What shaped stock should not be cut on a table saw? Well, have you ever wondered about the types of stock that might pose a challenge when it comes to using a table saw? If so, you’re in the right place! In this article, we’ll explore the answer to this question and delve into the reasons behind it. So, let’s get started and uncover the fascinating world of table saw safety!

Now, let’s talk about the importance of understanding the limitations of a table saw. While table saws are versatile and powerful tools, they’re not suitable for every type of cut. Certain shapes of stock can be difficult to handle or may even present safety hazards when used with a table saw. Learning which shapes to avoid can help keep you safe and ensure accurate and efficient cuts.

When it comes to using a table saw, there are a few key shapes of stock that are best left for other tools. One example is round stock, like pipes or dowels. Due to their cylindrical shape, it can be challenging to securely hold round stock against the table saw’s fence, increasing the risk for kickback or other accidents. So, if you have round stock that needs cutting, it’s best to explore other tools such as a bandsaw or a miter saw.

Remember, understanding the limitations of your tools is crucial for both your safety and the quality of your work. By knowing which shapes of stock are not ideal for a table saw, you can make informed decisions that lead to successful and accident-free woodworking projects. So, let’s dive deeper into this topic and find out more about the shapes that pose challenges for table saw cutting!

What Shaped Stock Should Not Be Cut on a Table Saw?

When it comes to using a table saw, it is essential to know which types of stock are suitable for cutting and which are not. Cutting certain shapes of stock on a table saw can be dangerous and can lead to accidents or damage to the material. In this article, we will explore the shapes of stock that should not be cut on a table saw and the reasons behind it. By understanding these limitations, you can ensure your safety and the quality of your projects.

The Importance of Safety in Table Saw Usage

Before diving into the specific shapes of stock that should not be cut on a table saw, it is crucial to emphasize the importance of safety when using this powerful tool. Table saws are versatile and effective for many woodworking tasks, but they can also be dangerous if not used properly. Always wear appropriate safety gear, such as goggles, ear protection, and a dust mask, when operating a table saw. Follow the manufacturer’s instructions, practice good woodworking techniques, and be mindful of your surroundings. Understanding what shapes of stock to avoid cutting on a table saw is one aspect of ensuring your safety in the workshop.

Cutting Curved Stock on a Table Saw

Curved stock refers to wood or other materials with a curved shape, such as bowtie-shaped inlays or round table legs. These shapes pose a challenge when using a table saw because the blade is designed to cut straight lines. Attempting to cut curved stock on a table saw can cause the stock to bind or kickback, increasing the risk of injury. Instead, it is best to use alternative tools such as a band saw or a jigsaw to make the necessary cuts on curved stock. These tools are more suitable for maneuvering around curves and will provide better results without compromising safety.

Irregularly Shaped Stock and Angles

Irregularly shaped stock and angles are another category of stock that should not be cut on a table saw. Examples of irregularly shaped stock include pieces with concave or convex edges or stock with intricate patterns and designs. The stability of irregularly shaped stock on the table saw can be compromised, leading to unpredictable movements and potential accidents. Additionally, cutting at angles on a table saw can be tricky, especially when dealing with compound angles or complex bevel cuts. It is recommended to use specialized tools such as a miter saw, a coping saw, or a scroll saw for these types of cuts, as they offer better control and precision.

Thick Stock and Ripping

While a table saw can handle a range of stock thicknesses, there are limitations when it comes to cutting thick stock. Trying to rip thick stock, which refers to cutting it parallel to the grain, can put excessive strain on the table saw’s motor and blade. This can result in a lack of control or potentially damage the saw. It is advisable to use a band saw or a circular saw with a straightedge guide for ripping thick stock. These tools are more suited to handle the increased cutting resistance and ensure a smooth and accurate cut.

Small Stock and Safety Precautions

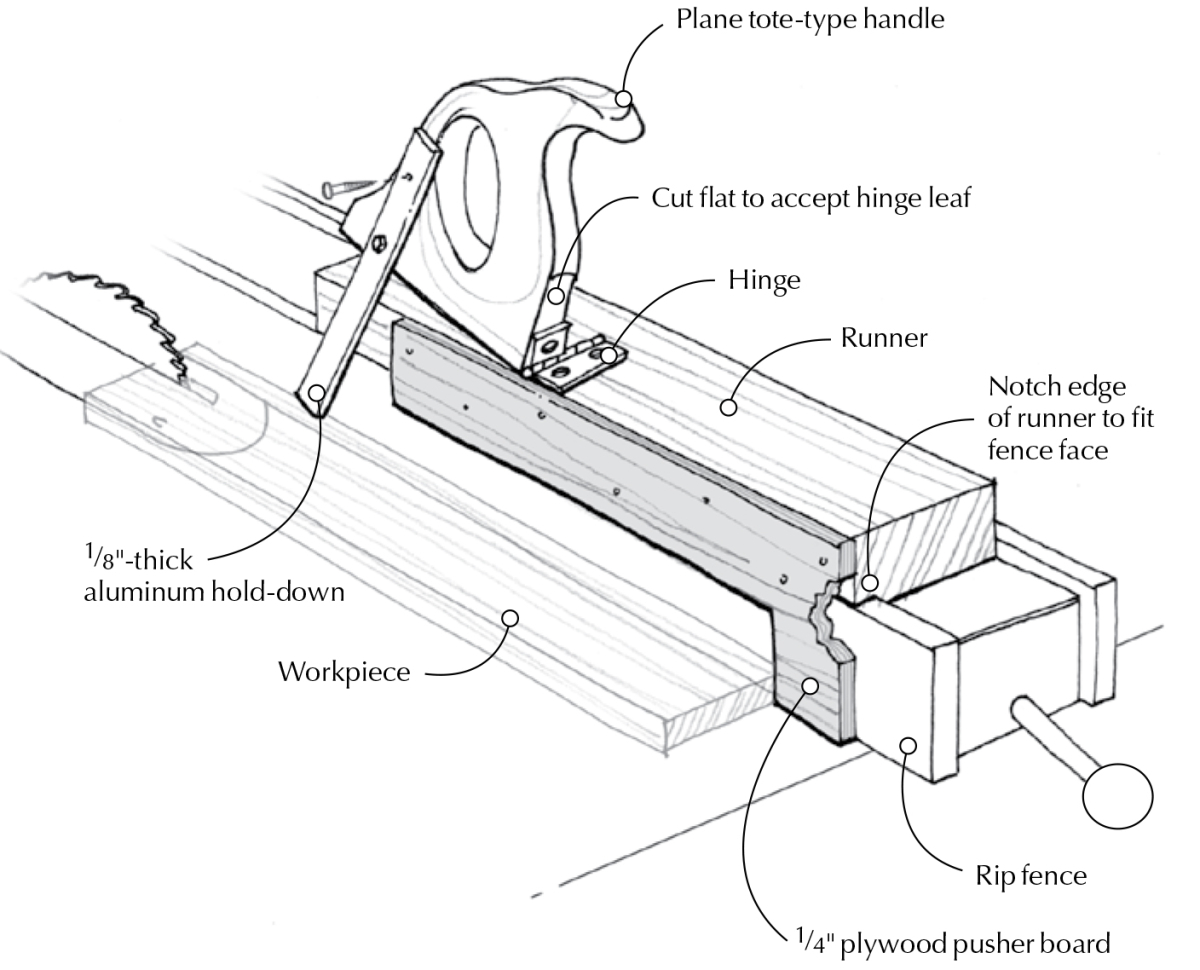

When working with small stock on a table saw, it is essential to take extra safety precautions. Small pieces of stock can be challenging to hold and keep stable during the cutting process. To minimize the risk of accidents, it is recommended to use a sled or a miter gauge with a hold-down clamp to keep small pieces in place while cutting. These accessories provide better control and stability, reducing the chances of accidents or injury.

Mitigating Risks with Proper Techniques

While there are certain shapes of stock that should not be cut on a table saw, it is possible to mitigate the risks associated with these cuts by using proper techniques. For example:

- When cutting irregularly shaped stock, secure it with clamps or jigs to minimize movement.

- For cutting thick stock, make multiple passes to gradually remove material instead of trying to cut it all at once.

- When cutting small stock, use a push stick or push block to maintain a safe distance between your hands and the blade.

By employing these techniques and using the appropriate tools for specific cuts, you can enhance safety and achieve better results in your woodworking projects.

Choosing the Right Tools for the Job

It’s important to remember that a table saw is not the ultimate solution for every type of cut or material. Depending on the shapes of the stock and the complexity of the cuts, different tools may be more suitable. Understanding the limitations of a table saw and having alternative tools on hand will enable you to achieve precise cuts while maintaining safety. Always evaluate the shape, size, and thickness of the stock before deciding on the appropriate tool for the job.

Conclusion

Knowing which shapes of stock should not be cut on a table saw is essential to protect your safety and the integrity of your projects. Curved stock, irregularly shaped stock, thick stock, and small stock all require alternative tools and techniques to ensure accurate cuts while minimizing the risk of accidents or damage. By prioritizing safety and selecting the appropriate tools for the job, you can enhance your woodworking skills and achieve outstanding results.

Key Takeaways: What Shaped Stock Should Not Be Cut on a Table Saw?

- Never try to cut round stock on a table saw.

- Avoid cutting irregularly shaped stock on a table saw.

- Do not attempt to cut stock with tapered edges on a table saw.

- Avoid cutting stock with excessive curves on a table saw.

- Never cut asymmetrical or misshapen stock on a table saw.

Frequently Asked Questions

When it comes to cutting stock on a table saw, there are certain shapes that should be avoided. Here are some commonly asked questions about what shaped stock should not be cut on a table saw, along with their answers:

1. Can I cut round stock on a table saw?

No, you should not attempt to cut round stock on a table saw. The rotating blade and the square fence of the table saw are not designed to accommodate round stock. The shape of the stock can cause instability and lead to dangerous kickbacks or other accidents. For cutting round stock, it is better to use a band saw or a specialized tool designed for curved cuts.

If you really need to make straight cuts on round stock, you can create a makeshift sled that holds the round stock securely and guides it through the table saw. However, this requires careful planning and precise construction to ensure safety and accuracy.

2. Is it safe to cut irregularly shaped stock on a table saw?

In general, it is not safe to cut irregularly shaped stock on a table saw. Irregular shapes can cause the stock to become unstable during the cutting process, leading to kickbacks or other accidents. The table saw is designed to cut straight lines on flat stock, so it is best to use other tools like a jigsaw or a bandsaw for irregular shapes.

If you really need to cut irregularly shaped stock on a table saw, you can try using a jig or a sled to stabilize the stock and guide it through the cut. However, this requires careful setup and should only be done with proper precautions and knowledge of the risks involved.

3. Can I cut triangular stock on a table saw?

Triangular stock should generally not be cut on a table saw. The sharp points of the triangle can cause the stock to catch on the rotating blade, leading to kickbacks or other accidents. It is better to use a miter saw or a handheld circular saw with a guide for making clean and safe cuts on triangular stock.

If you need to cut triangular stock on a table saw, you can try making a jig or a sled with a special cutout that accommodates the shape of the stock. This will help stabilize the stock and prevent it from catching on the blade. However, extra caution must be taken when using this method to ensure safety.

4. What about cutting stock with intricate or delicate designs?

Stock with intricate or delicate designs should be handled with care when using a table saw. The high-speed rotating blade can easily damage or break delicate pieces, and the intricate designs may get caught on the blade, causing kickbacks or other accidents. For such stock, it is better to use a scroll saw, a coping saw, or other specialized tools that allow for precise and safe cuts.

If you absolutely need to use a table saw for cutting stock with intricate or delicate designs, it is recommended to use a zero-clearance insert and a high-quality blade with a higher tooth count. This will help reduce the likelihood of tear-out, minimize the risk of damage to the stock, and ensure cleaner cuts.

5. What precautions should I take when cutting stock with non-standard shapes?

When cutting stock with non-standard shapes on a table saw, it is important to take extra precautions to ensure safety. This includes using appropriate jigs, sleds, or other accessories to stabilize the stock and guide it through the cut safely. It is also important to use proper personal protective equipment, such as safety glasses and hearing protection.

Before making any cuts, carefully plan and visualize the cut to identify potential risks and find the best approach. Take your time and make slow, deliberate cuts, ensuring that the stock is firmly and securely positioned. Always follow the manufacturer’s guidelines and recommendations for your specific table saw model, and never attempt any cuts that you are not confident or comfortable with.

Why Does My Table Saw Not Cut Straight?

Summary

So, to sum it all up, when using a table saw, it’s important to remember a few key things. First, never cut irregularly shaped stock. This can cause the wood to bind or kick back, leading to accidents. Additionally, always use a push stick or a push block to keep your hands safe and maintain control of the wood. And lastly, be sure to use appropriate safety measures like wearing safety glasses and keeping your work area clean and free of clutter. By following these guidelines, you can ensure a safer and more successful woodworking experience.