Are you thinking of getting a bandsaw? Wondering what you should look for in this versatile power tool? Well, you’ve come to the right place! In this article, we’ll break down the key factors to consider when searching for the perfect bandsaw. So, let’s dive in and explore what makes a bandsaw worth investing in!

First things first, when looking for a bandsaw, it’s crucial to consider the size and power of the machine. A bandsaw’s capacity and cutting abilities depend on its size, so pick one that suits your specific needs. Additionally, look for a bandsaw with a motor that provides ample power to tackle various cutting tasks effortlessly. You don’t want to end up with a bandsaw that struggles to handle the materials you work with, right?

Aside from size and power, the design and construction of a bandsaw play a significant role in its performance. Look for a sturdy and durable frame that can withstand heavy use. A well-built bandsaw will have less vibration, resulting in cleaner and more accurate cuts. Moreover, a bandsaw with easy-to-adjust features and clear markings makes your woodworking experience smoother and more enjoyable. So, keep an eye out for these factors when shopping for the perfect bandsaw for your workshop needs!

Now that we’ve covered the basics of what to look for in a bandsaw, it’s time to dig deeper into the various features and accessories that can enhance your woodworking experience. From blade speed and tracking to the availability of a fence, miter gauge, and dust collection system, there are plenty of factors to consider. We’ll explore all these details, providing you with the knowledge to make an informed decision. So, let’s get started on this exciting bandsaw journey together!

What Should I Look for in a Bandsaw?

Are you in the market for a new bandsaw but unsure of what to look for? Whether you’re a professional woodworker or a hobbyist, choosing the right bandsaw is crucial for achieving precise cuts and realizing your creative vision. With so many options available, it can be overwhelming to make the best choice. In this article, we will explore the key factors you should consider when selecting a bandsaw that meets your specific needs. From motor power to blade size, we will cover everything you need to know to make an informed decision. So, let’s dive in and discover what you should look for in a bandsaw!

Factors to Consider When Choosing a Bandsaw

Motor Power

The motor power of a bandsaw determines its cutting capacity and performance. The power is measured in horsepower (HP), and higher HP typically indicates a more capable machine. An adequate motor power ensures that the blade can cut through different types of wood effortlessly, even when dealing with thick or hardwood. For light-duty applications, such as small projects or crafts, a bandsaw with around 1 or 1.5 HP is sufficient. However, if you plan on working with denser materials or frequently resawing larger stock, you should consider a bandsaw with at least 2 HP for optimal performance.

It’s important to note that motor power is not the only factor to consider when determining a bandsaw’s cutting proficiency. Other components, such as blade speed and tension, also play a significant role. However, a bandsaw with an adequately powerful motor will provide you with the versatility and cutting capabilities required for a wide range of projects.

Additionally, consider whether the motor operates on a single-phase or three-phase power supply. Single-phase motors are more common in smaller bandsaws and are suitable for most home workshops. However, if you have access to three-phase power, investing in a bandsaw with a three-phase motor can provide enhanced power and efficiency.

Throat Size and Resaw Capacity

The throat size of a bandsaw refers to the distance between the blade and the vertical frame of the saw. It determines the maximum width of the stock that can be passed through the blade. When choosing a bandsaw, consider the size of the projects you typically work on and ensure that the throat size is appropriate. For general woodworking tasks, a bandsaw with a 14-inch throat size is usually sufficient. However, if you plan on working with wider or larger stock, you may need a bandsaw with a larger throat size, such as 18 inches or more.

Resaw capacity is another critical factor to consider. Resawing refers to the process of cutting a piece of wood into thinner slices, which is especially useful for creating veneers or bookmatched panels. A bandsaw’s resaw capacity is determined by the maximum distance between the blade and the table. If you anticipate frequently resawing thick stock or performing intricate cuts, choosing a bandsaw with a higher resaw capacity will provide you with more flexibility and precision.

Keep in mind that while bandsaws with larger throat sizes and higher resaw capacities offer greater cutting capabilities, they also require more space and are generally more expensive. Consider your available workshop space and budget when making your decision.

Blade Size and Tension

The size and tension of the blade are crucial factors that affect the intricacy and accuracy of the cuts you can achieve with a bandsaw. The blade width determines the minimum radius a bandsaw can cut. Typically, 1/8-inch to 1/4-inch wide blades are suitable for general curve-cutting tasks, while 1/2-inch blades are commonly used for straight cuts and resawing. Thicker blades are more durable and less prone to deflection, making them ideal for resawing thick stock.

Blade tension is equally important. Proper blade tension ensures that the blade remains rigid during cutting and prevents it from wandering off course. Most bandsaws come with a tensioning mechanism or gauge that allows you to adjust the tension. It is essential to maintain the correct tension for the blade to ensure clean and accurate cuts. Consult the manufacturer’s guidelines for the recommended tension for the specific blade you are using.

Consider the type of projects you will be working on, whether you need to perform intricate cuts or resawing, and choose a bandsaw that offers the appropriate blade size and tension adjustment mechanism for your needs.

Table Size and Stability

The size and stability of the bandsaw’s table are important factors, especially when working on larger or heavy projects. A larger table provides better support for the stock and allows you to work more comfortably, particularly when cutting large pieces of wood or resawing long stock. Look for a bandsaw with a spacious table that suits your workflow.

Additionally, the stability of the table is crucial for achieving accurate cuts. Look for a table that is sturdy and well-built to minimize vibrations and ensure precise and smooth operation. A solid, cast-iron table with ample weight and stability will help maintain blade alignment and improve overall cutting performance.

Some bandsaws also feature tilting tables, which allow you to make angled cuts with ease. If you anticipate the need for angled cuts in your woodworking projects, a bandsaw with a tilting table can be a valuable addition to your workshop.

Guides and Adjustments

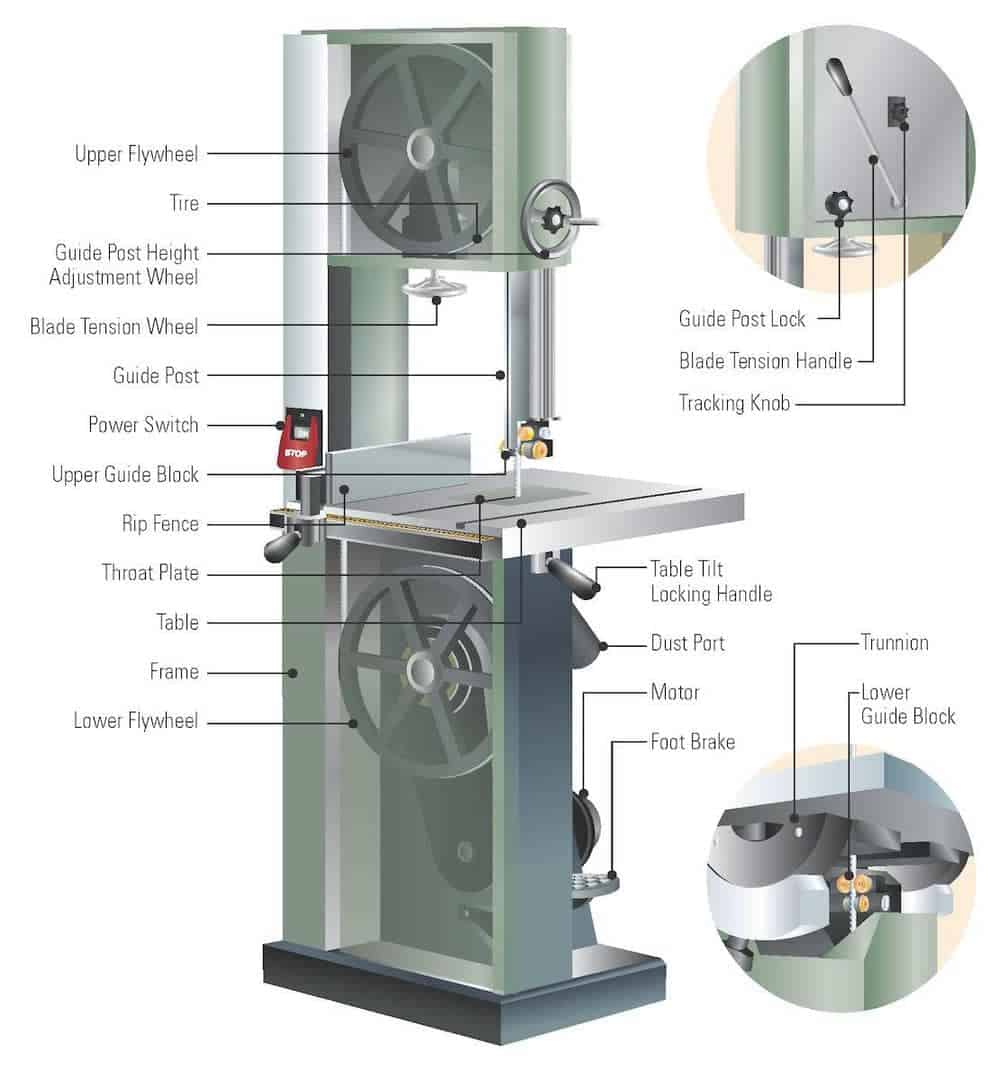

The guides and adjustments on a bandsaw play a significant role in achieving precise and accurate cuts. Look for a bandsaw that offers reliable blade guides that keep the blade aligned and minimize blade deflection. There are different types of guides available, including block guides, roller guides, and ceramic guides, each with its advantages and disadvantages. Consider your specific needs and the type of cuts you will be making to decide which guide type is best for you.

Moreover, a bandsaw with easy-to-use, accessible adjustments will enhance your overall woodworking experience. Look for features such as quick-release mechanisms for blade changes and tension adjustments, as well as easy-to-read and accurate depth and angle indicators. These features will save you valuable time during setup and adjustments, allowing you to focus more on your woodworking projects.

Dust Collection System

Woodworking can produce a significant amount of dust, which can be harmful to your health and affect the overall cleanliness of your workshop. A bandsaw equipped with an efficient dust collection system can help keep your workspace clean and minimize health risks.

Look for a bandsaw with a built-in dust port or a compatible dust collection attachment. The dust port should be adequately sized and strategically positioned to capture the majority of the dust generated during cutting. Consider whether the bandsaw offers options for connecting to a centralized dust collection system if you already have one in your workshop.

Proper dust collection also extends the life of the bandsaw by reducing the amount of dust that can accumulate on the internal components, ensuring smooth operation and minimal maintenance requirements.

Price and Brand Reputation

While it’s important to consider your budget when purchasing a bandsaw, it’s equally crucial to research the reputation of the brands you are considering. Look for brands that have a track record of producing high-quality and reliable bandsaws. Reading customer reviews and seeking recommendations from experienced woodworkers can provide valuable insights into the performance and reliability of different bandsaw models and brands. Choosing a reputable brand may offer better customer support and access to replacement parts, ensuring a satisfactory ownership experience.

Remember that the price of a bandsaw often correlates with its quality and features. However, it’s essential to strike a balance between your budget and the necessary features to meet your woodworking needs. Depending on your skills, project requirements, and frequency of use, you may not need the most expensive or feature-rich bandsaw on the market. Carefully consider your specific requirements and select a bandsaw that offers the best value for your investment.

Conclusion

Choosing the right bandsaw can significantly impact the quality of your woodworking projects. By considering factors such as motor power, throat size, blade size, table stability, guides, dust collection, and brand reputation, you can make an informed decision that aligns with your specific needs and budget. Remember, the key is to find a balance between your requirements and the available options. Whether you’re a beginner or a seasoned woodworker, investing in a high-quality bandsaw that meets your needs will open up endless possibilities for creativity and precision. Happy woodworking!

Key Takeaways: What Should I Look for in a Bandsaw?

- Consider the size and power of the bandsaw, ensuring it meets your specific needs.

- Check the cutting capacity of the bandsaw to make sure it can handle the materials you work with.

- Look for a bandsaw with a sturdy frame and solid construction for durability.

- Consider the features and accessories offered, such as blade guides and table tilt.

- Read reviews and compare brands to find a bandsaw that is reliable and has good customer feedback.

Frequently Asked Questions

Are you in the market for a bandsaw but aren’t sure what factors to consider? Don’t worry, we’ve got you covered! Here are answers to some common questions about what you should look for in a bandsaw.

1. How important is the horsepower of a bandsaw?

The horsepower of a bandsaw is a crucial factor to consider. Higher horsepower means the bandsaw can handle tougher materials and make more accurate cuts. If you frequently work with hardwood or large pieces of lumber, a bandsaw with higher horsepower is recommended. However, if you mainly work with softwoods or smaller projects, a lower horsepower bandsaw may suffice. It’s important to find the right balance between power and your specific woodworking needs.

Keep in mind that more horsepower often means a higher price tag, so consider your budget as well. Additionally, a bandsaw with variable speed settings can provide greater flexibility, allowing you to adjust the blade speed based on the material you’re working with.

2. What should I look for in terms of cutting capacity?

Cutting capacity refers to the maximum thickness and width of material a bandsaw can handle. When choosing a bandsaw, it’s essential to consider the size of the projects you typically work on. If you often tackle large-scale woodworking projects, opt for a bandsaw with a wider throat capacity and a higher resaw capacity. The throat capacity is the distance between the blade and the vertical frame of the bandsaw, while the resaw capacity is the maximum height of the material the bandsaw can cut through. These specifications determine the size of stock you can work with.

However, if you predominantly work on smaller projects, such as crafting or box-making, a bandsaw with a smaller cutting capacity might be more suitable. Just make sure the bandsaw is still capable of handling the material thickness you commonly work with.

3. What role does the blade size play in choosing a bandsaw?

Blade size is another crucial consideration when selecting a bandsaw. The size of the blade determines the minimum radius of the curve you can cut. Thinner blades are more flexible, allowing for tighter curves, while wider blades provide stability for straight cuts and resawing thicker stock. When choosing a bandsaw, consider the type of projects you’ll be working on. If you frequently work on intricate designs and curved cuts, a bandsaw with a smaller blade size is recommended. However, if you primarily focus on resawing and straight cuts, a wider blade size would be more suitable.

Additionally, pay attention to the availability and cost of replacement blades for the bandsaw you’re considering. Different bandsaw models may require specific blade sizes, so it’s important to factor in the cost and accessibility of replacement blades.

4. How important is the table size of a bandsaw?

The table size of a bandsaw is an essential feature to consider, particularly if you work with larger or longer stock. A larger table provides more support and stability, making it easier to work on larger pieces without compromising accuracy. It’s important to ensure the table is flat, rigid, and made of a durable material, such as cast iron, for optimal performance. A table with ample space for maneuvering your workpiece is also beneficial, as it allows for more flexibility and ease of use.

However, if you primarily work on smaller projects, a smaller table size might be more practical and take up less space in your workshop. The key is to find a balance between your workspace limitations, the size of your projects, and the level of support you require.

5. What should I look for in terms of safety features?

Safety should always be a top priority when working with power tools, and bandsaws are no exception. When choosing a bandsaw, consider the safety features it offers. Important safety features to look for include a blade guard that covers the blade during operation, a blade tension indicator for proper blade tensioning, and a dust collection system to keep your workspace clean and free of debris.

Additionally, a bandsaw with a reliable blade guide system is crucial. This ensures that the blade remains aligned and reduces the possibility of accidents or kickbacks during operation. Emergency stop buttons and paddle switches that are easy to reach should also be considered. Remember, investing in a bandsaw with adequate safety features is a valuable investment in your overall well-being as a woodworker.

Summary

So, when looking for a bandsaw, remember these important points. Firstly, think about what you’ll be using it for. Do you need it for small projects or bigger ones? Next, consider the size and power of the bandsaw. Will it fit in your workspace, and does it have enough strength for your needs? Also, pay attention to the features it offers. Does it have a reliable blade tracking system and a sturdy table? Lastly, don’t forget about safety. Look for a bandsaw with safety features like a blade guard and a magnetic switch.

In conclusion, finding the right bandsaw for your needs is all about considering what you’ll be using it for, checking its size and power, evaluating its features, and making sure it has the necessary safety measures. With these factors in mind, you’ll be able to make a well-informed decision and find the perfect bandsaw for your projects. Happy woodworking!