Ready to unleash your creativity and bring those amazing woodworking ideas to life? Wondering what size bandsaw blade is the perfect fit for cutting curves with precision and finesse? Look no further! In this article, we’ll dive into the world of bandsaw blades and explore the best options for those captivating curves you have in mind. So, grab your safety goggles, dust off that bandsaw, and let’s embark on an exciting journey of mastering the art of curved cuts!

When it comes to exploring the realm of curves, choosing the right bandsaw blade is like finding the missing piece to a puzzle. It’s crucial for achieving smooth, effortless, and accurate cuts. But finding that perfect fit can sometimes feel like searching for a needle in a haystack. That’s where we step in! We’re here to guide you through the process and demystify the world of bandsaw blades, helping you find the ideal size that suits your unique cutting needs.

Imagine gliding through wood like butter, effortlessly shaping those intricate curves you’ve always dreamt of. With the right bandsaw blade size, you can make it happen! But it’s not just about picking any old blade and hoping for the best. You see, each size has its own capabilities, ensuring that your curves turn out flawlessly, without any jagged edges or uneven contours. So, join us as we unlock the secrets of bandsaw blades and empower you to create curves that will leave everyone in awe. Get ready to unleash your artistic potential!

When it comes to cutting curves with a bandsaw, the size of the blade is crucial for achieving precise results. To determine the appropriate size, consider the radius of the curves you’ll be cutting. For tighter curves, opt for a thinner blade with a higher number of teeth per inch. For larger curves, a wider blade with fewer teeth per inch will work best. Finding the right balance will ensure clean and smooth cuts when working on your projects.

What Size Bandsaw Blade for Cutting Curves? A Comprehensive Guide

Curved cuts can add a beautiful design element to your woodworking projects, but choosing the right bandsaw blade for this task can be intimidating. With so many options available, it’s important to understand the factors that affect blade selection and how to make the best choice for your specific needs. In this article, we’ll delve into the world of bandsaw blades and explore the considerations that go into determining the ideal size for cutting curves. Whether you’re a beginner or a seasoned woodworker, this guide will equip you with the knowledge to create smooth, precise curves in your projects.

Understanding Bandsaw Blade Sizes

Before we dive into the specifics of choosing a bandsaw blade for cutting curves, it’s important to have a good understanding of how bandsaw blades are sized. Bandsaw blades are measured in terms of their length and width, with additional specifications for tooth pitch and tooth configuration. The length of a bandsaw blade corresponds with the circumference of the bandsaw’s wheels, while the width determines the cutting capacity of the blade. These measurements are crucial in ensuring a proper fit and optimal performance of the blade.

The Importance of Width

The width of the bandsaw blade is a critical factor to consider when cutting curves. Generally, wider blades are more stable and less prone to deflection, allowing for greater control while cutting intricate curves. A wider blade also provides more surface area, resulting in improved heat dissipation and reduced heat buildup during the cutting process. This is particularly beneficial when working with dense or thick materials that can generate significant heat, which can lead to blade dulling or even blade damage.

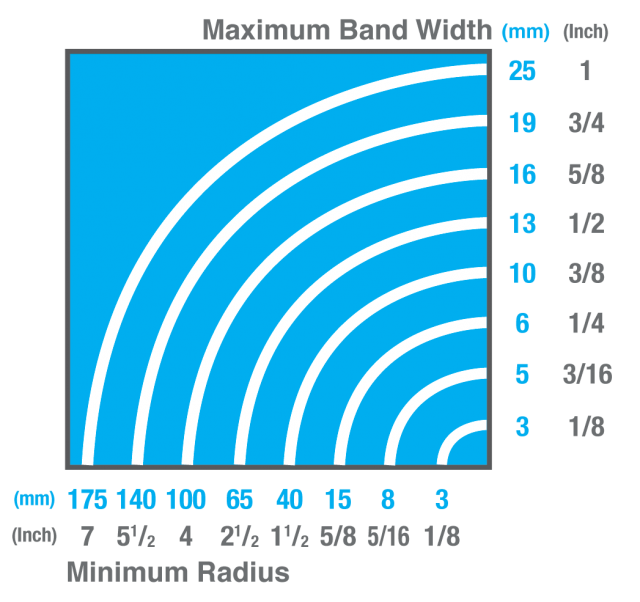

When selecting the width of your bandsaw blade for cutting curves, consider the radius of the curves you typically work with. As a general rule, a wider blade is more suitable for larger curves, while a narrower blade may be preferred for tighter, more intricate curves. However, keep in mind that using a very narrow blade on large curves can lead to excessive blade flexing and a loss of control.

It’s worth noting that the width of a bandsaw blade is limited by the bandsaw itself. Refer to your bandsaw’s user manual or consult the manufacturer’s guidelines to determine the maximum blade width that can be accommodated by your specific machine.

Factors to Consider When Choosing Blade Width for Cutting Curves

When deciding on the width of the bandsaw blade for cutting curves, there are several key factors to consider:

Material Thickness

The thickness of the material being cut plays a significant role in blade selection. Thicker materials require wider blades to ensure stability and minimize the risk of blade deflection. If you primarily work with thin stock, a narrower blade may be more suitable for your needs.

Curvature of the Cut

The radius of the curves you typically work with will influence the blade width. As mentioned earlier, wider blades are generally better suited for larger curves, while narrower blades excel in tight, intricate curves.

Cutting Speed

The speed at which you plan to cut also impacts blade choice. If you need to cut quickly or make rough cuts, a wider blade with a higher tooth count is recommended. On the other hand, for slower, more precise cuts, a narrower blade with a lower tooth count can provide better control.

Wood Type

The type of wood you work with can affect blade selection. Softer woods generally require fewer teeth per inch for efficient cutting, while hardwoods often necessitate blades with more teeth for smoother results. Consider the specific characteristics of the wood you frequently work with to determine the ideal blade width and tooth configuration.

Blade Thickness

In addition to the width of the bandsaw blade, the thickness of the blade is another crucial factor to consider. Thicker blades are more rigid and less prone to flexing, making them ideal for cutting curves. Thinner blades, on the other hand, provide tighter turning radii and are better suited for delicate curves. It’s important to strike a balance between blade thickness and width to achieve optimal performance.

Maintenance and Resawing

While the focus of this article is on cutting curves, it’s worth mentioning that bandsaw blades can serve multiple purposes. If you also plan to use your bandsaw for resawing or performing other tasks, you may want to invest in a separate blade specifically for those applications. Resawing typically requires a wider blade with a coarser tooth pitch to handle the larger cutting capacity and remove material efficiently.

Benefits of Choosing the Right Size Bandsaw Blade for Cutting Curves

Choosing the correct size bandsaw blade for cutting curves can offer several benefits:

- Improved Precision: A properly sized blade allows for precise, controlled cuts, resulting in smooth curves and minimal material waste.

- Enhanced Control: Using a wider blade with appropriate thickness and tooth configuration ensures stability and reduces blade deflection, giving you greater control over your cuts.

- Extended Blade Life: Selecting the optimal blade size for cutting curves reduces strain on the blade, leading to increased longevity and fewer blade replacements.

- Efficient Cutting: A well-chosen blade can minimize heat buildup and reduce friction, allowing for faster and more efficient cutting, saving you both time and effort.

Tips for Using Bandsaw Blades for Cutting Curves

To ensure the best results when using a bandsaw blade for cutting curves, keep the following tips in mind:

- Tension the Blade Properly: The right blade tension is crucial for optimal performance. Follow the manufacturer’s guidelines to ensure the blade is tensioned appropriately for the best cutting results.

- Choose the Right Tooth Configuration: Different tooth configurations are available for bandsaw blades, such as hook teeth, skip teeth, or regular teeth. Consider the characteristics of the wood you’re working with and the type of cuts you need to make to select the most appropriate tooth configuration.

- Monitor Blade Sharpness: Dull blades can lead to rough cuts and increase the risk of burning or stalling. Regularly inspect your blade for dullness and sharpen or replace it as necessary.

- Use Proper Feed Speed: Maintaining a consistent feed rate is important for achieving clean cuts. Experiment with different feed speeds to find the optimal rate for your specific bandsaw blade and material.

- Practice Safety Precautions: Always prioritize safety when working with a bandsaw. Wear appropriate safety gear, keep your fingers clear of the blade, and follow proper operating procedures to prevent accidents.

The Perfect Bandsaw Blade for Curved Cuts: Final Thoughts

Choosing the right bandsaw blade size for cutting curves is essential for achieving precise, clean results in your woodworking projects. By considering factors such as material thickness, curvature of the cut, cutting speed, wood type, blade thickness, and other considerations, you can make an informed decision about the ideal blade width and tooth configuration. Remember to take into account the limitations of your bandsaw and follow best practices for blade tensioning, sharpness, and safety. Armed with the right information and tools, you’ll be well-equipped to create beautiful, smooth curves that will elevate your woodworking projects to the next level.

Key Takeaways: What Size Bandsaw Blade for Cutting Curves?

- Choose a narrow blade for cutting tight curves.

- Opt for a wider blade to cut larger curves.

- Consider the blade width recommendations provided by the bandsaw manufacturer.

- Smaller blades are more maneuverable for intricate curves.

- Thicker blades provide stability when cutting long curves.

Frequently Asked Questions

Are you wondering what size bandsaw blade to use for cutting curves? Look no further! We’ve gathered some commonly asked questions to help guide you in choosing the right blade size for your bandsaw.

1. What factors should I consider when selecting a bandsaw blade for cutting curves?

When choosing a bandsaw blade for cutting curves, there are a few factors to consider. Firstly, the blade’s width plays a crucial role. A narrower blade provides better maneuverability and allows for tighter curves. However, keep in mind that narrower blades may have a higher risk of blade deflection or wandering.

Another important factor is the blade’s tooth pattern. Blades with a higher tooth count per inch (TPI) are better suited for cutting tight curves. A higher TPI helps to create smoother cuts and reduces the chances of the blade drifting off course. Additionally, the blade’s thickness is something to consider. Thicker blades provide more stability and are ideal for cutting thicker stock, while thinner blades are better suited for intricate curves in thinner materials.

2. Can I use any size bandsaw blade for cutting curves?

While you technically can use any size bandsaw blade for cutting curves, it’s important to choose the right size for optimal results. As mentioned earlier, narrow blades are better for tight curves, whereas wider blades are better suited for larger curves or resawing thicker stock. Using the right blade size will ensure smoother cuts, minimize blade wander, and reduce the risk of blade breakage.

Remember, the size of the bandsaw blade you choose will depend on the type of curves you plan to cut and the thickness of the material. It’s always advisable to consult the manufacturer’s recommendations or seek guidance from experts to select the appropriate blade size for your specific cutting needs.

3. Are there different blade sizes for different types of materials and curves?

Yes, there are different blade sizes available for different types of materials and curves. The size of the bandsaw blade you choose will depend on the thickness of the material and the radius of the curves you plan to cut. For thinner materials and tighter curves, a narrower blade with a higher tooth count per inch (TPI) is recommended. This allows for better maneuverability and smoother cuts.

If you’re working with thicker materials or larger curves, a wider blade with a lower TPI might be more suitable. Thicker blades provide more stability and prevent deflection, which is especially important when cutting through denser or thicker stock. It’s crucial to select the right blade size to ensure clean and accurate cuts for different materials and curve sizes.

4. How can I determine the blade size for my bandsaw?

To determine the appropriate blade size for your bandsaw, you can refer to the bandsaw’s manual or consult the manufacturer’s guidelines. The manual typically includes recommendations for blade width, tooth count per inch (TPI), and the maximum thickness of the material the bandsaw can handle.

If you don’t have access to the manual or guidelines, you can measure the diameter of the smallest curve you plan to cut and choose a blade with a width that fits within that radius. Additionally, consider the thickness of the material and select a blade that can comfortably handle its size. It’s important to find a balance between the blade’s width, tooth pattern, and the materials you’ll be working with to ensure the best cutting performance.

5. Are there any tips for maintaining the blade’s performance when cutting curves?

Yes, there are a few tips to help maintain the performance of your bandsaw blade when cutting curves. Firstly, ensure the blade is properly tensioned. Correct tensioning is crucial for optimal blade performance and prevents the blade from wandering or deflecting while cutting.

Regular blade maintenance is also important. Keep the blade clean, free from pitch and debris, and replace it if you notice any signs of damage or dullness. Applying a lubricant specifically designed for bandsaw blades can help reduce friction, prolong blade life, and ensure smoother cuts.

Lastly, take your time when cutting curves and maintain a steady, consistent feed rate. Rushing or applying excessive pressure can lead to poor quality cuts, blade overheating, or even blade breakage. Remember to use appropriate safety equipment, follow proper cutting techniques, and always prioritize your safety when operating a bandsaw.

Summary

The size of the bandsaw blade you need for cutting curves depends on the radius of the curves you will be cutting. Generally, a narrower blade is better for tighter curves, while a wider blade works well for larger curves. It’s important to choose the right size blade to ensure smooth and accurate cuts.

To determine the appropriate blade size, consider the thickness of the material you’ll be cutting, as well as the desired tightness of the curves. Thinner materials can be cut using a narrower blade, while thicker materials may require a wider blade. Remember to always follow the manufacturer’s recommendations and guidelines for your specific bandsaw model to ensure optimal performance and safety.