Do you ever wonder about the inner workings of a table saw? Well, one of the crucial aspects is the RPM, or revolutions per minute, at which it runs. But what does that actually mean? And why is it important? In this article, we’re going to dive into the world of table saws and explore what RPMs they typically operate at. So, if you’re curious about how fast these powerful tools spin, keep reading!

When it comes to woodworking, understanding the RPM of a table saw is essential for a couple of reasons. First and foremost, it affects the cutting speed and efficiency of the saw. The RPM determines how quickly the blade spins, which directly impacts how fast and smooth the cuts can be made. Additionally, knowing the RPM is crucial for ensuring the safety of the operator. Different materials and blade types require specific RPM settings to prevent accidents or damage to the saw.

Now, you might be wondering, “What RPM does a table saw run at?” Well, the exact RPM can vary depending on the specific model and purpose of the saw. However, most standard table saws typically run at speeds ranging from 3,000 to 4,000 rotations per minute. This range strikes a balance between cutting power and precision, allowing for efficient and accurate cuts across a variety of woodworking applications. Remember, though, always consult the manufacturer’s instructions to determine the recommended RPM for your particular table saw model.

What RPM Does a Table Saw Run At?

When it comes to woodworking, having the right tools is essential. One such tool that every woodworker needs is a table saw. Whether you are a professional carpenter or a DIY enthusiast, a table saw can greatly enhance your woodworking projects. But have you ever wondered what RPM (revolutions per minute) a table saw runs at? Understanding the RPM of a table saw is crucial for ensuring the accuracy and efficiency of your cuts. In this article, we will dive deep into the world of table saw RPMs and explore everything you need to know about this important aspect of woodworking.

How Does RPM Impact the Performance of a Table Saw?

Before we delve into the specific RPMs of table saws, let’s first understand how RPM impacts the overall performance of a table saw. The RPM of a table saw refers to the number of times the saw blade rotates per minute. The blade speed plays a crucial role in determining the quality of the cuts and the overall performance of the table saw.

Higher RPMs generally result in smoother and cleaner cuts as the blade can slice through the material with ease. On the other hand, lower RPMs may result in rough and jagged cuts. However, it’s important to note that the ideal RPM for a table saw depends on various factors such as the type of material being cut, the type and condition of the blade, and the desired finish of the cut. Let’s take a closer look at these factors and how they influence the RPM requirements of a table saw.

The Type of Material Being Cut

One of the key factors that determine the RPM requirements of a table saw is the type of material being cut. Different materials require different blade speeds for optimal performance. For example, cutting softwoods like pine or cedar may require a lower RPM compared to cutting hardwoods like oak or maple. Similarly, cutting materials like plastic or aluminum may require a different blade speed altogether. It’s important to consult the manufacturer’s guidelines or the blade’s specifications to determine the recommended RPM for the specific material you are working with.

Additionally, the thickness of the material can also impact the RPM requirements. Thicker materials may necessitate a lower RPM to prevent overheating or blade dulling, while thinner materials may benefit from a higher RPM for cleaner cuts. It’s important to consider both the material type and thickness when determining the optimal RPM for your table saw.

The Type and Condition of the Blade

The type and condition of the blade also play a significant role in determining the appropriate RPM for a table saw. Different blades are designed for specific tasks and have varying RPM requirements. For instance, a blade designed for ripping cuts may have a different RPM range than a blade meant for crosscuts or miter cuts. It’s vital to ensure that you are using the correct blade for the task at hand and that the blade is in good condition.

A dull or damaged blade can lead to a variety of issues, including increased vibration, poor cutting quality, and a higher risk of kickback. It’s crucial to regularly inspect your blades for any signs of wear or damage and replace them as needed. Using a blade that is suited to the task and in optimal condition will help ensure that you achieve the desired results and maintain the safety of your table saw.

The Desired Finish of the Cut

Another factor to consider when determining the RPM requirements of a table saw is the desired finish of the cut. Different finishes may require different blade speeds. For instance, if you are aiming for a smooth and polished finish, a higher RPM may be necessary to reduce tear-out and produce clean edges. Conversely, if you are intentionally going for a more rustic or rough finish, a lower RPM may be suitable.

It’s important to note that when adjusting the RPM for a specific finish, other factors such as the feed rate, the use of appropriate accessories like a guide, and the application of cutting lubricants or protective coatings should also be taken into consideration. Achieving the desired finish requires a combination of factors working together, with RPM being just one piece of the puzzle.

The Importance of Adjusting the RPM Correctly

Now that we understand the factors that influence the RPM requirements of a table saw, it’s crucial to emphasize the importance of adjusting the RPM correctly. Failure to set the correct RPM can lead to a range of issues, including decreased cutting quality, increased risk of kickback, and potential damage to the material or the table saw itself.

Working with an RPM that is too high for the material can result in excessive heat buildup, increased blade wear, and a greater likelihood of kickback. On the other hand, using an RPM that is too low may cause the blade to struggle, leading to rough cuts and potential damage to the motor or other components of the table saw.

Therefore, it is crucial to consult the manufacturer’s guidelines and the blade’s specifications to determine the recommended RPM for the specific task and material you are working with. Take the time to adjust the RPM accordingly and regularly inspect and maintain your table saw to ensure optimal performance and safety.

The Relationship Between Blade Size and RPM

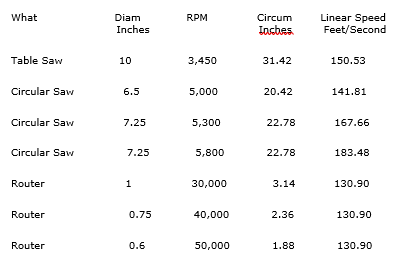

While the RPM is an essential consideration when working with a table saw, it’s also important to understand the relationship between blade size and RPM. The size of the blade used in a table saw can impact the RPM requirements and overall performance of the tool.

Table saws generally come with different blade sizes, ranging from 8 inches to 12 inches in diameter. Each blade size has its own RPM requirements, and it’s important to choose a blade that is compatible with your table saw’s RPM range. Using a blade that exceeds the recommended RPM can be dangerous and potentially cause the blade to become unbalanced or lead to other problems.

When purchasing blades for your table saw, always ensure that the blade is specifically designed for your saw’s RPM range. Look for blades that are labeled as compatible with your saw’s RPM specifications to ensure a safe and efficient cutting experience.

Ensuring Safety and Efficiency With the Right RPM

Now that we have explored the importance of RPM and how it impacts the performance of a table saw, let’s discuss some tips for ensuring safety and efficiency when working with different RPMs.

1. Read the Manual

Before operating your table saw, make sure to thoroughly read the manufacturer’s manual. The manual will provide specific instructions on adjusting the RPM, as well as other important safety guidelines and maintenance procedures. Familiarize yourself with the information provided to ensure safe and efficient operation.

2. Use the Right Blade

Using the right blade for the material and task at hand is crucial for achieving optimal results. Make sure to select a blade that is compatible with your desired RPM range and is designed for the specific cutting task you are undertaking. Using the wrong blade can lead to poor cutting performance and potential safety hazards.

3. Inspect and Maintain Your Table Saw

Regularly inspecting and maintaining your table saw is essential for maintaining its performance and safety. Check the blade for any signs of wear or damage, and replace it if necessary. Keep the table saw clean and free from debris, and regularly lubricate moving parts to ensure smooth operation. Additionally, adjust the RPM as needed for different tasks and materials to optimize cutting performance.

Conclusion

Understanding the RPM requirements of a table saw is crucial for achieving accurate and efficient cuts in your woodworking projects. Factors such as the type of material being cut, the type and condition of the blade, and the desired finish of the cut all influence the RPM requirements. By adjusting the RPM correctly and following safety guidelines, you can ensure both the safety and efficiency of your table saw. Remember to always consult the manufacturer’s guidelines and take necessary precautions to create a successful and enjoyable woodworking experience.

Key Takeaways: What RPM Does a Table Saw Run at?

- A table saw typically runs at around 3,000 to 4,000 revolutions per minute (RPM).

- The higher the RPM, the faster the blade spins, resulting in smoother and cleaner cuts.

- Lower RPMs are ideal for cutting denser materials like hardwood.

- Choosing the right RPM depends on the type of material and cut you want to achieve.

- Always follow the manufacturer’s guidelines for the specific table saw you are using.

Frequently Asked Questions

Here are some common questions related to the speed at which a table saw operates:

How fast does a table saw blade spin?

Table saw blades typically spin at speeds ranging from 3,000 to 5,000 revolutions per minute (RPM). This high speed allows for efficient cutting through various materials such as wood or plastic. The speed at which the blade spins helps to ensure smooth and precise cuts.

It’s important to note that different types of blades may have different recommended RPMs. For example, a blade specifically designed for cutting metal may have a higher RPM range, while a blade meant for more delicate materials may have a lower RPM range. Always refer to the manufacturer’s guidelines for the specific blade you are using.

Why is the RPM of a table saw important?

The RPM of a table saw holds great importance in determining the saw’s cutting performance and overall efficiency. The higher the RPM, the faster the blade is spinning, which allows for quicker cuts and more efficient material removal. A higher RPM can minimize the risk of kickback and prevent burning of the material being cut.

On the other hand, if the RPM is set too low, the blade may struggle to cut through the material effectively and may end up burning it or causing rough edges. Therefore, it’s essential to choose the appropriate RPM for the type of material and blade you’re using to achieve the best results.

Can the RPM of a table saw be adjusted?

Yes, the RPM of some table saws can be adjusted to suit different cutting needs and materials. However, not all table saws have adjustable RPM settings. In general, higher-end table saws may offer the flexibility to adjust the blade speed to optimize cutting performance. This allows users to adapt the saw to different materials and achieve better results.

If your table saw has an adjustable RPM feature, consult the manufacturer’s instructions or the saw’s manual to learn how to make the necessary adjustments safely. It’s essential to follow the recommended guidelines to avoid damaging the saw or compromising safety.

How can I determine the RPM of my table saw?

The RPM of your table saw can be determined by checking the manufacturer’s specifications either in the user manual or on the saw’s label or plate. It’s important to refer to the specific model and type of table saw you have, as different saws may have different operating speeds.

If you can’t find the RPM information on the saw or in the user manual, consider reaching out to the manufacturer’s customer support or checking their website for the required details. Remember to have the model and serial number of your table saw handy when contacting the manufacturer for accurate information.

What are the risks of operating a table saw at the wrong RPM?

Operating a table saw at the wrong RPM can pose several risks. If the RPM is too high for the material and blade being used, it can cause the material to burn and produce rough or jagged edges. Additionally, cutting at an incorrect RPM can increase the chances of kickback, where the material being cut is forcefully thrown back towards the operator.

Conversely, using too low of an RPM can result in a slower cutting speed and may cause the blade to struggle, overheat, or even stall. This can impact the quality of the cut and increase the risk of accidents. It’s important to always match the RPM to the specific material and blade to ensure safe and effective cutting.

Summary

So, what rpm does a table saw run at? Table saws usually run at speeds between 3,000 to 5,000 rotations per minute (rpm). These high speeds help the saw blades cut through wood quickly and efficiently.

It’s important to know the speed of your table saw because different cutting tasks require different speeds. Slower speeds are better for cutting thick or harder woods, while faster speeds work well for cutting thinner or softer materials.

Remember, always follow the manufacturer’s guidelines and wear safety gear when using a table saw to keep yourself safe.