Are you wondering what size bandsaw blade to use for cutting curves? Well, you’ve come to the right place! Whether you’re a woodworking enthusiast or a beginner, understanding the right blade size is essential for achieving smooth and precise curved cuts. In this article, we’ll explore the ins and outs of selecting the perfect bandsaw blade for curves, demystifying the process and empowering you to make informed choices.

When it comes to cutting curves on a bandsaw, the size of the blade plays a crucial role. Choosing the right blade width can make a world of difference in the quality of your cuts. But how do you determine the ideal size? Hang tight as we dive into the factors that affect blade selection, including the radius of the curve, the thickness of the material, and the desired level of precision.

If you’re eager to create intricate designs or tackle challenging woodworking projects that involve curves, it’s essential to understand the importance of selecting the right bandsaw blade size. By the end of this article, you’ll be equipped with the knowledge to confidently choose the ideal blade size for cutting curves with precision and ease. Let’s get started on this exciting journey of discovering the perfect bandsaw blade for your next curved masterpiece!

How to choose the right size bandsaw blade for curves:

– Determine the radius of the curves you’ll be cutting.

– Measure the blade width. For tighter curves, choose a narrower blade.

– Consider the blade thickness. Thicker blades are more durable but may struggle with tight curves.

– Assess the blade’s tooth style. Skip-tooth or hook-tooth blades are ideal for cutting curves.

– Finally, match the blade length to the size of your bandsaw.

Happy curve-cutting!

Choosing the Right Size Bandsaw Blade for Curves: A Comprehensive Guide

Understanding Bandsaw Blades for Curves

When it comes to cutting curves on a bandsaw, choosing the right blade size is crucial for achieving accurate and smooth results. Bandsaw blades come in various widths and tooth configurations, each designed to handle specific cutting tasks. For curves, you’ll want to select a blade with a narrow width and a high TPI (teeth per inch) count. This combination allows for more intricate maneuvering and precision cutting.

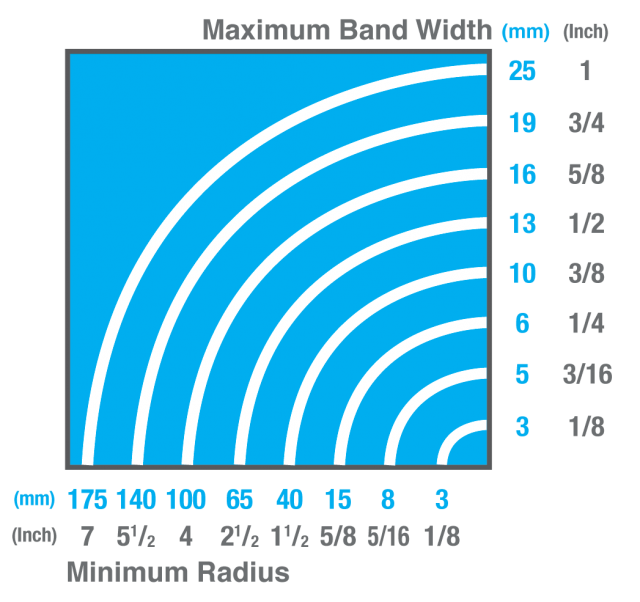

The width of a bandsaw blade determines its ability to make tight radius curves. Narrow blades, usually 1/8″ or 1/4″ wide, are the most suitable for navigating intricate curves. The narrower the blade, the tighter the curve it can handle. On the other hand, wider blades are better suited for straight cuts or larger, gradual curves.

Additionally, the TPI count is equally important. A higher TPI count means more teeth per inch, resulting in a smoother cut. Blades with higher TPI counts are perfect for cutting complex curves with minimal tear-out, leaving behind clean and precise edges.

Blade Width and Curvature

Blade width plays a significant role in determining the tightness of the curves you can achieve. A 1/4″ blade provides better stability and control when cutting medium-sized curves, while a 1/8″ blade is ideal for intricate and tight curves. It’s important to note that blade width isn’t the sole factor affecting your ability to make curves. The bandsaw’s capacity and overall design also come into play. However, when it comes to small radii and detailed cuts, a narrow blade is essential.

The narrower the blade, the easier it is to maneuver around tight corners and intricate patterns. This allows for greater creativity and precision in your woodworking projects. On the other hand, wider blades are better suited for straight cuts or larger, gradual curves. It’s crucial to select a blade width that complements the curves you intend to cut, enabling you to achieve the desired results without sacrificing control or safety.

Keep in mind that while narrow blades are excellent for tight curves, they may be more prone to blade drift. Blade drift refers to the tendency of the blade to veer off-course during cutting, resulting in less precise cuts. However, with proper technique and adjustments, you can minimize blade drift and achieve accurate and refined curves.

TPI Count and Cut Quality

The TPI (teeth per inch) count on a bandsaw blade directly affects the smoothness and quality of the cut. Higher TPI counts are preferable for cutting curves as they result in finer and cleaner cuts. Blades with higher TPI counts have more teeth in contact with the wood, reducing tear-out and leaving smooth edges. This is particularly important when working with delicate or high-value materials where precision matters.

For cutting curves, a blade with a TPI count between 4 and 14 is suitable. A lower TPI count is better for rough cuts and faster material removal, while a higher TPI count is ideal for intricate and detailed cuts. However, it’s important to strike a balance between TPI count and feed rate. Higher TPI blades require a slower feed rate to prevent overheating, while lower TPI blades can handle faster feed rates. Finding the right TPI count for your cutting needs will result in cleaner cuts, reduced sanding or finishing, and overall better project outcomes.

Experimenting with different TPI counts can help you find the sweet spot for the type of curves you often cut. It’s advisable to keep a selection of blades with varying TPI counts to accommodate different projects and materials. This way, you can achieve optimal cutting results while prolonging the lifespan of your blades by using the right one for each task.

Factors to Consider when Choosing a Bandsaw Blade for Curves

When selecting the right bandsaw blade size for curves, it is important to consider a few factors:

- The type of material you will be cutting: Different materials require different blade characteristics. For example, a blade suitable for cutting wood may not be ideal for cutting metal.

- The complexity and tightness of the curves: If you frequently work with intricate patterns and tight curves, a narrower blade with a higher TPI count would be necessary.

- The thickness of the material: Thicker materials may require a wider blade to provide the necessary stability and control.

- Your skill level and experience: If you are a beginner or less experienced, starting with a wider blade for more stability may be beneficial.

By considering these factors, you can select the appropriate blade size that caters to your specific cutting needs, ensuring the best results in your woodworking or metalworking projects.

Benefits of Using the Right Size Bandsaw Blade for Curves

Choosing the right bandsaw blade size for curves offers several benefits:

- Improved precision: The right blade size allows for more accurate and intricate cutting, giving you the ability to achieve precise curves and patterns in your projects.

- Reduced tear-out: Blades with higher TPI counts minimize tear-out, leaving clean and smooth edges, especially in delicate materials.

- Enhanced maneuverability: Narrow blades provide better maneuverability around tight corners and complex curves, allowing for greater creative freedom in your designs.

- Efficient material removal: Narrow blades with high TPI counts are efficient at removing material during cutting, reducing the need for extensive sanding or finishing.

Tips for Optimal Bandsaw Blade Performance

Here are a few tips to ensure optimal performance when using bandsaw blades for cutting curves:

- Proper tensioning: Ensure that the blade is appropriately tensioned according to the manufacturer’s guidelines for optimal performance and cutting results.

- Blade tracking: Regularly check the blade tracking to ensure it is properly aligned on the bandsaw wheels. Improper tracking can lead to blade drift and less accurate cuts.

- Feeding speed: Adjust the feeding speed to match the TPI count of the blade. Lower TPI blades can handle faster feeding speeds, while higher TPI blades require slower feed rates.

- Blade maintenance: Keep your bandsaw blades clean and free from debris to prevent premature dulling or damage. Regularly inspect the blades for signs of wear or defects and replace as necessary.

- Proper technique: Practice good cutting technique, such as guiding the material smoothly and evenly through the blade, to ensure clean and precise cuts.

Common Bandsaw Blade Sizes for Curves

Here is a list of common bandsaw blade sizes suitable for cutting curves:

| Blade Width (inches) | Blade TPI Count | Curvature |

|---|---|---|

| 1/8″ | 14 | Tight curves and intricate patterns |

| 1/4″ | 10 | Medium-sized curves and general-purpose cutting |

| 3/8″ | 6 | Larger curves and straight cuts |

These sizes serve as a general guideline and can vary depending on the specific bandsaw model, project requirements, and material being cut. It’s essential to experiment and find the blade size that works best for your individual needs.

Ensuring Safety

Remember that bandsaws can be dangerous tools if not used correctly. Always prioritize safety when operating a bandsaw. Wear appropriate safety gear, such as goggles and gloves, and keep your hands a safe distance from the blade. Follow all safety guidelines provided by the manufacturer and take the time to familiarize yourself with the bandsaw’s features and controls before using it.

Choosing the Right Bandsaw for Curves: Key Factors to Consider

While choosing the right size bandsaw blade is essential for cutting curves, selecting the appropriate bandsaw machine itself is equally important. Here are some factors to consider when choosing a bandsaw for curves:

Bandsaw Type

There are various types of bandsaw machines available, including benchtop models, floor-standing models, and portable bandsaws. The type of bandsaw you choose depends on your workspace, mobility needs, and project requirements. For cutting curves, a benchtop or floor-standing bandsaw with a tilting table is ideal, as it provides stability and maneuverability.

Bandsaw Throat Capacity

The throat capacity of a bandsaw refers to the distance between the blade and the vertical frame of the machine. This measurement determines the maximum width of a workpiece that the bandsaw can accommodate. For cutting large curves, a higher throat capacity is required to allow for wider materials.

Bandsaw Motor Power

The motor power of a bandsaw affects its cutting capabilities. More power allows for smoother and faster cuts, especially in dense or thick materials. When cutting curves, a powerful motor can reduce the risk of stalling or bogging down when making intricate or tight turns.

Bandsaw Table Size and Tilting Capability

The size of the bandsaw table affects the support and stability provided to the workpiece. A larger table allows for better control and maneuvering during curve cutting. Additionally, a tilting table feature offers greater versatility when making angled cuts or more complex curves.

Bandsaw Blade Guides

The blade guides on a bandsaw machine play a crucial role in ensuring smooth and accurate cuts. Look for models with quality blade guides that provide adequate support and allow for easy adjustments to accommodate different blade sizes and cut depths.

Bandsaw Blade Tensioning System

A good blade tensioning system ensures that the blade remains properly tensioned during use, reducing the risk of blade slippage or breakage. Consider bandsaw models with user-friendly tensioning systems that allow for quick and easy adjustments.

Bandsaw Dust Collection

Dust collection is an important factor to consider, as bandsaws can generate a significant amount of dust and debris during cutting. Look for bandsaw models with effective dust collection systems or the ability to connect to an external dust collector. This helps maintain a clean and safe working environment.

Bandsaw Brand and Reputation

Lastly, consider the brand and reputation of the bandsaw manufacturer. Research customer reviews and ratings to ensure that you are investing in a reliable and durable machine. Brands with a proven track record of producing high-quality bandsaws are more likely to provide reliable performance and excellent customer support.

Troubleshooting Common Issues when Cutting Curves

Even with the right bandsaw blade and machine, you may encounter some challenges when cutting curves. Here are a few common issues and possible solutions:

Blade Drift

Blade drift occurs when the bandsaw blade veers off-course during cutting, resulting in less accurate cuts. To minimize blade drift, ensure that the blade is properly tensioned and aligned on the bandsaw wheels. Additionally, adjusting the fence or using a drift-adjustment technique can help compensate for blade drift and achieve straighter cuts.

Tear-out or Splintering

Tear-out or splintering can occur when cutting curves, especially on delicate or brittle materials. To reduce tear-out, use blades with higher TPI counts and slower feed rates. Additionally, placing a sacrificial backing board behind the workpiece can help prevent tear-out by supporting the fibers during the cut.

Burning or Scorching

Burning or scorching of the wood can be caused by excessive friction between the blade and the material. This can occur when the feed rate is too slow or the blade is dull. Adjusting the feed rate or using a newly sharpened blade can help reduce burning and achieve cleaner cuts.

Conclusion

Choosing the right size bandsaw blade for curves is essential for achieving accurate, precise, and smooth cuts. By considering factors such as blade width, TPI count, and the specific curves you intend to cut, you can select the perfect blade size for your projects. Additionally, pairing the appropriate bandsaw machine with the right blade enhances overall cutting performance and outcomes. Regular maintenance and proper technique further ensure optimal blade performance and safety. By following these guidelines and troubleshooting any issues, you’ll be well-equipped to tackle curved cuts with confidence and precision.

Key Takeaways: What Size Bandsaw Blade for Curves?

- Choosing the right size bandsaw blade is crucial for cutting curves effectively.

- A narrow blade, such as 1/4 inch or 3/8 inch, is ideal for tight curves and intricate designs.

- A wider blade, like 1/2 inch or 3/4 inch, provides stability and is suitable for larger curves.

- Consider the thickness of the material you are cutting when selecting the blade size.

- Remember to adjust the tension and speed of the bandsaw to achieve smooth and precise curves.

Frequently Asked Questions

Welcome to our frequently asked questions section on choosing the right bandsaw blade for curves! Below, you’ll find answers to common queries to help you make informed decisions for your woodworking projects. Read on for valuable insights!

1. What factors should I consider when choosing a bandsaw blade for cutting curves?

When selecting a bandsaw blade for curved cuts, you need to consider three main factors: blade width, tooth configuration, and blade thickness. For cutting tight curves, choose a narrower blade width. The narrower the blade, the tighter the curves you can cut. Tooth configuration refers to the pattern and shape of the teeth. For cutting curves, a blade with fewer teeth per inch (TPI) is recommended. Lastly, a thinner blade allows for tighter turns. However, keep in mind that the thinner the blade, the more it can flex, affecting the precision and stability of your cuts.

By assessing these factors and finding the right balance, you can select a bandsaw blade that will provide optimal performance and accuracy when cutting curves.

2. What is the ideal blade width for cutting curves on a bandsaw?

An ideal blade width for cutting curves on a bandsaw ranges from 1/8 inch to 1/4 inch. A narrower blade allows for more precise and tighter turns, enabling you to create intricate curved cuts with ease. However, it’s essential to note that a narrower blade may have limitations when it comes to cutting thicker or denser materials.

If you primarily work with thin stock or require detailed curved cuts, consider using a 1/8-inch blade. For general curved cutting in a variety of materials, a 1/4-inch blade strikes a good balance between maneuverability and stability.

3. Should I choose a skip tooth or a hook tooth blade for cutting curves?

Both skip tooth and hook tooth blades have their advantages for cutting curves. A skip tooth blade has teeth with large gaps between them, allowing for efficient chip removal. This helps prevent clogging and ensures smoother cuts. Skip tooth blades also reduce the risk of wood burning during the cutting process.

On the other hand, a hook tooth blade has teeth that angle forward, which provides more aggressive cutting action. This type of blade is beneficial when cutting thick or dense materials, as it removes material more effectively. However, for intricate or fine curved cuts, a skip tooth blade with its smoother cutting action is generally preferred.

4. Can I use a wider bandsaw blade for cutting tight curves?

Using a wider bandsaw blade for cutting tight curves is not recommended. A wider blade has a larger radius, making it more challenging to achieve sharp turns and precise cuts. The added width can lead to more resistance and the potential for blade wander, resulting in less accurate curved cuts.

To ensure the best results when cutting tight curves, stick to a narrower blade width that offers increased maneuverability and control.

5. Can I use the same bandsaw blade for straight cuts and cutting curves?

While it is possible to use the same bandsaw blade for both straight cuts and cutting curves, it may not yield the best results. Bandsaw blades optimized for straight cuts typically have a different tooth configuration, with more teeth per inch (TPI) to ensure smooth, clean cuts through the wood fibers. Curved cuts benefit from blades with a lower TPI, as they need more space for chip removal and to prevent blade clogging.

If your woodworking projects involve both straight cuts and curves, it is recommended to have separate bandsaw blades for each application. This will ensure optimal performance and the best quality cuts for your specific needs.

Summary

So, when it comes to choosing the right bandsaw blade for curves, there are a few things to keep in mind. First, the width of the blade is crucial – narrower blades are better for smaller curves, while wider blades work well for larger curves. Second, the number of teeth per inch is important too – more teeth means smoother cuts on curves. Lastly, don’t forget about the blade’s thickness – thicker blades are better for more intricate and delicate curves. By considering these factors, you can pick the perfect bandsaw blade for all your curved cutting projects!

In conclusion, the size of the bandsaw blade matters when cutting curves. Remember to consider the width, teeth per inch, and thickness of the blade to achieve the best results. Happy woodworking!