Wondering what size circular saw blade you need for your next woodworking project? Well, you’ve come to the right place! Choosing the right blade size is crucial for achieving clean and precise cuts. So, let’s dive in and explore the world of circular saw blades together!

When it comes to circular saws, the size of the blade plays a vital role in determining the depth and quality of your cuts. So, understanding blade sizes is essential for any woodworking enthusiast. Don’t worry, we’ll break it down for you in simple terms!

From small projects like crafting a birdhouse to larger tasks like building a bookshelf, the correct blade size can make a world of difference. So, let’s grab our safety goggles, roll up our sleeves, and embark on this exciting journey to discover the perfect circular saw blade size for your needs!

Choosing the right size circular saw blade is essential for getting precise and clean cuts. To determine the size you need:

- Identify the type of material you’ll be cutting.

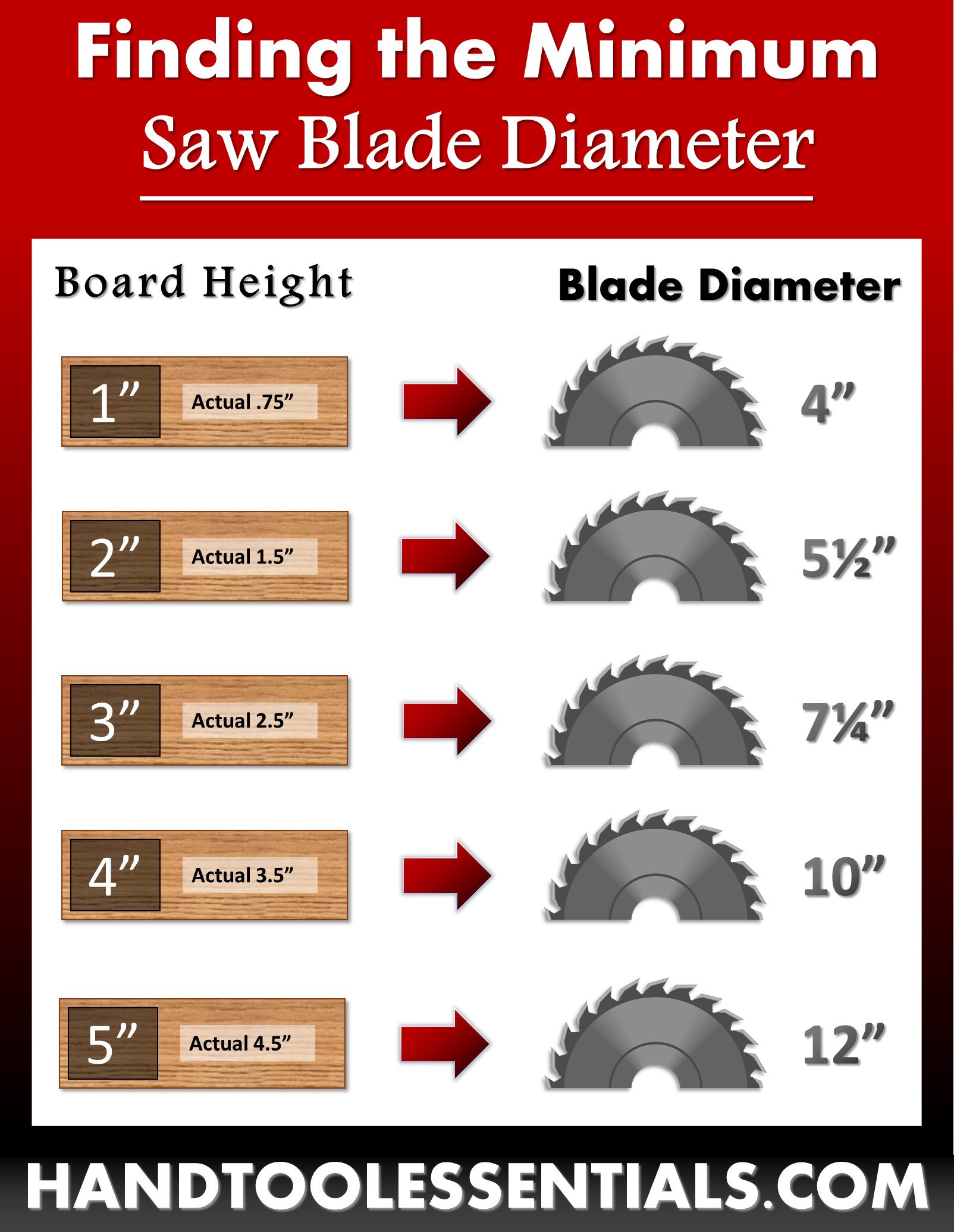

- Consider the thickness of the material.

- Check the saw’s blade size requirements.

- Choose a blade with the appropriate diameter.

- Ensure the blade has the right number of teeth for the job.

Follow these steps to select the perfect circular saw blade size for your project!

What Size Circular Saw Blade Do I Need? A Comprehensive Guide

Choosing the right circular saw blade size is essential for achieving precise and efficient cuts. Whether you’re a professional carpenter or a DIY enthusiast, understanding the factors that determine the appropriate blade size for your project is crucial. In this comprehensive guide, we will delve into the details of what size circular saw blade you need, taking into account various factors such as blade diameter, teeth count, and material compatibility. By the end of this article, you’ll have the knowledge and confidence to choose the perfect circular saw blade for any cutting task.

The Importance of Blade Diameter

Blade diameter is a critical factor in determining the size of a circular saw blade needed for a specific job. The blade diameter directly affects the cutting depth: larger diameter blades allow for deeper cuts while smaller blades are better suited for shallower cuts. When selecting a circular saw blade, consider the maximum cutting depth required for your project. For instance, if you need to cut through thicker materials, a larger blade diameter, such as 7 ¼ inches, would be ideal. On the other hand, if you’re working with thinner materials, a 6 ½-inch blade would suffice.

It’s important to note that the size of the saw itself will limit the maximum blade diameter it can accommodate. Be sure to check your saw’s specifications to ensure compatibility and safety. While it may be tempting to use a blade larger than what is recommended for your saw, this can result in inaccurate cuts, increased risk of kickback, and potential damage to the tool.

In addition to cutting depth, blade diameter can also affect the saw’s RPM (rotations per minute). Smaller diameter blades tend to spin faster than larger ones. It’s crucial to select a blade that matches the RPM range of your specific circular saw to prevent overheating or premature wear.

Understanding Teeth Count and Blade Performance

The number of teeth on a circular saw blade determines its performance and the finish it provides on different materials. Blades with more teeth tend to produce smoother cuts with minimal tear-out, making them suitable for fine woodworking or cutting melamine-coated surfaces. Conversely, blades with fewer teeth are better suited for rough cuts in construction or when you want to remove material quickly.

The teeth count also affects the blade’s cutting speed. Blades with more teeth generally cut more slowly but provide cleaner results, while those with fewer teeth cut faster but may leave rougher edges. It’s essential to select a blade with the appropriate teeth count for the type of material you’re cutting and the desired finish. For instance, a blade with 40 to 60 teeth might be ideal for general purpose cutting, while a blade with over 80 teeth would be better for fine woodworking or cutting delicate materials like laminates or veneers.

Keep in mind that some blades feature alternating top bevel (ATB) or triple chip grind (TCG) tooth configurations, each designed for specific materials. ATB blades are excellent for crosscutting wood, while TCG blades are better suited for cutting materials like laminate, plastic, or non-ferrous metals. Considering the tooth count and configuration ensures optimal performance and longevity of the blade.

Material Compatibility: Matching the Blade to the Job

One of the most critical factors to consider when determining the size of a circular saw blade you need is the compatibility with the material you are cutting. Different blade tooth designs, kerf widths, and special coatings are engineered to provide optimal cutting performance for specific materials.

For general purpose cutting of softwood or hardwood, a standard crosscutting blade with ATB or combination tooth design is suitable. These blades are versatile and can handle a variety of cutting tasks. However, if you frequently work with plywood, melamine, or laminates, consider using blades specifically designed for clean cuts without chip-out.

For specialized tasks, there are a variety of circular saw blades available. Carbide-tipped blades, for example, offer exceptional durability and longevity, making them ideal for cutting dense and abrasive materials like hardwoods, MDF, or particleboard. Diamond-tipped blades are specifically designed for cutting through hard materials like concrete, ceramic tiles, or natural stone, making them perfect for construction or remodeling jobs.

Blade Care and Maintenance Tips

1. Clean and Store Properly:

After each use, be sure to remove any sawdust or debris from the blade to prevent build-up or corrosion. Store the blade in a dry, clean place to maintain its sharpness.

2. Check for Damage:

Regularly inspect your circular saw blade for any signs of damage, such as chipped or missing teeth. Replace damaged blades immediately to ensure clean and safe cuts.

3. Sharpen or Replace:

If you notice that your blade is becoming dull or cutting less efficiently, consider sharpening it. However, keep in mind that this should be done by a professional, as improper sharpening can result in poor performance or even damage the blade. If a blade is severely worn or damaged, it’s best to replace it.

4. Use the Right Speed:

Adjust the saw’s speed according to the cutting task and blade size. Running the saw at a speed that is too high can cause overheating, while a speed that is too low may result in poor cutting performance or premature wear.

5. Follow Manufacturer’s Guidelines:

Always refer to the manufacturer’s instructions and guidelines for your specific circular saw and blade. They will provide valuable information on safety precautions, maintenance, and usage recommendations.

Choosing the Right Circular Saw Blade: Tips and Recommendations

Now that you have a comprehensive understanding of what size circular saw blade you need and the factors to consider, let’s summarize some essential tips and recommendations to help you make the best choice for your specific cutting needs:

1. Measure the Cutting Depth:

Before selecting a blade, measure the required cutting depth for your project to determine the appropriate blade diameter that will allow you to achieve the desired results.

2. Consider the Material:

Take into account the type of material you’ll be cutting. Different materials require specific blade designs and tooth configurations for optimal performance.

3. Understand Teeth Count and Configuration:

Choose a blade with the appropriate teeth count and configuration based on the desired finish and the speed at which you want to cut the material.

4. Check Your Saw’s Specifications:

Ensure that the blade you choose is compatible with your circular saw. Refer to the saw’s specifications in terms of maximum blade diameter and RPM range to guarantee safe and accurate cuts.

5. Quality over Price:

Investing in high-quality blades will result in cleaner cuts, smoother finishes, and longer blade life. While they may be more expensive upfront, they often offer better value in the long run.

6. Seek Expert Advice:

If you’re unsure about the right circular saw blade for your specific project, don’t hesitate to consult with experts or professionals in the field. They can provide valuable insights and recommendations based on their experience.

Conclusion

Choosing the right circular saw blade size is crucial for achieving precise, clean, and efficient cuts. Consider factors such as blade diameter, teeth count, and material compatibility to select the appropriate blade for your specific project. By taking the time to understand these factors and following the tips and recommendations provided, you’ll be well-equipped to choose the perfect circular saw blade for any cutting task. Remember to prioritize safety, maintain and care for your blades properly, and always refer to the manufacturer’s guidelines for the best results.

Key Takeaways: What Size Circular Saw Blade Do I Need?

- 1. The size of the circular saw blade you need depends on the type of material you’ll be cutting.

- 2. For general woodworking tasks, a 7 1/4-inch circular saw blade is commonly used.

- 3. If you’re cutting thicker material, such as beams or large panels, consider using a larger blade, like 10 inches.

- 4. Smaller blades, like 6 1/2 inches, are often used for compact or lightweight saws.

- 5. It’s important to match the blade’s arbor size with your saw’s arbor size to ensure proper fit and safe operation.

Frequently Asked Questions

Are you unsure of what size circular saw blade you need for your project? Don’t worry, we’ve got you covered. Check out these commonly asked questions to help you find the perfect blade for your needs.

1. Can I use any size circular saw blade with my saw?

Not all circular saw blades are created equal. Each saw is designed to work with a specific blade diameter and arbor size. It’s essential to consult your saw’s manual or manufacturer’s website to determine the appropriate blade size. Using the wrong size blade may result in poor performance, increased risk of kickback, and potential damage to your saw.

To find the right blade size, look for the diameter measurement printed on the blade itself. This should match the recommended blade size for your saw. Additionally, check the arbor size, which refers to the hole in the center of the blade that fits onto the saw’s spindle. Ensure that the arbor size matches your saw’s spindle size to guarantee a proper fit.

2. What factors should I consider when choosing a circular saw blade size?

Several factors influence the choice of blade size for your circular saw. First, consider the thickness and type of material you plan to cut. Different blade sizes are more suitable for specific materials and cutting depths. For example, smaller blades are ideal for precision cuts on thin materials, while larger blades are better for cutting through thicker materials.

Additionally, take into account the power of your saw. Smaller saws may struggle to handle larger blades, while larger saws may overpower smaller blades. Ensuring the compatibility between your saw’s power and the selected blade size will help achieve optimal cutting results.

3. How do I know if I need a smaller or larger circular saw blade?

The decision to use a smaller or larger circular saw blade depends on your cutting requirements. If you need to make intricate cuts or work with delicate materials, a smaller blade with a narrower kerf will provide better precision. On the other hand, larger blades are suitable for cutting thicker materials or making long, straight cuts.

Consider the project at hand and evaluate the depth, accuracy, and intricacy of the cuts you’ll be making. This will guide you in determining whether a smaller or larger blade size will be the most appropriate for your needs.

4. Can I change the size of the circular saw blade for different cuts?

Yes, you can change the blade size of your circular saw to accommodate different cuts. However, it’s important to ensure that the new blade size is compatible with your saw. Always refer to your saw’s manual or manufacturer’s guidelines before swapping out blades.

When changing the blade size, remember to adjust the saw’s cutting depth accordingly. Different blade sizes may require adjustments to ensure optimal cutting performance and prevent accidents. Follow the instructions provided by the manufacturer to set the correct cutting depth.

5. Are there any safety precautions I should take when changing circular saw blades?

Changing circular saw blades requires careful handling to ensure your safety. Before starting, always unplug the saw or remove the battery to prevent accidental starts. Wear protective gloves to prevent cuts and injuries, and use a blade removal tool or a proper wrench to secure the blade during the replacement process.

Additionally, inspect the new blade for any defects or damage before installation. Make sure it is sharp and free from any imperfections. Follow the manufacturer’s instructions for proper installation, including tightening the blade securely onto the saw’s spindle. Lastly, ensure the blade guard is functioning correctly and covers the blade when not in use, providing an additional layer of safety.

Summary

Choosing the right circular saw blade is important for a good cutting experience. It depends on the material you’re cutting and the size of your saw. For cutting wood, use a blade with more teeth for smoother cuts. To cut metal or concrete, a blade with fewer teeth and carbide tips is ideal. Remember to check the size of your saw to ensure the blade fits properly.

Additionally, consider the blade’s diameter and its arbor size, which must match your saw. Make sure to follow safety precautions and use proper protective gear while operating the saw. By selecting the right blade and using it correctly, you’ll achieve cleaner and safer cuts with your circular saw.