Have you ever wondered what rules should be followed when using a drill press? Well, you’re in the right place! Using a drill press can be an exciting and useful skill to have, but it’s important to know the proper safety measures and guidelines. In this article, we’ll explore the essential rules you need to follow to ensure a safe and successful drilling experience with a drill press. So, let’s dive in and discover the key rules for using a drill press effectively!

When using a drill press, it’s important to follow certain rules to ensure safety and efficiency. Here are some guidelines to keep in mind:

- Wear appropriate safety gear, including safety glasses and ear protection.

- Secure the workpiece firmly in place.

- Select the correct drill bit and adjust the speed accordingly.

- Maintain control of the drill press by applying steady pressure.

- Keep your hands away from the rotating parts.

- Always turn off the drill press and unplug it when not in use.

By following these rules, you can use a drill press safely and effectively.

What Rules Should Be Followed When Using a Drill Press?

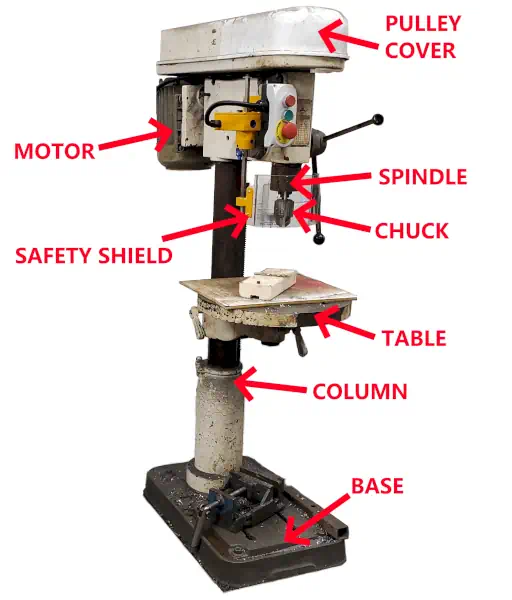

Drill presses are powerful and versatile tools used for drilling holes in various materials, such as wood, metal, and plastic. While they are essential for many DIY projects and professional applications, they can also be dangerous if not used correctly. To ensure safety and maximize efficiency, it is crucial to follow specific rules when operating a drill press. In this article, we will discuss seven important rules that should be followed when using a drill press.

Rule 1: Wear Safety Gear

When using a drill press, safety should be your top priority. Always wear appropriate safety gear, including safety glasses, hearing protection, and gloves. Safety glasses protect your eyes from flying debris, while hearing protection helps reduce noise levels that can damage your hearing. Additionally, gloves can provide a better grip and protect your hands from sharp edges or hot surfaces.

1. Safety Glasses

Wearing safety glasses is vital when using a drill press as they protect your eyes from flying debris, such as wood or metal chips. Even a small particle can cause severe eye damage if it enters your eyes while drilling. Ensure that your safety glasses are ANSI-rated for impact resistance and fit snugly on your face. Regular prescription glasses do not offer adequate protection and should be replaced with safety glasses.

2. Hearing Protection

Drilling can create loud noise levels that may exceed safe limits and damage your hearing. Invest in high-quality hearing protection, such as earmuffs or earplugs, to reduce the noise’s intensity. It is especially crucial when operating a drill press for an extended period or in a noisy environment.

3. Gloves

While gloves are not strictly necessary when operating a drill press, they can provide a better grip and protect your hands during certain tasks. Choose gloves made from durable materials that offer flexibility and ensure a comfortable fit. Avoid loose-fitting gloves that can get caught in the drill press or hinder your movements.

Rule 2: Select the Right Drill Bit and Speed

Choosing the correct drill bit and setting the appropriate speed is crucial for achieving accurate and efficient drilling results. Different materials require different drill bits and speeds. Using the wrong combination can lead to poor drilling performance, damaged bits, or even accidents.

1. Selecting the Right Drill Bit

Consider the material you are drilling when selecting a drill bit. For wood, use wood drill bits with a sharp point and wide flutes to remove chips effectively. Metal drill bits have a different design with a more pronounced angle and sharper cutting edges to handle metal materials. Masonry drill bits are specially designed for drilling into concrete, brick, or stone.

2. Setting the Proper Speed

Many drill presses allow you to adjust the speed based on the material and drill bit size. Refer to the manufacturer’s guidelines or consult drilling speed charts to determine the appropriate speed settings. Using a low speed for a high-speed application can damage the material or overheat the bit, while using a high speed for a low-speed application can result in poor drilling performance.

3. Lubrication

Some drilling applications, such as drilling through metal, may require lubrication to reduce friction and prevent overheating. Apply cutting oil or a suitable lubricant to ensure smooth drilling and prolong the life of your drill bits. Be sure to follow the manufacturer’s instructions regarding the type and application of the lubricant.

Rule 3: Secure the Workpiece and Adjust the Depth Stop

To ensure stability and precision during drilling, always secure the workpiece properly and adjust the depth stop as necessary. This will prevent the material from shifting or the drill bit from penetrating too deep, which can cause damage or ruin the project.

1. Securing the Workpiece

Use clamps, vices, or a drill press table with built-in clamping mechanisms to securely hold the workpiece in place. The material should be firmly fixed to prevent any movement during drilling. Ensure that the clamps or vices are positioned away from the drilling path to avoid interference with the drill press or potential accidents.

2. Adjusting the Depth Stop

Most drill presses have a depth stop feature that allows you to set the desired drilling depth. Adjust the depth stop according to your project requirements to ensure consistent and accurate hole depths. This feature is particularly useful when drilling multiple holes to achieve uniformity.

3. Pre-drilling Pilot Holes

For certain materials, such as hardwood or metal, it may be necessary to pre-drill pilot holes to guide the drill bit and prevent any unwanted movements. Pilot holes also help reduce the risk of splitting wood or damaging the material. Use a smaller drill bit than the final hole size as a guide for the pilot hole.

Rule 4: Maintain Clean and Organized Work Area

A clean and organized work area is essential for a safe and efficient drilling experience. Cluttered workspaces can lead to accidents, damaged equipment, or incorrect drilling. By maintaining a clean and organized environment, you can focus on the task at hand, reduce distractions, and ensure better productivity.

1. Clear the Work Area

Before starting any drilling operation, clear the work area of any unnecessary objects or debris. Remove any loose tools, materials, or obstacles that may interfere with the drilling process. Maintain a clutter-free workspace to minimize the risk of tripping or knocking over equipment.

2. Organize Tools and Accessories

Arrange your drill bits, accessories, and tools in a logical and easily accessible manner. Use storage containers, racks, or toolboxes to keep everything in its place. This organization will save you time and prevent the loss of smaller items, such as screws or drill bits, which can become misplaced or damaged.

3. Clean Up After Use

After you have finished drilling, take a few moments to clean up the work area. Remove any leftover wood chips, metal shavings, or debris generated during the drilling process. Use a brush or vacuum to clean the drill press, table, and surrounding areas. Regular maintenance and cleaning help prolong the lifespan of your equipment.

Rule 5: Keep Hands and Clothing Clear of the Drill Bit

When operating a drill press, it is essential to keep your hands and clothing away from the drill bit. This prevents accidents, such as entanglement or injury, and ensures safe and uninterrupted drilling.

1. Do Not Hand-Hold Small or Unstable Workpieces

Avoid hand-holding small or unstable workpieces while drilling. Always use clamps or a suitable workholding device to secure the material firmly. Hand-holding can lead to slips or jolts, causing injury or damage to the workpiece and drill bit.

2. Do Not Wear Loose Clothing or Jewelry

Loose clothing, jewelry, or accessories can get entangled in the spinning drill bit, leading to serious injury. Avoid wearing anything that could be caught by the rotating parts. Roll up long sleeves, remove necklaces, bracelets, or rings, and tie back long hair to keep them away from the drill press.

3. Use Appropriate Feeding Techniques

When drilling, use proper feeding techniques to maintain control and avoid accidents. Apply even and steady pressure to feed the workpiece into the drill bit. Do not force the material or use excessive pressure that could cause kickback. Let the drill do the work and guide the material carefully.

Rule 6: Power Off and Disconnect Before Making Adjustments or Changing Bits

Safety should always be the first consideration when making adjustments or changing drill bits on a drill press. Before making any changes, ensure that the power is turned off, and the drill press is unplugged or disconnected from the power source. This prevents accidental start-ups and protects against electrical hazards.

1. Turn Off the Drill Press

Before making any adjustments, turning the power off ensures that the drill press does not accidentally engage while you’re working on it, reducing the risk of injury. Locate the power switch or button and turn it to the “off” position.

2. Unplug or Disconnect from Power Source

To further enhance safety, unplug the drill press from the power outlet or disconnect it from the power source. This step prevents any accidental start-up, even if the power switch is activated accidentally.

3. Wait for the Drill Bit to Come to a Complete Stop

After turning off the drill press and disconnecting the power, wait for the drill bit to come to a complete stop before making any adjustments or attempting to change the bit. This ensures that you are not working with a moving or spinning drill bit, reducing the risk of injury.

Rule 7: Follow Manufacturer’s Guidelines and Seek Professional Training

Lastly, always follow the manufacturer’s guidelines and instructions specific to your drill press model. Each drill press may have unique features or limitations that are crucial to understand for safe and efficient operation. Additionally, seeking professional training or guidance from experienced users can provide valuable insights and improve your skills in using a drill press.

1. Read the User Manual

When you purchase a drill press, carefully read the user manual provided by the manufacturer. Familiarize yourself with the specific features, safety precautions, and maintenance instructions for your drill press model. Understanding the tool’s capabilities and limitations will help you operate it more effectively and safely.

2. Seek Professional Training

If you are new to using a drill press or need to enhance your skills, consider seeking professional training or attending workshops. Joining a woodworking or metalworking class can provide hands-on experience, direct guidance, and safety tips from experts. This training will help you gain confidence and develop proper techniques for using a drill press.

3. Stay Updated with Safety Guidelines

Stay informed about any safety guidelines or updates related to drill press operations. Manufacturers may release safety bulletins or notifications, which can provide valuable information to enhance your safety knowledge and prevent any potential hazards.

In conclusion, using a drill press requires careful adherence to safety rules and guidelines. By wearing appropriate safety gear, selecting the right drill bit and speed, securing the workpiece, maintaining a clean work area, keeping hands and clothing clear of the drill bit, powering off and disconnecting before making adjustments, and following the manufacturer’s guidelines, you can ensure safe and efficient drilling operations. Remember, safety should always be your top priority when using a drill press.

Key Takeaways

- Always wear safety goggles to protect your eyes.

- Securely clamp the workpiece before drilling.

- Adjust the speed and depth of the drill press according to the material being drilled.

- Keep your hands away from the rotating drill bit.

- Never wear loose clothing or jewelry that could get caught in the drill press.

Frequently Asked Questions

Welcome to our Frequently Asked Questions section, where we’ll address some important rules to follow when using a drill press. Whether you’re a beginner or an experienced user, it’s crucial to prioritize safety and proper technique. Read on to find answers to some commonly asked questions about drill press usage.

1. How can I ensure my safety while using a drill press?

When using a drill press, safety should always be your top priority. Here are some rules to follow:

Firstly, wear appropriate personal protective equipment (PPE) like safety goggles to protect your eyes from debris. Additionally, use a dust mask to prevent inhalation of dust particles. Avoid wearing loose clothing, jewelry, or anything that could get entangled in the machine.

Secondly, secure your workpiece firmly to prevent it from spinning or moving during the drilling process. Use clamps or a vise to hold it securely in place. Finally, always ensure the machine is switched off and unplugged when making adjustments, changing drill bits, or performing any maintenance tasks.

2. What are the correct steps for drilling a hole using a drill press?

To drill a hole effectively and safely using a drill press, follow these steps:

Start by securing your workpiece and adjusting the height of the drill bit to the desired depth. Next, align the center of the drill bit with the intended drilling spot on your workpiece. Once everything is properly aligned, turn on the drill press and gradually lower the spinning drill bit onto the workpiece.

Apply consistent downward pressure while drilling, allowing the machine’s motor to do the work. Avoid excessive force, as it can cause the drill bit to break or the workpiece to splinter. Finally, once the drilling is complete, switch off the drill press and safely remove the workpiece from the machine.

3. What type of drill bits are recommended for a drill press?

When using a drill press, it’s important to select the appropriate drill bits for the task at hand. Generally, twist drill bits are commonly used with drill presses. These bits are versatile and suitable for drilling different materials like wood, metal, and plastic.

Before using a particular drill bit, ensure it matches the size and type of hole you need. Always refer to the drill bit manufacturer’s recommendations for the proper drill speed, as running the drill press at excessive speeds can damage both the bit and the workpiece.

4. How can I maintain my drill press in good working condition?

To keep your drill press in good working condition, regular maintenance is essential. Here are some maintenance tips:

Start by cleaning the machine after each use. Remove any sawdust, debris, or chips that may have accumulated. Lubricate moving parts, such as the drill shaft, with a suitable lubricant to prevent rust and ensure smooth operation. Check the belts for any signs of wear and replace them if necessary.

Ensure the drill press is properly calibrated and aligned to ensure accurate drilling. Periodically clean and check the drill chuck for any signs of damage. If you notice any issues or unusual noises during operation, consult the user manual or contact the manufacturer for assistance.

5. Are there any precautions I should take when using a drill press on different materials?

Yes, it’s important to consider specific precautions when drilling different materials with a drill press:

For drilling wood, always ensure the drill bit is sharp and in good condition. Use a lower drill speed and avoid excessive force to prevent splintering or tearing of the wood. When drilling metal, use cutting oil to lubricate the drill bit and prevent overheating. Start with a slower drill speed and gradually increase if needed.

When working with plastics, use a drill bit specifically designed for plastic materials. Avoid high drill speeds to prevent melting or deformation. Always read the manufacturer’s recommendations for drilling different materials and adjust the speed and technique accordingly.

Summary

When using a drill press, it’s important to follow some key rules to stay safe and get the best results. First, always wear safety goggles to protect your eyes from flying debris. Second, secure the workpiece firmly in place before drilling to avoid accidents. Third, adjust the drill press speed according to the type of material you’re drilling. Fourth, use the correct drill bit for the job to prevent damage to the workpiece or the drill press. Finally, always keep your hands away from the drill bit and use a clamp or vice when necessary.

Remember, safety should always come first when working with any power tool. By following these rules, you can enjoy a successful and injury-free drilling experience with your drill press. Stay safe and have fun exploring the world of DIY projects!