Are you wondering what size drill bit to use for a 1/8 NPT tap? Well, you’ve come to the right place! We’ve got all the answers you need to tackle this common DIY question. So, let’s dive in and find out the perfect drill bit size for your 1/8 NPT tap.

Now, before we get into the specifics, let’s quickly go over what a 1/8 NPT tap is. NPT stands for National Pipe Taper, which is a type of threading used in plumbing and other applications. The number “1/8” refers to the size of the tap, indicating that it creates threads for 1/8 inch diameter pipes.

So, what size drill bit should you use for a 1/8 NPT tap? The recommended drill bit size for this particular tap is 11/32 inch or 8.73 millimeters. This size allows for the perfect fit between the tap and the drill hole, ensuring smooth and precise threading. Using the correct drill bit size is essential for achieving strong and leak-free connections. So, grab your 11/32 inch drill bit, and you’ll be ready to tackle any 1/8 NPT project with confidence!

Let’s move on to the next section where we’ll explore some additional tips and tricks for using a 1/8 NPT tap effectively. Get ready to become a DIY pro in no time!

Step 1: Identify the tap size. In this case, it’s 1/8 NPT.

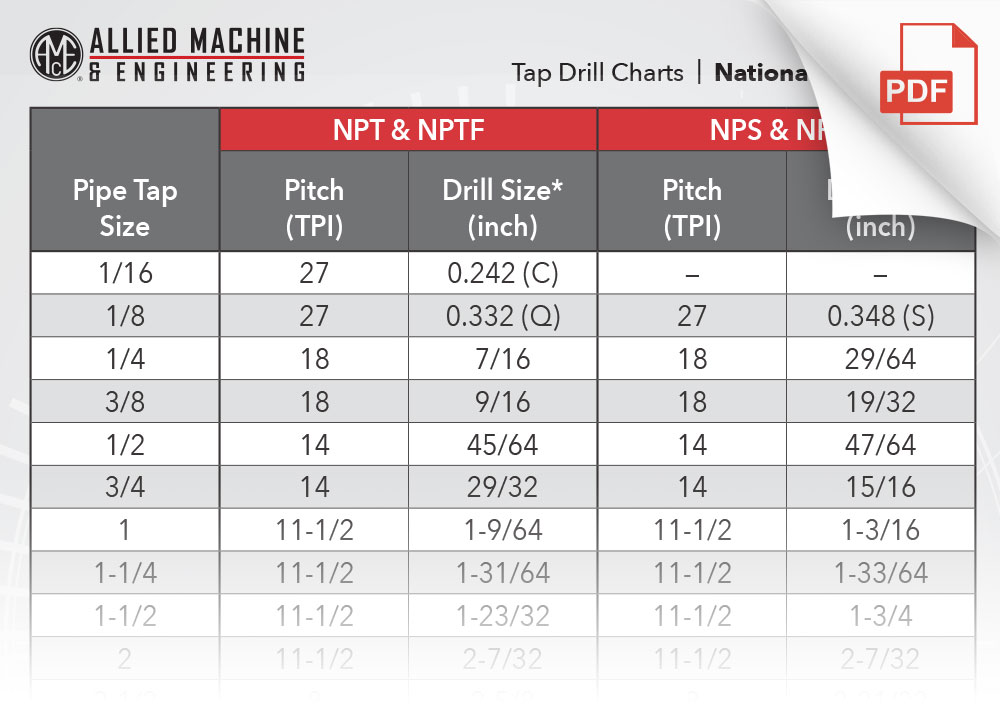

Step 2: Use a tap drill chart or online calculator to find the recommended drill bit size for 1/8 NPT. It is typically 11/32 inches or 8.73mm.

Step 3: Select the appropriate drill bit and secure it in a drill press or handheld drill.

Step 4: Drill a hole with the selected drill bit, ensuring it matches the recommended size.

Step 5: Once the hole is drilled, you can proceed with tapping using the 1/8 NPT tap tool.

What Size Drill Bit for 1/8 NPT Tap?

Introduction: When it comes to tapping holes for specific thread sizes, using the right drill bit is crucial. One commonly used thread size is 1/8 NPT (National Pipe Taper). In this article, we will explore the optimal drill bit size for tapping a hole to accommodate a 1/8 NPT tap. We will also discuss the importance of using the correct size and provide tips for tapping threads effectively.

Understanding Thread Sizes and Tapping

Tapping is the process of creating threads inside a hole to allow screws or bolts to be securely fastened. It involves using a tapping tool, such as a tap, to cut the threads. The size of the hole and tap needed depends on the type of thread being used. In the case of 1/8 NPT, the thread size refers to the outer diameter of the pipe thread, and the NPT stands for National Pipe Taper.

To determine the drill bit size for tapping a hole for a 1/8 NPT tap, we need to consider the recommended tap drill size. According to industry standards, the tap drill size for a 1/8 NPT tap is 11/32 inches. This means that before tapping the hole, you should drill a hole with a diameter of 11/32 inches. It is important to note that the specific drill bit size may vary slightly depending on the manufacturer’s recommendations or other factors.

The Importance of Using the Correct Drill Bit Size

Using the correct drill bit size is essential for successful tapping. If the drill bit is too small, it won’t provide enough space for the tap to create the desired threads. On the other hand, if the drill bit is too large, the tap may not be able to cut sufficient material to form proper threads, resulting in loose or weak connections.

By using the recommended drill bit size for a 1/8 NPT tap, you ensure that the threads are properly formed, allowing for a secure and tight connection. It is also important to use a sharp and high-quality drill bit to achieve clean and precise holes, minimizing the risk of thread damage or stripping.

Tips for Tapping Threads with 1/8 NPT Tap

To tap threads effectively with a 1/8 NPT tap, consider the following tips:

1. Prepare the hole: Before tapping, ensure that the hole is clean, free from debris, and properly aligned. Remove any burrs or sharp edges that may interfere with the tapping process.

2. Use lubricant: Applying a suitable cutting fluid or lubricant helps reduce friction and heat during the tapping process. This prolongs the life of the tap and ensures smoother thread formation.

3. Tap in stages: Start the tapping process by turning the tap a few turns in one direction, then back it off slightly to break any chips. Repeat this process, gradually increasing the depth of the threads with each pass until the desired depth is reached.

4. Use a tapping guide: In cases where precision is crucial, using a tapping guide can help ensure that the tap remains perpendicular to the surface of the material. This helps prevent the tap from drifting off course and ensures accurate threads.

Remember, tapping threads requires patience and careful attention to detail. Taking the time to properly prepare the hole, use the correct drill bit size, and follow best practices will result in strong and reliable threads.

Related Topics to “What Size Drill Bit for 1/8 NPT Tap?”

Choosing the Right Tap for the Job

When it comes to tapping, selecting the right tap for the job is essential. Different taps have specific applications and features that make them suitable for certain materials and thread sizes. In this section, we will explore the factors to consider when choosing a tap and provide guidance on selecting the appropriate tap for your needs.

Benefits of Tapping Threads

Tapping threads offers numerous benefits in various applications, from creating strong connections to facilitating easy disassembly and reassembly. In this section, we will examine the advantages of tapping threads and discuss situations where tapping is preferred over other joining methods.

Tips for Tapping Threads in Different Materials

The process of tapping threads can vary depending on the material being tapped. Different materials have varying levels of hardness and machinability, which can influence the choice of tap and the techniques used. In this section, we will provide helpful tips and considerations for tapping threads in different materials such as metal, wood, and plastic.

Choosing the Right Tap for the Job

Introduction: Selecting the right tap for the job is crucial to achieve high-quality and properly formed threads. In this section, we will explore the factors to consider when choosing a tap and provide guidance on selecting the appropriate tap for your needs.

Factors to Consider When Choosing a Tap

When choosing a tap, there are several factors to keep in mind:

1. Material: Consider the material you will be tapping. Different materials require different tap materials and coatings to effectively cut threads. For example, high-speed steel (HSS) taps are suitable for general-purpose tapping in most materials, while cobalt taps are better suited for hard materials like stainless steel.

2. Thread size and pitch: Determine the thread size and pitch required for your application. These specifications will dictate the type of tap you need. There are various thread standards, such as metric, UNC (Unified Coarse), and UNF (Unified Fine), each requiring a corresponding tap.

3. Tap type: There are different types of taps designed for specific applications. Some common types include taper taps, plug taps, and bottoming taps. Taper taps have a more gradual taper at the end, making them suitable for starting new threads. Plug taps have a slightly longer taper and are used for general tapping. Bottoming taps have a shorter taper and are used to finish threads close to the bottom of blind holes.

4. Cutting direction: Taps can be classified as either right-hand or left-hand, referring to the direction in which they cut threads. Right-hand taps are the most common and cut threads in a clockwise direction. Left-hand taps cut threads in a counterclockwise direction and are used for special applications.

Selecting the Appropriate Tap

Once you have considered the factors mentioned above, you can select the appropriate tap for your needs. Consult tap size charts or tap drill size guides to determine the specific tap size you require. Ensure that the tap is of high quality and suitable for the material you will be working with. Using the correct tap will result in clean, accurate threads and reduce the chances of thread damage or stripping.

Remember, when in doubt, consult tap manufacturers’ recommendations or seek guidance from professionals who specialize in threading operations.

Benefits of Tapping Threads

Introduction: Tapping threads is a widely used method to create secure connections and enable easy assembly and disassembly. In this section, we will explore the benefits of tapping threads and discuss situations where tapping is preferred over other joining methods.

Strong and Secure Connections

One of the primary benefits of tapping threads is the ability to create strong and secure connections. Threads offer increased holding power compared to other methods like self-tapping screws or adhesives. The interlocking nature of threaded fasteners ensures that the connection remains tight, even under heavy loads or vibrations.

Additionally, tapping threads allows for the use of threaded fasteners, such as bolts and screws, which offer adjustable and reusable connections. This flexibility is particularly useful in applications where disassembly and reassembly are necessary, such as equipment maintenance or prototyping.

Easy Assembly and Disassembly

Tapping threads provides the advantage of easy assembly and disassembly. With threaded connections, parts can be readily joined or separated using simple hand tools. This makes repairs, adjustments, or modifications more convenient, reducing downtime and costs associated with complex disassembly processes.

For applications where regular maintenance or component replacement is required, tapping threads simplifies the task by enabling quick and hassle-free access to the assembled parts. This is especially beneficial in industries like automotive, aerospace, and machinery, where efficient maintenance and frequent part replacement are essential.

Versatility and Compatibility

Threads are a universal language in the fastening world, providing compatibility and versatility across a wide range of applications. Regardless of the industry or materials being joined, there is a thread standard or type that can accommodate the specific requirements.

Whether it’s metric threads, UNC threads, UNF threads, or pipe threads like NPT, tapping allows for seamless integration and compatibility with various fasteners and components. This versatility makes threaded connections a popular choice in industries ranging from construction and manufacturing to plumbing and electronics.

In conclusion, tapping threads offers a multitude of benefits, including strong connections, easy assembly and disassembly, and versatility. Understanding these advantages can help you determine when tapping is the ideal choice for your specific application. Always ensure you follow best practices for tapping threads to achieve optimal results.

Key Takeaways: What Size Drill Bit for 1/8 NPT Tap?

- 1/8 NPT tap requires a drill bit size of 21/64 inch.

- Use a drill bit with a pointed tip for better accuracy.

- Make sure to use a drill press or steady hand when drilling.

- Apply cutting fluid to lubricate the drill bit and tap while drilling.

- Take your time and use light pressure to prevent the bit from breaking or getting stuck.

Frequently Asked Questions

Welcome to our FAQ section, where we answer all your questions about finding the right drill bit size for a 1/8 NPT tap. We understand that it can be confusing, but don’t worry, we’re here to help you!

1. What is an NPT tap and why is it important to choose the right drill bit size?

An NPT (National Pipe Taper) tap is used to create tapered threads in pipe fittings for a solid seal. It’s crucial to choose the right drill bit size when using an NPT tap because it determines the size and shape of the hole that needs to be created. If the drill bit size is too small, the tap won’t fit properly and the threads may not form correctly. On the other hand, if the drill bit size is too large, it can compromise the strength and integrity of the threads.

To ensure a proper fit and a secure connection, it’s important to select the correct drill bit size for your 1/8 NPT tap.

2. How do I determine the drill bit size for a 1/8 NPT tap?

The drill bit size for a 1/8 NPT tap can be determined using a tap drill chart. These charts provide the recommended drill bit sizes based on the thread size. For a 1/8 NPT tap, the recommended drill bit size is 0.332 inches or 8.4328 millimeters. This will give you the right size hole to create properly threaded connections.

Keep in mind the tap drill chart is a general guide, and for specific applications or materials, it’s always best to consult the manufacturer’s recommendations or a professional to ensure accuracy.

3. Are there alternative methods to determine the drill bit size for a 1/8 NPT tap?

If you don’t have access to a tap drill chart, you can calculate the drill bit size for a 1/8 NPT tap manually. To do this, subtract the pitch of the thread from the nominal size (1/8 inch) and convert the result to decimal inches or millimeters. For an 1/8 NPT tap, the pitch is 0.035 inches. Subtracting this from 1/8 inch gives you 0.093 inches or approximately 2.36 millimeters, which is the drill bit size you would need.

Again, it’s important to note that these calculations are approximate and may not be suitable for all applications. It’s recommended to double-check with a tap drill chart or consult with an expert for accurate results.

4. Can I use a drill bit that is slightly smaller or larger than the recommended size?

While it’s generally best to use the recommended drill bit size for a 1/8 NPT tap, there is a slight tolerance. Using a drill bit that is slightly smaller or larger can still work, but it may affect the quality and strength of the threads. A slightly smaller drill bit may result in tighter threads, while a slightly larger drill bit may lead to looser threads. However, it’s important not to deviate too far from the recommended size as it can compromise the connection and potentially cause leaks.

If you’re unsure, it’s always best to err on the side of caution and stick with the recommended drill bit size for the best results.

5. What precautions should I take when using a drill bit with a 1/8 NPT tap?

When using a drill bit with a 1/8 NPT tap, there are a few precautions to keep in mind. First, make sure to wear appropriate safety gear, such as safety glasses and gloves, to protect yourself from any potential hazards. Additionally, ensure that your workpiece is securely clamped to prevent any movement while drilling. This will help maintain accuracy and prevent injury.

When drilling, apply steady pressure but avoid excessive force, as it may lead to broken drill bits or damaged threads. It’s also important to use cutting oil or lubricant to reduce friction and prolong the life of the drill bit. Finally, take your time and work at a suitable speed to ensure clean and precise holes.

Summary

So, to recap, when tapping a 1/8 NPT thread, you should first drill a hole with a 11/32-inch drill bit. This size will give you the perfect starting point for your tap. Once the hole is drilled, you can then use a 1/8 NPT tap to create the desired thread. Remember to go slowly and use the proper tools to achieve the best results.

In conclusion, drilling a hole with a specific size is crucial when using a tap to create threads. By following the recommended drill bit size for a 1/8 NPT tap, you can ensure a proper fit and achieve the desired thread depth for your project. Happy tapping!