Have you ever wondered, “What size drill bit should I use for a 1/2 tap?” Well, you’re in the right place!

Choosing the correct drill bit size is crucial for achieving great results when tapping.

In this guide, we’ll break down everything you need to know about selecting the perfect drill bit size for a 1/2 tap. Let’s dive in!

When using a 1/2-inch tap, it’s important to use the correct size drill bit for optimal results. To determine the right size, you’ll want to choose a drill bit that is slightly smaller than the tap’s diameter. In this case, a 29/64-inch drill bit is commonly used for a 1/2-inch tap. This size allows for easy threading of the tap while ensuring a secure and robust connection. Happy drilling!

What Size Drill Bit for 1/2 Tap: A Comprehensive Guide

When it comes to working with taps and drills, it’s essential to have the right size drill bit for the tap you’re using. In this article, we will delve into the world of drill bits and taps, specifically focusing on the question “what size drill bit for 1/2 tap?”. Whether you’re a seasoned professional or a DIY enthusiast, understanding the correct drill bit size for a 1/2 tap is crucial for creating accurate and efficient holes. Join us as we explore everything you need to know about drill bits and 1/2 taps, providing you with the information you need to tackle your drilling projects with confidence.

Understanding Drill Bit Sizes

To determine the right drill bit size for a 1/2 tap, it’s important to understand how drill bit sizes are measured. Drill bit sizes are typically denoted in fractional inches, number sizes, or letter sizes. Fractional inches are the most common measurement for drill bits and are represented as a fraction of an inch (e.g., 1/4, 3/8, 1/2). Number sizes are another commonly used measurement system, ranging from 1 to 80, with higher numbers indicating smaller drill bits. Letter sizes, such as A, B, C, etc., are used to measure drill bits beyond number 80.

When it comes to selecting the right drill bit size for a 1/2 tap, you’ll need to consider the tap size and the material you’re drilling into. The tap size refers to the thread size of the tap, which in this case is 1/2. It’s important to choose a drill bit that matches or is slightly smaller than the tap size to ensure proper threading. However, factors such as the type of material being drilled and the desired hole depth can also affect the drill bit size selection.

The Relationship Between Drill Bit Sizes and Tap Threads

The relationship between drill bit sizes and tap threads is crucial for achieving accurate and functional threaded holes. When drilling holes for a tap, the drill bit creates a hole that is slightly smaller than the tap’s thread size. This allows for the threads of the tap to grip the material securely while still allowing for smooth and precise threading. Using a drill bit that is too large can result in loose threads or an oversized hole, while a drill bit that is too small may cause the tap to bind or break.

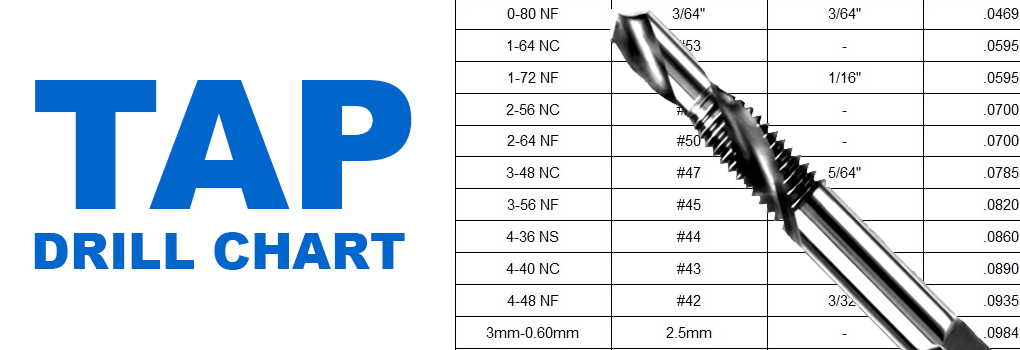

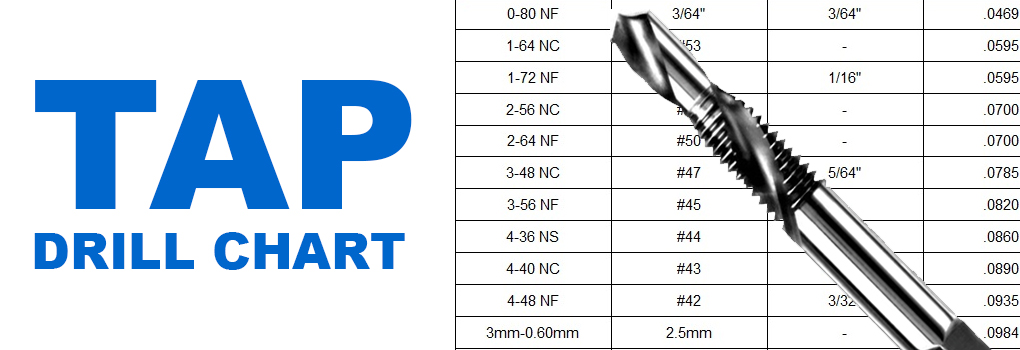

To determine the proper drill bit size for a 1/2 tap, you can refer to a drill bit and tap size chart. These charts provide a comprehensive guide for matching drill bits with specific tap sizes, taking into account the desired thread engagement and the material being drilled. It’s important to note that different charts may provide slightly different recommendations, so it’s a good idea to consult multiple sources to ensure accurate sizing.

Factors to Consider When Selecting the Drill Bit Size

While the tap size is the primary consideration when selecting a drill bit, there are other factors that should be taken into account to optimize your drilling results. Here are a few important factors to consider:

1. Material: Different materials require different drill bit sizes for optimal results. Harder materials typically require a slightly larger drill bit size to accommodate for the increased resistance, while softer materials may require a smaller drill bit size for precision.

2. Thread Engagement: The desired thread engagement, or the depth that the tap will be threaded into the material, can influence the drill bit size selection. If you require a deeper thread engagement, you may need a larger drill bit size to accommodate for the increased hole depth.

3. Tap Design: The design of the tap, specifically the number of threads per inch (TPI), can also affect the drill bit size selection. Taps with a higher TPI may require a slightly smaller drill bit size to ensure efficient threading.

4. Hole Depth: The depth of the hole you’re drilling will also impact the drill bit size selection. If you need to drill a shallow hole, a smaller drill bit size may be appropriate, while a deeper hole may require a larger drill bit size.

By considering these factors, you can determine the most suitable drill bit size for your 1/2 tap, ensuring accurate and efficient drilling results.

Benefits of Using the Correct Drill Bit Size

Using the correct drill bit size for your 1/2 tap offers several benefits. Firstly, it ensures proper thread engagement, guaranteeing secure and functional threaded holes. Secondly, it minimizes the risk of tap breakage or binding by providing the necessary clearance for smooth threading. Lastly, using the correct drill bit size promotes accuracy, reducing the likelihood of oversized or undersized holes. By paying attention to drill bit size selection, you can optimize your drilling process and achieve professional-grade results.

Common Drill Bit Sizes for 1/2 Taps

While the specific drill bit size for a 1/2 tap may vary depending on the factors mentioned earlier, there are commonly recommended sizes that can serve as a starting point for your drilling projects. Here are a few common drill bit sizes for 1/2 taps:

1. 15/32″ (approx. 0.47″)

2. #2 (approx. 0.221″)

3. 7/16″ (approx. 0.4375″)

4. 7mm (approx. 0.2756″)

5. P (approx. 0.323″)

6. 21/64″ (approx. 0.3281″)

It’s important to note that these sizes may vary based on the specific tap, material, and drilling requirements. Always refer to a drill bit and tap size chart or consult with experts for accurate sizing recommendations for your specific application.

Some Tips for Choosing the Right Drill Bit Size

Choosing the right drill bit size for your 1/2 tap can sometimes feel like a daunting task. To simplify the process, here are a few tips to help you make the right choice:

1. Use a drill bit and tap size chart as a reference to determine the recommended drill bit size for your specific tap size.

2. Consider the material you’re drilling into. Harder materials may require a slightly larger drill bit size, while softer materials may require a smaller size for precision.

3. Take into account the desired thread engagement. If you need a deeper thread engagement, you may need to choose a larger drill bit size.

4. Consult with experts or seek guidance from experienced professionals who have worked with similar materials and tap sizes.

Remember, selecting the correct drill bit size is crucial for achieving precise and functional threaded holes. Taking the time to choose the right drill bit will save you time, effort, and ensure successful drilling results.

The Importance of Proper Drilling Techniques

While having the right drill bit size is essential, proper drilling techniques are equally important for successful drilling projects. Here are a few key factors to consider:

1. Securely clamp the workpiece: To prevent movement and ensure stability during drilling, secure the workpiece using clamps or a vice.

2. Use cutting fluid: When drilling into metal or other hard materials, applying cutting fluid can help reduce heat buildup and prolong the life of your drill bit.

3. Maintain the correct drilling speed: Different materials require different drilling speeds. Follow the manufacturer’s recommendations or consult drilling guides to determine the appropriate drilling speed for your specific material.

4. Apply steady pressure: Apply consistent and even pressure to the drill as you are drilling, but avoid excessive force that might damage the drill bit or workpiece.

5. Clear chips regularly: Clearing chips from the hole as you drill will prevent clogging and improve the efficiency of the drilling process.

By following these drilling techniques, you can ensure accurate and efficient drilling results while maintaining the longevity of your drill bits.

Where to Find Drill Bit Size Information

When in doubt about the correct drill bit size for your 1/2 tap or any other drilling project, there are several reliable sources you can refer to for accurate information. Here are a few sources to consider:

1. Drill bit and tap size charts: These charts are widely available online and provide comprehensive size information for different tap sizes and materials.

2. Drill bit and tap manufacturers: Manufacturers often provide detailed information and recommendations on their websites or product packaging.

3. Hardware stores and specialty tool retailers: Visit your local hardware store or specialty tool retailer, where knowledgeable staff can assist you in finding the correct drill bit size for your specific needs.

Remember, when it comes to drill bit sizing, accuracy is key. Always verify the information from multiple sources and consult with experts to ensure you have the correct drill bit size for your specific application.

Summing It Up:

Selecting the right drill bit size for a 1/2 tap is crucial for achieving accurate and functional threaded holes. By understanding drill bit sizes, the relationship between drill bit sizes and tap threads, and considering factors like material, thread engagement, tap design, and hole depth, you can choose the appropriate drill bit size for your specific application. Utilize drill bit and tap size charts and consult experts or experienced professionals when in doubt. Remember to follow proper drilling techniques to ensure successful results. With the right drill bit size and technique, you’ll be well-equipped to tackle any drilling project with confidence.

Key Takeaways: What Size Drill Bit for 1/2 Tap?

- 1/2 tap requires a drill bit size of 29/64.

- This size ensures a proper fit for tapping threads into the material.

- Using the correct drill bit size prevents issues like stripped threads or loose fittings.

- It is important to use a high-quality drill bit for durability and precision.

- Always wear appropriate safety gear when drilling and tapping.

Frequently Asked Questions

Welcome to our Frequently Asked Questions section where we provide answers to some common inquiries about drill bits and tap sizes. Whether you’re a DIY enthusiast or a professional, we’re here to help you understand what size drill bit to use for a 1/2 tap. Read on to find out more!

1. What drill bit size should I use for a 1/2 tap?

When using a 1/2 tap, it is recommended to use a drill bit that measures 29/64 inches or 11.51 millimeters in diameter. This size allows for the perfect fit between the tap and the hole, ensuring efficient and accurate threading.

It’s important to note that using the right drill bit size is crucial for achieving the desired results. Using a different size may result in the tap not fitting properly or the threads being too loose or too tight.

2. Can I use a regular drill bit for tapping holes with a 1/2 tap?

A regular drill bit is not suitable for tapping holes with a 1/2 tap. Tapping requires specific drill bits known as “tap drill bits” that are designed to create holes with the correct diameter and depth for threading with a tap.

Tap drill bits are built to match the thread size of the tap, ensuring proper engagement between the tap and the hole. Using a regular drill bit will not provide the necessary precision and may lead to inaccurate or damaged threads.

3. How do I determine the right drill bit size for tapping with a 1/2 tap?

To determine the right drill bit size for tapping with a 1/2 tap, you can refer to a drill bit size chart or use a tap and drill size guide. These resources provide information on the drill bit size that corresponds to the thread size of the tap you are using.

Alternatively, you can calculate the drill bit size by deducting the pitch diameter of the tap from its major diameter. The resulting value will give you the recommended drill bit size for tapping with a 1/2 tap.

4. What happens if I use the wrong drill bit size with a 1/2 tap?

If you use the wrong drill bit size with a 1/2 tap, you may encounter several issues. Using a smaller drill bit will result in a hole that is too tight for the tap, making it difficult or impossible to thread the hole properly.

On the other hand, using a larger drill bit will create a hole that is too loose for the tap, causing the threads to be insufficiently engaged. This can lead to weak connections, stripped threads, or the tap losing grip within the hole.

5. What are the consequences of using an incorrect drill bit size when tapping with a 1/2 tap?

Using an incorrect drill bit size when tapping with a 1/2 tap can have several consequences. If the drill bit is too small, it may cause the tap to bind or break, resulting in damaged threads and a compromised connection.

If the drill bit is too large, the threads may not be adequately engaged, leading to a weak joint or a loose connection. Additionally, an incorrect drill bit size can affect the thread quality and compromise the overall strength and integrity of the tapped hole.

#### Summary:

Choosing the right drill bit for a 1/2″ tap is important for successful threading. A drill bit size around 13/32″ is suggested, allowing for precision and efficient tapping. Remember to go slow and use cutting fluid for best results!

#### Key Points:

– The right drill bit size for a 1/2″ tap is around 13/32″.

– Going slow and using cutting fluid helps achieve clean and accurate threads.