If you’ve ever wondered what safety features a drill press has, you’ve come to the right place! In this article, we’ll explore the various safety measures that are commonly found on drill presses. So, let’s dive in and learn how these features ensure a secure and protected drilling experience.

When it comes to operating a drill press, safety should always be a top priority. That’s why drill presses often come equipped with a range of safety features. These features are designed to minimize the risk of accidents and injuries while working with this powerful tool. So, let’s take a closer look at some of the key safety features you can find on a drill press.

From adjustable depth stops to emergency stop buttons, drill presses offer a multitude of safety features. These features help prevent common accidents, such as the drill bit penetrating too deeply or unexpectedly. With these safety measures in place, you can confidently focus on your drilling tasks, knowing that your well-being is being prioritized. So, let’s explore these safety features in more detail and understand their importance.

So, if you’re curious about the safety features of a drill press, keep reading to discover how these features protect you during your drilling adventures. With a combination of advanced safety mechanisms and user-friendly designs, drill presses ensure a secure drilling experience. So, let’s uncover the safety features that make drill presses a reliable tool in your workshop.

A drill press is equipped with various safety features to ensure user protection. These features include:

- Emergency stop switch: Allows for immediate shutdown in case of an emergency.

- Chuck guard: Protects the user from rotating parts during operation.

- Depth stop: Prevents the drill bit from going too far into the material.

- Workpiece clamps: Securely holds the material in place for stability.

- Table extensions: Provide additional support for larger workpieces.

With these safety features, a drill press minimizes the risk of accidents and promotes a safe working environment.

Exploring the Safety Features of a Drill Press

A drill press is a powerful tool used for drilling holes in various materials. When working with such a machine, safety becomes a top priority. Understanding the safety features available in a drill press is essential for preventing accidents and ensuring a secure working environment. This article will delve into the different safety features that a drill press may possess, providing detailed information on their functionality and benefits.

The Importance of Safety Features in a Drill Press

Safety features in a drill press are designed to protect the user from potential hazards and reduce the risk of injury. These features are implemented to address specific dangers associated with operating a drill press, such as accidental starts, flying debris, and contact with the rotating drill bit. By understanding and utilizing these safety features, operators can work with confidence and minimize the likelihood of accidents.

1. Emergency Stop Button

The emergency stop button, often located within easy reach on the drill press, provides an immediate means of stopping the machine in case of an unforeseen incident. This feature allows users to quickly halt the drill press operation, preventing further harm or damage. It is crucial to familiarize oneself with the location and operation of the emergency stop button before operating a drill press.

Instances where the emergency stop button proves valuable include situations where clothing or hair gets caught in the drill bit or when a workpiece becomes loose, causing instability. By swiftly activating the emergency stop button, potential injuries and equipment damage can be avoided.

Additionally, the emergency stop button is useful during emergencies such as power outages or sudden machine malfunctions. Being able to shut down the drill press immediately can prevent accidents and further damage due to loss of control.

2. Safety Guards

The use of safety guards is a standard practice in drill press safety. These guards are typically transparent and serve as a physical barrier between the user and the drill bit, protecting against accidental contact and flying debris. Safety guards are positioned around the drill bit and may feature adjustable levels of coverage, enabling users to adapt to different drilling requirements while maintaining adequate protection.

Operators should never remove or bypass safety guards in order to gain better visibility or maneuverability. Safety guards are designed to prevent accidents and should always be in place during drill press operation. With the proper use of safety guards, the risk of injuries from drill bit contact or debris being propelled from the workpiece is significantly reduced.

It is important to note that safety guards should also be regularly inspected and maintained to ensure their effectiveness. Any damage or deterioration should be promptly addressed by replacing or repairing the guard.

3. Adjustable Depth Stop

The adjustable depth stop is a safety feature that allows users to set the maximum depth to which the drill bit can penetrate a workpiece. This feature ensures consistent and controlled drilling, preventing accidental over-drilling or drilling into unintended areas. By accurately defining the drilling depth, the adjustable depth stop enhances the precision and safety of drilling operations.

To utilize this feature effectively, users must determine the appropriate depth based on the nature of the material being drilled and the specific requirements of the task at hand. Once set, the adjustable depth stop ensures that the drill bit stops at the desired depth, preventing potential damage to the workpiece or accidental puncturing of underlying surfaces.

By employing the adjustable depth stop, users can confidently perform repetitive drilling tasks without the need for constant measurement, reducing the risk of errors and associated safety hazards.

4. Safety Release Trigger

The safety release trigger is a feature commonly found in newer models of drill presses. This mechanism requires a deliberate two-step activation process, ensuring that accidental starts are prevented. The safety release trigger requires the user to engage a secondary button or lever before the drill press can be turned on, significantly reducing the risk of unintentional activation.

When using a drill press equipped with a safety release trigger, it is important to adhere to the correct activation sequence. This ensures that the drill press operates only when the user intentionally initiates the mechanism, minimizing the chances of accidents caused by inadvertently starting the machine.

While the safety release trigger may initially require an adjustment in operating habits, it provides added peace of mind and promotes a safer working environment.

5. Built-in Workpiece Clamping

A drill press may be equipped with a built-in workpiece clamping mechanism to secure the material being drilled. This feature prevents the workpiece from moving or vibrating while under the pressure of the drilling operation, reducing the risk of misalignment and potential injuries caused by sudden movements or workpiece dislodgement.

The built-in workpiece clamping feature is particularly useful when drilling larger or heavier materials that may be prone to shifting during the drilling process. By firmly holding the workpiece in place, this safety feature ensures stability and improves the accuracy of the drilling operation.

Users should always make use of the built-in workpiece clamping feature when it is available. In cases where this feature is not present, auxiliary clamps or other methods should be employed to secure the workpiece adequately.

6. Laser Guide System

The laser guide system is a useful safety feature that aids in accurate drilling placement. This feature projects a laser beam onto the workpiece, signaling the drilling location and providing a visual guide for positioning. The laser guide system enhances precision, allowing users to align the drill bit accurately without the need for additional measurement devices.

Aside from its convenience and efficiency, the laser guide system also contributes to safety. By clearly indicating the drilling point, users can avoid accidental slips or drilling at incorrect angles, which can lead to injuries and damage to the workpiece.

It is important to note that the laser guide system should not be solely relied upon for accurate drilling. Users should still exercise caution, verify proper alignment, and follow recommended safety practices to ensure optimal results.

7. Overload Protection

Overload protection is a safety feature designed to prevent the drill motor from being damaged due to excessive strain or overheating. It automatically shuts off the drill press when it senses that the motor is operating beyond its capacity. This feature is especially important in situations where the drill bit encounters a drill-resistant material or when the drill press is being used for extended periods without rest.

By incorporating overload protection, drill presses are safeguarded against potential damage that can compromise their performance and longevity. This safety feature not only protects the machine but also helps prevent accidents that may result from a compromised drill press.

Users should be aware of the capacity of their drill press and should not attempt to drill materials or perform tasks that exceed its capabilities. Adhering to the limitations outlined by the manufacturer and utilizing the overload protection feature will help prolong the life of the drill press and ensure safe operation.

Maintenance and Safety Tips for Using a Drill Press

In addition to the safety features provided by the drill press, users should adhere to certain maintenance and safety practices to further enhance their safety and the longevity of the machine. Here are some important tips to consider:

1. Regularly Inspect and Maintain the Drill Press

Inspect the drill press regularly for any signs of wear, damage, or loose parts. Check that all safety features, such as guards and clamps, are functioning properly. Clean the drill press regularly to prevent dust and debris from accumulating, which can affect performance and safety.

Perform routine maintenance tasks recommended by the manufacturer, such as lubricating moving parts and replacing worn-out components. By keeping the drill press in good condition, operators can ensure optimal performance and prolong its lifespan.

2. Wear Appropriate Personal Protective Equipment (PPE)

Always wear the appropriate personal protective equipment, including safety glasses or goggles, ear protection, and gloves. This will help protect against potential hazards such as flying debris, noise, and accidental contact with the rotating drill bit.

Ensure that clothing and accessories are securely fastened so that they cannot become entangled in the drill press. Loose items can pose a significant risk of injury, so it is important to dress appropriately and avoid wearing loose-fitting clothing or jewelry.

3. Familiarize Yourself with the Drill Press Manual

Read and understand the drill press manual before operating the machine. The manual provides important safety instructions, guidelines, and information specific to the model or brand. Pay attention to the recommended operating procedures, safety precautions, and any specific features or limitations of the drill press.

If you encounter any difficulties or have questions, consult the manual or contact the manufacturer for clarification. It is always better to be well-informed and confident in the operation of the drill press.

4. Maintain a Clean and Organized Work Area

Keep your work area clean and organized to minimize the risk of accidents. Remove any unnecessary clutter and ensure that the drilling area is free from obstructions. This will provide a clear workspace, reducing the chances of tripping or interfering with the operation of the drill press.

Properly store and organize drill bits, tools, and accessories to maintain a safe and efficient workspace. This will also save time and prevent accidents caused by searching for misplaced items during drilling operations.

5. Use Proper Drilling Techniques

Follow recommended drilling techniques to maintain control and accuracy. Apply steady pressure without excessive force, and avoid exerting sideways or angular pressure on the drill bit. This will help prevent breakage and potential injury.

Drill at an appropriate speed, allowing the drill bit to cut through the material efficiently. Forcing the drill press or drilling at high speeds can lead to overheating, reduced performance, and potential safety risks.

6. Avoid Distractions and Maintain Focus

When operating a drill press, it is important to maintain focus and avoid distractions that can compromise safety. Ensure that your workspace is free from distractions, and refrain from using the drill press when fatigued, under the influence of alcohol or medication, or in a rushed or compromised state of mind.

By remaining alert and focused on the task at hand, users can minimize the chances of accidents due to lapses in attention or judgment.

Wrap-Up:

Drill presses come equipped with various safety features to protect users and ensure a secure working environment. These features include emergency stop buttons, safety guards, adjustable depth stops, safety release triggers, built-in workpiece clamping mechanisms, laser guide systems, and overload protection.

By understanding the functions and benefits of these safety features, operators can work confidently and minimize the risk of accidents. It is important to adhere to regular maintenance practices, wear appropriate personal protective equipment, and follow proper drilling techniques to further enhance safety when using a drill press.

By combining the use of safety features with good safety practices, drill press users can enjoy a productive and secure drilling experience.

Key Takeaways: What Safety Features Does a Drill Press Have?

- A drill press typically has a safety guard that covers the drill bit, preventing accidental contact.

- Some models have a built-in laser guide to help ensure accurate drilling.

- Many drill presses are equipped with a depth stop feature, allowing you to set the drilling depth and avoid going too far.

- Most drill presses have a stop button or switch within easy reach, enabling you to quickly stop the machine in case of emergencies.

- Some advanced drill presses have a digital display that shows the speed, allowing you to choose the appropriate setting for your task.

Frequently Asked Questions

In this section, we will answer some common questions about the safety features found in a drill press.

1. How does a drill press ensure safety?

A drill press has several safety features designed to protect the user. One of the main features is a safety switch or button that needs to be engaged to operate the drill. This prevents accidental activation and keeps the user safe. Additionally, drill presses often have adjustable depth stops and clamps to secure the workpiece, reducing the risk of it moving or slipping during drilling.

Many drill presses also have built-in emergency stop buttons, which immediately halt the spinning motion of the drill bit. These buttons are easily accessible and can be pressed to stop the drill in case of an emergency. Additionally, some drill presses have automatic power-off functions that turn off the machine after a certain period of inactivity to prevent accidents.

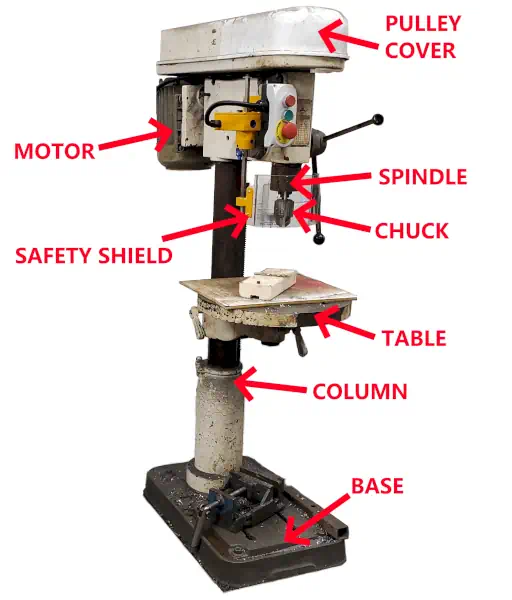

2. Does a drill press have any protective shields?

Yes, most drill presses come with protective shields. These shields surround the drill bit and help contain any flying chips or debris, preventing them from hitting the operator. The shields are typically transparent, allowing the user to see the drilling area while still providing protection. The shields can often be adjusted or rotated to provide the best visibility and protection for the specific drilling task.

It’s important to note that the shields should always be in place while operating a drill press. They serve as a barrier between the operator and potential hazards, reducing the risk of injury. Removing or bypassing the safety shields should never be done as it compromises the safety of the user.

3. What is a safety key or lockout feature for a drill press?

A safety key or lockout feature is an added safety measure in some drill presses. It usually involves a removable key that needs to be inserted into the machine to enable operation. This key can be taken out when the drill press is not in use, preventing unauthorized use or accidental activation, especially in a shared workspace or around curious children.

The safety key or lockout feature acts as a physical barrier, ensuring that only individuals with access to the key can operate the drill press. This helps prevent accidents and promotes overall workplace safety.

4. Are there any safety features specifically for handling large workpieces?

Yes, drill presses often have safety features that cater to handling large workpieces. One common feature is an adjustable table or work surface that allows the user to position and secure larger materials. This helps ensure stability and reduces the risk of the workpiece moving during drilling.

In addition, some drill presses have extended drill bit reach or adjustable spindle height capabilities, which can accommodate thicker or taller workpieces. These features make it easier to work with larger materials while maintaining proper control and safety.

5. How can I maintain the safety features of a drill press?

To ensure the safety features of a drill press remain effective, regular maintenance is important. Keep the machine clean, removing any dust or debris that may interfere with the moving parts or safety mechanisms. Lubricate the drill press according to the manufacturer’s instructions to ensure smooth operation.

Regularly inspect the safety switches, buttons, and guards to ensure they are in good working condition. If any parts are damaged or malfunctioning, they should be repaired or replaced immediately to maintain a safe operation. It is also crucial to read and follow the user manual provided by the manufacturer, as it contains specific guidelines for proper usage and maintenance.

Summary

A drill press has important safety features to keep you safe while using it. One key feature is the safety guard that covers the drill bit to prevent accidental contact. Another important feature is the emergency stop button that allows you to quickly turn off the power in case of an emergency. Additionally, a drill press often has a depth stop that helps control how deep the drill bit goes into the material. Remember to always follow safety guidelines when using a drill press to keep yourself protected.