuits and control modules.

Advantages of Electric-Powered TBMs

There are several advantages to using electric-powered tunnel boring machines:

1. Environmental Benefits: Electric-powered TBMs produce zero exhaust emissions, resulting in improved air quality, reduced noise pollution, and decreased carbon footprint compared to diesel-powered alternatives.

2. Greater Efficiency: Electric motors provide smoother and more controlled operation, enhancing the overall efficiency of tunneling projects. This increased efficiency translates to faster completion times and reduced costs.

3. Flexibility: Electric-powered TBMs can be easily adapted to different power sources, including renewable energy, making them more sustainable and future-proof.

In summary, tunnel boring machines are powered primarily by electricity, with large electric motors driving the main cutterhead and propulsion systems. Auxiliary power systems, consisting of electric motors and hydraulic systems, operate various components and systems within the TBM. The shift towards electric-powered TBMs brings numerous benefits, including environmental sustainability and improved efficiency. As tunnelling technology continues to advance, it is likely that we will see further innovations in the power systems of tunnel boring machines, leading to even more remarkable feats of engineering.

Key Takeaways: What Powers a Tunnel Boring Machine?

- A tunnel boring machine is powered by electricity or diesel engines.

- Electric-powered tunnel boring machines use a series of electric motors to drive the cutterhead.

- Diesel-powered tunnel boring machines have a diesel engine that powers a hydraulic system.

- The hydraulic system generates the necessary force and pressure to operate the cutterhead and the other components of the machine.

- Both electric and diesel-powered tunnel boring machines require a constant supply of power to operate efficiently.

Frequently Asked Questions

Curious about the inner workings behind tunnel boring machines? Below are some commonly asked questions and detailed answers related to what powers these impressive machines.

How is a tunnel boring machine powered?

A tunnel boring machine (TBM) is typically powered by electric motors. These motors receive their electrical power from a combination of sources. In most cases, TBMs are connected to an external power supply, such as the grid or a temporary power station. Electricity is then transmitted through cables and distributed to various components of the machine.

Additionally, TBMs may also have an onboard power generation system to provide electricity when an external power supply is not available or practical. This onboard power generation is often achieved through diesel engines or generators powered by fossil fuels, batteries, or even renewable sources such as solar panels. These power sources ensure that the TBM operates smoothly and efficiently throughout the tunneling process.

What are the advantages of using electric power for tunnel boring machines?

Using electric power for tunnel boring machines offers several advantages. Firstly, electric-powered TBMs produce fewer emissions compared to diesel-powered ones, making them more environmentally friendly. This is especially important when working in enclosed spaces like tunnels.

Additionally, electric power allows for better control and flexibility. The speed and torque of the electric motors can be easily adjusted to suit different ground conditions, reducing the likelihood of machine malfunctions or accidents. Electric-powered TBMs also tend to be quieter, reducing noise pollution for workers and nearby residents. Overall, relying on electric power is a more sustainable and efficient choice for tunnel boring machines.

Can renewable energy sources be used to power tunnel boring machines?

Yes, renewable energy sources can be harnessed to power tunnel boring machines. In recent years, the industry has been exploring the use of renewable energy options such as solar panels and battery storage systems. Solar panels can be installed on the surface or on the TBM itself, converting sunlight into electricity to power the machine’s operations.

Battery storage systems are another viable option. These batteries can store excess energy generated from renewable sources, like wind or solar power, and provide a consistent power supply to the TBM. By utilizing renewable energy sources, tunnel boring machines can significantly reduce their environmental impact and contribute to a more sustainable construction process.

Are there any safety measures in place to ensure the power supply of tunnel boring machines?

Yes, there are stringent safety measures in place to ensure the reliable power supply of tunnel boring machines. One essential aspect is the use of redundant power supply systems. TBMs often have multiple power sources, including redundant cables and backup generators, to prevent power outages that could disrupt the tunneling process.

Furthermore, advanced monitoring systems are utilized to continuously monitor the power supply, detect any fluctuations or abnormalities, and provide real-time alerts to operators. Regular maintenance and inspections are also carried out to identify potential issues before they become critical. These safety measures ensure that tunnel boring machines are powered efficiently and safely throughout their operation.

Can tunnel boring machines operate without an external power supply?

Yes, tunnel boring machines can operate without an external power supply. They can be equipped with onboard power generation systems to generate electricity independently. This is particularly useful in remote areas where connecting to an external power supply may not be feasible or cost-effective.

Onboard power generation can be achieved through various means, including diesel engines, generators, or renewable energy sources such as solar panels or wind turbines. These onboard power sources provide the necessary energy to operate the tunnel boring machine, enabling it to carry out excavation and tunnel construction even in locations that lack access to an external power grid.

Summary

So, to sum it all up: tunnel boring machines are powered by electricity and hydraulics. The electric motors drive the cutterhead, while the hydraulics control the movement and pressure. These machines are massive, efficient, and help build tunnels for various purposes. Tunnel boring machines are true engineering marvels!

In conclusion, tunnel boring machines are the superheroes of construction, using electricity and hydraulics to dig tunnels and make our lives easier. So next time you see a tunnel being built, remember the incredible power behind it!