Picture this: you’re standing in a workshop, surrounded by woodworking machines. The smell of sawdust fills the air, and you can’t wait to get started on your latest project. But before you dive in, there’s something important you need to know. What should you avoid when working with woodworking machines? Let’s find out!

Woodworking can be a thrilling and rewarding hobby, but it’s essential to prioritize safety. In this article, we’ll explore the potential hazards and common mistakes that you should steer clear of when operating woodworking machines. So, whether you’re a beginner or a seasoned woodworker, this guide will help you stay safe and protect your fingers from those menacing spinning blades. Let’s get started on this woodworking adventure!

Now, I know what you’re thinking – “Why should I pay attention to safety? Can’t I just jump right in?” Trust me, my friend, safety is the key to a successful woodworking journey. By understanding what to avoid when working with these powerful machines, you’ll be well-equipped to tackle any project with confidence and peace of mind. So, let’s delve into the dos and don’ts of woodworking, shall we?

The Ultimate Guide: What to Avoid When Working with Woodworking Machines

Woodworking is a rewarding hobby and profession, allowing individuals to create beautiful and functional pieces from raw materials. However, it is crucial to prioritize safety when working with woodworking machines to prevent accidents and injuries. In this comprehensive guide, we will discuss the key things you should avoid when working with woodworking machines, ensuring that you can enjoy your craft while staying safe. From table saws to planers, we will cover the various machines commonly used in woodworking and provide essential tips to keep in mind. So, let’s dive in and explore the dos and don’ts of woodworking machine operation.

Understanding the Risks: Table Saws

Woodworkers, both beginners and experienced, are no strangers to table saws. These versatile machines are essential in any woodworking shop, but they can also be dangerous if not used correctly. Here are three key things to avoid when working with table saws:

To prevent kickback accidents, avoid:

Kickback is one of the most common accidents associated with table saws and can occur when the wood being cut is forcefully ejected back toward the operator. To avoid kickback, always ensure proper adjustments to the blade height, fence alignment, and blade guard installation. Additionally, use a push stick or push block when making narrow or small cuts, keeping your hands a safe distance from the blade.

Avoid exposing your hands to the blade:

Never attempt to guide the wood with your hands too close to the blade. Always use a push stick or a similar device to maintain a safe distance between your hands and the blade. Even experienced woodworkers can make mistakes, and a momentary lapse in attention can have severe consequences.

Do not remove safety features:

Some woodworkers may be tempted to remove certain safety features from their table saws for convenience or to improve performance. However, this is extremely dangerous and should never be done. Safety features such as blade guards, anti-kickback pawls, and riving knives are designed to protect you. Removing them increases the risk of accidents and should be avoided at all costs.

Staying Safe with Planers: What to Keep in Mind

Planers are excellent tools for shaping and smoothing wood, but they can also pose risks if not used properly. Here are some essential tips to avoid accidents when working with planers:

Avoid excessive material removal:

When using a planer, it is crucial to avoid removing too much material at once. Trying to remove a large amount of wood in a single pass can place excessive strain on the machine and may result in kickback, damaging the wood or causing injury. Take small increments with each pass to achieve a smooth and even finish.

Do not wear loose clothing or jewelry:

When operating a planer, it is essential to dress appropriately. Loose clothing or jewelry can become entangled in the rotating blades, causing severe injuries. Always wear fitted clothing and remove any accessories before using the machine.

Avoid running stock that is too short:

Planers require a certain length of stock to ensure stability and safe operation. Running stock that is too short can cause it to become unstable and kick back during the planing process. Always check the manufacturer’s guidelines for the minimum stock length required and avoid feeding pieces that fall below that threshold.

Keeping Your Fingers Safe: Router Safety Tips

Routers are versatile tools used for shaping, trimming, and cutting wood. While they offer a range of possibilities in woodworking, it is crucial to follow safety guidelines to prevent accidents. Here are three key safety tips to keep in mind when working with routers:

Avoid freehand routing:

Freehand routing, where you guide the router without the use of any support or guide, can be risky and result in uncontrolled cutting paths. This technique increases the likelihood of slips and cuts. Instead, always use a router table or a guide fence to achieve precision and stability during routing.

Don’t neglect eye and ear protection:

Routers produce a significant amount of noise and can create flying debris, including small wood chips. To protect your eyes and ears, always wear safety goggles and earmuffs or earplugs. Don’t rely on your experience alone; accidents can happen at any time.

Avoid climbing cuts:

A climbing cut occurs when the router bit rotates in the opposite direction to the direction of the wood movement. This can result in kickback or the wood being forced out of control. Always work with the grain and avoid making cuts in the opposite direction to maintain control over the tool and the wood.

Maintaining Safety Across all Woodworking Machines

Although we have covered some key safety tips for specific woodworking machines, there are general precautions that apply to all machinery. Here are a few essential guidelines to keep in mind for overall machine safety:

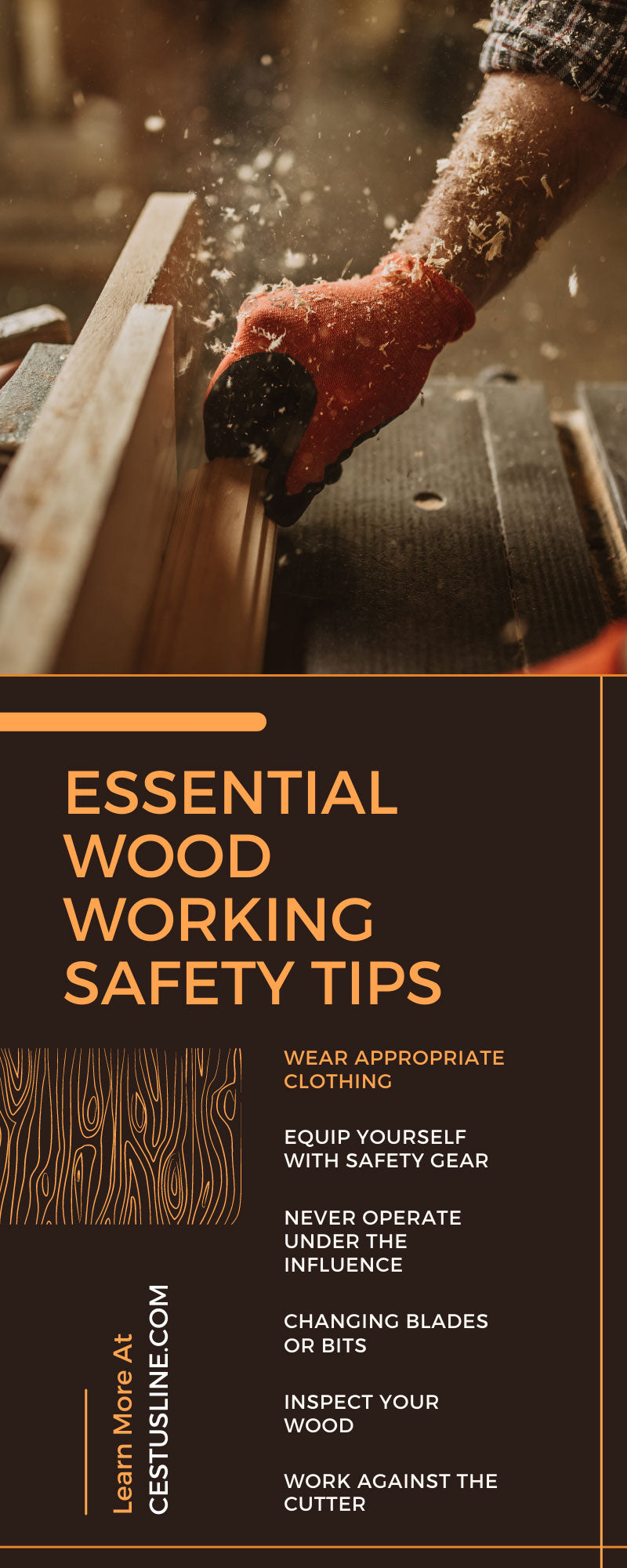

Wear appropriate protective gear:

Always wear safety glasses, ear protection, and dust masks when operating woodworking machines. This protects your eyes, ears, and lungs from potential hazards such as flying debris and fine dust particles.

Keep your workspace clean and organized:

A cluttered workspace can increase the risk of accidents. Keep your work area clear of obstructions, tools, and wood scraps. This allows for better maneuverability and minimizes the chances of tripping or falling.

Read and follow the manufacturer’s instructions:

Each woodworking machine has specific usage guidelines outlined by the manufacturer. It is crucial to familiarize yourself with these instructions and follow them diligently. This includes proper setup, maintenance, and safety recommendations.

In conclusion, working with woodworking machines can be a rewarding and fulfilling experience, but it is essential to prioritize safety. By avoiding common pitfalls and following the necessary precautions, you can create beautiful pieces while keeping yourself safe. Remember to always read the instruction manuals, wear appropriate protective gear, and avoid taking shortcuts that compromise safety. Happy woodworking!

Key Takeaways: What to Avoid When Working with Woodworking Machines

Given below are some important things to remember when working with woodworking machines:

1. Always wear safety goggles to protect your eyes from flying debris.

2. Avoid loose clothing or jewelry that can get caught in the machinery.

3. Never work with dull or damaged tools, as they can cause accidents.

4. Do not use your hands to hold the workpiece; use appropriate tools and clamps instead.

5. Stay focused and avoid distractions while operating woodworking machines to prevent mistakes or injuries.

Remember, following these guidelines will help keep you safe and ensure a successful woodworking experience.

Frequently Asked Questions

When working with woodworking machines, it’s important to prioritize safety and take precautions to avoid accidents. Here are some common questions and answers regarding what to avoid when working with woodworking machines.

1. How can I avoid accidents when using woodworking machines?

When working with woodworking machines, there are several precautions you can take to avoid accidents. First, always wear the appropriate safety gear including safety glasses, ear protection, and a dust mask. Avoid loose clothing or jewelry that could get caught in the machines. Additionally, make sure the machines are properly maintained and in good working condition. Check for any loose parts or damaged components before using them. It’s also important to familiarize yourself with the user manual and follow all safety guidelines provided.

Furthermore, never rush or try to force materials through the machines. Use the appropriate cutting tools and techniques for the specific task at hand. Keep your workspace clean and clutter-free to prevent tripping hazards. Finally, never leave a machine unattended while it’s running and always turn it off and unplug it after use.

2. Should I use woodworking machines without proper training?

No, it is not advisable to use woodworking machines without proper training. Woodworking machines can be complex and dangerous if not used correctly. It’s important to receive appropriate training on how to operate the machines safely. Many vocational schools, community colleges, and woodworking associations offer courses or workshops where you can learn the proper techniques and safety procedures. Taking the time to acquire the necessary skills and knowledge will greatly reduce the risk of accidents and ensure that you are using the machines correctly.

Additionally, if you are a beginner, it is recommended to start with simpler tools and machines before moving on to more advanced ones. This will allow you to build your skills and confidence gradually. Remember, safety should always be a top priority when working with woodworking machines.

3. Can I ignore safety guards and devices when using woodworking machines?

No, you should never ignore or remove safety guards and devices when using woodworking machines. These are specifically designed to protect you from potential hazards and should always be in place. Safety guards, such as blade guards and fences, help prevent accidental contact with moving parts and guide the material being worked on. Ignoring or removing these safety features can significantly increase the risk of injury.

Furthermore, never attempt to bypass or alter safety devices on woodworking machines. They are designed with your well-being in mind and tampering with them can lead to serious accidents. Always follow the manufacturer’s instructions and guidelines regarding safety guards and devices.

4. Can I work with woodworking machines in an unventilated area?

No, it is not recommended to work with woodworking machines in an unventilated area. When operating these machines, there may be dust, fumes, or particles released into the air. Inhaling these substances can be harmful to your respiratory system. It’s important to work in a well-ventilated area, preferably with a dust collection system or proper ventilation to minimize the amount of airborne particles.

If working in a ventilated area is not possible, wearing a dust mask or respirator is essential. These protective devices will help filter out the particles and protect your lungs. It’s crucial to prioritize your health and take the necessary precautions to minimize exposure to airborne contaminants when working with woodworking machines.

5. Can I perform maintenance or repairs on woodworking machines while they are still running?

No, you should never attempt to perform maintenance or repairs on woodworking machines while they are still running. Always turn off the machines and unplug them before carrying out any maintenance or repair work. Working on machines that are still running poses a significant risk of accidents and injuries.

Before performing any maintenance or repairs, ensure that the machines are completely powered off. Use lockout/tagout procedures to prevent accidental startups. If you are unsure about how to properly carry out maintenance or repairs, it’s best to consult a professional or seek guidance from the manufacturer. Remember, safety should always be the top priority when working with woodworking machines.

Summary

When working with woodworking machines, there are certain things you should avoid. First, never wear loose clothes or jewelry that can get caught in the machinery. Second, make sure to keep your fingers away from the cutting area at all times. Third, never use a machine if you are tired or under the influence of drugs or alcohol. Fourth, avoid distractions and stay focused on the task at hand. Lastly, always follow safety guidelines and use protective equipment to prevent accidents.

Remember, safety should always be your top priority when working with woodworking machines. By avoiding these hazards and taking necessary precautions, you can ensure a safe and enjoyable woodworking experience.